CSP lamp bead packaging structure and manufacturing process thereof

A technology of packaging structure and manufacturing process, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that the process temperature cannot be approached or exceeded, the secondary melting of the die-bonding solder, and the small adhesion, etc., to improve the small welding area , increase the weldable area, improve the effect of welding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Such as Figure 3-13As shown, a manufacturing process of a CSP lamp bead packaging structure includes the following steps:

[0054] S1. Cutting and bonding: prepare the metal substrate 31 of the metal layer 3 and the insulating substrate 21 of the insulating carrier layer 2 with suitable sizes, and bond the materials of the metal substrate 31 and the insulating substrate 21 together;

[0055] S2. Making circuits and opening holes: making a preset metal pattern on the metal substrate 31, and opening holes on the insulating substrate;

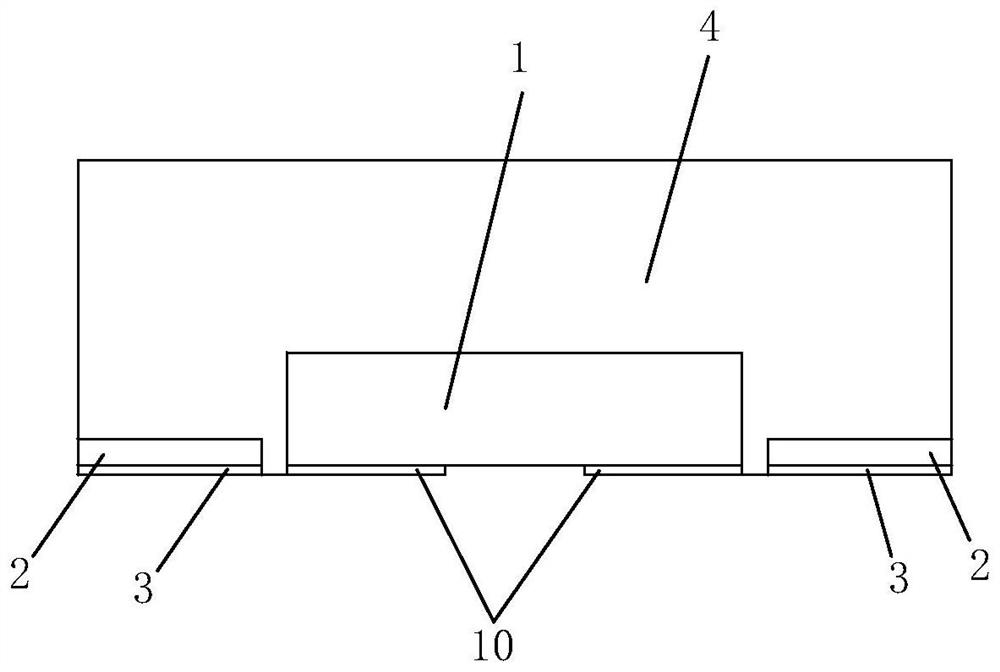

[0056] S3. Arranging crystals: arranging the LED chips 1 in the openings, and forming a distance between the electrodes 10 of the LED chips 1 and the metal substrate 31;

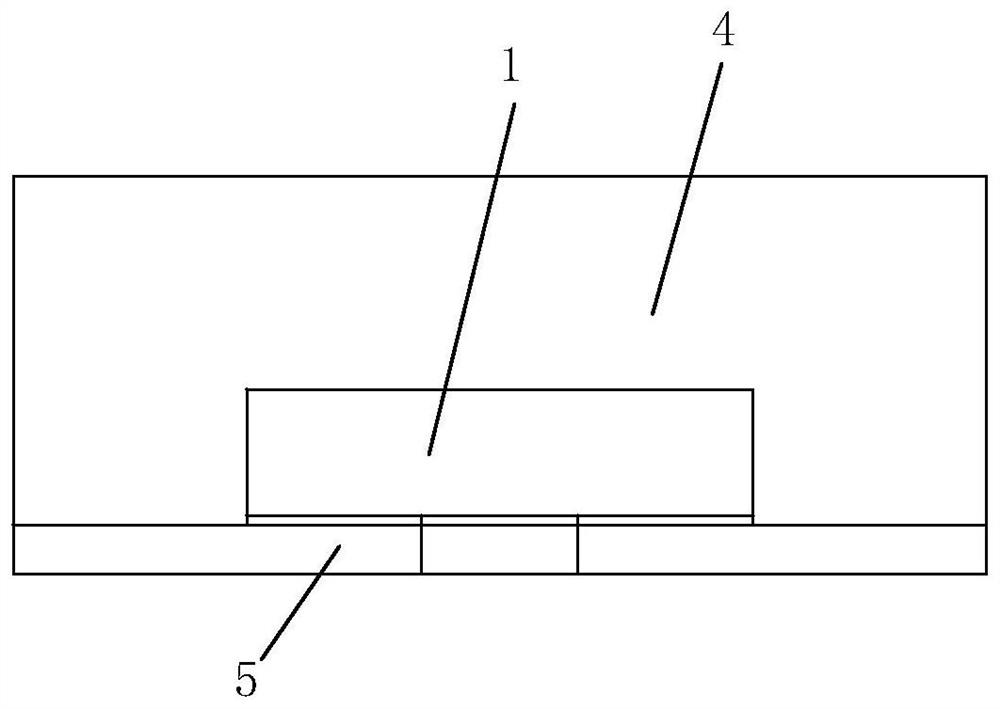

[0057] S4. Film pressing: Press the prepared fluorescent adhesive film from the top of the chip, and package the LED chip 1, insulating substrate 21 and metal substrate 31 to form a fluorescent adhesive layer. The fluorescent adhesive 4 is on the LED chip 1. filling th...

Embodiment 2

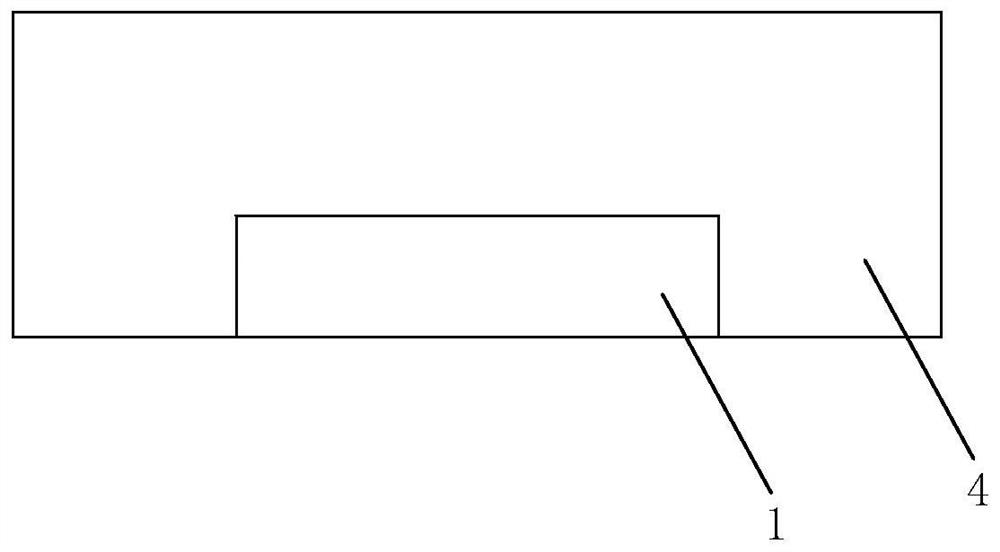

[0081] Such as Figure 3-13 As shown, a CSP lamp bead packaging structure includes LED chip 1, insulating carrier layer 2, metal layer 3 and fluorescent glue 4; electrode 10 is provided at the bottom of LED chip 1; insulating carrier layer 2 is arranged around said LED chip 1 side; the metal layer 3 is arranged at the bottom of the insulating carrier layer 2, and has a distance from the electrode 10; the fluorescent glue 4 encapsulates the LED chip 1, the insulating carrier layer 2 and the metal layer 3, and makes the electrode 10. The bottom surface and the bottom surface of the metal layer 3 are exposed. An insulating carrier layer is arranged around the LED chip, and a metal layer with a distance from the electrode of the LED chip is arranged at the bottom of the insulating carrier layer. The LED chip and the insulating carrier layer are bonded together by fluorescent glue. Packaged with the metal layer, this application sets the metal layer at intervals on the side of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com