Magnesium oxysulfate cement board and method for preparing same by using semidry method

A technology of magnesium oxysulfate cement board and magnesium oxysulfate cement, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of affecting the bonding strength of cement, insufficient fire resistance, difficult handling, etc., so as to improve the scope of application and use Long life, good thermal insulation effect, avoiding the effect of moisture absorption and halogen return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

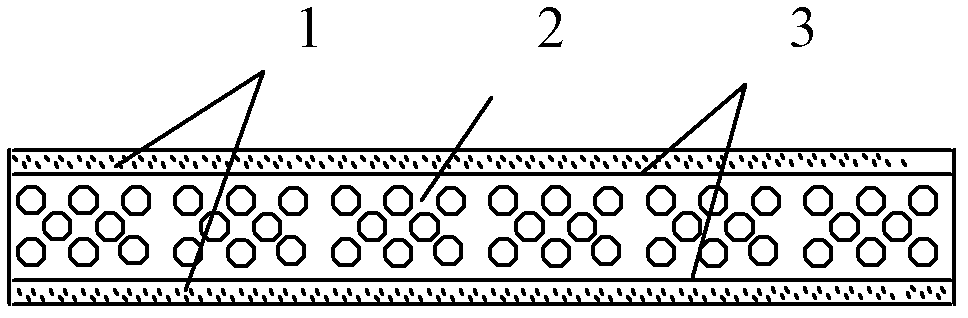

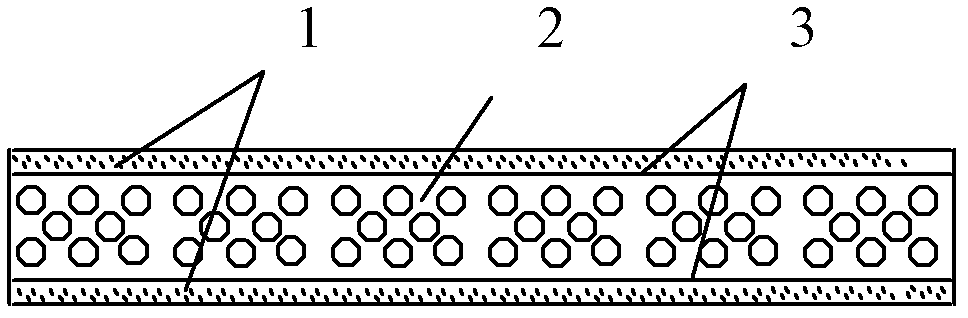

[0027] Example: A kind of magnesium oxysulfate cement board, such as figure 1 As shown, it includes a heat-insulating core layer 2, and strength structure layers 1 respectively compounded on both surfaces of the heat-insulating core layer. The heat insulation core layer is a layered structure formed by stirring and pressing magnesium oxysulfate cement as the gelling agent and light material as the filler. The strength structure layer is a layered structure formed by magnesium oxysulfate cement as a gelling agent, and a layered structure formed by stirring and pressing.

[0028] In order to increase the bending strength of the strength structure layer, another preferred solution of the strength structure layer is: the strength structure layer is formed by stirring and pressing magnesium oxysulfide cement as the gelling agent and reinforcing fiber as the strength supplement material. layered structure. Among them, the preferred solution of the strength supplementary material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com