2,5-furandicarboxylic-terephthalic-aliphatic copolyester and preparation method thereof

A technology of aliphatic dihydric alcohol and terephthalic acid, which is applied in the field of polyester, can solve the problems of high price and limited production of terephthalic acid, and achieve good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

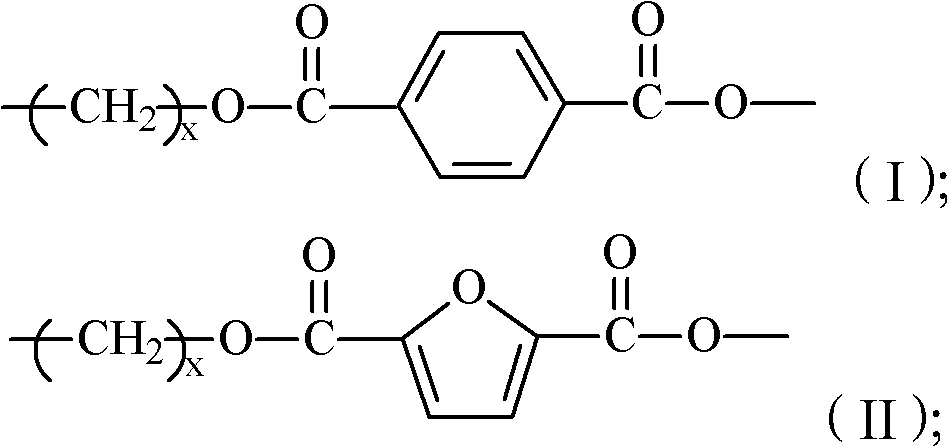

[0035] The present invention also provides a kind of 2, the preparation method of 5-furandicarboxylic acid-terephthalic acid-aliphatic glycol copolyester, comprises the following steps:

[0036] Under the action of a catalyst, 2,5-furandicarboxylic acid, terephthalic acid and aliphatic dihydric alcohol undergo an esterification reaction to obtain a first intermediate product;

[0037] The first intermediate product is subjected to polycondensation reaction to obtain 2,5-furandicarboxylic acid-terephthalic acid-aliphatic dihydric alcohol copolyester.

[0038] In the invention, firstly, 2,5-furandicarboxylic acid, terephthalic acid and aliphatic dihydric alcohol are uniformly mixed, and a catalyst is added for esterification reaction to obtain a first intermediate product.

[0039] The present invention uses 2,5-furandicarboxylic acid from a wide range of sources as a raw material. The source of the 2,5-furandicarboxylic acid is not particularly limited in the present invention,...

Embodiment 1

[0056] Mix 3mol 2,5-furandicarboxylic acid, 3mol terephthalic acid and 7.2mol ethylene glycol evenly, and add 0.018% titanium with a mass of 2,5-furandicarboxylic acid, terephthalic acid and ethylene glycol tetrabutyl acid, under the protection of nitrogen, the esterification reaction was carried out at a temperature of 190 ° C and a pressure of 0.25 MPa. After 200 minutes of reaction, the first intermediate product was obtained;

[0057] After the esterification reaction is finished, continue to add 0.004% trimethyl phosphate with a mass of 2,5-furandicarboxylic acid, terephthalic acid and ethylene glycol, raise the temperature to 220°C, and reduce the pressure to The reaction was carried out at 20 Pa, and after 260 minutes of reaction, light brown 2,5-furandicarboxylic acid-terephthalic acid-ethylene glycol copolyester was obtained.

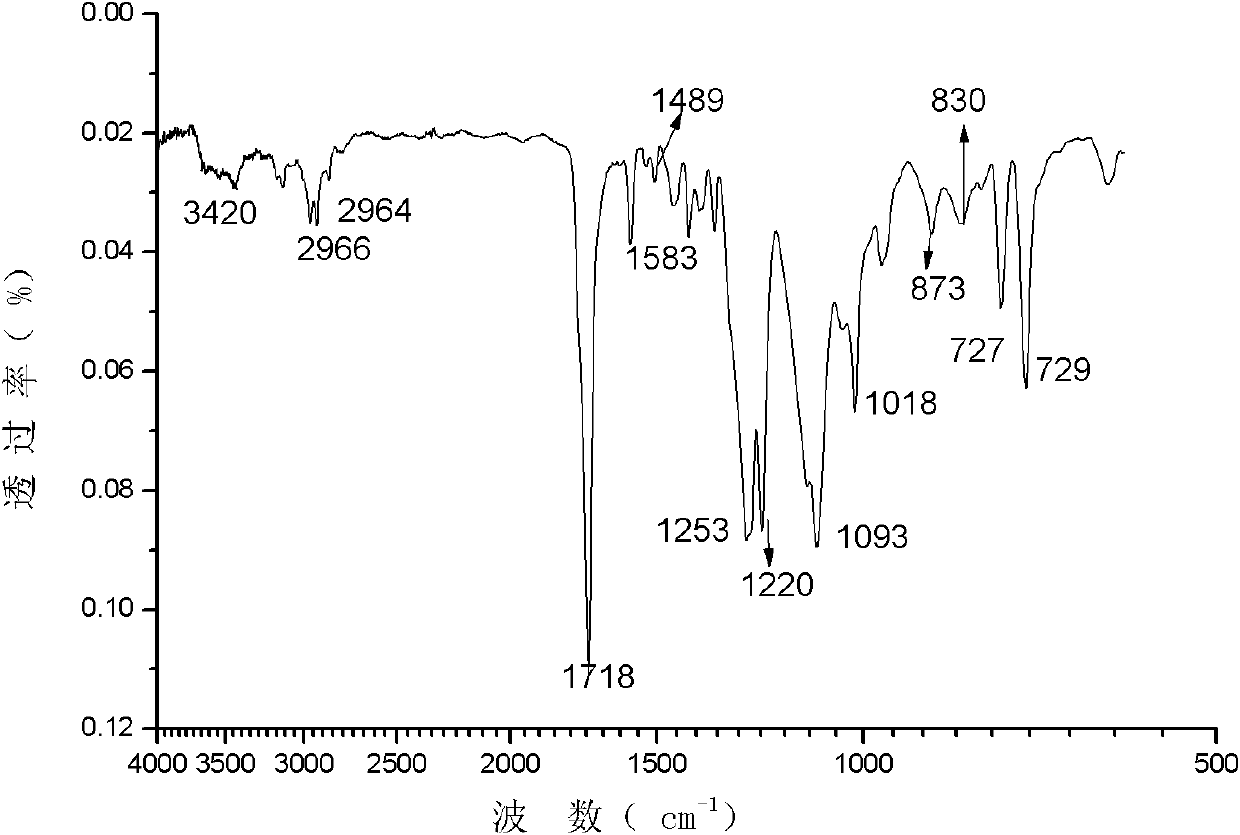

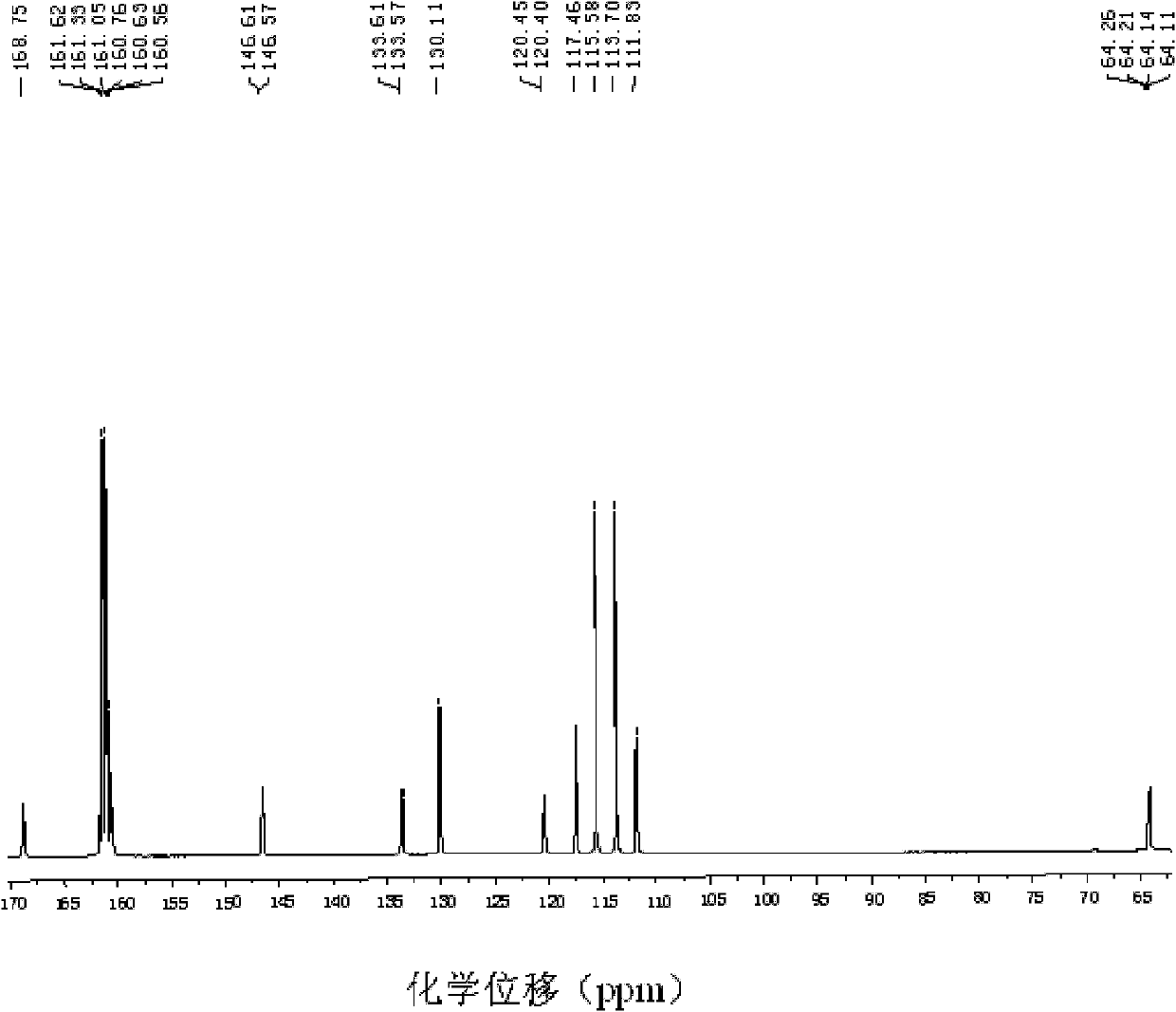

[0058] Infrared spectrum analysis is carried out to described 2,5-furandicarboxylic acid-terephthalic acid-ethylene glycol copolyester, analys...

Embodiment 2

[0064]Mix 3mol 2,5-furandicarboxylic acid, 3mol terephthalic acid and 9.6mol ethylene glycol evenly, and add 0.018% titanium with a mass of 2,5-furandicarboxylic acid, terephthalic acid and ethylene glycol tetrabutyl acid, under the protection of nitrogen, the esterification reaction was carried out at a temperature of 190 ° C and a pressure of 0.25 MPa, and after 200 minutes of reaction, the first intermediate product was obtained;

[0065] After the esterification reaction is finished, continue to add trimethyl phosphate whose mass is 0.004% of the total mass of 2,5-furandicarboxylic acid, terephthalic acid and ethylene glycol, raise the temperature to 220°C, and reduce the pressure to The reaction was carried out at 50 Pa, and after 360 minutes of reaction, light brown 2,5-furandicarboxylic acid-terephthalic acid-ethylene glycol copolyester was obtained.

[0066] The intrinsic viscosity of the 2,5-furandicarboxylic acid-terephthalic acid-ethylene glycol copolyester was meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com