Preparation method of composite material capable of realizing high efficiency adsorption-photocatalysis degradation of antibiotics

A composite material and photocatalysis technology, applied in the field of materials science, can solve problems such as poor effect, and achieve the effect of significant technological progress, good adsorption effect, and improved removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] g-C 3 N 4 Preparation: Weigh a certain quality of melamine and place it in a covered crucible, then put it in a muffle furnace and raise it to 500℃, keep it warm for 2h and then raise it to 520℃, keep it for 2h and then drop to room temperature, and grind the obtained product for backup use. Subsequently, weigh a certain mass of powder and spread it in a porcelain boat, place it in a muffle furnace and raise it to 520℃, and calcinate for 6 hours to obtain g-C 3 N 4 .

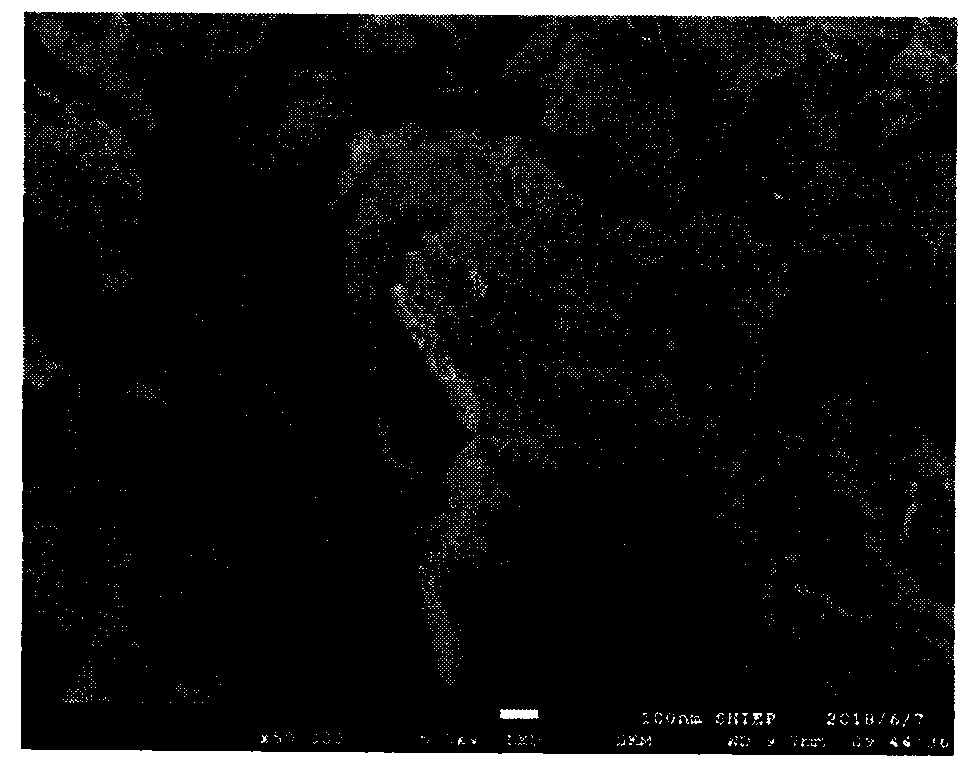

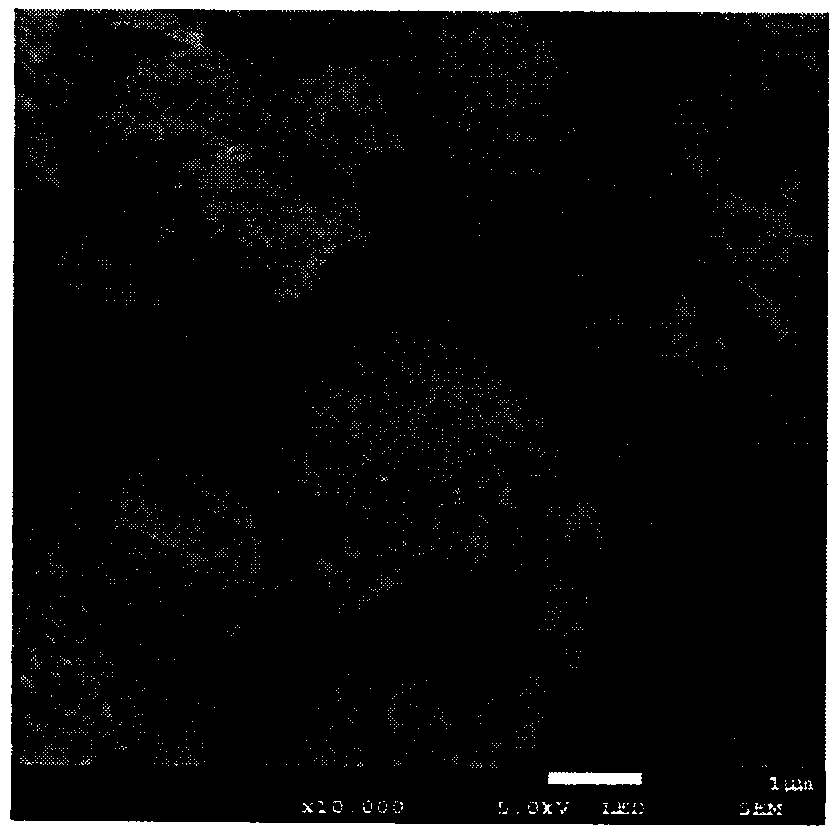

[0021] figure 1 It is the g-C prepared in Example 1 of the present invention 3 N 4 Scanning electron microscope (SEM) photos, you can see the g-C obtained by each system 3 N 4 A sheet structure.

Embodiment 2

[0023] g-C 3 N 4 / HAp composite material preparation: prepare 30mL, 0.2M CaCl respectively 2 And Na 2 CO 3 Solution, will be prepared with CaCl 2 The solution was poured into 300mL, 10mg / mL polystyrene sodium sulfonate (PSS) solution, and then Na 2 CO 3 The solution was added dropwise to the above solution, stirred at room temperature for 1 hour, after centrifugal drying, white powdery CaCO was obtained 3 , Weigh out 0.17g Na 2 HPO 4 , Formulated into 0.1M Na 2 HPO 4 Solution, weigh 0.2g CaCO 3 Join Na 2 HPO 4 In the solution, weigh 15wt% g-C 3 N 4 Dissolve in the above solution, then adjust the pH to 11 with 0.1M NaOH, place in an autoclave at 120°C for 1 hour, centrifuge and dry to obtain g-C 3 N 4 / HAp composite material.

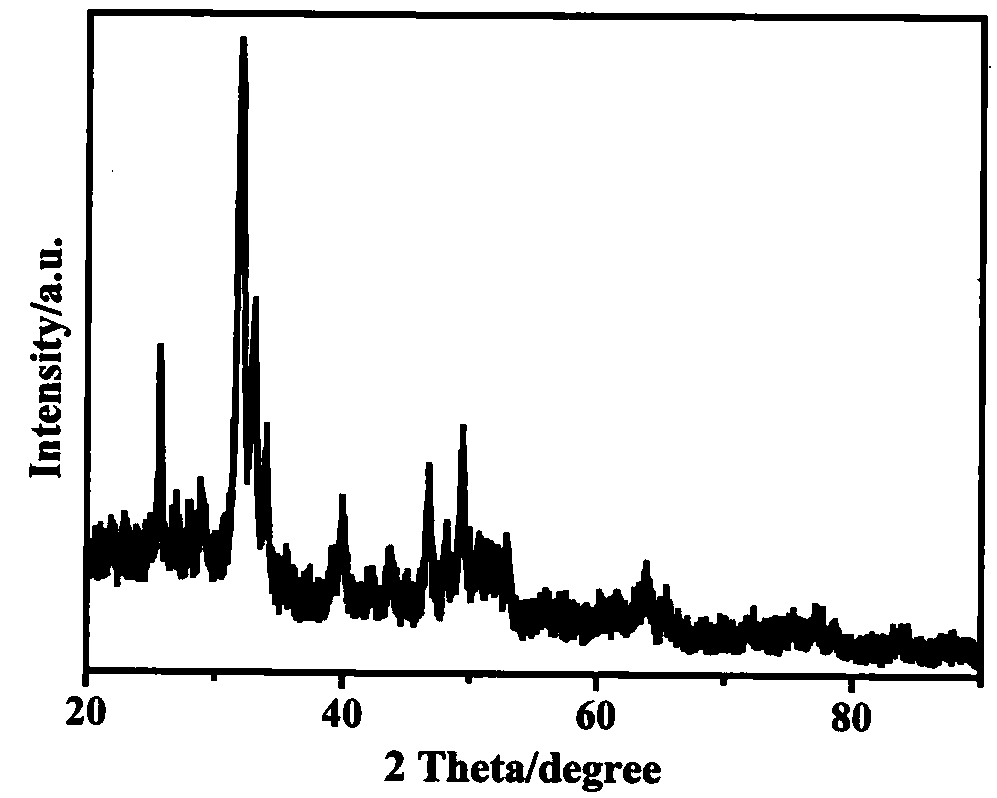

[0024] figure 2 This is the g-C prepared in Example 2 of the present invention 3 N 4 The X-ray powder diffraction (XRD) spectrum of the / HAp composite material was confirmed to be consistent with JCPDS#09-0423, indicating that the product obtained was of high...

Embodiment 3

[0029] Adsorption-photocatalytic performance experiment: weigh 0.1g of g-C 3 N 4 / HAp composite material is placed in 100mL, 50mg / L tetracycline solution, dark reaction for 40min to reach the adsorption-desorption equilibrium; using Porfila 300WXe xenon lamp as the light source, simulating sunlight, take 4mL every 5min after the start of illumination The sample was centrifuged, the supernatant was placed in a cuvette, and the absorption value of tetracycline was measured by Shimadzu UV-2550 ultraviolet spectrophotometer, using C / C 0 To evaluate the degradation rate, where C is the concentration of tetracycline in the sample after a certain period of light, C 0 Is the initial tetracycline concentration of the sample.

[0030] Image 6 This is the g-C prepared in Example 2 of the present invention 3 N 4 The adsorption-photocatalytic performance curve of tetracycline by / HAp composite material. The experimental results show that the obtained product has very fast and efficient adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com