Preparation method of thin film transistor of flexible electronic device

A technology for flexible electronic devices and thin film transistors, which is applied in the field of solution manufacturing of thin film transistors of flexible electronic devices, can solve problems such as reduced structural reliability, structural voids, cracks, etc., so as to improve manufacturing efficiency, reduce production costs, and reduce The effect of key dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

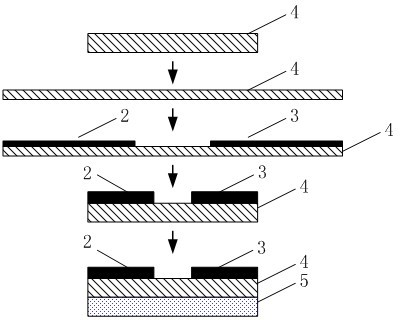

[0049] image 3 It is a schematic diagram of the process for preparing all-organic thin-film transistor (TFT) in Example 1 of the present invention. As can be seen from the figure, the preparation process of the present invention is:

[0050] (1) prepare the substrate unit 4, the substrate unit is a rubber substrate, which can be bent and stretched;

[0051] The flexible substrate chooses a rubber substrate with high elastic deformation capacity, which requires more than 50% elastic strain, and can still return to its original shape after releasing the external force.

[0052] (2) Stretching and surface treatment for the substrate unit, usually stretching more than 50%, and coating the surface with adhesive;

[0053] In order to achieve the above goals, the rubber substrate needs to have sufficient strength, and the thickness of the rubber substrate can be referred to In order to restore the original state as much as possible after releasing the external load after the rubbe...

Embodiment 2

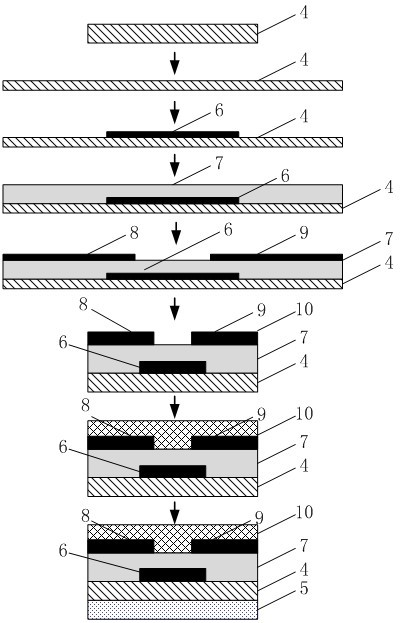

[0065] Figure 4 It is a schematic diagram of the process of manufacturing an organic-inorganic thin film transistor in Embodiment 2 of the present invention. It can be seen from the figure that the process of manufacturing an organic-inorganic thin film transistor of the present invention is:

[0066] (1) prepare the substrate unit 4, the substrate unit is a rubber substrate, which can be bent and stretched;

[0067] The flexible substrate chooses a rubber substrate with high elastic deformation capacity, which requires more than 50% elastic strain, and can still return to its original shape after releasing the external force.

[0068] (2) Stretching and surface treatment for the substrate unit, usually stretching more than 50%, and coating the surface with adhesive;

[0069] An adhesive layer with a lower glass transition temperature is coated on the surface of the rubber substrate to achieve bonding between the substrate and the functional layer. It is required that the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com