Polyaspartate polyurea coating and application thereof

A technology of aspartic acid ester and polyurea, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as inconvenient construction, low adhesion, too fast gelation, etc., to prolong the use time, Improves flexibility and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

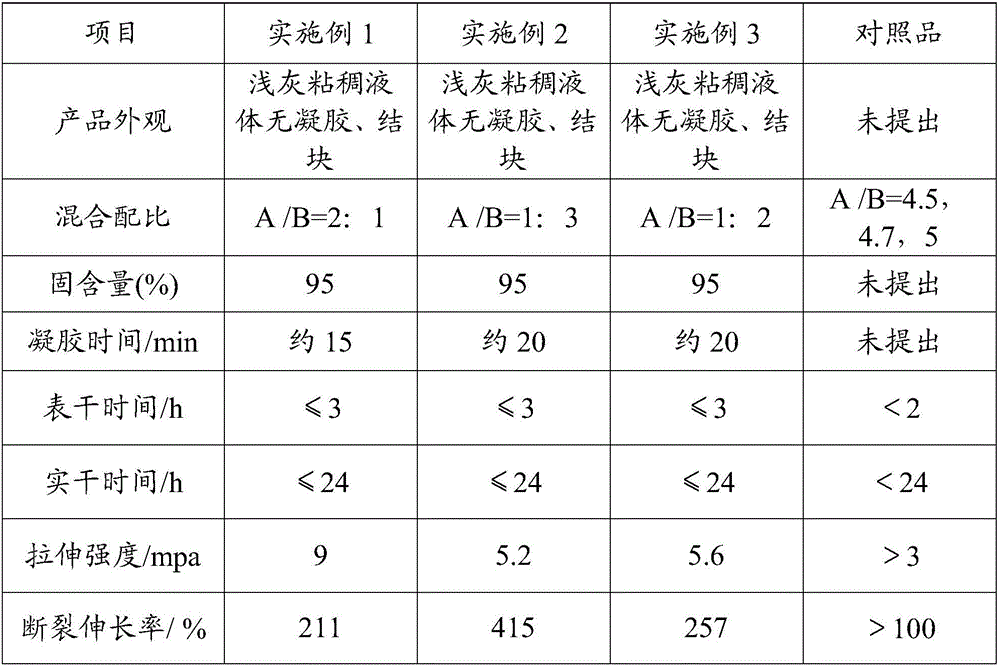

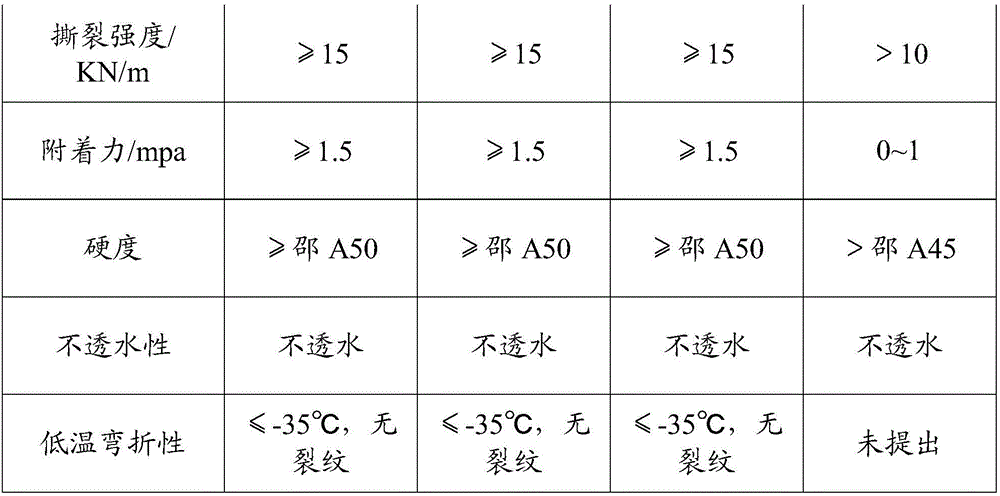

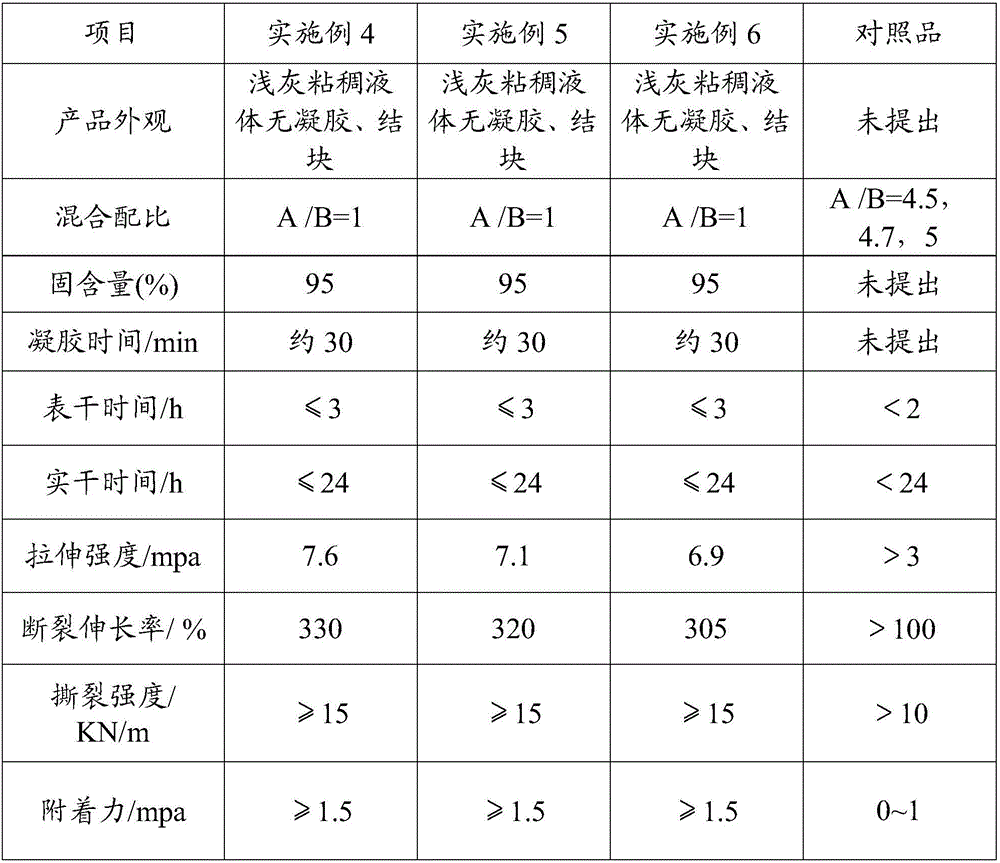

Embodiment 1

[0025] A kind of embodiment of polyaspartic acid ester polyurea coating of the present invention, the raw material and the parts by weight of polyaspartic acid ester polyurea coating described in the present embodiment are respectively: polyaspartic acid ester 46 parts , 2 parts of polyether modified silicon defoamer, 2.6 parts of polyether ammonia wetting and dispersing agent, 0.4 part of fumed silica, 44 parts of talcum powder and 5 parts of water absorbing agent; the B component is polyether modified 50 parts of permanent toluene diisocyanate.

[0026] The polyaspartate described in this example is Bayer NH1420, the polyether modified silicon defoamer is Wancheng BYC-710, the polyetheramine wetting and dispersing agent is Huntsman FM-300, and the water absorbing agent For Dibaa-30X, the modified polyether used in polyether-modified toluene diisocyanate is polycarbonate diol.

Embodiment 2

[0028] A kind of embodiment of polyaspartic acid ester polyurea coating of the present invention, the raw material and the parts by weight of polyaspartic acid ester polyurea coating described in this embodiment are respectively: 40 parts of polyaspartic acid ester , 1 part of vinyl defoamer, 1 part of polyether amine wetting and dispersing agent, 1 part of fumed silica, 55 parts of heavy calcium powder and 2 parts of water-absorbing agent; the B component is polyether modified toluene 300 parts of diisocyanate.

[0029] The polyaspartate described in this example is Bayer NH1420, the vinyl defoamer is ZY-357, the polyetheramine wetting and dispersing agent is Huntsman FM-300, and the water absorbing agent is Dibaa-30X. The modified polyether used in the polyether-modified toluene diisocyanate is polytetramethylene glycol.

Embodiment 3

[0031] A kind of embodiment of polyaspartic acid ester polyurea coating of the present invention, the raw material and the parts by weight of polyaspartic acid ester polyurea coating described in this embodiment are respectively: 50 parts of polyaspartic acid ester , 4 parts of silicone defoamer, 3 parts of polyether amine wetting and dispersing agent, 0.1 part of kaolin, 45 parts of calcium carbonate and 3.9 parts of water absorbing agent; the B component is 200 parts of polyether modified toluene diisocyanate .

[0032] The polyaspartate described in this embodiment is Bayer NH1420 and Bayer NH1520 (the ratio of the two is 4:5), the silicone defoamer is Defeng DF-853, and the polyetheramine wetting and dispersing agent is Huntsman FM-300, the water absorbent is Dibaa-30X, and the modified polyether used in polyether-modified toluene diisocyanate is polypropylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com