Lead-free glass printing ink for automobile toughened glass and preparation method of printing ink

A lead-free glass and automotive steel technology, applied in the field of automotive glass ink, can solve problems such as easy damage to nerves, digestive system and kidneys, human lead poisoning, restrictions on the use of lead-containing glass and lead-containing glass ink, and reduce the thermal expansion coefficient. , The effect of improving acid and alkali resistance and connecting closely to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

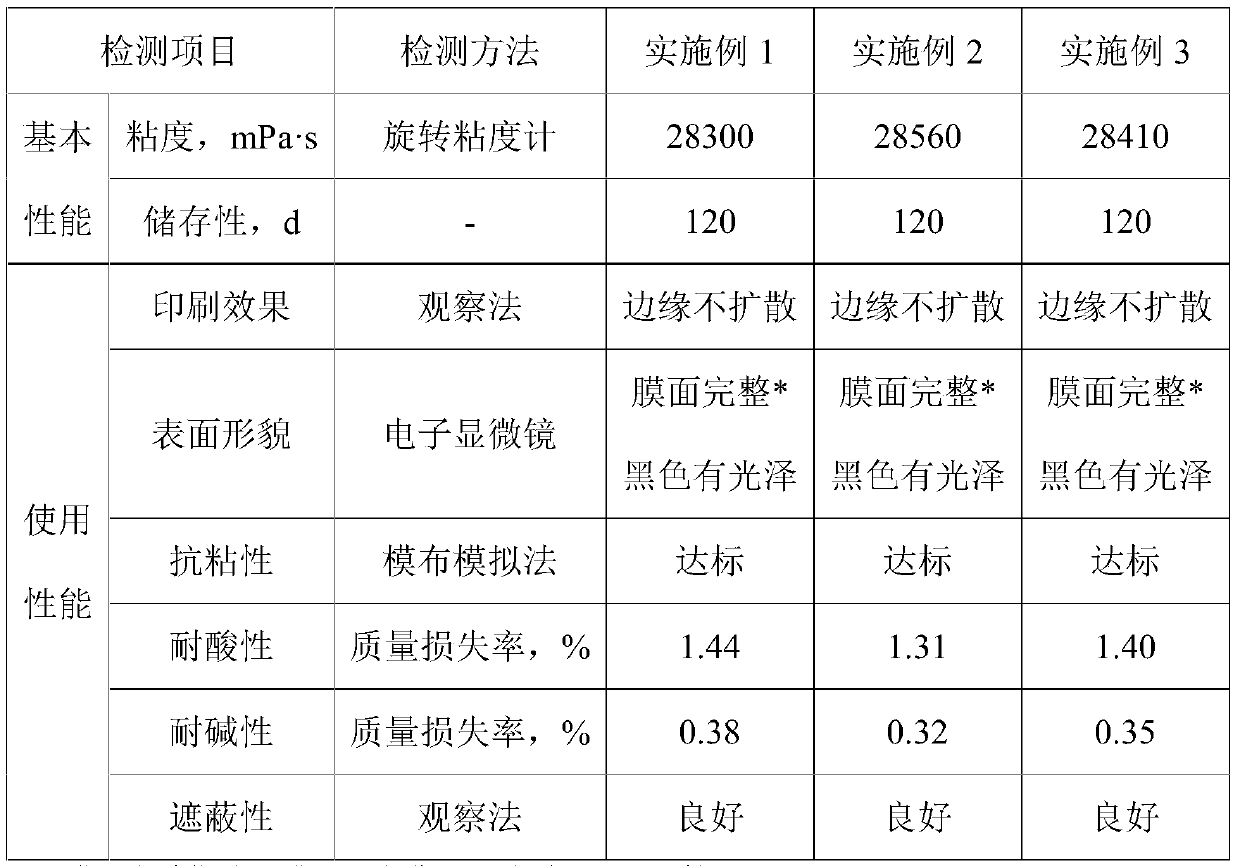

Examples

Embodiment 1

[0044] The automotive glass ink of the present embodiment uses the lead-free low-melting point glass powder, is made up of the component of following mol percentage: SiO 2 32.0%, B 2 o 3 15.7%, Bi 2 o 3 12.25%, ZnO23.4%, TiO 2 4.0%, Al 2 o 3 3.2%, Li 2 O2.2%, Na 2 O2.4%, CaO2.6%, ZrO 2 1.8%, Y 2 o 3 0.45%.

[0045] The preparation method of lead-free low-melting point glass powder for automotive glass ink of the present embodiment may further comprise the steps:

[0046] a) Take the chemical oxide or precursor (carbonate) raw material powder according to the above glass powder formula, mix it evenly, put it in a corundum crucible, put it into a high-temperature furnace, and raise the temperature to 1200°C at a rate of 15°C / min And keep it warm for 100 minutes to fully melt the glass to obtain a molten glass body, and then quickly pour the molten glass into deionized water for water quenching to obtain glass slag;

[0047] b) Put the glass slag obtained in st...

Embodiment 2

[0056] The automotive glass ink of the present embodiment uses the lead-free low-melting point glass powder, is made up of the component of following mol percentage: SiO 2 32.6%, B 2 o 3 15.1%, Bi 2 o 3 12.8%, ZnO22.8%, TiO 2 4.6%, Al 2 o 3 2.6%, Li 2 O2.8%, Na 2 O2.2%, CaO2.0%, ZrO 2 2.0%, Y 2 o 3 0.5%.

[0057] The preparation method of lead-free low-melting point glass powder for automotive glass ink of the present embodiment may further comprise the steps:

[0058] a) Take the chemical oxide or precursor (carbonate) raw material powder according to the above glass powder formula, mix it evenly, put it in a corundum crucible, put it into a high-temperature furnace, and raise the temperature to 1200°C at a rate of 15°C / min And keep it warm for 110 minutes to fully melt the glass to obtain a molten glass body, and then quickly pour the molten glass into deionized water for water quenching to obtain glass slag;

[0059] b) Put the glass slag obtained in step...

Embodiment 3

[0068] The automotive glass ink of the present embodiment uses the lead-free low-melting point glass powder, is made up of the component of following mol percentage: SiO 2 32.3%, B 2 o 3 15.4%, Bi 2 o 3 12.5%, ZnO23.15%, TiO 2 4.3%, Al 2 o 3 2.9%, Li 2 O2.5%, Na 2 O2.3%, CaO2.3%, ZrO 2 1.88%, Y 2 o 3 0.47%.

[0069] The preparation method of lead-free low-melting point glass powder for automotive glass ink of the present embodiment may further comprise the steps:

[0070] a) Take the chemical oxide or precursor (carbonate) raw material powder according to the above glass powder formula, mix it evenly, put it in a corundum crucible, put it into a high-temperature furnace, and raise the temperature to 1190°C at a rate of 15°C / min And keep it warm for 120 minutes to fully melt the glass to obtain a molten glass body, and then quickly pour the molten glass into deionized water for water quenching to obtain glass slag;

[0071] b) Put the glass slag obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com