Method for optimizing light gathering ability of micro-lens array of back-illuminated infrared detector

A technology of microlens array and light-gathering ability, which is applied in the direction of lenses, instruments, optics, etc., can solve the problems of little research on the light-gathering ability of microlenses, and achieve improved device performance, reduced optical crosstalk, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

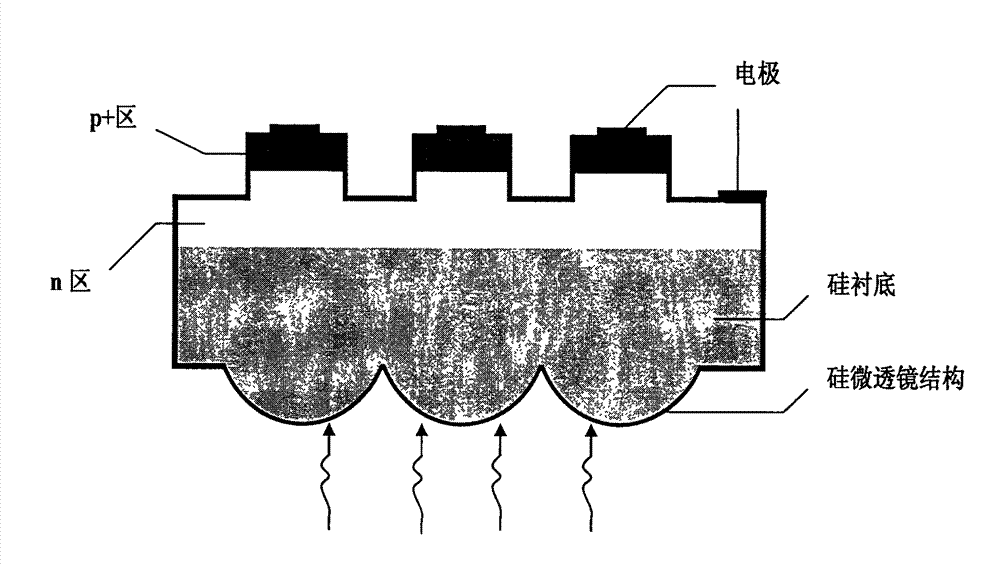

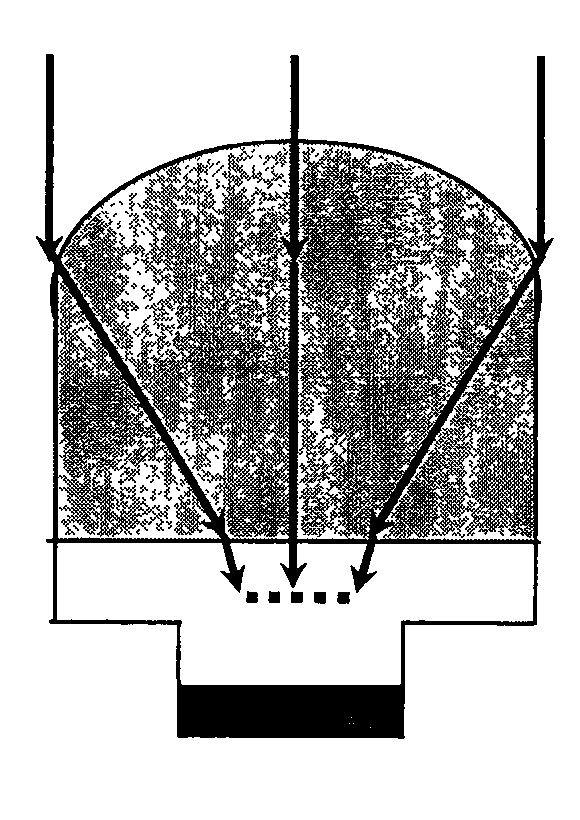

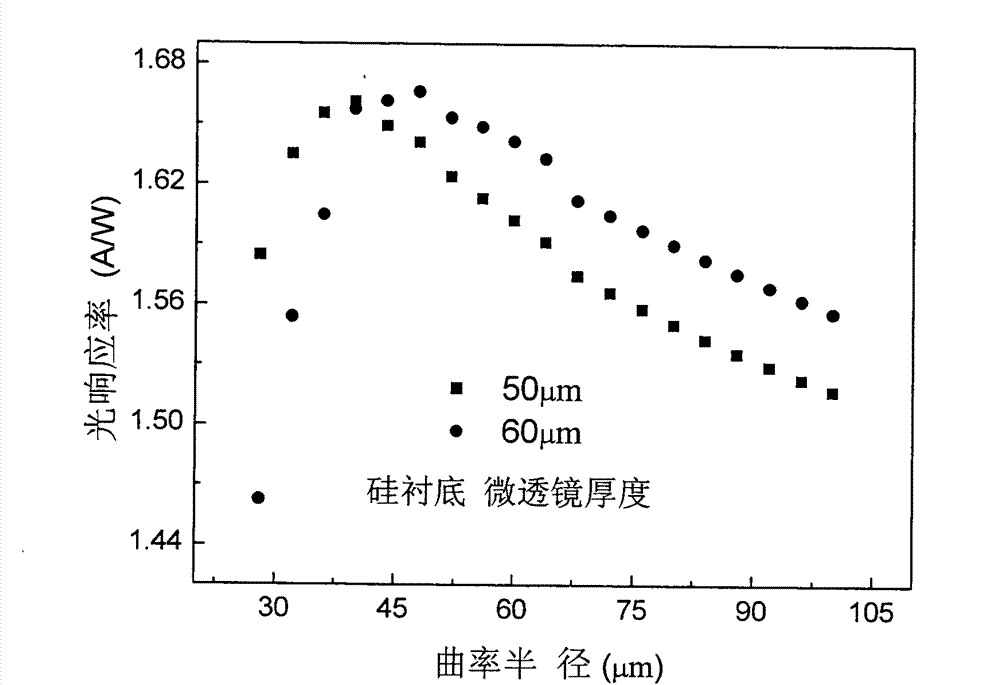

[0021] 1. First construct a two-dimensional simulated device model based on the indium antimonide infrared focal plane detector array, that is, p + -on-n type indium antimonide infrared focal plane detector array structure: the p-region thickness is 0.8 μm and the doping concentration is 10 17 cm -3 , the n-region thickness is 12.2μm and the doping concentration is 10 15 cm -3 , the substrate material is a silicon material with a thickness of 200 μm that has no absorption effect on the incident light, and the n-type indium antimonide material is grown on the silicon substrate by epitaxial method, p + The region is formed by ion implantation, and then a mesa structure is formed by wet chemical etching, and a layer of SiO is passivated on the entire outer surface of the device. 2 , while electrodes are installed in the p-region and n-region respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com