High-voltage CSP lamp bead packaging structure and manufacturing process thereof

A technology of packaging structure and manufacturing process, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of easy secondary melting, small pads, and unsuitability for use in high-voltage environments, and improve the effective welding area. , increase the weldable area, and release the effect of temperature limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

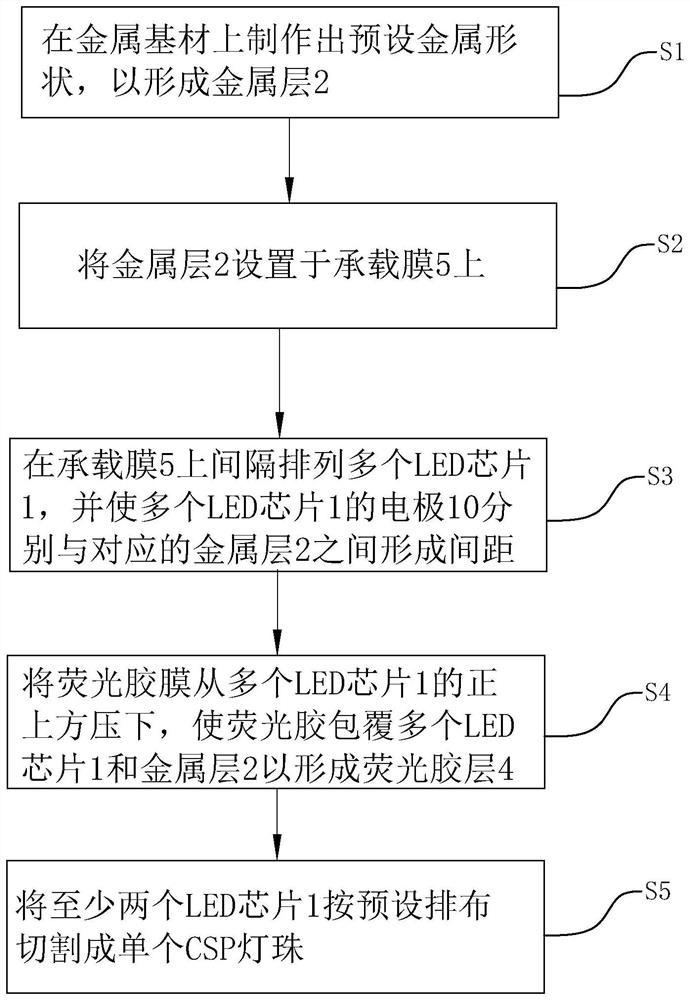

[0062] Such as Figure 4-11 As shown, a manufacturing process of a high-voltage CSP lamp bead packaging structure includes the following steps:

[0063] S1. Make a preset metal pattern on the metal substrate, clean and leave the metal layer 2 required for this application;

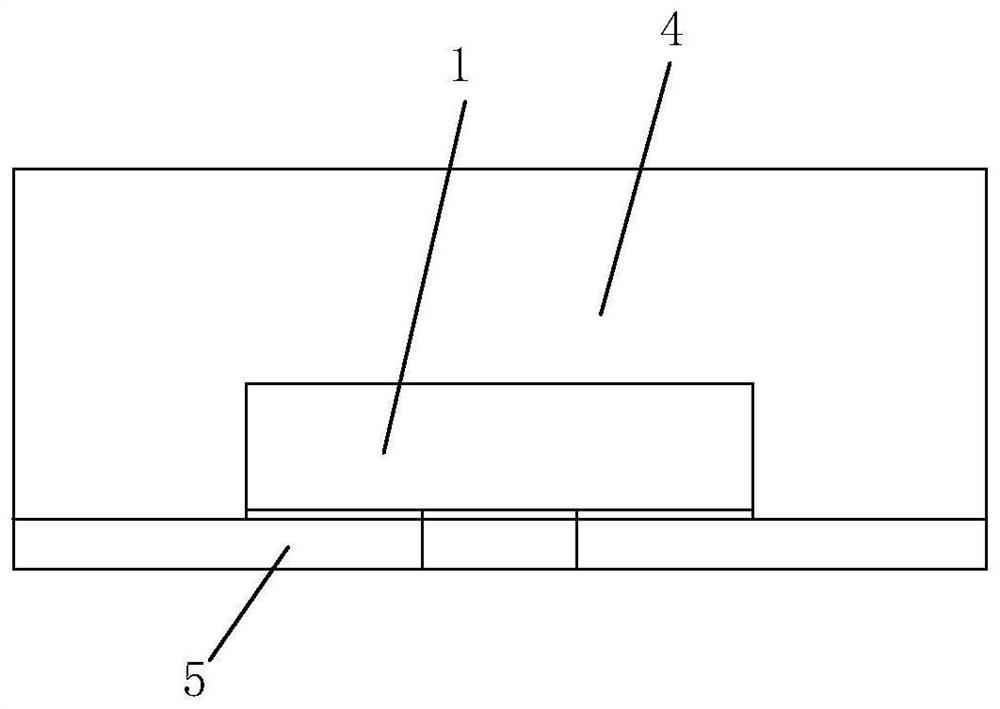

[0064] S2, disposing the metal layer 2 on the carrier film 5;

[0065] S3, arranging a plurality of LED chips 1 at intervals on the carrier film 5, and forming a distance between the electrodes 10 of the plurality of LED chips 1 and the corresponding metal layer 2;

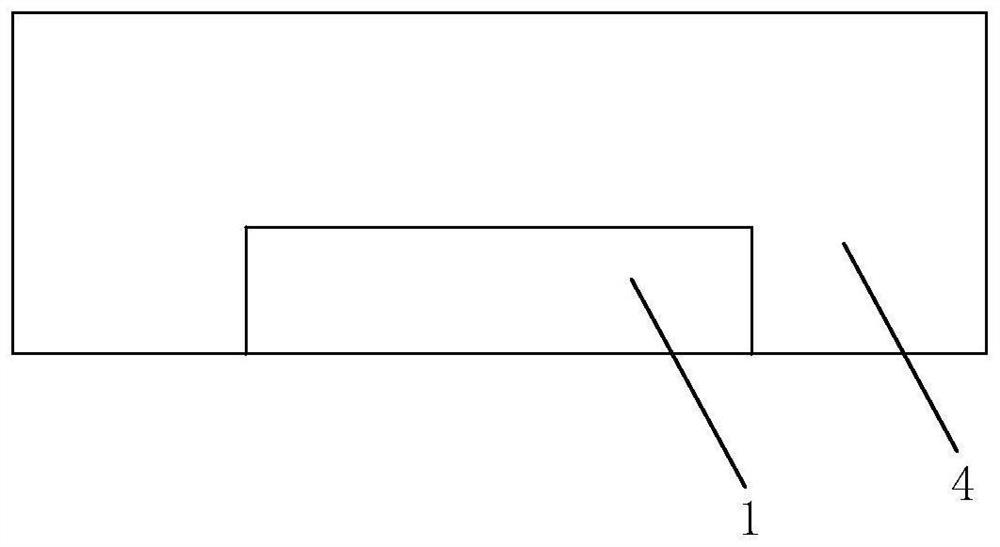

[0066] S4. Press the fluorescent adhesive film from directly above the plurality of LED chips 1, make the fluorescent adhesive cover the plurality of LED chips 1 and the metal layer 2 to form the fluorescent adhesive layer 4, and make the bottom surface of the electrode 10 of the LED chip 1 and the bottom surface of the LED chip 1 The bottom surface of the metal layer 2 is exposed;

[0067] S5. Cutting at least two LED chips 1 into a single...

Embodiment 2

[0072] Such as Figure 12-19 As shown, a manufacturing process of a high-voltage CSP lamp bead packaging structure includes the following steps:

[0073] S1. Make a preset metal pattern on the metal substrate, clean and leave the metal layer 2 required for this application;

[0074] S2, disposing the metal layer 2 on the carrier film 5;

[0075] S3, arranging a plurality of LED chips 1 at intervals on the carrier film 5, and forming a distance between the electrodes 10 of the plurality of LED chips 1 and the corresponding metal layer 2;

[0076] S4. Press the fluorescent adhesive film from directly above the plurality of LED chips 1, make the fluorescent adhesive cover the plurality of LED chips 1 and the metal layer 2 to form the fluorescent adhesive layer 4, and make the bottom surface of the electrode 10 of the LED chip 1 and the bottom surface of the LED chip 1 The bottom surface of the metal layer 2 is exposed;

[0077] S5. Cutting at least two LED chips 1 into a singl...

Embodiment 3

[0082] Such as Figure 20-28 As shown, a manufacturing process of a high-voltage CSP lamp bead packaging structure includes the following steps:

[0083] S1. Make a preset metal pattern on the metal substrate, clean and leave the metal layer 2 required for this application;

[0084] S2, disposing the metal layer 2 on the carrier film 5;

[0085] S3, arranging a plurality of LED chips 1 at intervals on the carrier film 5, and forming a distance between the electrodes 10 of the plurality of LED chips 1 and the corresponding metal layer 2;

[0086] S4. Set up a retaining wall 3 around the side of the LED chip 1 through glue dispensing, film pressing or injection molding process;

[0087] S5. Press the fluorescent adhesive film from directly above the plurality of LED chips 1, make the fluorescent adhesive cover the plurality of LED chips 1, the metal layer 2 and the retaining wall 3 to form the fluorescent adhesive layer 4, and make the electrodes of the LED chips 1 10 the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com