Method and device for spraying and depositing dispersed tin and zinc nuclei on the surface of high-purity aluminum foil for medium and high voltage anodes

A spray deposition, medium and high voltage technology, applied in the direction of electrolytic capacitors, electrical components, circuits, etc., can solve the problems of reducing the yield rate of aluminum foil corrosion foil mechanical properties, accelerating the self-corrosion of aluminum foil surface, unfavorable corrosion foil specific capacitance, etc., to improve Utilization and mechanical properties, improve uniformity, reduce the effect of merging holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

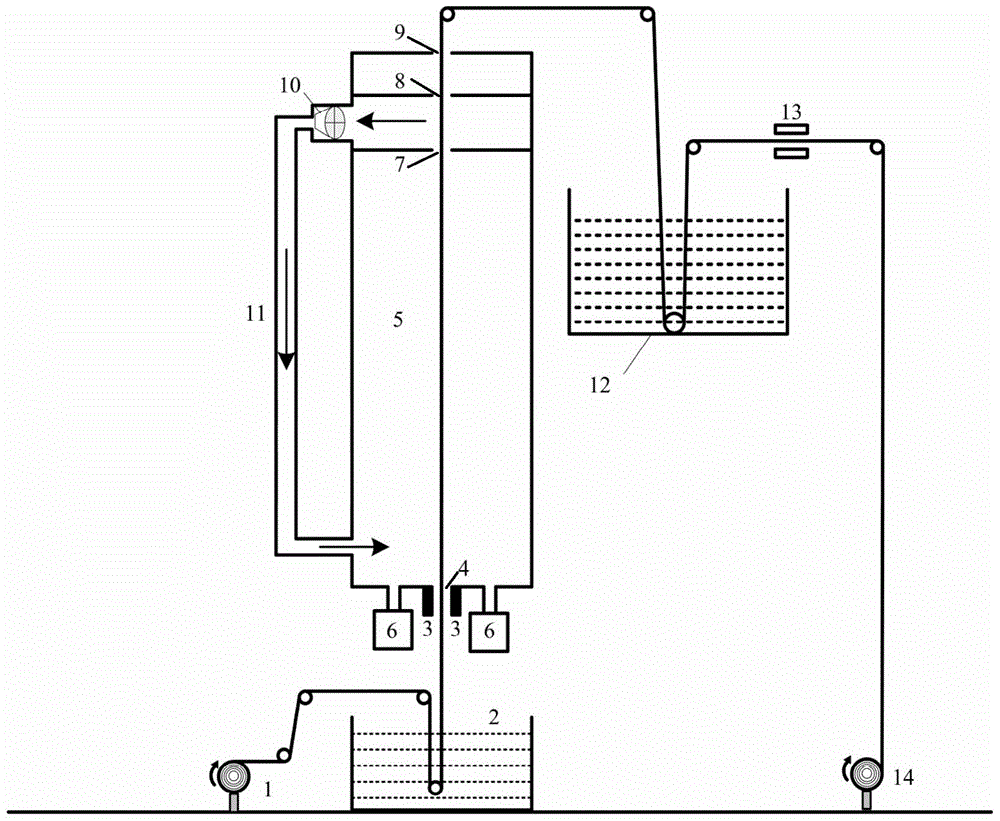

Method used

Image

Examples

Embodiment 1

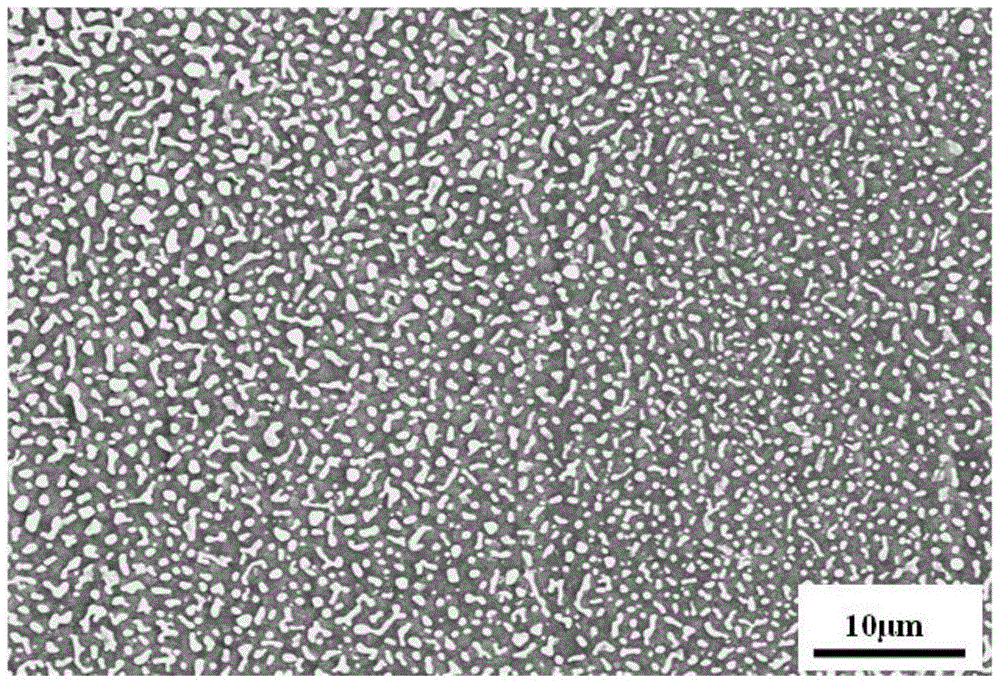

[0033] The rolled aluminum foil with an Al purity of 99.99%, a thickness of 110 μm, and a {100} plane texture occupancy of more than 95% is not enriched in Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga after recrystallization annealing , Ge, In, Sn, Pb, which have higher electrode potential than aluminum, use high-purity aluminum foil for medium and high-voltage anodes, and place them in a sodium hydroxide alkali solution with a temperature of 40 °C and a concentration of 1 mol / L for 30 seconds, and then do not go through deionization. Wash with water to cover the surface of the aluminum foil with a pretreatment lye film; place the above aluminum foil in a fog chamber for spray deposition tin crystal nucleus treatment, the composition of the solution is: 0.2mol / L sodium stannate+0.1mol / L sodium hydroxide +0.005 mol / L potassium sodium tartrate; the temperature in the spray deposition fog box is 60°C, and the spray deposition time is 2 minutes.

[0034] The above-mentioned aluminum foil that h...

Embodiment 2

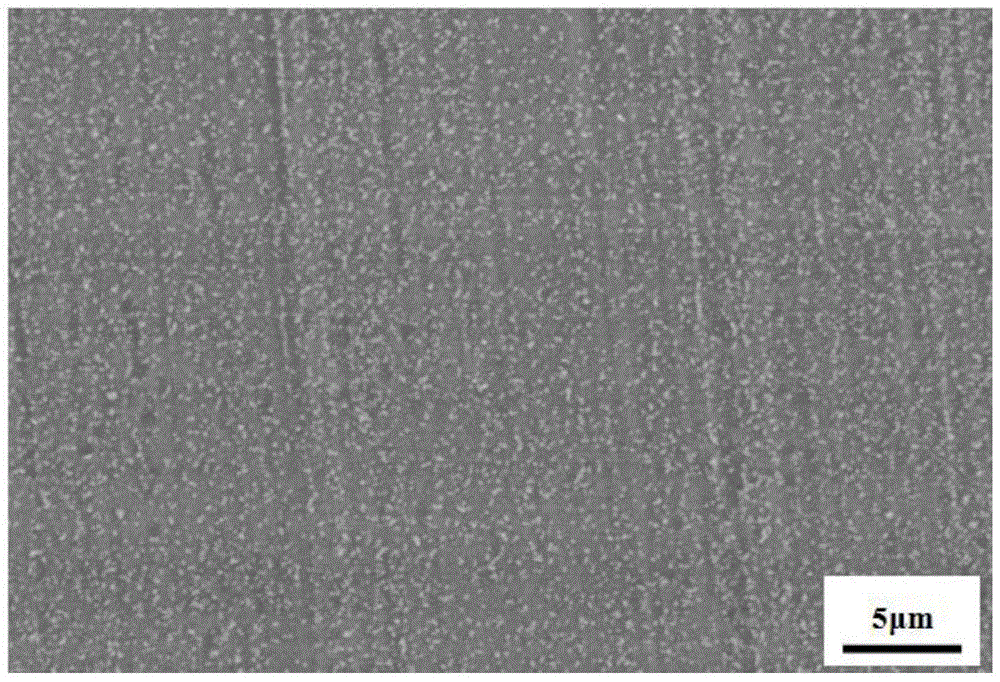

[0036] The rolled aluminum foil with an Al purity of 99.99%, a thickness of 110 μm, and a {100} plane texture occupancy of more than 95% is not enriched in Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga after recrystallization annealing , Ge, In, Sn, Pb, these medium and high voltage anodes whose electrode potential is higher than that of aluminum are treated with high-purity aluminum foil in a sodium hydroxide alkali solution with a temperature of 40°C and a concentration of 1mol / L for 30 seconds, and then without deionization cleaning , so that the surface of the aluminum foil is covered with a pretreatment lye film; the above-mentioned aluminum foil is placed in a fog box for spray deposition zinc crystal nucleus treatment, and the composition of the solution is: 0.2mol / L zinc oxide+0.3mol / L sodium hydroxide; spray deposition The temperature of the fog box is 60 °C, and the spray deposition time is 2 min.

[0037] The above-mentioned aluminum foil that has been deposited on the surface by ...

Embodiment 3

[0039] The rolled aluminum foil with an Al purity of 99.99%, a thickness of 110 μm, and a {100} plane texture occupancy of more than 95% is not enriched in Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga after recrystallization annealing , Ge, In, Sn, Pb, these medium and high voltage anodes whose electrode potential is higher than that of aluminum are treated with high-purity aluminum foil in a sodium hydroxide alkali solution with a temperature of 60°C and a concentration of 1mol / L for 15 seconds, and then without deionization cleaning , so that the surface of the aluminum foil is covered with a pre-treated lye film; then the above-mentioned aluminum foil is placed in a fog box for spray deposition tin crystal nucleus treatment, and the composition of the solution is: 0.2mol / L sodium stannate+0.1mol / L sodium hydroxide+ 0.005 mol / L potassium sodium tartrate; the temperature in the spray deposition fog box is 60° C., and the spray deposition time is 2 minutes.

[0040] The above-mentioned alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com