A kind of ultra-thin seamless flat belt and its preparation method

A flat belt and forming belt technology, applied in the field of transmission belts, can solve the problems of large belt jumping, lack of high-end market, and inability to use small torque transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

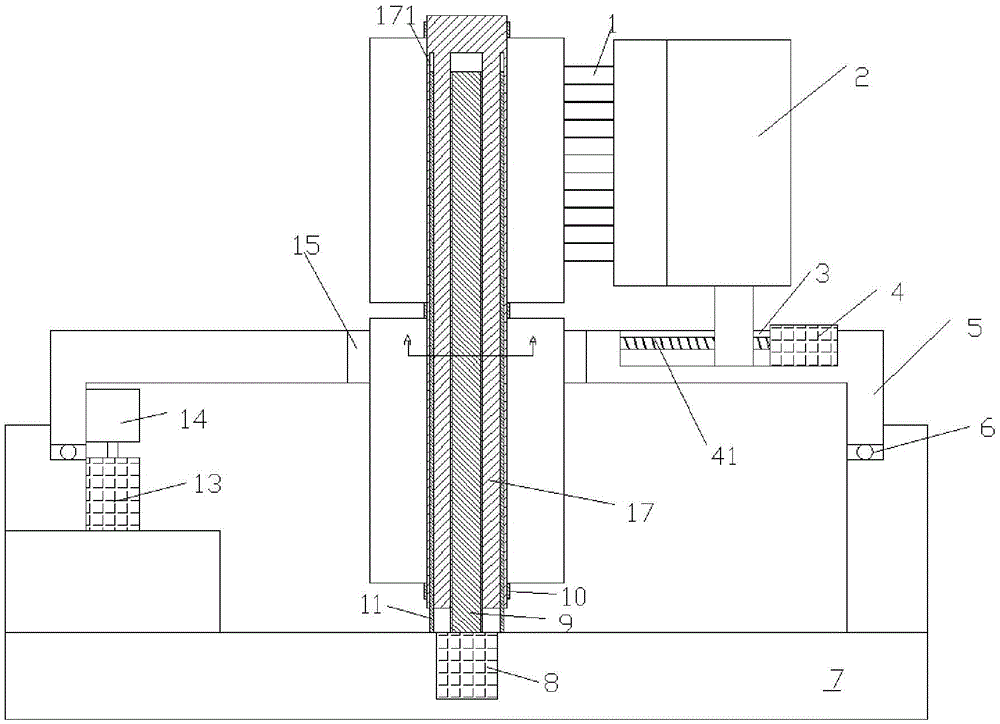

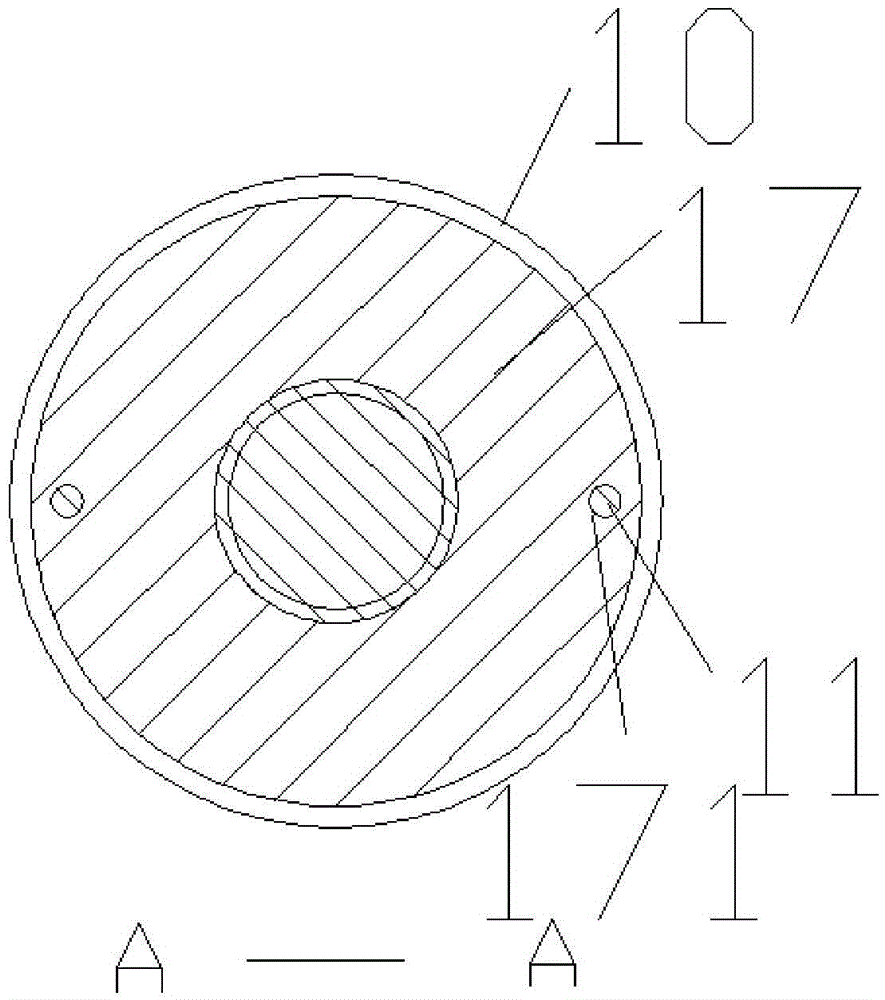

[0017] The best mode for carrying out the present invention will be described below with reference to the appropriate drawings.

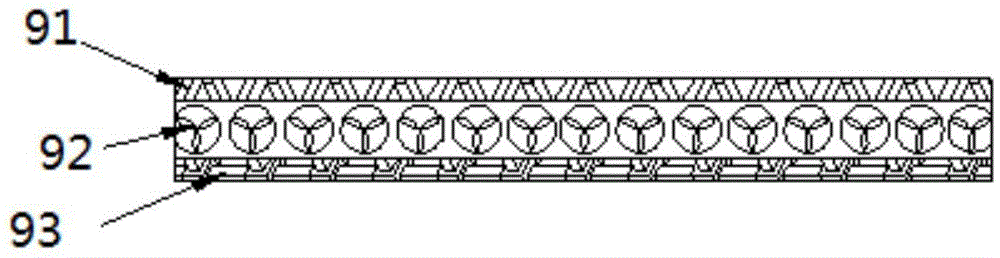

[0018] figure 1 It is a cross-sectional view of the ultra-flat seamless flat belt of the present invention. Because it is used in various office automation (OA), factory automation (FA), and system automation (SA) equipment, the flat belt is required to have the characteristics of thin thickness, softness, bending resistance, and wear resistance.

[0019] The preparation method of transmission flat belt of the present invention, wherein, figure 1 As shown, the structure of the endless belt body of the transmission flat belt is as follows: the elastic nylon cloth 91 is the inner layer of the flat belt, the glass fiber or aramid fiber skeleton layer 92 is the middle tensile body layer, and the nylon and cotton fabric is the flat The outer wear layer 93 of the belt; the method comprises the steps of:

[0020] Mixing the rubber mixture → beating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com