Photodetector

A photoelectric detector and photoelectric detection technology, applied in the direction of electric solid-state devices, instruments, circuits, etc., can solve problems such as optical crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

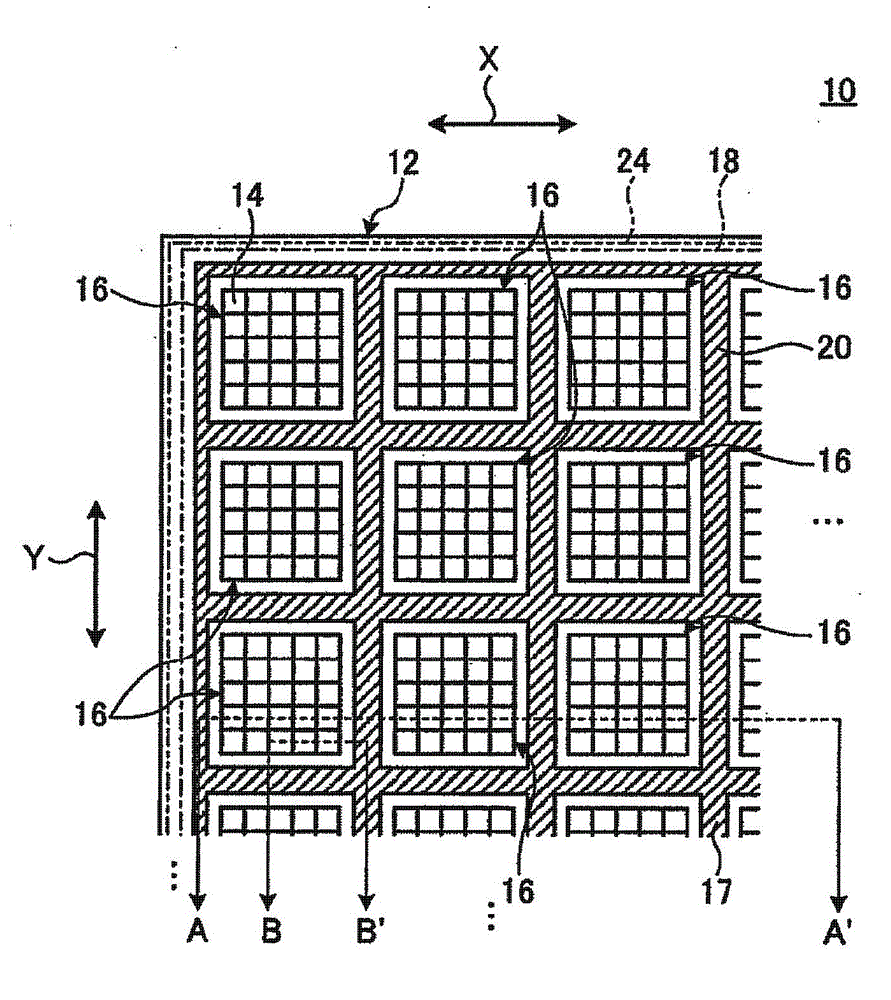

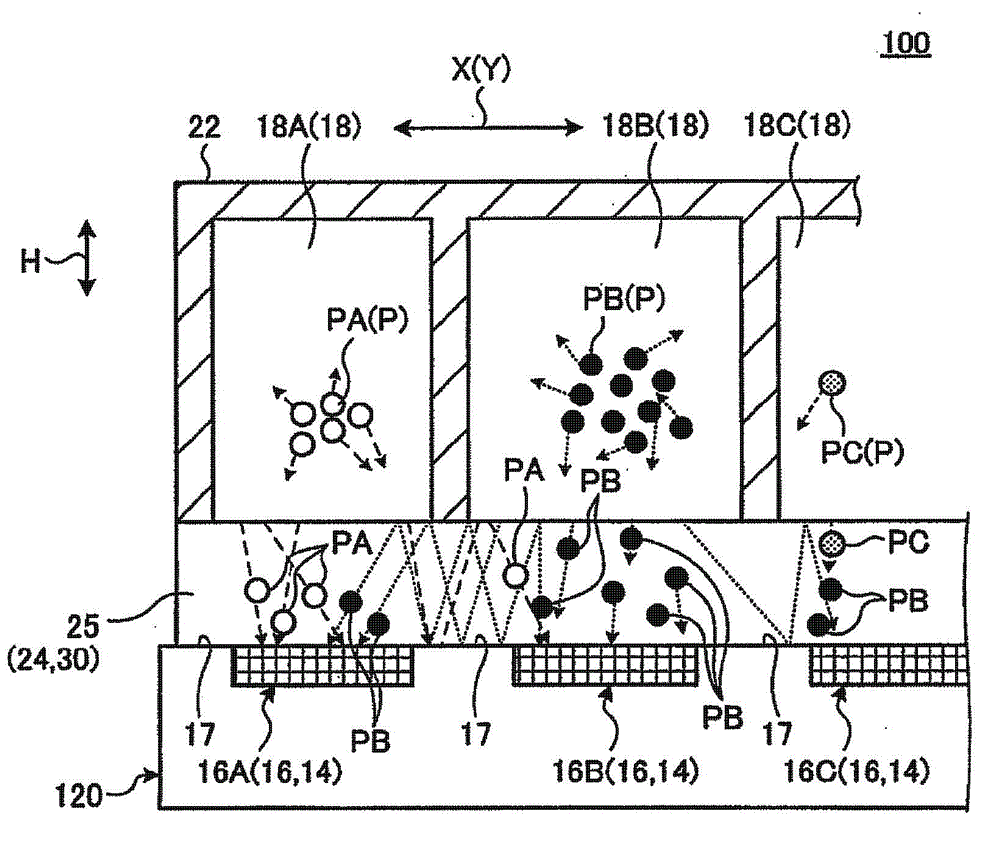

[0084] In the above embodiment, it is described that the antireflection member 20 is continuous and surrounds the pixel regions 16 on the surface of the photodetection layer 12 facing the scintillator layer 18 (see figure 1 )Case. The anti-reflection member 20 only needs to be disposed between the pixels on the surface of the photodetection layer 12 facing the scintillator layer 18, and is not limited to figure 1 Example shown in .

[0085] Figure 13 is a schematic diagram showing a photodetector 10A of the present modified example. Such as Figure 13 As shown in , the antireflection member 20 may be disposed in a discontinuous manner in the direction along the surface between pixels on the surface of the photodetection layer 12 facing the scintillator layer 18 . Except for the arrangement of the anti-reflection member 20 between the pixels, the photodetector 10A is the same as figure 1 The photodetector 10 shown in is the same.

example 2

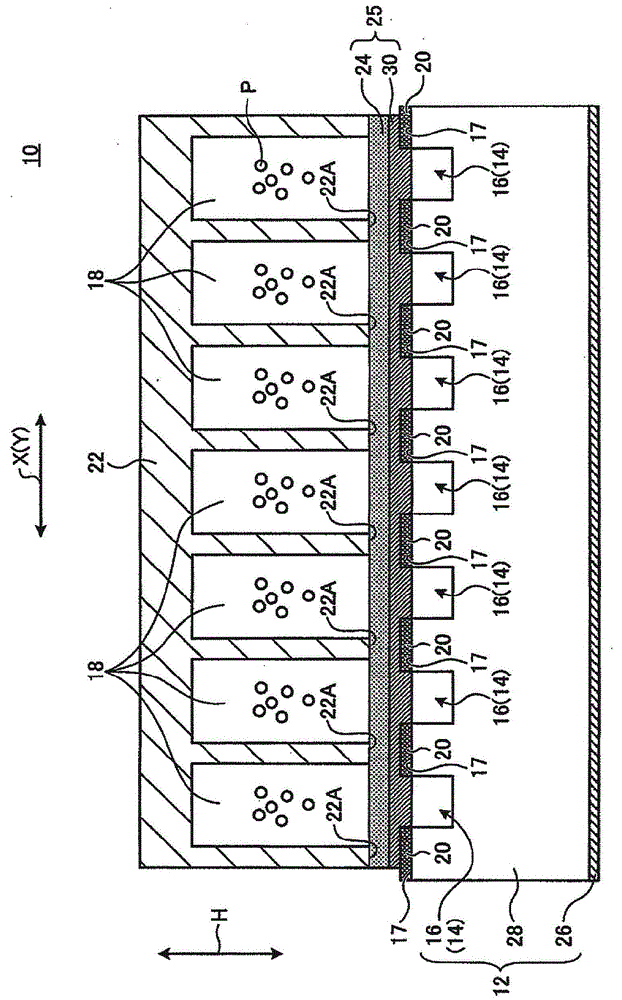

[0087] exist figure 2 In the illustrated example, a case is described in which the antireflection member 20 has a width equal to the distance between pixels. However, the anti-reflection member 20 may have a width smaller than the distance between pixels.

[0088] Figure 14 is a schematic diagram showing a photodetector 10B of the present modified example. Such as Figure 14 As shown, the anti-reflection member 20 may have a distance smaller than the distance between pixels (see Figure 14 The width of W5) in the width (see Figure 14 in the width W4). In addition to the position of the anti-reflection member 20 between pixels is different, the photodetector 10A and figure 2 The photodetector 10 shown is the same.

example 3

[0090] exist figure 2 In the illustrated example, the position and cross-sectional shape of the anti-reflection member 20 in the thickness direction (direction of arrow H) of the photodetector 10 are described so that the anti-reflection member 20 includes light-receiving surfaces corresponding to the APDs 14 position and make the cross-sectional shape protrude from the position to the rectangular shape of the scintillator layer 18 . However, in the thickness direction of the photodetector 10 (see figure 2 The direction of the middle arrow H) the position and cross-sectional shape of the anti-reflection member 20 can be any position and shape so that the anti-reflection member 20 includes areas corresponding to the light-receiving surfaces of the APDs 14, and are not limited to figure 2 Example shown.

[0091] Figure 15 is a schematic diagram showing a photodetector 10C of the present modified example. Such as Figure 15 As shown, in the thickness direction (see Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com