Glass frit for silicon solar cell paste and its preparation method and paste

A silicon solar cell and glass frit technology, applied in the field of solar cells, can solve the problems of insufficient adhesion, insufficient adhesion, over-soldering, etc., and achieve the effect of enhancing welding resistance and improving welding adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 (preparation of glass frit and comparative example)

[0014] Dosing according to the glass frit ratio (mass fraction) in Table 1 and Table 2, use a muffle furnace to melt the glass raw materials at 1100°C for 1 hour, after fully homogenizing, use a water-cooled counter-roller discharger for glass the quenching process. Afterwards, the glass is ball milled using a planetary ball mill to obtain powdered glass frit of suitable particle size. The particle size distribution D50 of the obtained glass frit is ≤ 2 μm.

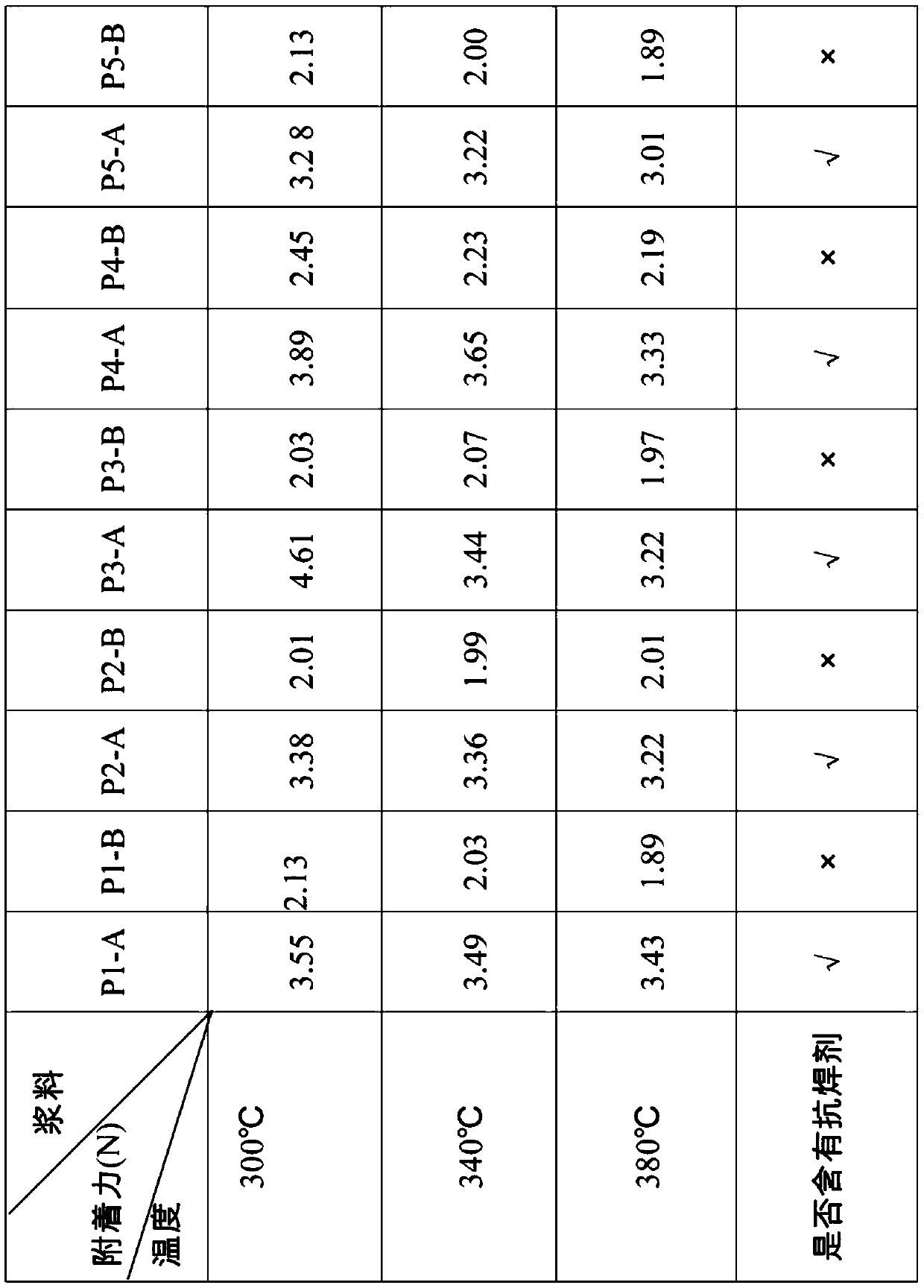

[0015] Included in the following table 1 are 10 example samples, G1-A, G2-A, G3-A, G4-A, G5-A, G6-A, G7-A, G8-A, G9-A and G10-A And 10 comparative samples G1-B, G2-B, G3-B, G4-B, G5-B, G6-B, G7-B, G8-B, G9-AB and G10-B.

[0016] Table 1

[0017] PbO B 2 o 3

ZnO SiO 2

Al 2 o 3

MgO CuO G1-A 10 15 10 5 5 5 50 G1-B 10 30 20 15 15 10 0 G2-A 40 7 5 3 5 0 40 G2-B 40 20 2...

Embodiment 2

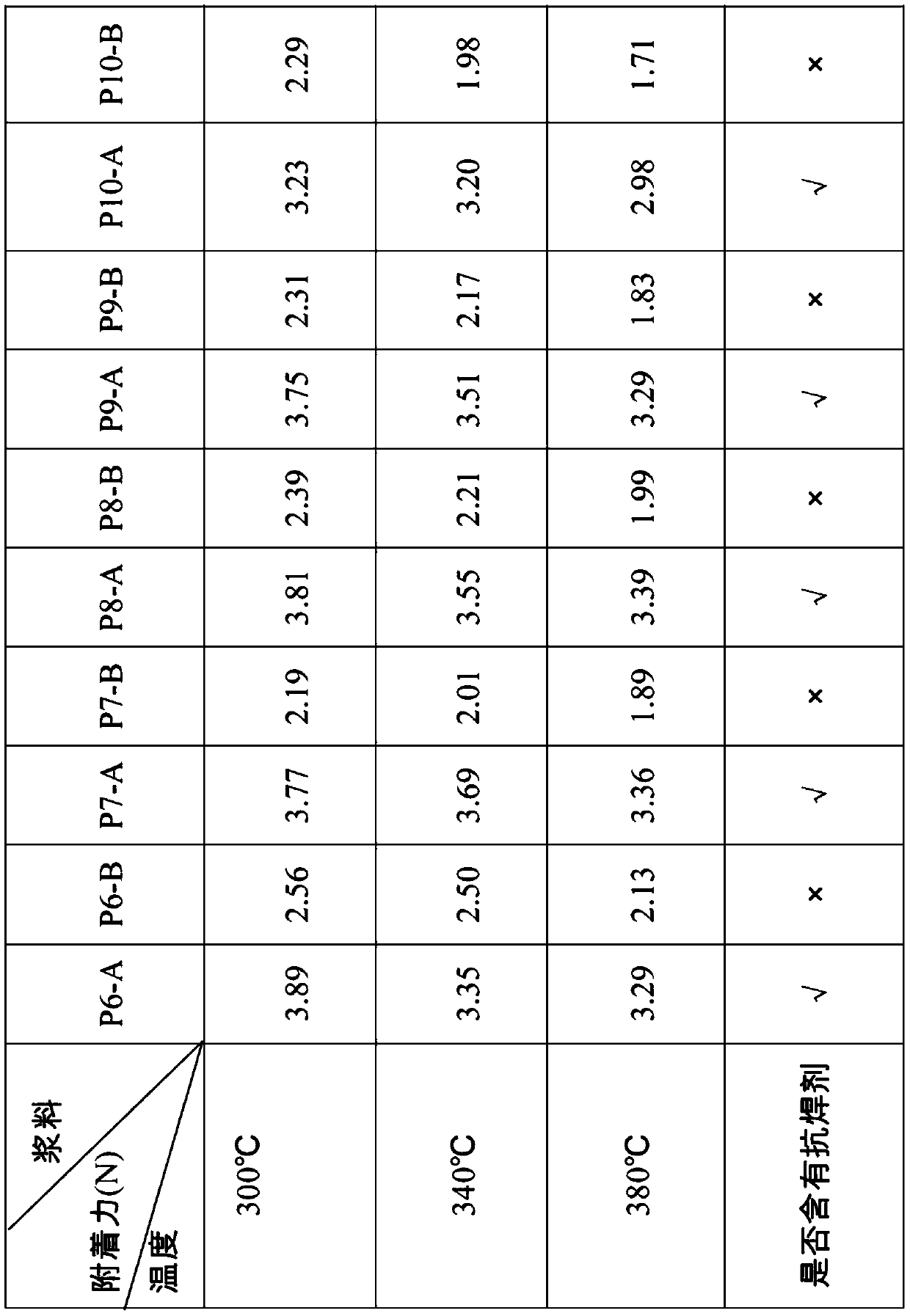

[0025] Fully mix 87wt% conductive silver powder, 2wt% G1-A glass frit, and 11wt% organic medium, use a three-roll mill to grind the slurry, and use a scraper fineness tester to test the grinding fineness. The slurry grinding fineness is below 6 μm. The prepared slurry was named P1-A.

Embodiment 3

[0027] Fully mix 88wt% conductive silver powder, 2wt% G2-A glass frit, and 10wt% organic medium, use a three-roll mill to grind the slurry, and use a scraper fineness tester to test the grinding fineness. The slurry grinding fineness is below 6 μm. The resulting slurry was named P2-A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com