Alloy silver powder and its preparation method and solar conductive paste prepared therefrom

A technology of conductive paste and solar energy, which is applied in the field of solar cells, can solve problems such as the decrease of adhesion of solar cell electrodes, high temperature damage of solar cells, and affecting the conversion efficiency of cells, and achieve the effects of reducing migration, prolonging life, and improving soldering adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

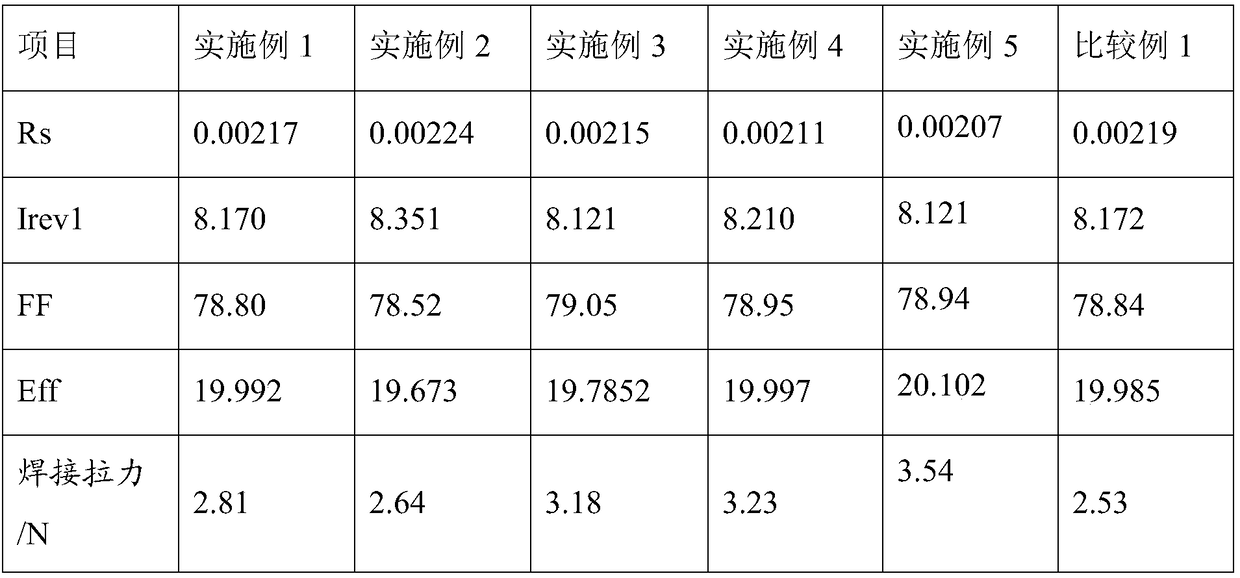

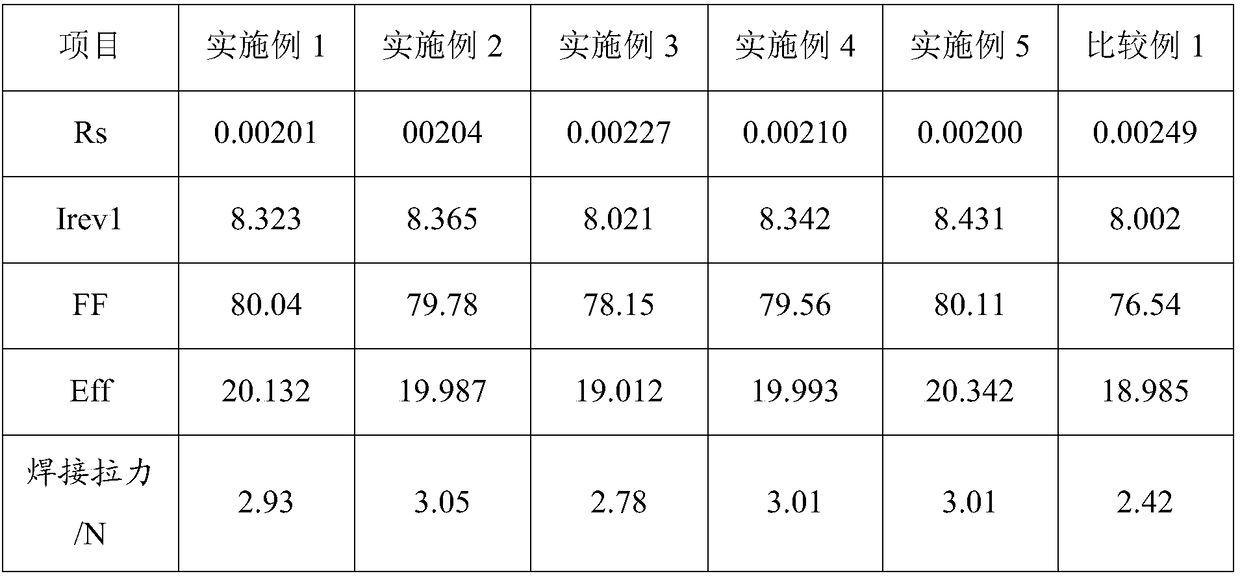

Embodiment 1

[0038] Take by weighing prepared Ag / Bi alloy powder 10g (wherein Bi content is 1.0%-1.3% by mass percentage), pure silver powder 80g, inorganic glass powder Bi-B-Si series 2.0g, organic carrier 8g, in mixer Pre-mixing, and then mixing and rolling on a three-roller machine to obtain front-side silver conductive paste.

Embodiment 2

[0040] Take by weighing prepared Ag / Ni alloy powder 20g (wherein Ni content is 1.5%-1.7% by mass percentage), pure silver powder 70g, inorganic glass powder Te-Bi-B series 2.0g, organic carrier 8g, in mixer Pre-mixing, and then mixing and rolling on a three-roller machine to obtain front-side silver conductive paste.

Embodiment 3

[0042] Take by weighing prepared Ag / Al alloy powder 5g (wherein Al content is 1.2%-1.4% by mass percentage), pure silver powder 85g, inorganic glass powder Te-Bi-B series 2.0g, organic vehicle 8g, in mixer Pre-mixing, and then mixing and rolling on a three-roller machine to obtain front-side silver conductive paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com