Method and device for separating lead-antimony alloys by supergravity

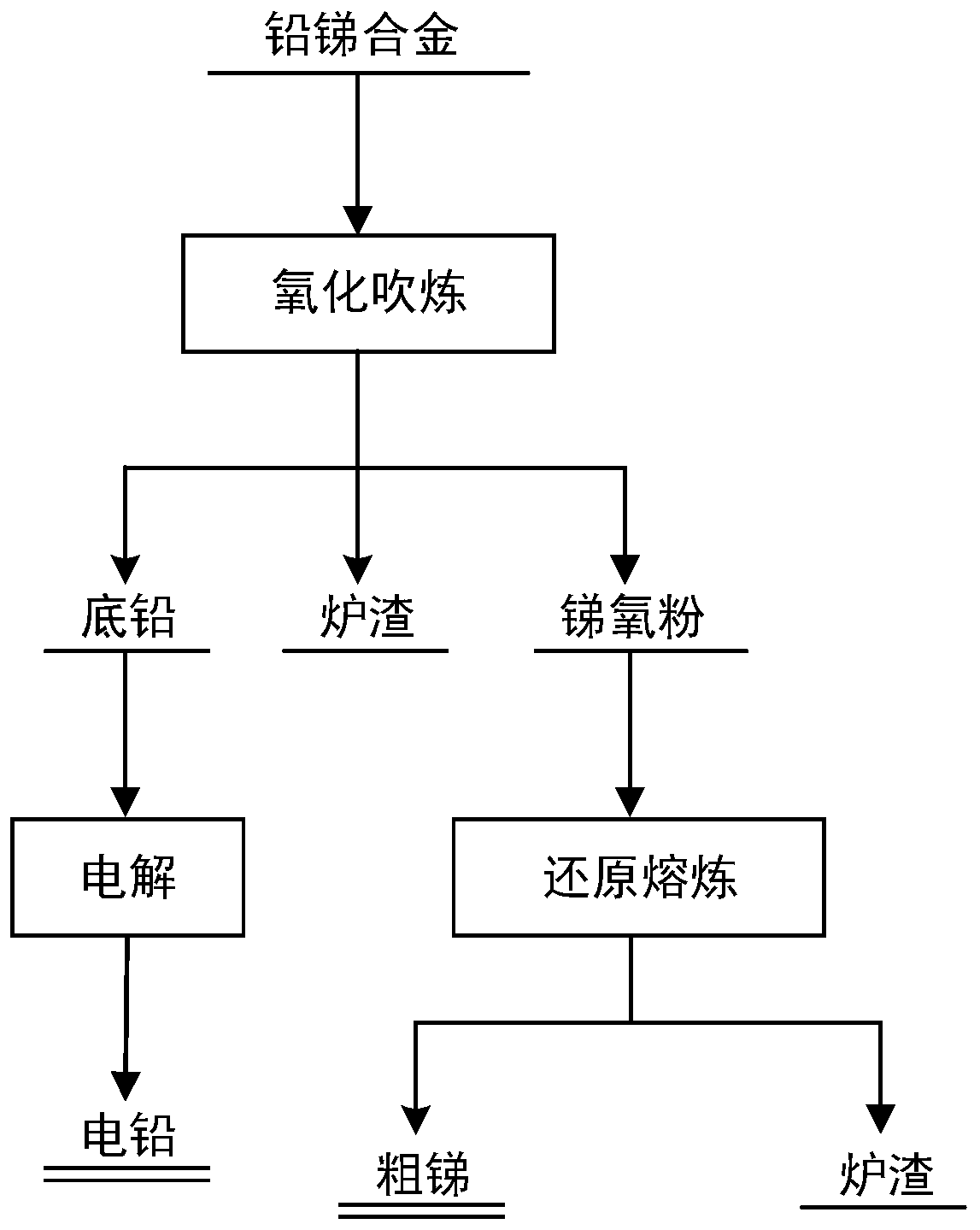

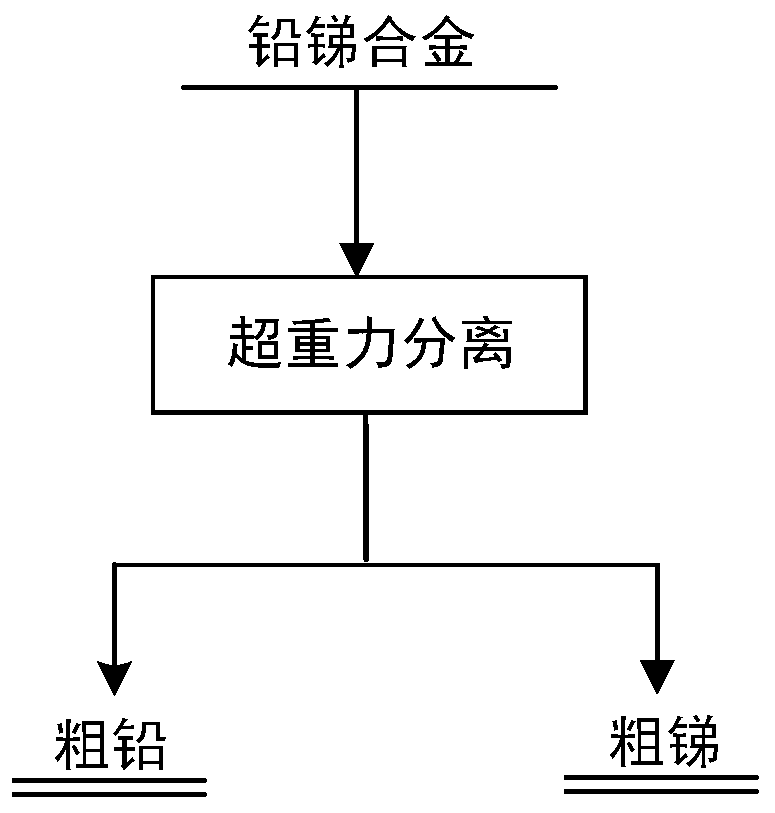

An antimony alloy and supergravity technology, which is applied in the field of alloy separation and lead-antimony alloy separation, can solve the problems of high equipment requirements, high production cost, three wastes in the production process, etc., and achieves improved metal recovery rate, improved production efficiency, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

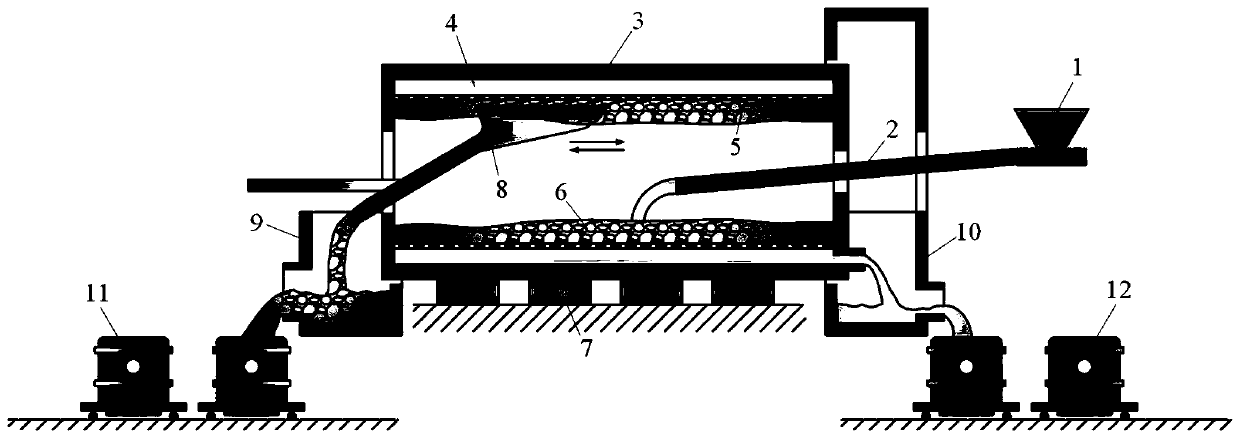

Embodiment 1

[0025] The main components of the lead-antimony alloy produced by pyrometallurgy of the brittle sulfur-lead-antimony concentrate in the S smelter contain 65.07wt% lead, 31.55wt% antimony, 0.36wt% silver, 1.01wt% copper, and 0.56wt% bismuth. Take 120kg of the raw material, and continuously add the lead-antimony alloy into the rotating supergravity separation reactor through the feeding system, control the superheating temperature to 680K, immediately start the supergravity separation system, and drive the supergravity separation reactor on the roller through the speed regulating motor Carry out high-speed rotation, adjust the speed of the supergravity separator so that the inner wall reaches a gravity coefficient of 400g, and control the separation time to 5 minutes. After the lead-antimony alloy is separated, close the supergravity separator, let it cool naturally, and take samples for chemical composition analysis. The lead-rich liquid mainly accumulates in the lower part of t...

Embodiment 2

[0028] The lead-antimony alloy produced by pyrometallurgy of brittle sulfur-lead-antimony concentrate in T smelter contains 52.69wt% lead, 44.38wt% antimony, 0.41wt% silver, 1.26wt% copper, and 0.48wt% bismuth. Take 150kg of the raw material, and continuously add the lead-antimony alloy into the rotating supergravity separation reactor through the feeding system, control the superheating temperature to 650K, immediately start the supergravity separation system, and drive the supergravity separation reactor on the roller through the speed regulating motor Carry out high-speed rotation, adjust the speed of the supergravity separator so that the inner wall reaches a gravity coefficient of 800g, and control the separation time to 10 minutes. After the lead-antimony alloy is separated, close the supergravity separator, cool naturally, and take samples for chemical composition analysis. The lead-rich liquid mainly accumulates in the lower part of the reaction chamber, while the antim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com