Layered hybrid thin film with adjustable band gap and preparation method of layered hybrid thin film

A hybrid and layered technology, applied in the field of materials, can solve the problems that batteries can only be stored in an inert gas environment, battery efficiency declines, and lead content is not solved, so as to achieve environmental protection, reduce use, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

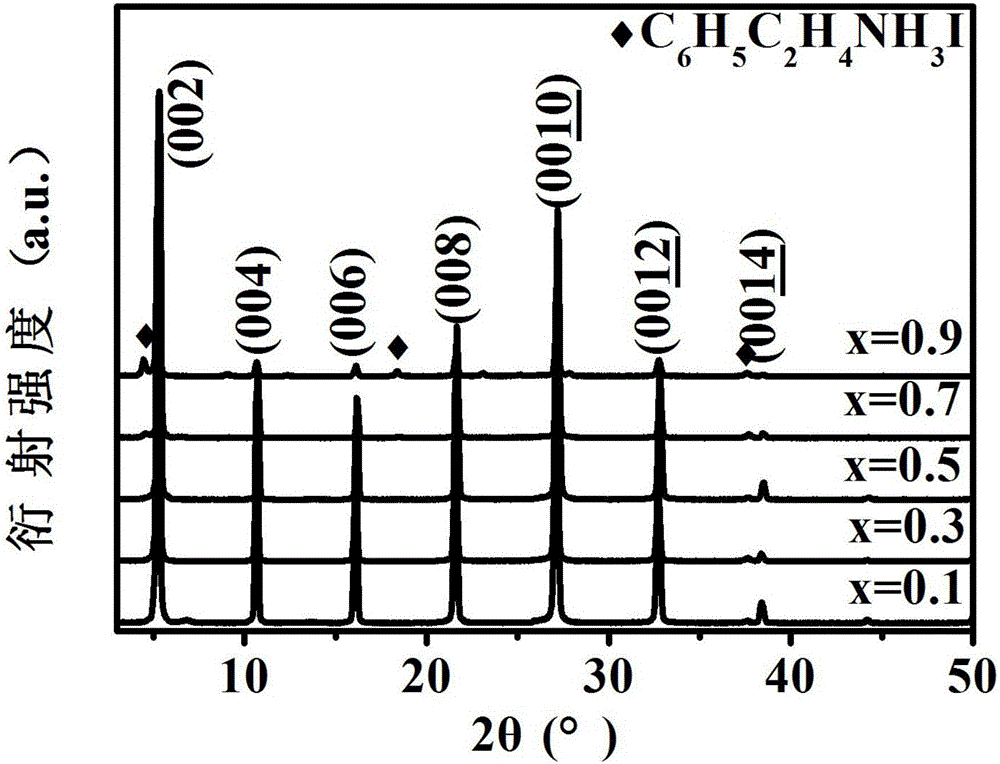

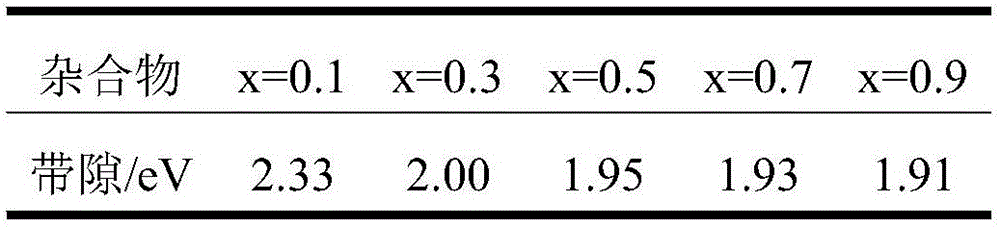

[0021] Weigh 0.1992gC in the MBRAUN glove box filled with high-purity nitrogen, the water pressure and oxygen partial pressure are both ≤0.1ppm 6 h 5 C 2 h 4 NH 3 I, 0.0149gSnI 2 , 0.1660gPbI 2 Mix, take 1 mL of N,N-dimethylformamide as a solvent, shake and stir for 10 min to obtain a precursor solution. Use a pipette gun to take 30 μL of the precursor solution on a fluorine-doped tin oxide transparent conductive glass substrate with a size of 15mm×15mm for spin-coating. The speed of the coater is 6000r / min, and the spin-coating time is 30s. The substrate was heat-treated on a heating plate at 100°C for 15 min to obtain a layered hybrid (C 6 h 5 C 2 h 4 NH 3 ) 2 sn 0.1 Pb 0.9 I 4 (x=0.1) Film. The layered hybrid prepared in this example is as figure 1 shown.

Embodiment 2

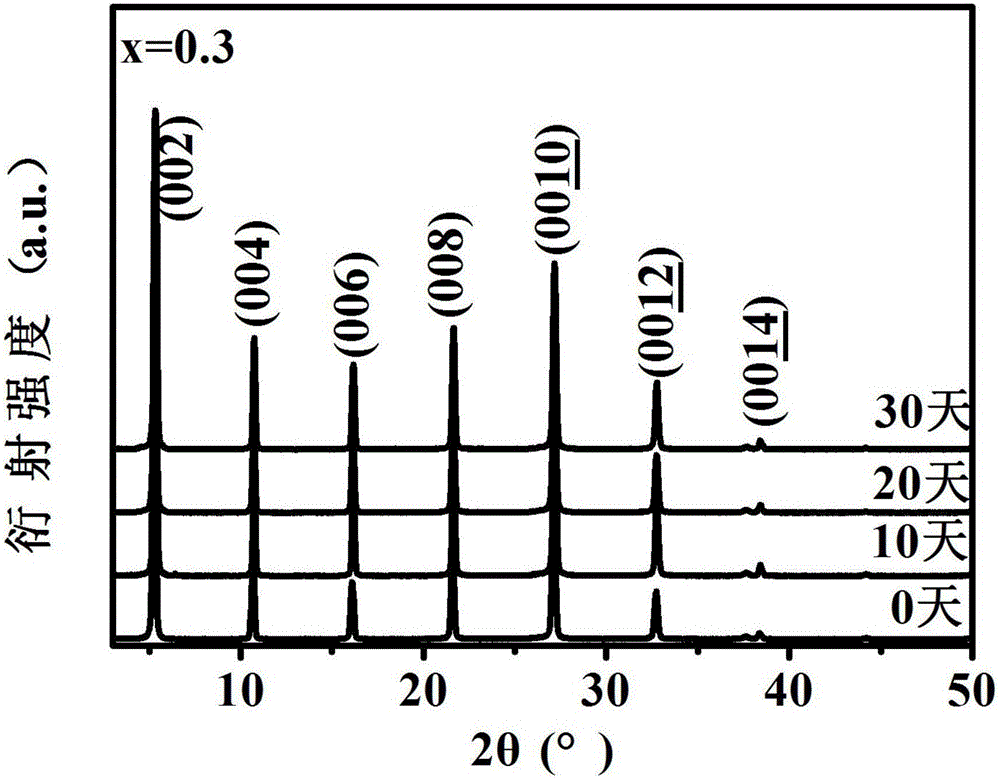

[0023] Weigh 0.1992gC in the MBRAUN glove box filled with high-purity nitrogen, the water pressure and oxygen partial pressure are both ≤0.1ppm 6 h 5 C 2 h 4 NH 3 I, 0.0447gSnI 2 , 0.1291gPbI 2 Mix, take 1 mL of N,N-dimethylformamide as a solvent, shake and stir for 10 min to obtain a precursor solution. Use a pipette gun to take 30 μL of the precursor solution on a fluorine-doped tin oxide transparent conductive glass substrate with a size of 15mm×15mm for spin-coating. The speed of the coater is 6000r / min, and the spin-coating time is 30s. The substrate was heat-treated on a heating plate at 100°C for 15 min to obtain a layered hybrid (C 6 h 5 C 2 h 4 NH 3 ) 2 sn 0.3 Pb 0.7 I 4 (x=0.3) Film. The layered hybrid prepared in this example is as figure 1 Shown; Place the XRD variation pattern of 30 days in the air as figure 2 Place.

[0024] figure 2 It can be seen that even after 30 days, the hybrid (C 6 h 5 C 2 h 4 NH 3 ) 2 sn 0.3 Pb 0.7 I 4 (x=0.3...

Embodiment 3

[0026] Weigh 0.1992gC in the MBRAUN glove box filled with high-purity nitrogen, the water pressure and oxygen partial pressure are both ≤0.1ppm 6 h 5 C 2 h 4 NH 3 I, 0.0745gSnI 2 , 0.0922gPbI 2Mix, take 1 mL of N,N-dimethylformamide as a solvent, shake and stir for 10 min to obtain a precursor solution. Use a pipette gun to take 30 μL of the precursor solution on a fluorine-doped tin oxide transparent conductive glass substrate with a size of 15mm×15mm for spin-coating. The speed of the coater is 6000r / min, and the spin-coating time is 30s. The substrate was heat-treated on a heating plate at 100°C for 15 min to obtain a layered hybrid (C 6 h 5 C 2 h 4 NH 3 ) 2 sn 0.5 Pb 0.5 I 4 (x=0.5) Film. The layered hybrid prepared in this example is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com