PZT/Si diffusion bonding method

A diffusion bonding and bonding technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, electrical components, circuits, etc., can solve the problems of difficult operation, complicated transfer bonding process, etc. Commercial promotion and application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

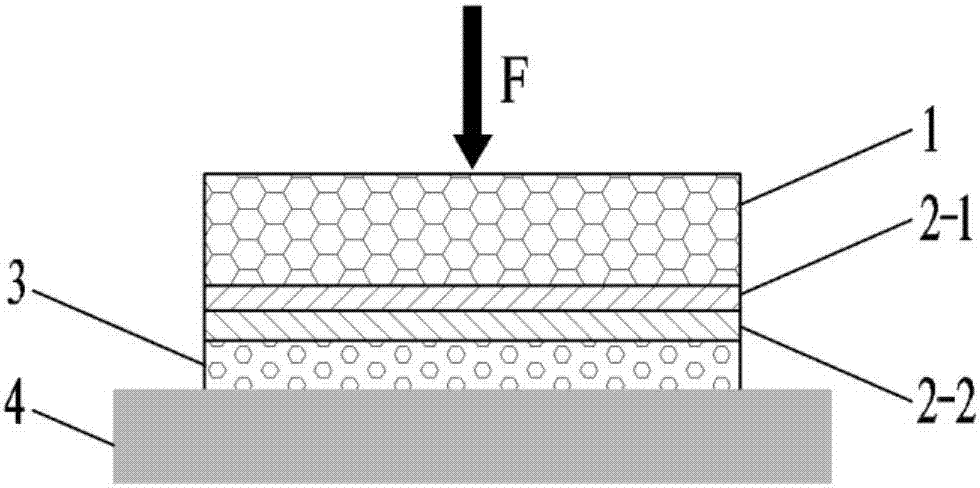

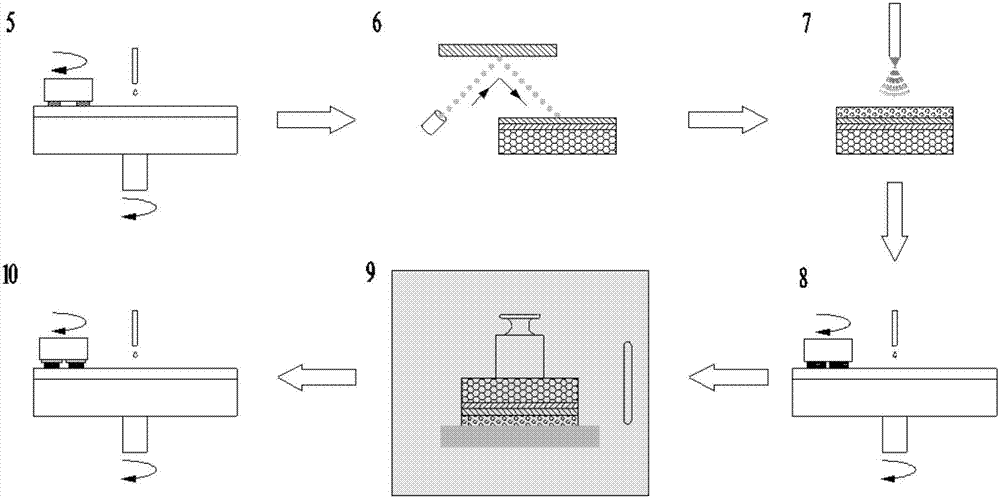

[0030] Firstly, the PZT block is ground, polished, and degreased; then, the Ti electrode and the Pt electrode are sputtered on the surface of the PZT block, and a certain thickness of PZT film is deposited on the surface of the Pt electrode. The PZT block and electrode layer and a PZT film constitute a PZT element. The PZT / Si diffusion bonding process is: under certain temperature conditions, by applying pressure to the PZT element and the silicon substrate, the PZT film and the silicon are diffusely bonded to achieve a stable combination of the PZT element / silicon; Grinding and polishing process to obtain PZT piezoelectric layer of desired thickness.

[0031] The concrete implementation steps of embodiment are as follows:

[0032] 1) Surface pretreatment of PZT blocks

[0033] In this embodiment, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com