Multicompentnt granular urea and its production process

A technology of granular urea and production method, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problem of single urea fertilizer, and achieve the effect of good fertilizer efficiency, uniform particles, and good absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

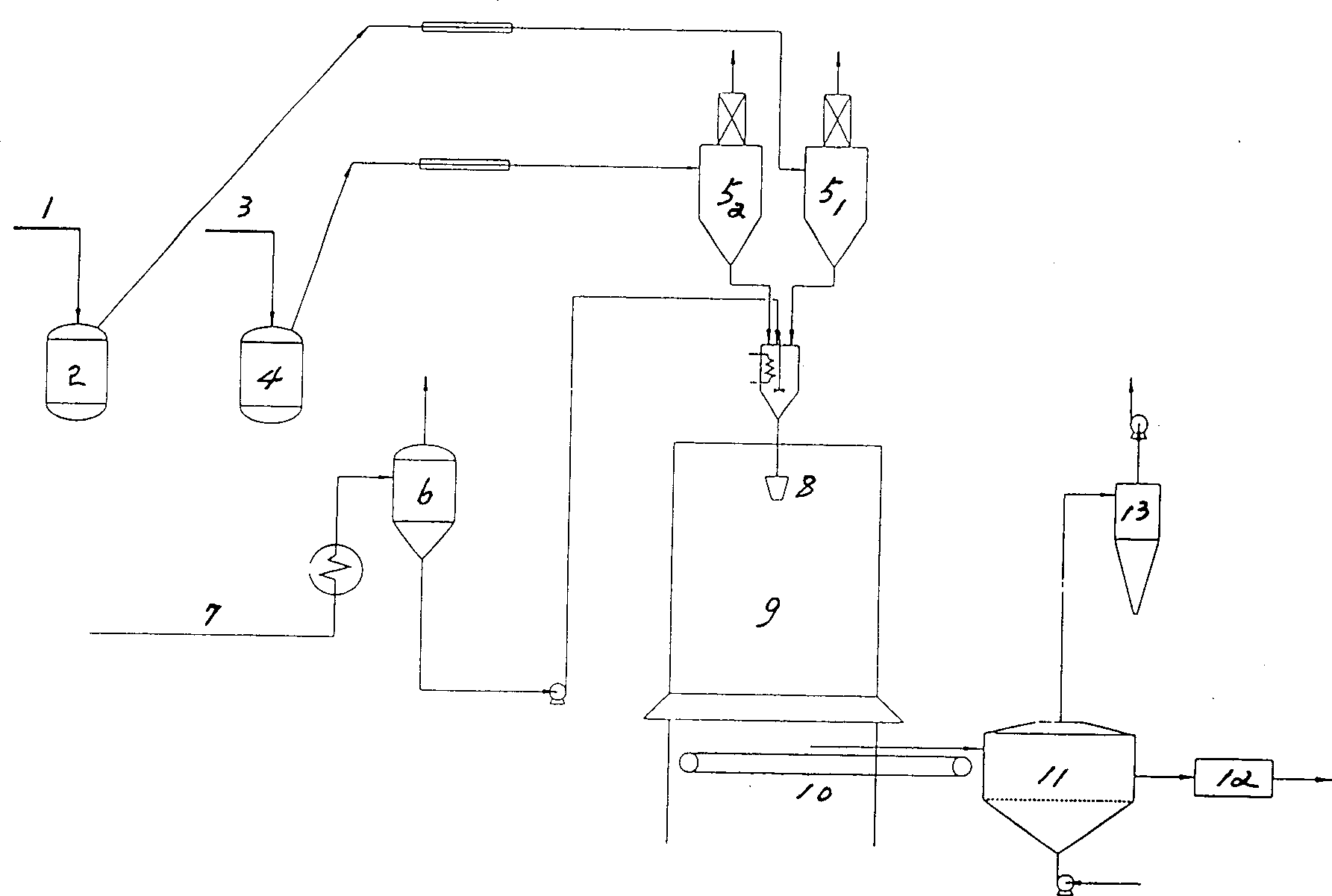

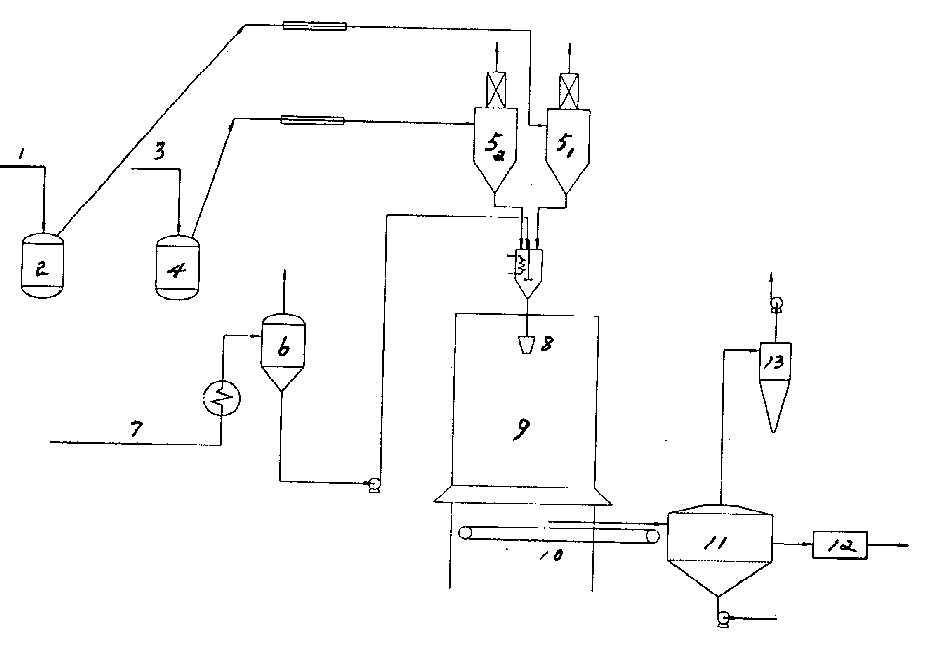

[0030] 1. The aqueous urea solution is evaporated in one stage and two stages, concentrated to a concentration of 99.0-99.7% (weight) by vacuum evaporation at a temperature of 135--140° C., and pumped from the molten urea to the mixer on the tower through the separator 6.

[0031] 2. Preheat the powdery dry ammonium sulfate crystals and dolomite to 135°C respectively through the preheating equipment, and send them to the high-level tank for solid materials on the tower (5 1 , 5 2 ), and then quantitatively feed into the mixer by the rotary feed valve.

[0032] 3. In the mixer, ammonium sulfate crystals, dolomite and urea melt are fully mixed, and the mixing ratio is: 70% (weight) urea solution, 20% (weight) ammonium sulfate crystals, 10% (weight) dolomite, while heating While stirring, a mixed dissolved salt was obtained.

[0033] 4. At 135-140°C, the mixed molten salt is quickly sent to the granulation nozzle 8 in the granulation tower 9 to spray down, and it is in reverse ...

Embodiment 2

[0036] 1. The aqueous urea solution is evaporated in one stage and two stages, concentrated to a concentration of 99.0-99.7% (weight) by vacuum evaporation at a temperature of 135--140° C., and pumped from the melted urea to the mixer on the tower through the separator 6.

[0037] 2. Preheat the powdery dry ammonium sulfate and dolomite to 140°C through the preheating equipment, and send them directly to the mixer on the tower.

[0038] 3. In the mixer, ammonium sulfate, dolomite and urea melt are fully mixed, and the mixing ratio is: 70% (weight) urea solution, 10% (weight) ammonium sulfate crystal, 20% (weight) dolomite, while heating Stir to obtain mixed molten salt.

[0039] 4. At 135-140°C, the mixed molten salt is quickly sent to the prilling tower 9 for granulation and spraying down, and is in reverse contact with the cold air in the tower, and is cooled to 100°C to crystallize into large-grained products.

[0040] 5. The large particle product that is preliminarily co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com