Frit mixture as well as application and preparation method thereof

A glass frit and mixture technology, applied in the field of glass frit composition, can solve the problems of unfavorable environmental protection, unfavorable for energy saving and environmental protection, high thermal expansion coefficient, etc., and achieve the effect of lowering the glass transition temperature and softening temperature, and excellent low-temperature firing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

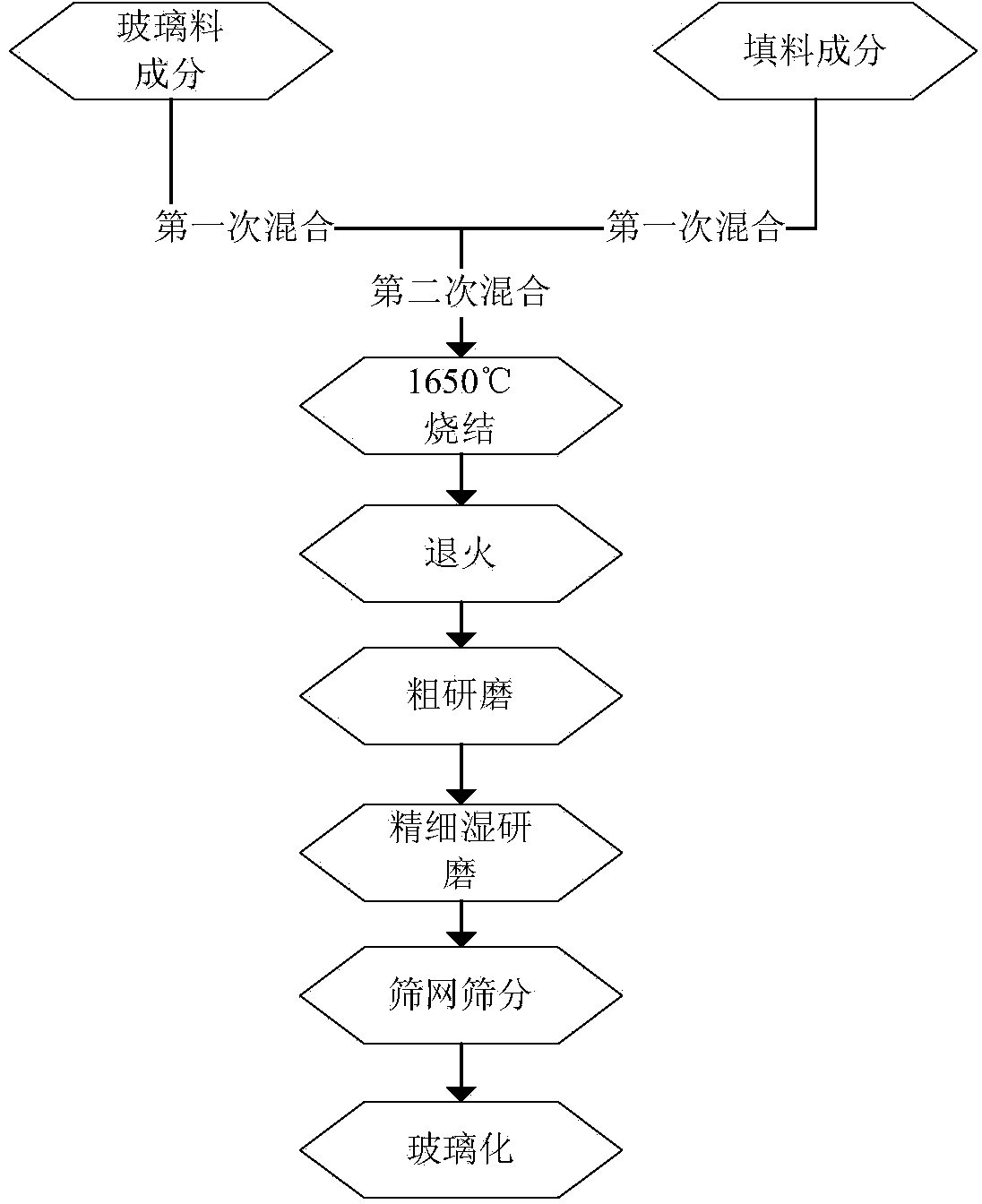

Method used

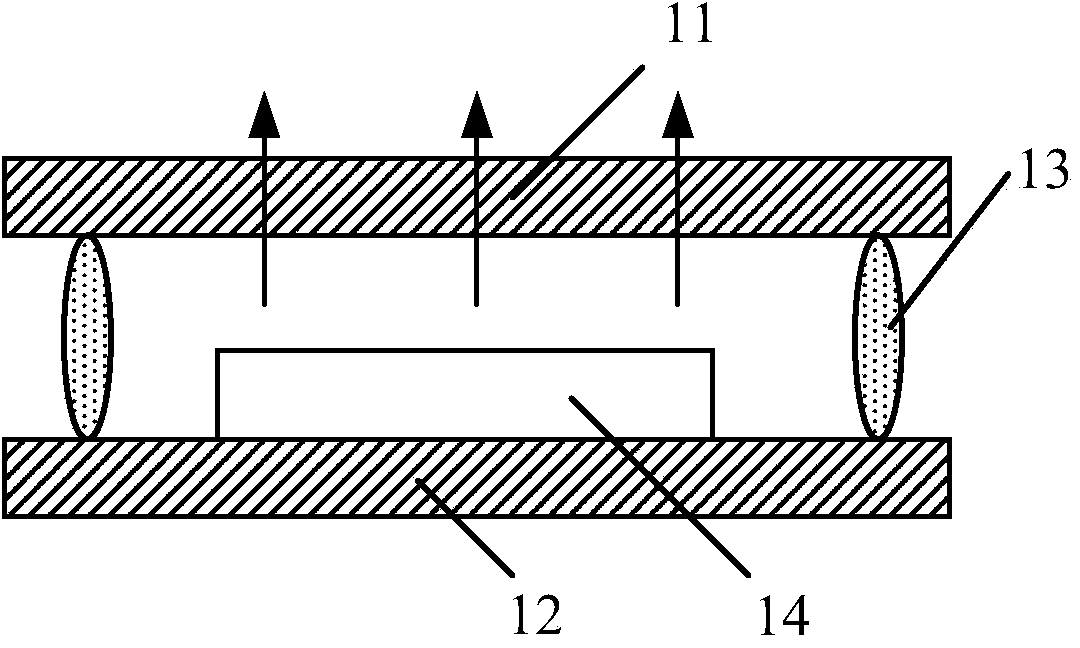

Image

Examples

Embodiment 1

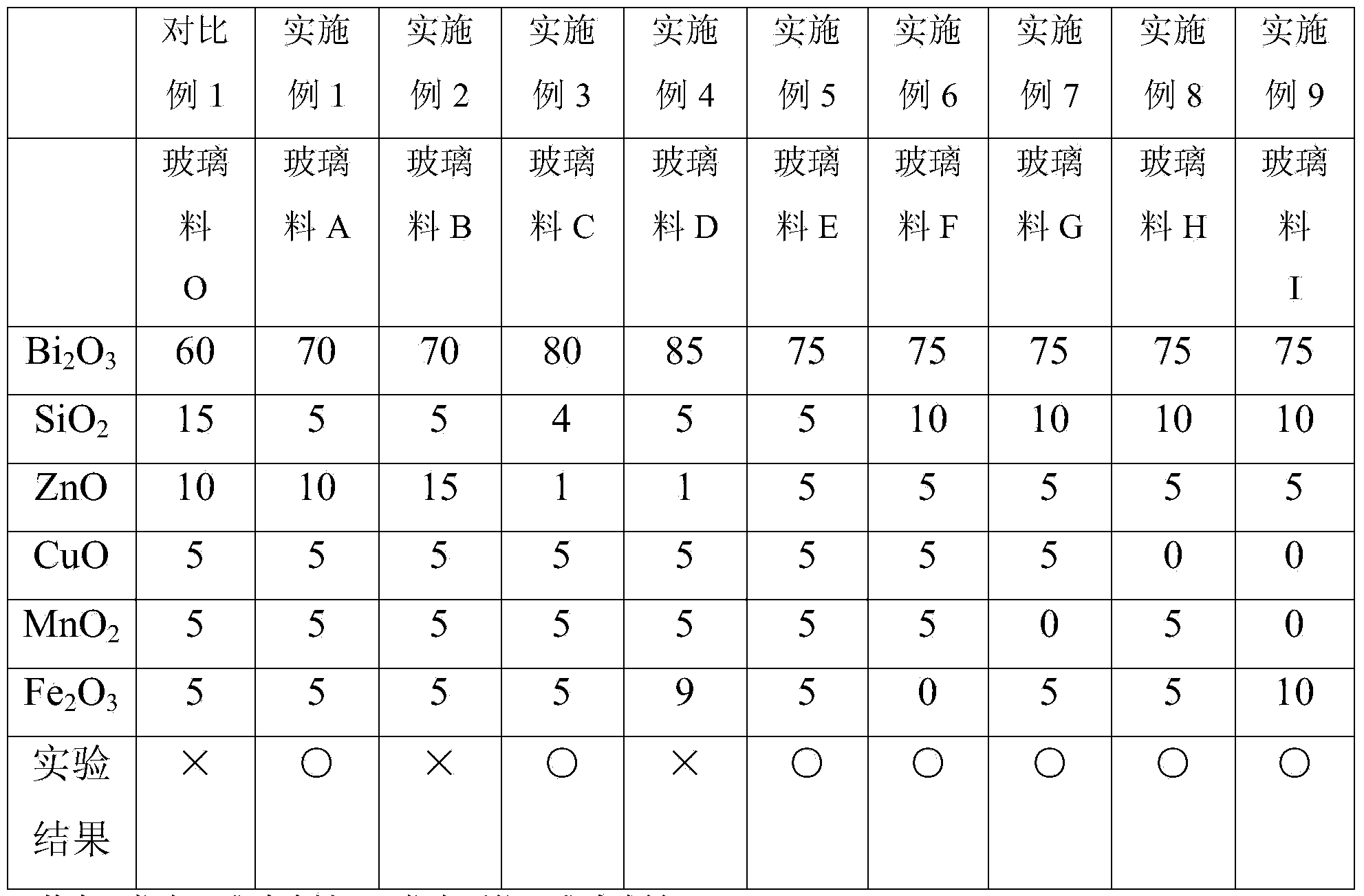

[0058] The formula composition of table 1 comparative example 1 and embodiment 1-9

[0059]

[0060] * Among them, ○ represents the formation of glass frit, and × represents that the glass frit cannot be formed.

[0061] In the above Table 1, Comparative Example 1, Example 2 and Example 4 did not form glass frit and could not seal electrical components, while in other examples, glass frit of 0.1 μm-20 μm could be produced.

[0062] Utilize the glass frit mixture of the above-mentioned embodiment 5-9 that can form the glass frit to manufacture the low-temperature soldering frit mixture, the glass frit mixture in the above-mentioned embodiment 5-9, the polymer binder and the organic solvent are according to the weight of the following table 2 Weigh and mix the parts, the type of polymer adhesive and solvent and different weight ratios can be adjusted according to the needs, and different viscosities of the low-temperature soldering glass frit mixture can be obtained, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com