Process for reclaiming lead and producing environment-friendly building material by waste flint glass and corollary equipment thereof

A technology of supporting equipment and glass, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of polluted soil and groundwater, heavy metal hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

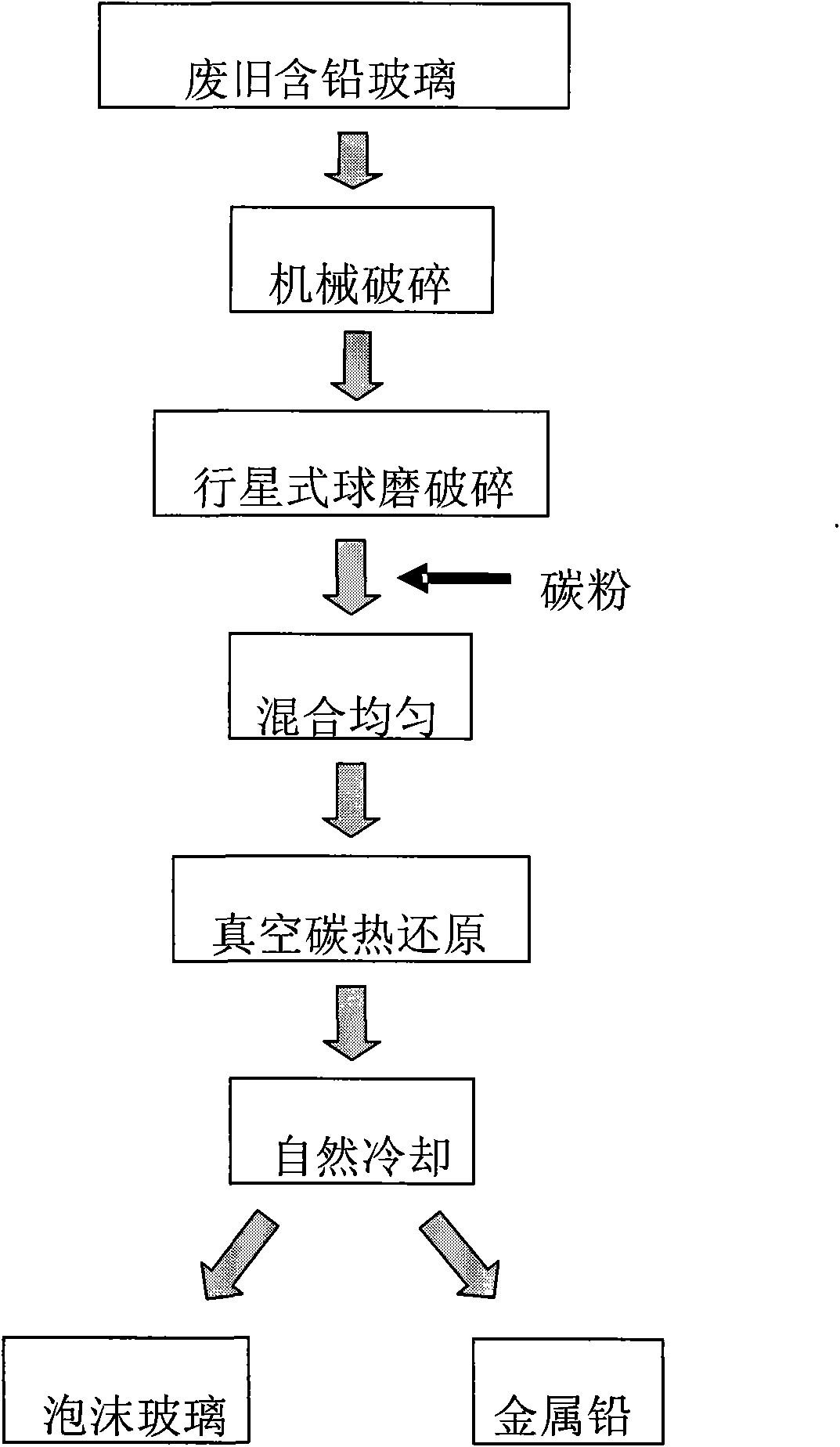

[0007] Material pretreatment part: use waste lead-containing glass as raw material, first use mechanical crushing method to crush the glass to about 1-3 cm, and then use planetary ball mill to further crush it to a particle size of less than 100 mesh, and dry it at 105°C for 24 hours for later use.

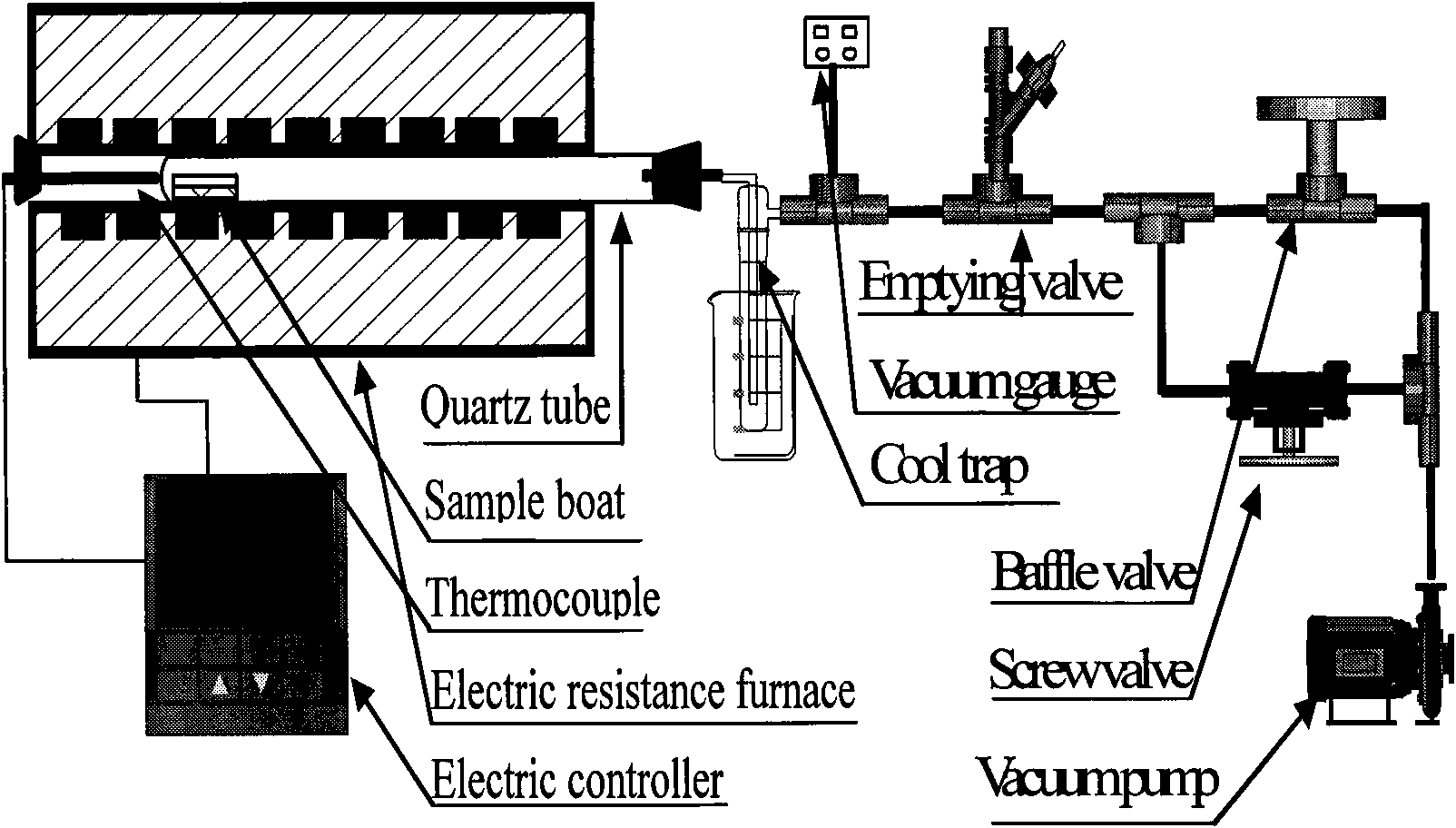

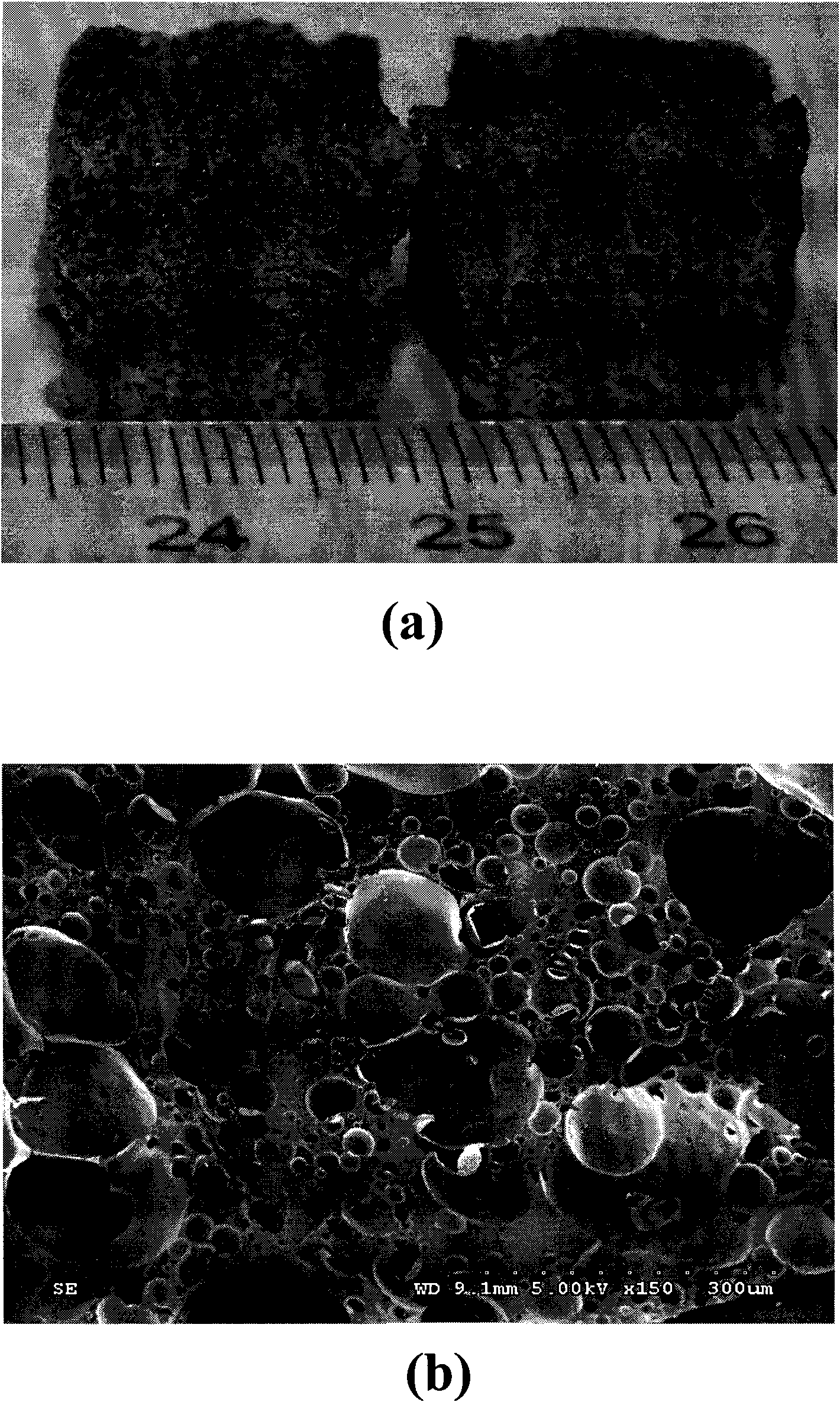

[0008] Vacuum carbothermal reduction part: Weigh a certain amount of lead-containing glass powder, add carbon powder ( figure 2 As shown, the quartz tube is directly inserted into the tubular resistance furnace, connected to the vacuum system and pumped to 10Pa; the temperature rise program is: 30°C / min to 400°C, then 10°C / min to 1000°C, keep for 2 hours, take out the quartz The tube was kept under vacuum and after cooling to room temperature the sample was removed and weighed. After collecting metallic lead, the calculated recovery rate is 99.32%, and the foaming condition of the residue observed by scanning electron microscope is shown in image 3 , Toxicity leaching experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com