Projection lens and projection apparatus

A projection lens and projection device technology, applied in optical components, optics, instruments, etc., can solve the problems of aspherical lens thermal variation, defocus, and affecting the imaging quality of projection lenses, etc., and achieve the effect of eliminating chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

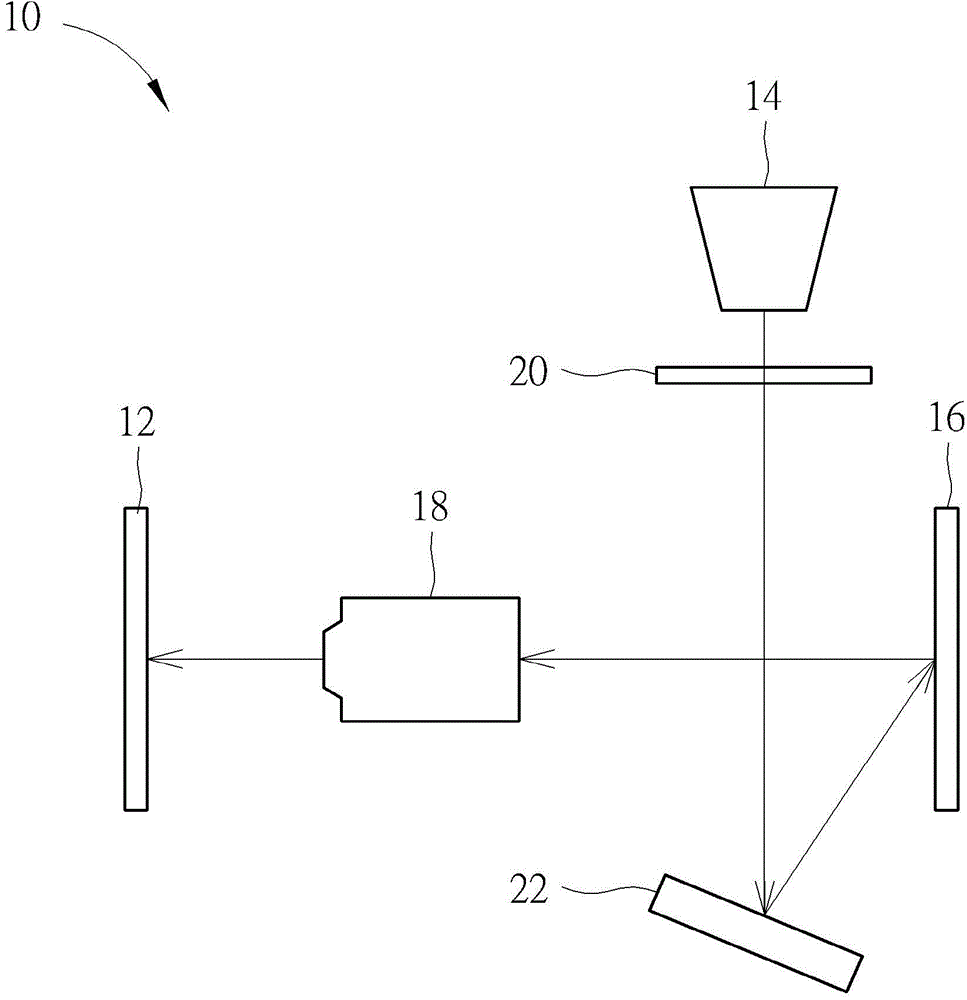

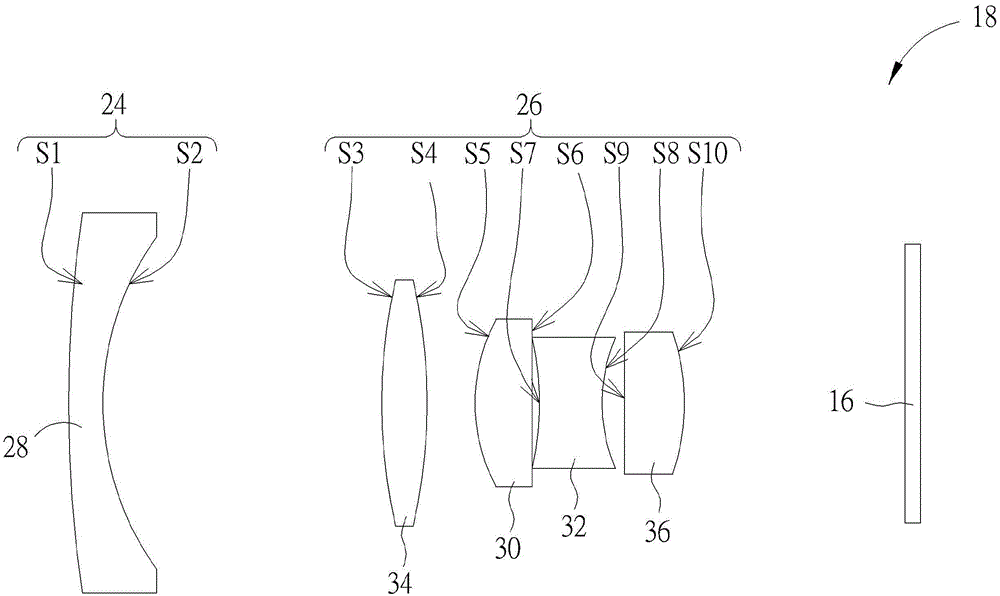

[0035] see figure 1 , figure 1 is a schematic diagram of a projection device 10 according to an embodiment of the present invention. The projection device 10 is used for projecting images onto a screen 12 . The projection device 10 includes a light source 14 , an imaging unit 16 , a projection lens 18 , a filter unit 20 and a reflective element 22 . The light source 14 outputs light, the filter unit 20 receives the light and filters the light into multiple colored lights, and the light processed by the filter unit 20 is reflected by the reflective element 22 and received by the imaging unit 16 . The imaging unit 16 receives multiple colored lights from the reflective element 22 and transmits them to the projection lens 18 . The projection lens 18 is disposed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com