Ferrite material and preparation method and application thereof

A ferrite material and application technology, applied in the direction of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of unfavorable environment and human health, complicated production process, high pre-burning temperature, etc., and achieve high dielectric strength Effects of electric constant and Curie temperature, reduction of production cost, and stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

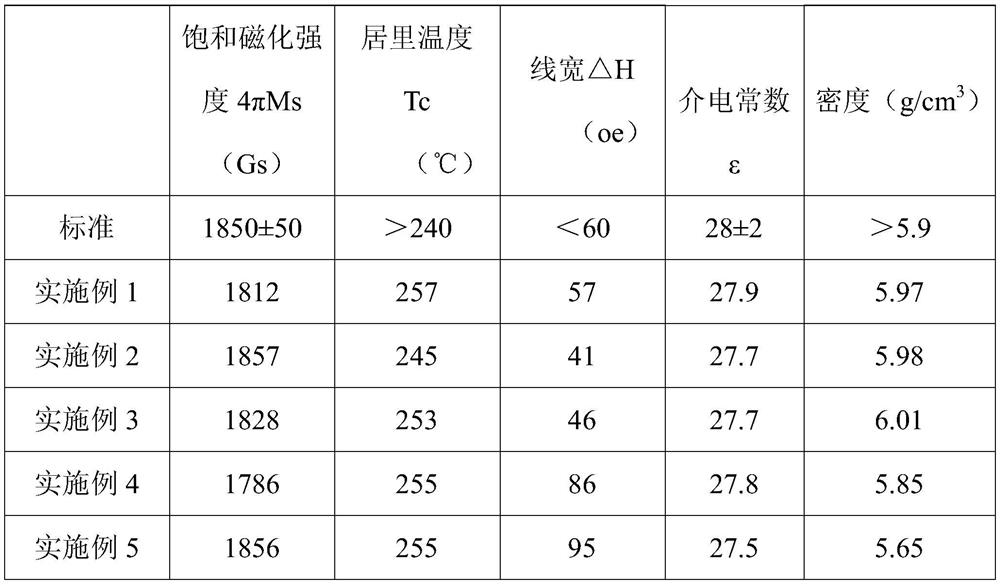

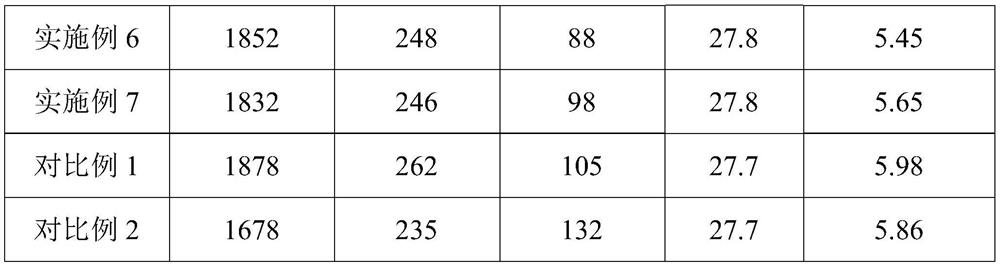

Embodiment 1

[0066] The present embodiment provides a kind of ferrite material, and the chemical formula of described ferrite material is (Bi 1.3 Ca 0.5 Y 1.2 Fe 4.6 Zr 0.3 W 0.1 o 12 ) The raw material of the ferrite material includes Y with a purity of 99.95%. 2 o 3 , with a purity of 99.95% Bi 2 o 3 , CaCO with a purity of 99% 3 , with a purity of 99.2% ZrO 2 , with a purity of 99.5% Fe 2 o 3 , and WO with a purity of 99.5% 3 .

[0067] Its preparation method comprises the following steps:

[0068] (1) Add the raw material of the ferrite material according to the above chemical formula ratio, alcohol and zirconia grinding balls into the ball milling tank according to the weight ratio of 1000:1000:4000, and ball mill for 15 hours at a ball milling speed of 60r / min. Put the ball-milled slurry into an oven and dry at a drying temperature of 120°C for 16 hours, pass the dried powder through a 60-mesh sieve into an air sintering furnace for pre-sintering, and heat up to the hi...

Embodiment 2

[0071] This embodiment provides a ferrite material, the chemical formula of the ferrite material is Bi 1.3 Ca 0.5 Y 1.2 Fe 4.55 Zr 0.4 W 0.05 o 12 . The raw material of the ferrite material includes Y with a purity of 99.95%. 2 o 3 , with a purity of 99.95% Bi 2 o 3 , CaCO with a purity of 99% 3 , with a purity of 99.2% ZrO 2 , with a purity of 99.5% Fe 2 o 3 , and WO with a purity of 99.5% 3 .

[0072] Its preparation method comprises the following steps:

[0073] (1) Add the raw material of the ferrite material according to the above chemical formula ratio, alcohol and zirconia grinding balls into the ball milling tank according to the weight ratio of 1000:1000:4000, and ball mill for 10 hours at a ball milling speed of 100r / min. Put the ball-milled slurry into an oven and dry at a drying temperature of 180°C for 12 hours, pass the dried powder through a 60-mesh sieve into an air sintering furnace for pre-sintering, and heat up to the highest temperature at a...

Embodiment 3

[0076] This embodiment provides a ferrite material, the chemical formula of the ferrite material is Bi 1.3 Ca 0.4 Y 1.3 Fe 4.65 Zr 0.3 W 0.05 o 12 . The raw material of the ferrite material includes Y with a purity of 99.95%. 2 o 3 , with a purity of 99.95% Bi 2 o 3 , CaCO with a purity of 99% 3 , with a purity of 99.2% ZrO 2 , with a purity of 99.5% Fe 2 o 3 , and WO with a purity of 99.5% 3 .

[0077] Its preparation method comprises the following steps:

[0078] (1) Add the raw material of the ferrite material according to the above chemical formula ratio, alcohol and zirconia grinding balls into the ball milling tank according to the weight ratio of 1000:1000:4000, and ball mill for 10 hours at a ball milling speed of 100r / min. Put the ball-milled slurry into an oven and dry at a drying temperature of 180°C for 12 hours, pass the dried powder through a 60-mesh sieve into an air sintering furnace for pre-sintering, and heat up to the highest temperature at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molding density | aaaaa | aaaaa |

| Molding density | aaaaa | aaaaa |

| Molding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com