Polylactic acid and plant fiber composite material and preparation method thereof

A composite material and plant fiber technology, which is applied in the field of polylactic acid and plant fiber composite materials and their preparation, can solve the problems of complex operation, difficulty in industrialization, insufficient research on the heat resistance of polylactic acid composite materials, etc., and achieve simple operation , high production efficiency, and the effect of maintaining biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

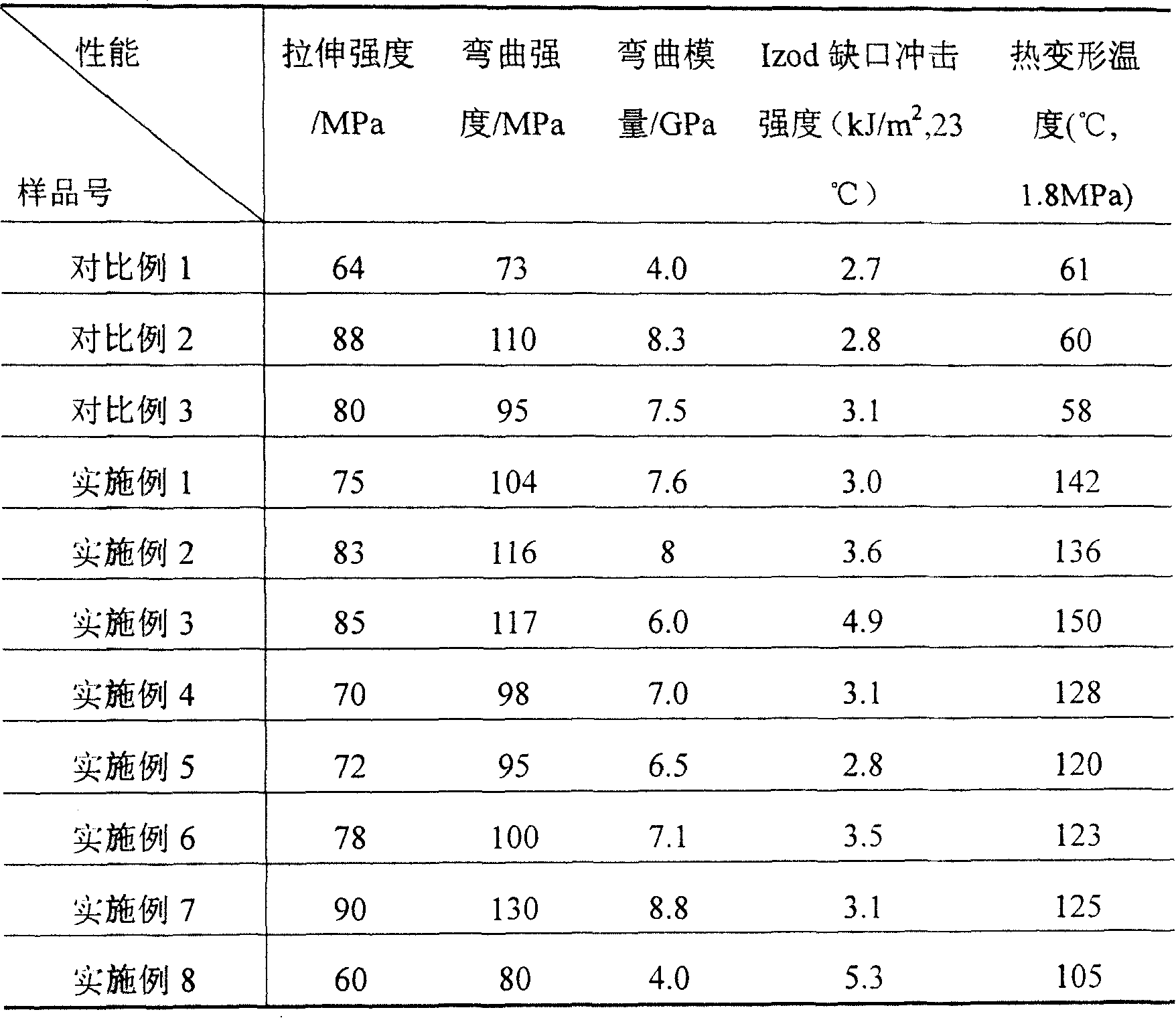

Embodiment 1

[0035] Accurately weigh 65 parts of polylactic acid (the weight-average molecular weight Mw is 100,000, and the content of D-lactic acid monomer unit is 2%), 2 parts of talcum powder and 3 parts of polyethylene glycol, and add from the main feed hopper after mixing In the extruder, 30 parts of ramie fiber yarn (the average length of the fiber is 20mm) is added from the side feed port, melt extrusion pelletization is carried out at 200 ° C, after drying, the sample is made according to the ASTM standard and its mechanical properties are measured and heat resistance (heat distortion temperature). Its properties are shown in Table 1.

Embodiment 2

[0037] Accurately weigh 68 parts of polylactic acid (Mw is 500,000, without dextrorotation), 2 parts of white carbon black, 0.5 part of polypropylene oxide and mix them evenly, then add them into the extruder from the main feed port, 29 parts of random flax Fibers (with an average fiber length of 100 μm) were added from the side feed port, melt-extruded and granulated at 210 ° C, dried and made into samples according to ASTM standards, and their mechanical properties and heat distortion temperature were measured. Its properties are shown in the table.

Embodiment 3

[0039] Accurately weigh 74 parts of polylactic acid (Mw is 250,000, dextrorotatory content is 10%), 1 part of kaolin, 5 parts of block copolymers of ethylene oxide and propylene oxide are mixed uniformly and then added to the In the extruder, 20 parts of bamboo fiber yarns (the average length of the fiber is 10mm) are added from the side feed port, melted and extruded to pelletize at 180°C, after drying, make samples according to the ASTM standard and measure its mechanical properties and Heat distortion temperature. Its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com