Polyolefin wood-plastic composite and preparation method thereof

A wood-plastic composite material, polyolefin-based technology, applied in the field of polyolefin-based wood-plastic composite material and its preparation, can solve problems such as unrecognized compatibility, achieve low production cost, reduce environmental pollution, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

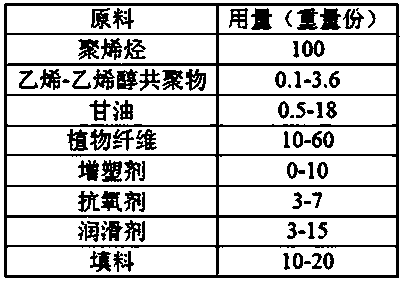

Method used

Image

Examples

Embodiment 1

[0023] The raw material components are by weight: 100 parts of high-density polyethylene, 0.1 part of ethylene-vinyl alcohol copolymer (the molar content of ethylene is 70%), 0.5 parts of glycerin, 10 parts of wood flour, 1 part of antioxidant 1076, 1 part of antioxidant 2 parts of agent 330, 1 part of polyethylene wax, 2 parts of liquid paraffin, 20 parts of calcium carbonate.

[0024] The wood flour was cleaned of impurities, crushed, sieved, and dried in vacuum at 80 °C for 2 h. At the same time, the ethylene-vinyl alcohol copolymer was pulverized and dried in a vacuum oven at 92 °C for 8 h. After mixing the dried ethylene-vinyl alcohol copolymer powder with glycerin evenly, the dried wood powder was activated in a high mixer at 150 °C at 3000 r / min for 5 min to obtain surface-modified wood powder. pink. Then add high-density polyethylene, antioxidant 1076, antioxidant 330, polyethylene wax, liquid paraffin, modified wood powder and calcium carbonate into another high-mix...

Embodiment 2

[0027] The raw material components are by weight: 100 parts of polyvinyl chloride, 3.6 parts of ethylene-vinyl alcohol copolymer (the molar content of ethylene is 30%), 18 parts of glycerin, 60 parts of bamboo powder, 5 parts of composite heat stabilizer, phthalate 5 parts of octyl tridecyl formate, 5 parts of acetyl tributyl citrate, 3 parts of antioxidant 1010, 4 parts of antioxidant 300, 9 parts of n-butyl stearate, 6 parts of oleamide, 10 parts of silicon dioxide .

[0028] Bamboo powder was cleaned of impurities, crushed, sieved, and vacuum-dried at 100 °C for 2 h. At the same time, the ethylene-vinyl alcohol copolymer was pulverized and dried in a vacuum oven at 90 °C for 8 h. After mixing the dried ethylene-vinyl alcohol copolymer powder and glycerin evenly, the dried bamboo powder was activated in a high mixer at 190 °C at 6000 r / min for 10 min to obtain surface-modified bamboo powder. pink. Then add polyvinyl chloride, composite heat stabilizer, octyl tridecyl phth...

Embodiment 3

[0031] Raw material components by weight: 100 parts of polypropylene, 2.4 parts of ethylene-vinyl alcohol copolymer (ethylene molar content is 44%), 12 parts of glycerin, 40 parts of straw, 3 parts of antioxidant CA, antioxidant 2246 2 parts, 3 parts of monoglyceride stearate, 6 parts of organosilane, 10 parts of wollastonite.

[0032] The wheat straw was cleaned of impurities, crushed, sieved, and vacuum-dried at 80 °C for 2 h. At the same time, the ethylene-vinyl alcohol copolymer was pulverized and dried in a vacuum oven at 91° C. for 8 hours. After mixing the dried ethylene-vinyl alcohol copolymer powder and glycerin evenly, the dried wheat straw was activated in a high-mixer at 175°C at 4500 r / min for 7 minutes to obtain the surface-modified wheat straw. stalk. Then add polypropylene, antioxidant CA, antioxidant 2246, monoglyceride stearate, organic silane, modified wheat straw and wollastonite to another high mixer and mix for another 5 minutes. Take out the compound,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com