Heavy lanthanum flint glass prefabricated part, optical element and optical instrument thereof

A technology of lanthanum flint glass and glass prefabrication, which is applied in optical components, optics, instruments, etc., and can solve the problems of poor glass stability, poor erosion resistance, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Heavy Lanthanum Flint Glass

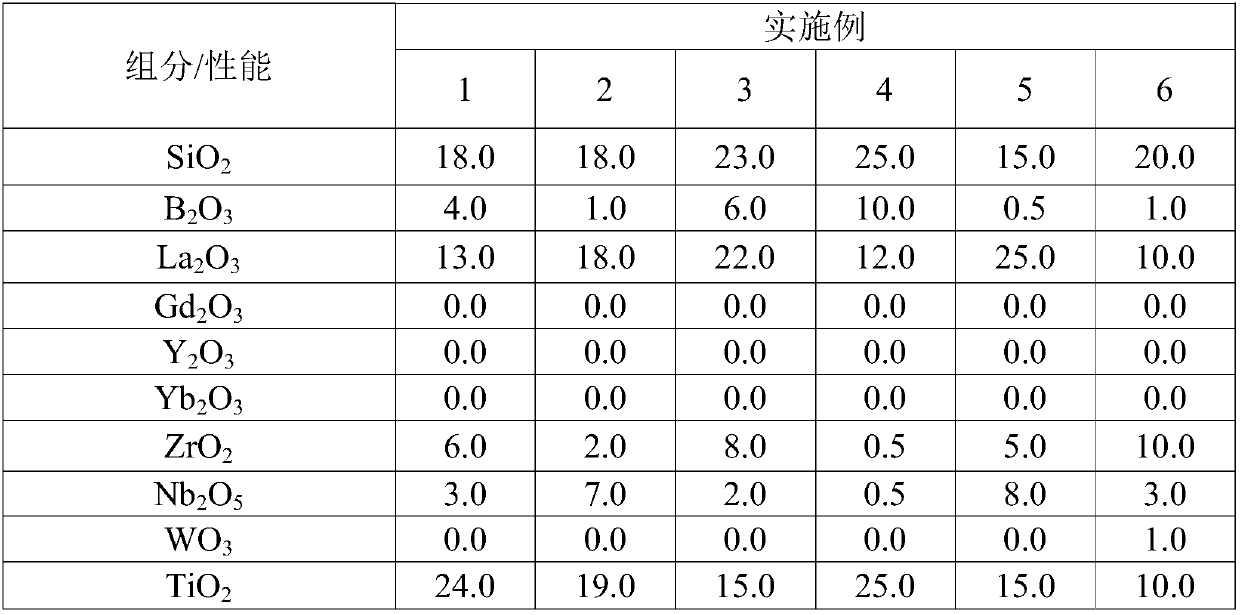

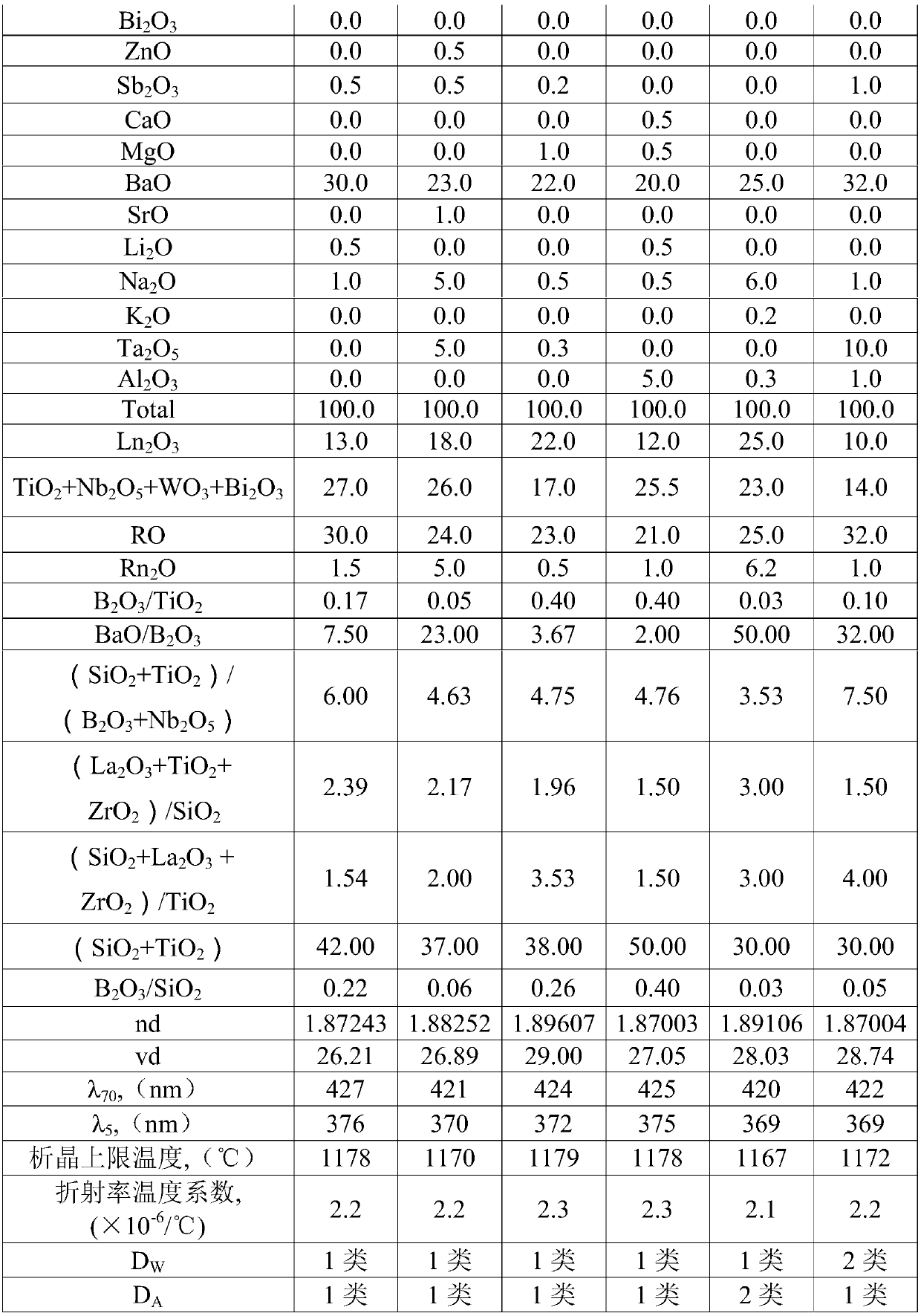

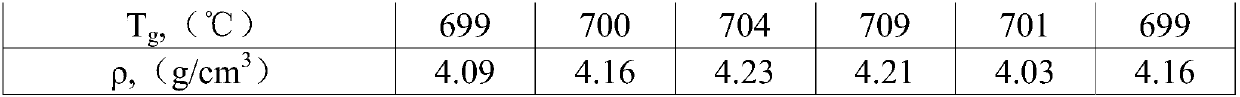

[0044] The composition of the heavy lanthanum flint glass of the present invention will be described in detail below. When there is no special description, the content and total content of each glass component refer to the weight content, expressed in weight %, which is the weight of a certain component or several groups The percentage of the sum of the weights of the components in the total weight of the optical glass; the ratio of each glass component, or the ratio of the sum of several components, is the ratio of the corresponding weight content or the sum of the weight content.

[0045] The heavy lanthanum flint glass of the present invention contains SiO in % by weight 2 : 12-30%, Ln 2 o 3 : 10-25% of the Ln 2 o 3 for la 2 o 3 、Gd 2 o 3 , Y 2 o 3 and Yb 2 o 3 The total content of TiO 2 +Nb 2 o 5 +WO 3 +Bi 2 o 3 : 10.5-40%, RO: 20-35%, the RO is one or more of BaO, CaO, MgO and SrO, ZrO 2 : 0.5-10%, the refractive ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization upper limit temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com