Packaging laminate with gas and aroma barrier properties

a technology of packaging laminate and aroma barrier, which is applied in the direction of flexible cover, chemical vapor deposition coating, containers, etc., can solve the problems of food products such as orange juice, packaged in such cartons, losing their nutritional valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

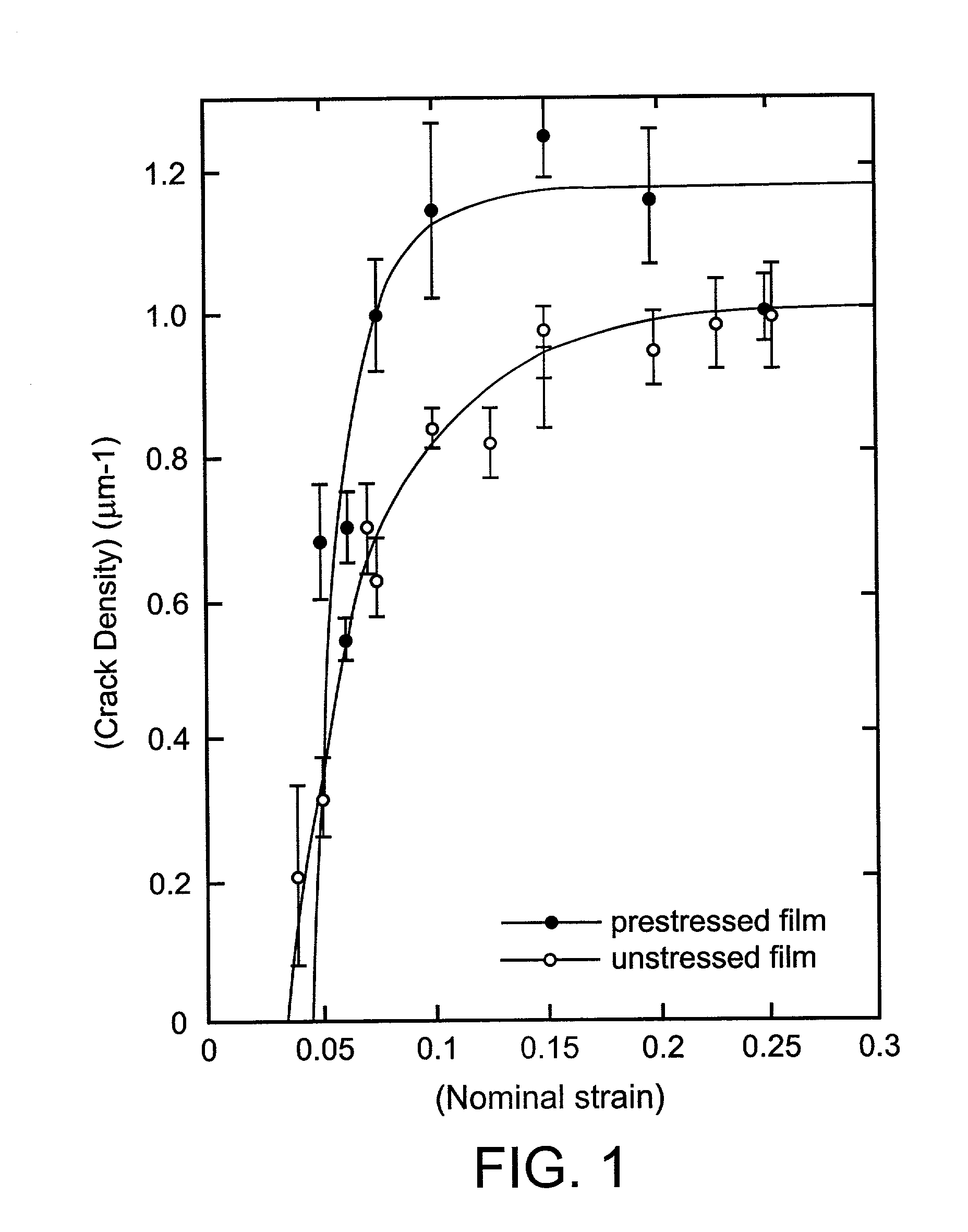

[0044] FIG. 1

[0045] While pre-straining a substrate film according to this invention, a silicon oxide coating was vapor deposited using the above-mentioned plasma enhanced chemistry deposition method. The effect of the controlled inner compressive stress in the coating was examined by subjecting some PET samples to an elasticity tensile load during the deposition process.

[0046] The coated film was subsequently unloaded, resulting in a well-defined level of compression in the coating. The adhesion was derived from the classic stress transfer theory of Kelly and Tyson adapted to the geometry of the coating film to model the fragmentation process of the coating during the strain of the polymer substrate. This theory accounts for a Weibull-type coating strength, and introduces a critical stress transfer strength, related to the average coating fragmentation length at fragmentation saturation, which was found to be the most relevant parameter to describe the level of adhesion.

[0047] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interface shear strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com