Lead-free glass powder, preparation method thereof, silver paste containing glass powder and crystal silicon solar cell manufactured by using silver paste

A technology of lead-free glass powder and silver paste, applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problems of large particle size of glass powder, complex raw materials, high melting temperature, etc. Achieve the effect of low softening temperature, simple preparation process and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]The preparation method of the lead-free glass powder comprises the following steps: (1) weighing each component raw material according to the weight percentage to prepare a mixture; (2) heating and melting the mixture; (3) water quenching the melted glass liquid; 4) drying the water-quenched glass frit; (5) crushing the dried water-quenched glass frit into powder; (6) sieving and controlling the particle size of the glass powder to an ultrafine glass powder of 0.5-5 μm. Finally, the linear expansion coefficient and softening point of the glass frit were measured. Melting the mixture in step (2) is to put the mixture into a crucible and heat and melt in an electric furnace. The crucible is a corundum crucible, and the melting temperature is 1100-1300° C. for 10-30 minutes. In step (5), the dried water-tempered glass frit is pulverized into powder by a planetary ball milling method.

[0032] The silver paste containing the above-mentioned lead-free glass powder is obtain...

Embodiment 1

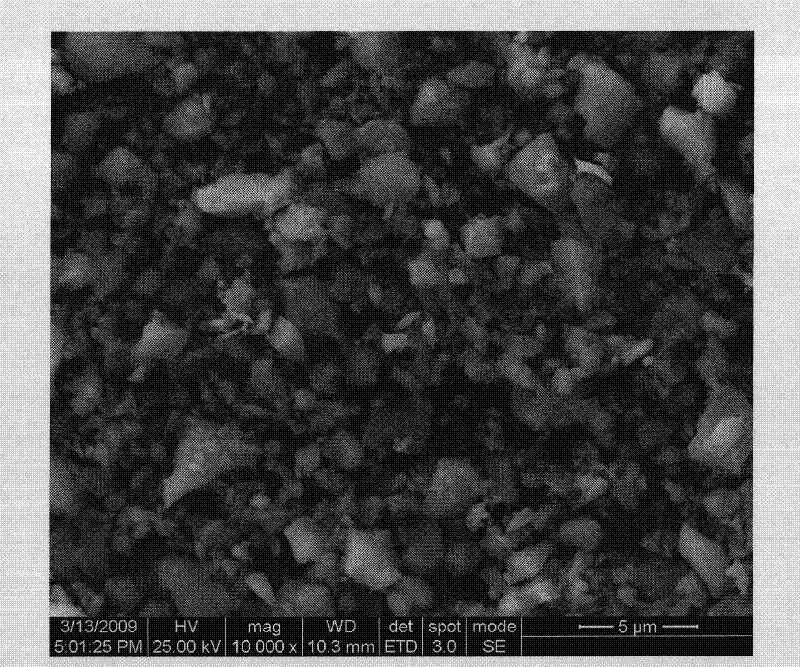

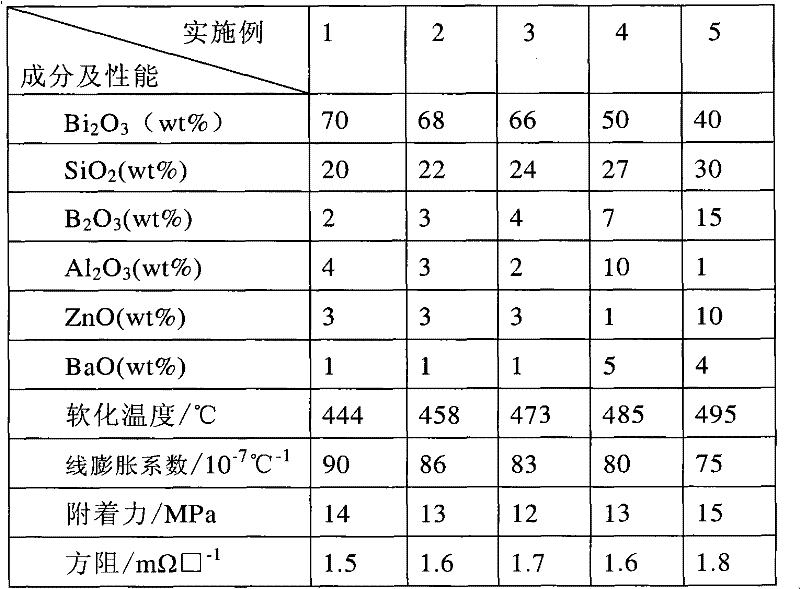

[0036] Batch 100g according to the formula of Example 1 in Table 1, and mix evenly, put the mixture into a corundum crucible, then heat and melt the corundum crucible in an electric furnace at a melting temperature of 1250°C and keep it warm for 10 minutes. The melted glass liquid is immediately poured into water for quenching, dried, and the glass frit is crushed into powder by planetary ball milling method, and sieved to obtain ultrafine glass powder with a particle size of 0.5-5 μm or less. The SEM scanning electron microscope picture of the prepared glass powder is as follows: figure 1 As shown, the figure proves that the particle size of the prepared glass powder is within the required range of 5 μm or less. After testing, the softening temperature of the lead-free glass powder is 444°C and the coefficient of linear expansion is 90×10 -7 ℃ -1 (See Table 1), compared with the softening temperature of the lead-free glass powder mentioned in CN101215091A in the background ...

Embodiment 2

[0038] Mix 100 g according to the formula of Example 2 in Table 1, and mix evenly. Put the mixture into a corundum crucible, and then heat and melt the corundum crucible in an electric furnace at a melting temperature of 1260° C. for 15 minutes. The melted glass liquid is immediately poured into water for quenching, dried, and the glass frit is crushed into powder by planetary ball milling method, and sieved to obtain ultrafine glass powder with a particle size of 0.5-5 μm or less. The SEM scanning electron micrograph of the prepared glass powder and figure 1 It is similar, so it is omitted to prove that the particle size of the prepared glass powder is within the required range of 5 μm or less. After testing, the softening temperature of the lead-free glass powder is 458°C and the coefficient of linear expansion is 86×10 -7 ℃ -1 (See Table 1), compared with the softening temperature of the lead-free glass powder mentioned in CN101215091A in the background technology up to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com