3D printing method for building beam component

A technology of 3D printing and beam components, applied in the field of 3D printing technology, can solve the problem of less application of 3D printing technology, achieve the effect of high quality, reduce labor costs and production costs, and improve manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

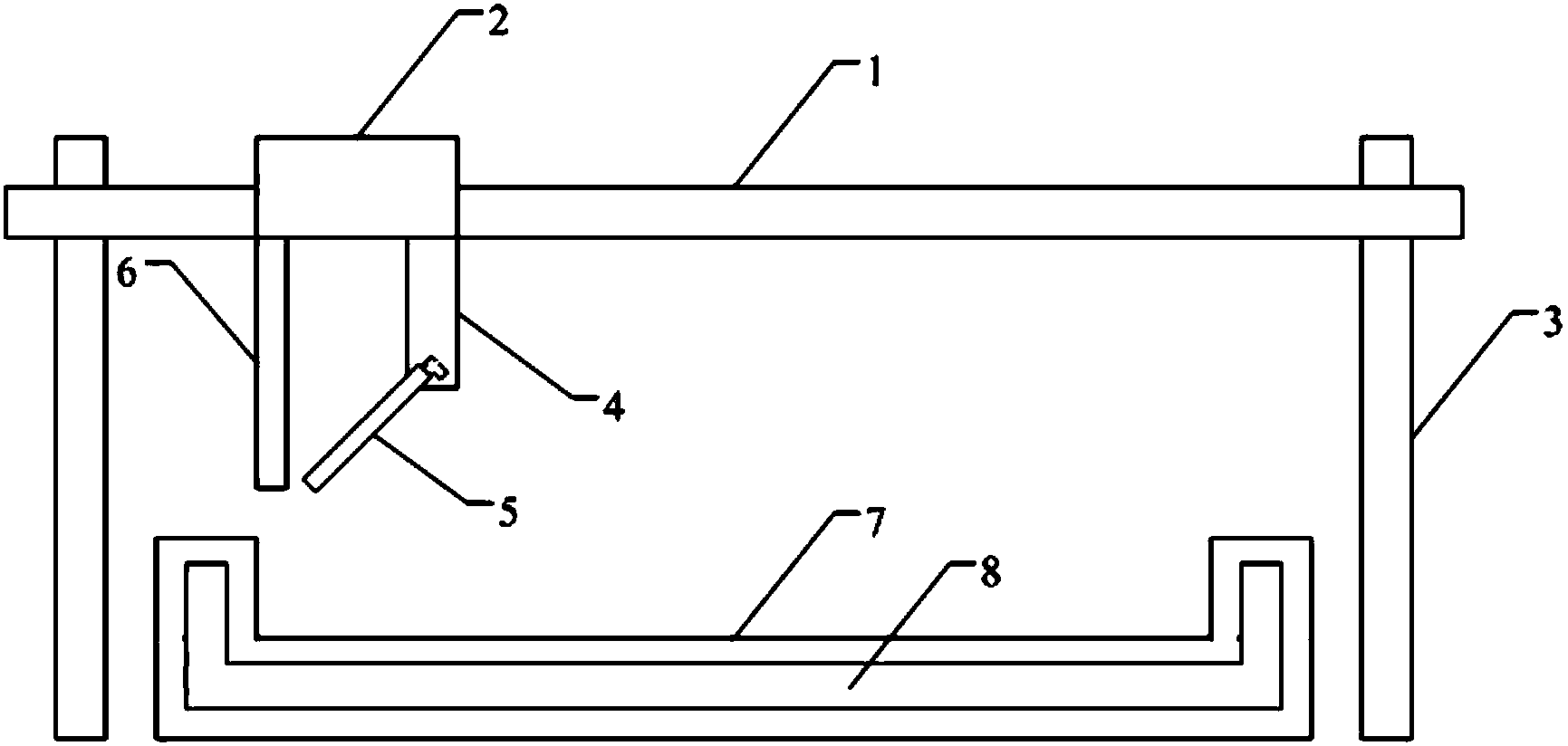

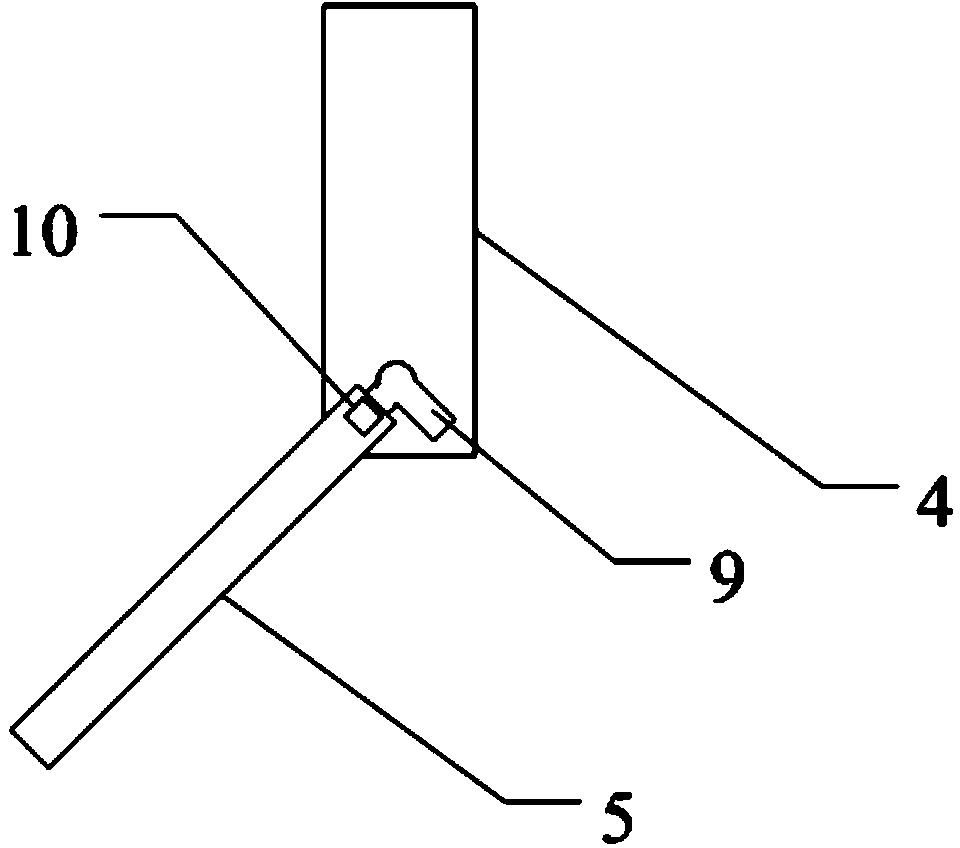

[0020] Such as figure 1 As shown, the present invention provides a 3D printing method for a building beam member, comprising the following steps: Step 1, manufacturing a forming mold frame, the forming mold frame has a square groove 7 with one side opening, and the forming mold frame is also A cavity 8 is provided, and the cavity 8 wraps the square groove in the middle; step 2, manufacture a support frame body 3, and a crossbeam 1 can move in a vertical direction relative to the support frame body 3 Set on the beam, a traveling mechanism 2 is arranged on the beam in a movable manner along the beam, a printing mechanism and a hot steam injection mechanism 6 are installed on the running mechanism, and the hot steam injection The mechanism is arranged on the rear side of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com