Frit for front silver paste of monocrystalline silicon solar cell and preparation method and application of frit

A solar cell and glass frit technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Achieve high tensile properties, low contact resistance, and strong corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In some embodiments, the preparation method comprises:

[0030] Respectively prepare raw materials according to the composition of the main glass frit and the auxiliary glass frit in the glass frit for the front silver paste of the monocrystalline silicon solar cell, mix the raw materials of the main glass frit or the auxiliary glass frit evenly, and then carry out Melting for 30-90 minutes; and,

[0031]The glass melt obtained by melting is subjected to quenching treatment, and then ball milled and dried to obtain the main glass frit or auxiliary glass frit, and the glass frit for the front silver paste of the monocrystalline silicon solar cell.

[0032] Further, the preparation method includes: mixing and homogenizing the raw materials of the main glass frit or the auxiliary glass frit by using a twin-roller or a three-dimensional mixer.

[0033] Further, the preparation method includes: performing the quenching treatment by quenching with deionized water or quenchin...

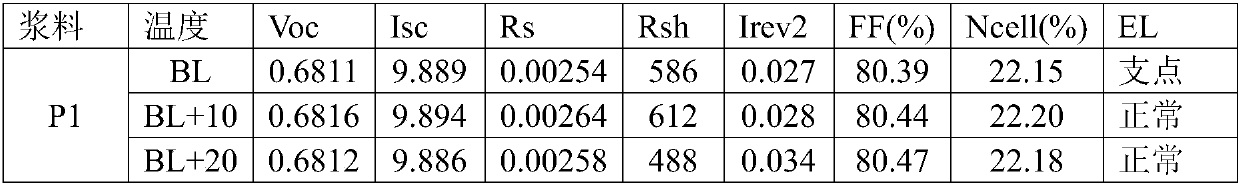

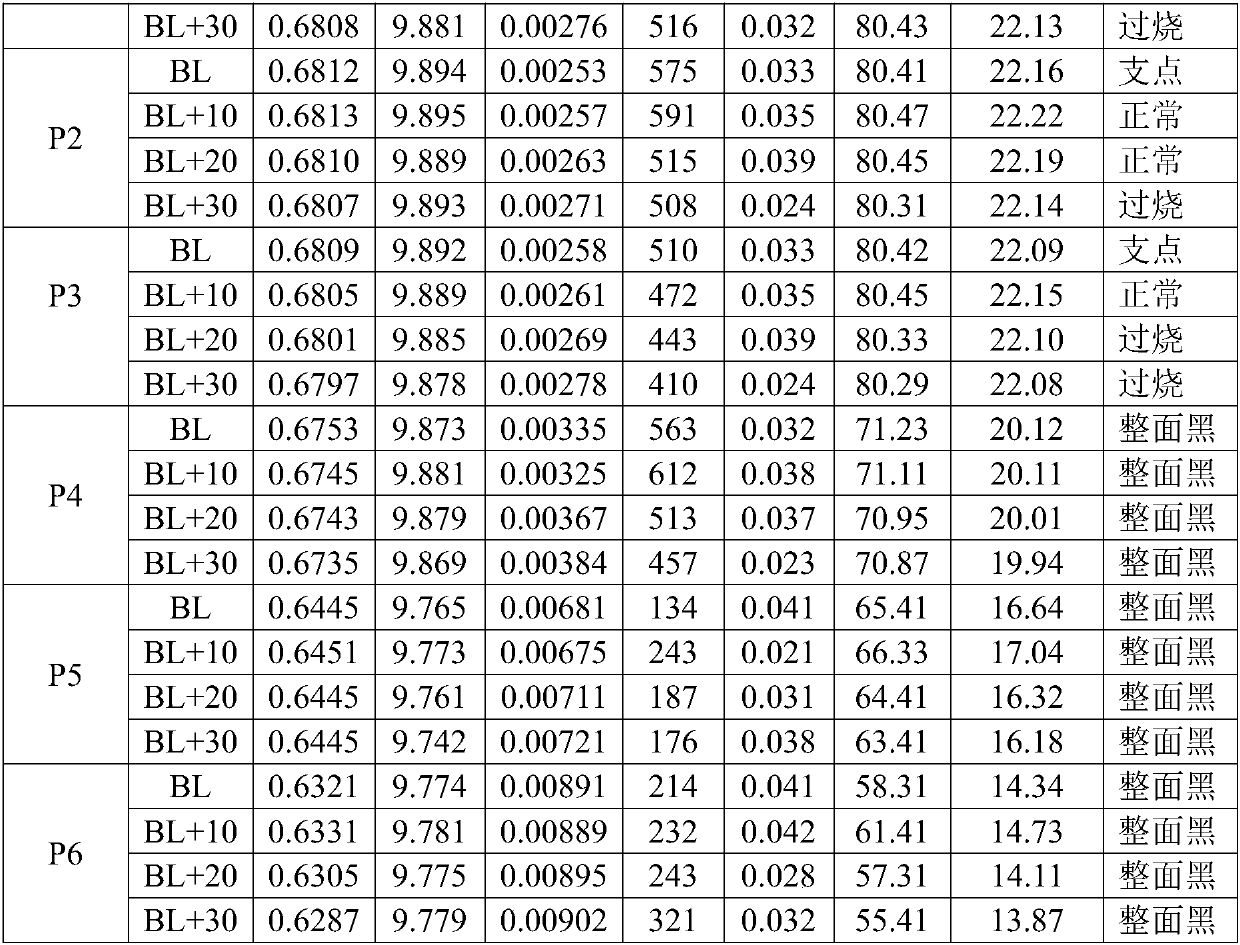

Embodiment 1

[0054] 1. The main glass frit A for the front silver paste of monocrystalline silicon solar cells, its components are: 60mol% TeO 2 , 15mol% Li 2 O, 15mol% ZnO, 10mol% Na 2 O, the preparation steps are: use a muffle furnace to melt the glass raw materials at 1300°C for 1 hour, after fully homogenizing, use the water quenching method to quench the glass, and use a planetary ball mill to mill the glass to obtain powder with a suitable particle size Shaped glass frit, the particle size distribution of the obtained glass frit D50≤4μm.

[0055] 2. Auxiliary glass frit B for front silver paste of monocrystalline silicon solar cell, its components are: 40mol%PbO, 20mol%Bi 2 o 3 , 20mol% Li 2 O, 10mol% SiO 2 , 10mol% WO 3 . Prepare according to the method of step 1 to obtain auxiliary glass frit B.

[0056] 3. the main glass frit A that 2wt% step 1 makes, the auxiliary glass frit B that 0.4wt% step 2 makes, 87.6wt% conductive silver powder, 3wt% polyvinyl butyral, 3wt% ethyl c...

Embodiment 2

[0058] 1. The main glass frit A for the front silver paste of monocrystalline silicon solar cells, its components are: 55mol% TeO 2 , 30mol% Li 2 O, 5mol% ZnO, 10mol% CuO, the preparation steps are: use a muffle furnace to melt the glass raw materials at 1000°C for 30 minutes, after fully homogenizing, use the water quenching method to quench the glass, and use a planetary ball mill to process the glass Ball milling to obtain powdered glass frit with suitable particle size, the particle size distribution D50 of the obtained glass frit is ≤ 4 μm.

[0059] 2. Auxiliary glass frit B for front silver paste of monocrystalline silicon solar cell, its components are: 50mol% PbO, 40mol% Bi 2 o 3 , 9mol% Li 2 O, 1mol% MoO 3 , the preparation steps are: use a muffle furnace to melt the glass raw materials at 1000°C for 30 minutes, after fully homogenizing, use the water quenching method to quench the glass, and use a planetary ball mill to mill the glass to obtain a powder with a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com