Secondary integrally-forming shoe, shoe-making die and producing method

A shoe-making mold and manufacturing method technology, applied in footwear, apparel, applications, etc., can solve the problems of resource waste, multi-environmental pollutants, water seepage, etc., to prevent detachment and water seepage, high manufacturing efficiency, and good support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

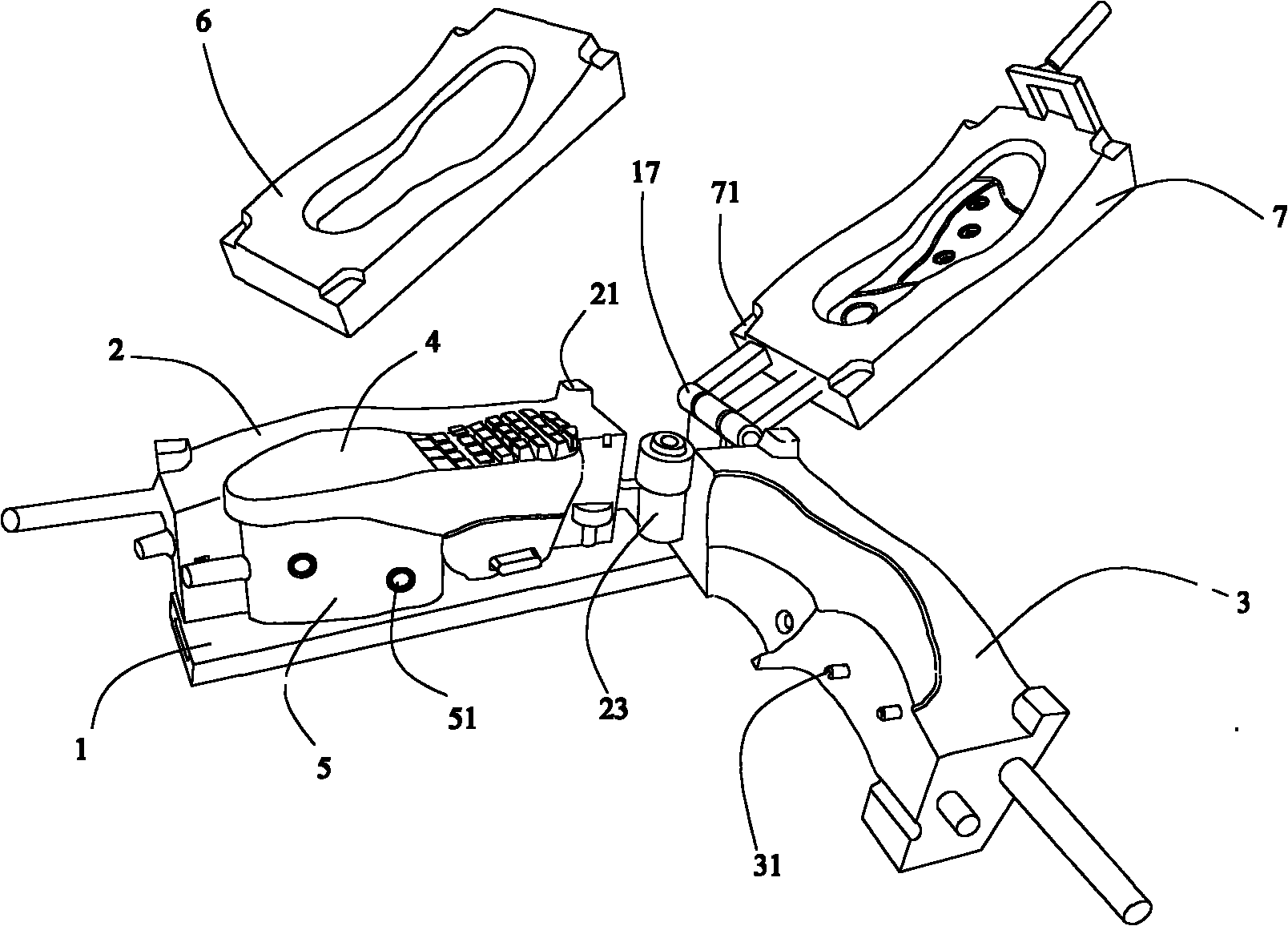

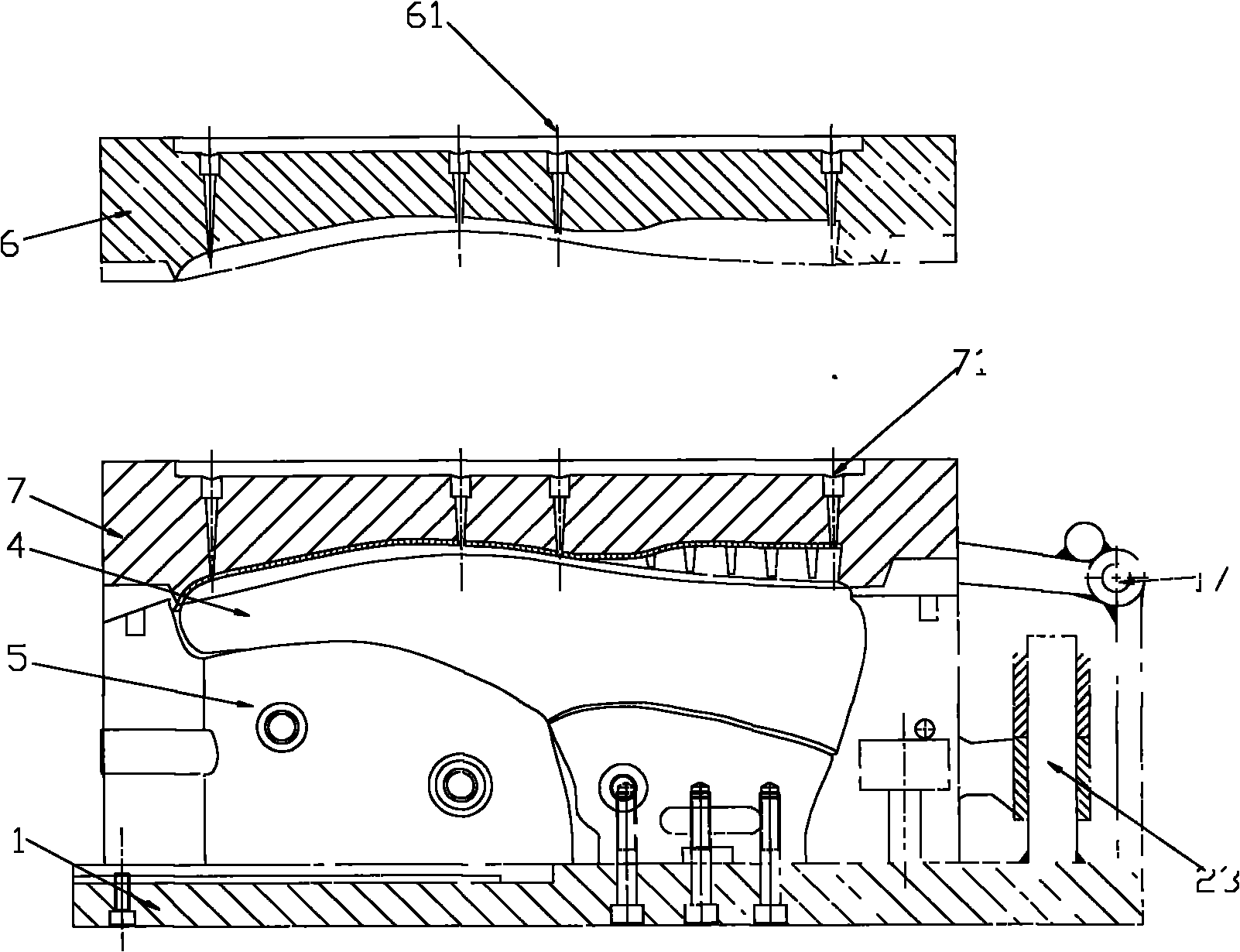

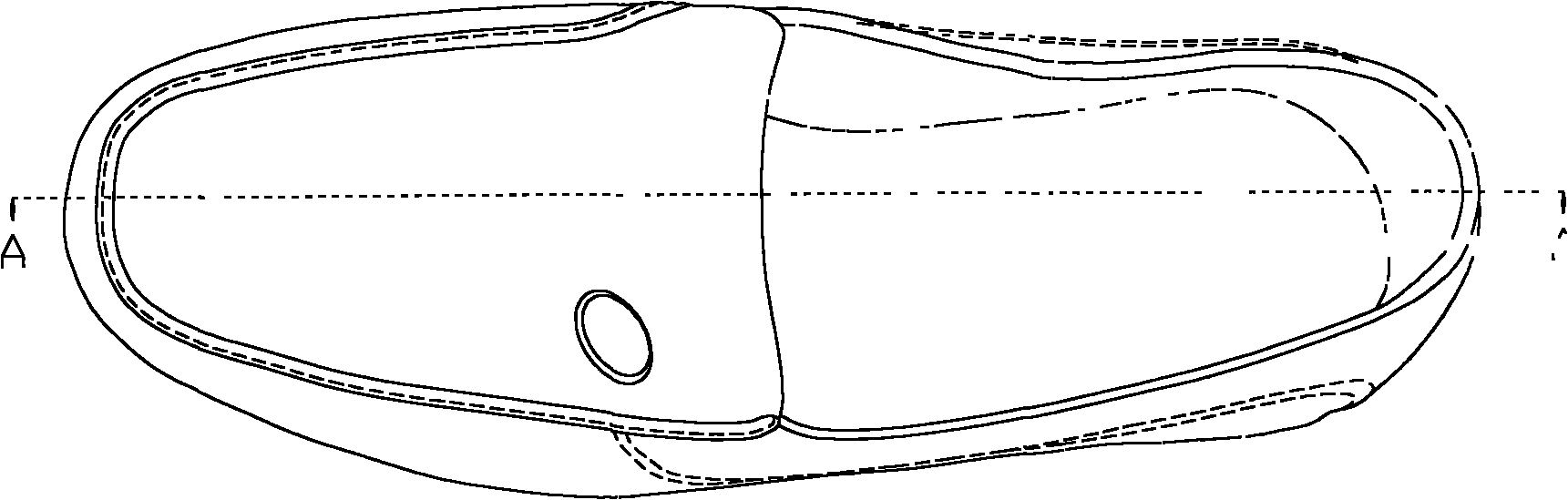

[0024] Such as figure 1 and figure 2 As shown, the shoemaking mold of the present invention includes a mold base plate 1, a left side baffle plate 2, a right side baffle plate 3, a shoe last 4, a toe front baffle plate 5, a middle cover baffle plate 6 and a sole cover plate 7, The shoe last 4 is set on the mold bottom plate 1, the toe front baffle 5 is set on the mold bottom plate 1, the front part of the shoe last 4, the left side baffle 2 and the right side baffle 3 They are respectively arranged on the left side and the right side of the shoe last 5, the middle cover baffle 6 and the sole cover 7 can be arranged on the bottom of the shoe last, the left side baffle 2, the right Side baffle 3, shoe last 4, toe front baffle 5, and middle cover baffle 6 form a vamp cavity, the left side baffle 2, right side baffle 3, shoe last 4, toe cap The front baffle 5 and the sole cover 1 enclose the shoe upper and the sole mold cavity, and the middle cover baffle 6 and the sole cover 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com