Independent vehicle suspension with wheel guide leaf spring elements made of fiber composite material

A technology of independent suspension and components, applied in the direction of suspension, vehicle spring, elastic suspension, etc., can solve the problem of occupying large structural space, and achieve the effect of high wheel load, large adjustable damping, and large spring stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] All features described in detail here can be essential to the invention.

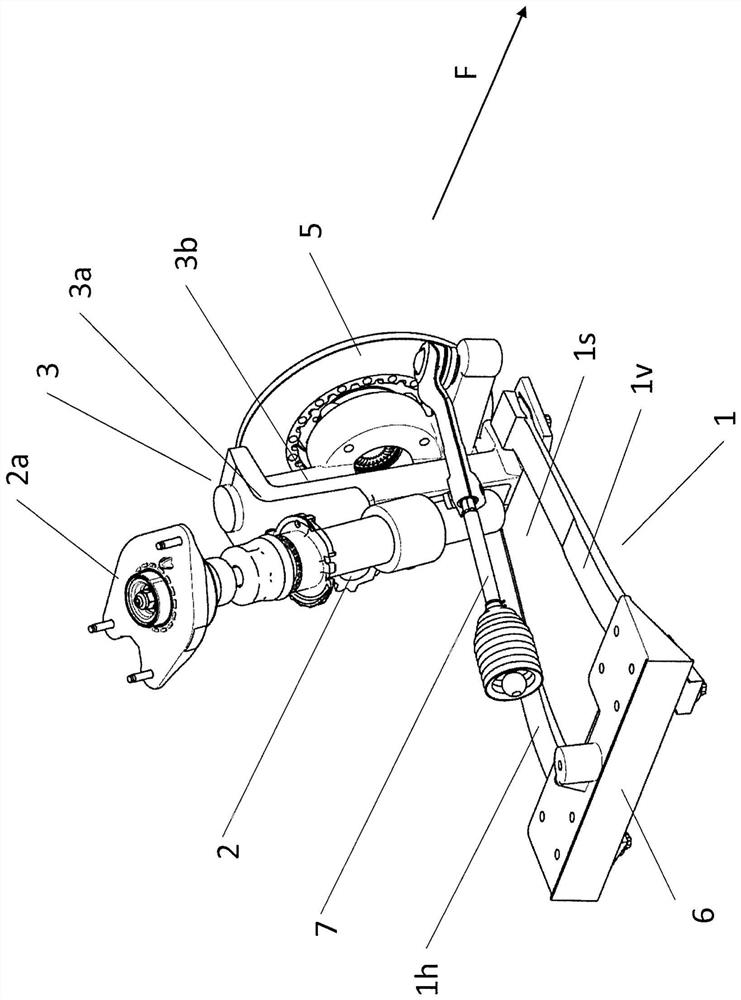

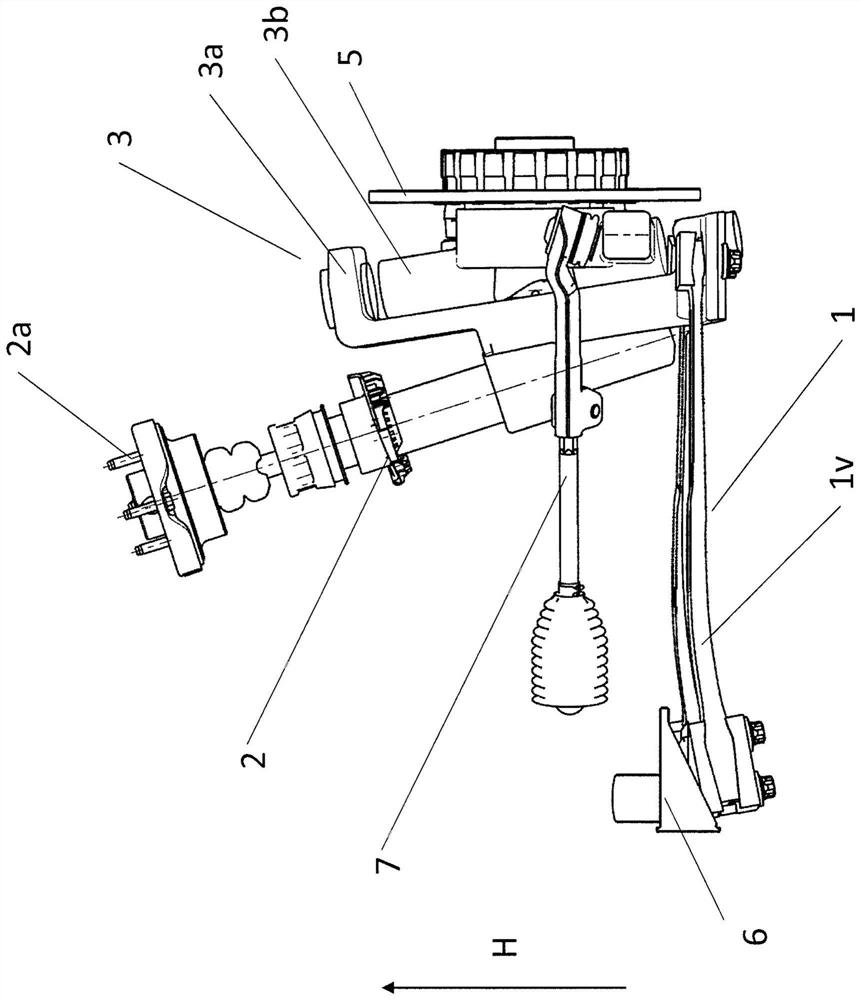

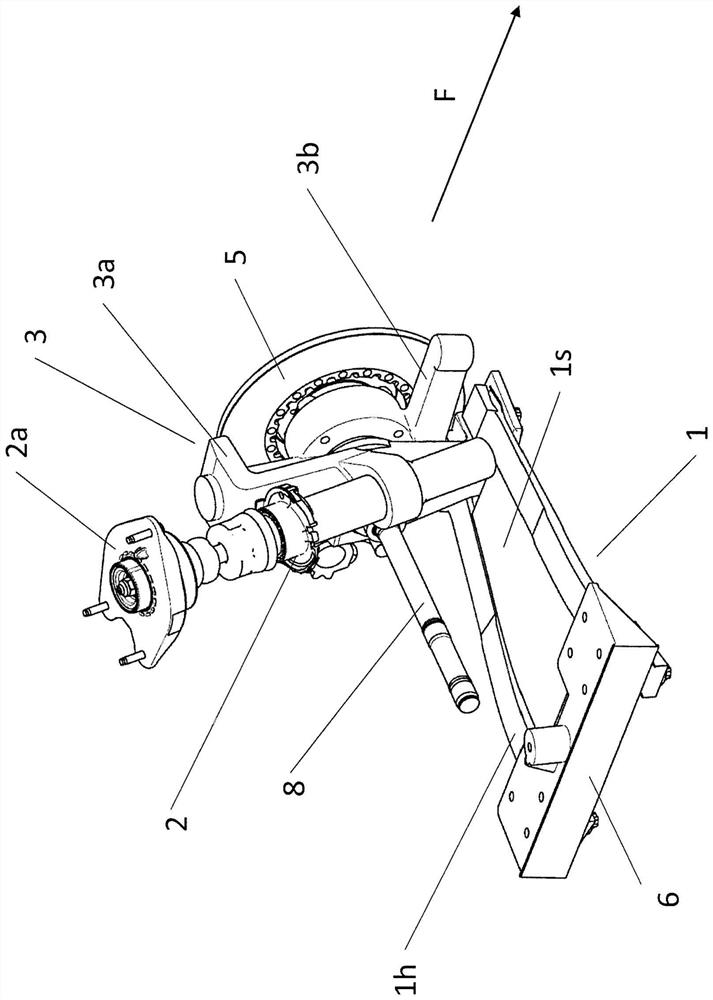

[0062] A leaf spring element 1 is arranged as a so-called spring link in the independent suspension in order to guide the wheel in cooperation with a conventional shock absorber 2 and at the same time reduce its vibration relative to the only partially shown body 6, damping The shock absorber 2 is arranged as usual to reduce the vertical elastic retraction and extension movements of the wheel. The wheels themselves are not shown in the drawings, but only the corresponding independently suspended wheel carrier 3 on which the wheel, not shown, is usually mounted rotatably with an intermediate functional connection of the wheel bearing unit together with exist Figures 1a-3b Visible brake disc 5. exist Figure 3c-4c , the brake disc 5 is basically covered by the brake protection plate 4. In order for the wheels, which are not shown, to also be provided with a reference number, the wheels also us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com