Method for recycling tail gas generated by granulation of compound fertilizer

A compound fertilizer and tail gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as polluting the environment and wasting resources, and achieve the effects of saving energy, reducing production costs, and highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

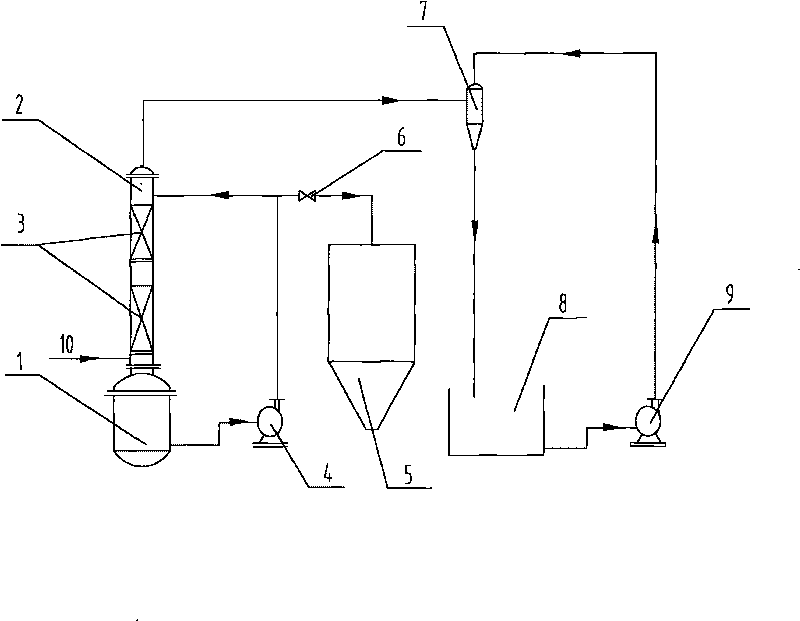

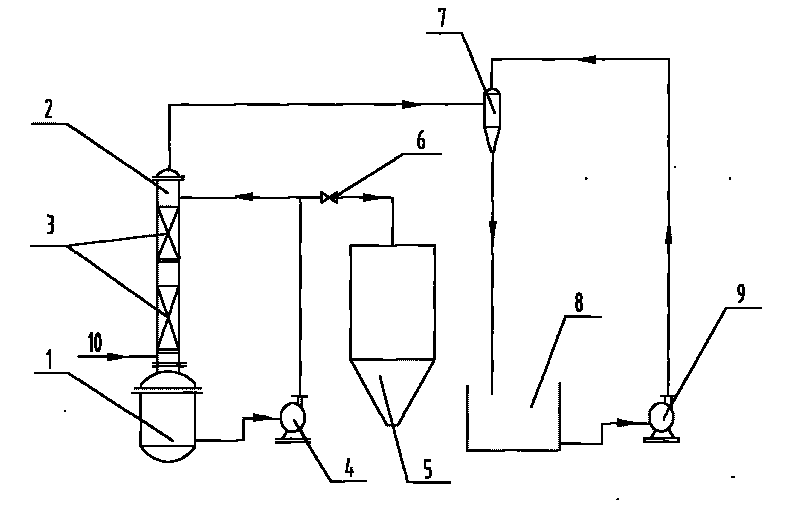

[0030] Embodiment 1 The recycling method of compound fertilizer granulation tail gas of the present invention

[0031] It includes dust recovery and tail gas water washing, and is characterized in that all washing liquids are recycled and utilized. Including the following process steps:

[0032] a. Acidification

[0033] Add an aqueous mineral acid solution to the circulating water washing solution to make the pH of the washing solution ≤ 6.5;

[0034] b. Vacuum absorption

[0035] The circulating washing liquid in the circulation tank (1) enters the top of the absorption tower (2) through the circulation pump (4), and the exhaust gas (10) after dust removal flows through the tower from bottom to top under the vacuum condition generated by the jet pump (7). The plate (3) is in countercurrent contact with the circulating washing liquid to absorb fine fertilizer dust and decompose NH3 gas.

[0036] c. Solid-liquid separation

[0037] When the circulating washing liquid is a...

Embodiment 2

[0041] According to the method and step of embodiment 1, wherein in step a, add H 2 SO 4 Aqueous solution, the pH of the washing liquid is between 5-6, and the vacuum degree of vacuum absorption described in step b is controlled between -0.01~-0.06Mpa.

Embodiment 3

[0043] According to the method and step of embodiment 1, wherein in step a, add H 3 PO 4 Aqueous solution, make the pH of washing solution between 5-6, the vacuum absorption vacuum degree described in step b is controlled at-0.03Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com