Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

a technology for sports shoes and manufacturing methods, applied in the field of sports shoes, can solve the problems of large efforts to safely dispose of shoes, waste of shoes, and a large amount of shoes, and achieve the effects of reducing the number of shoes that end up in landfills, and reducing the number of shoes worn ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

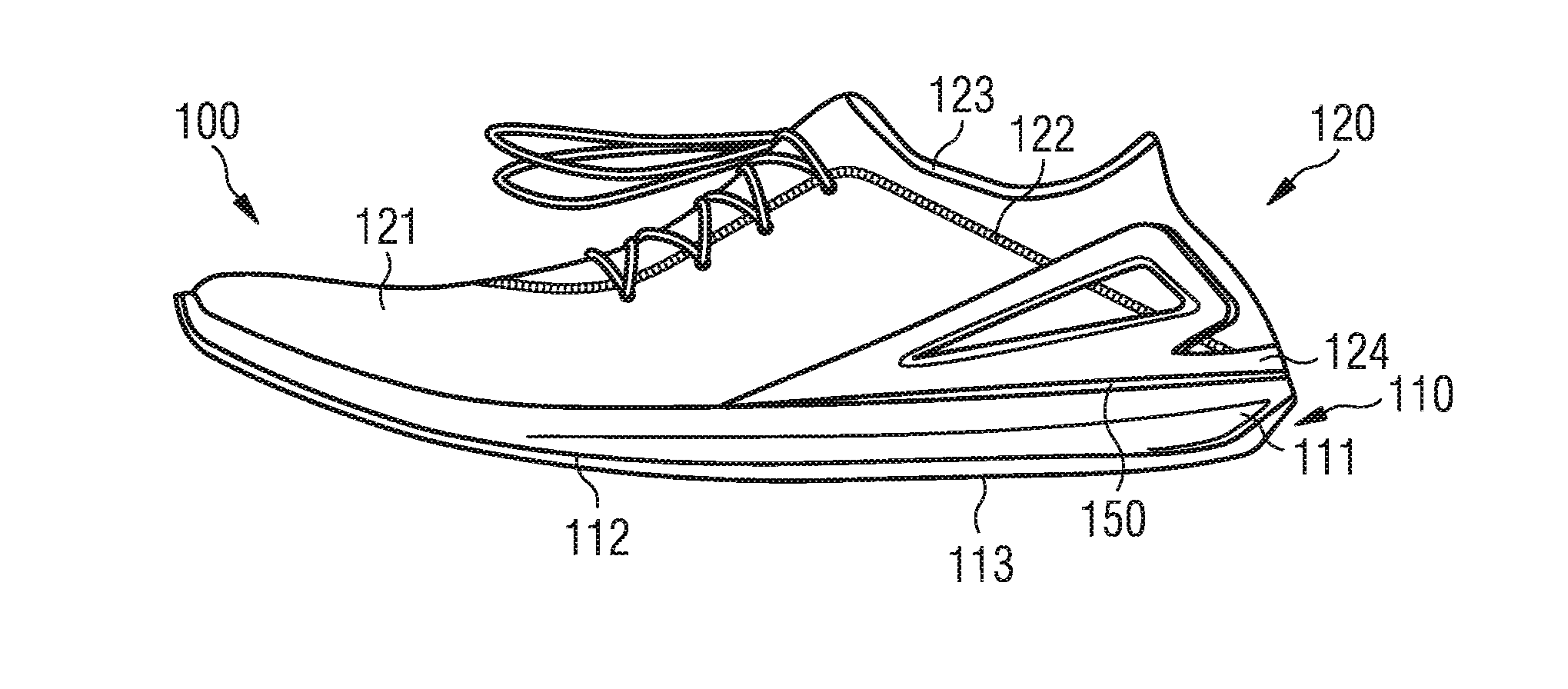

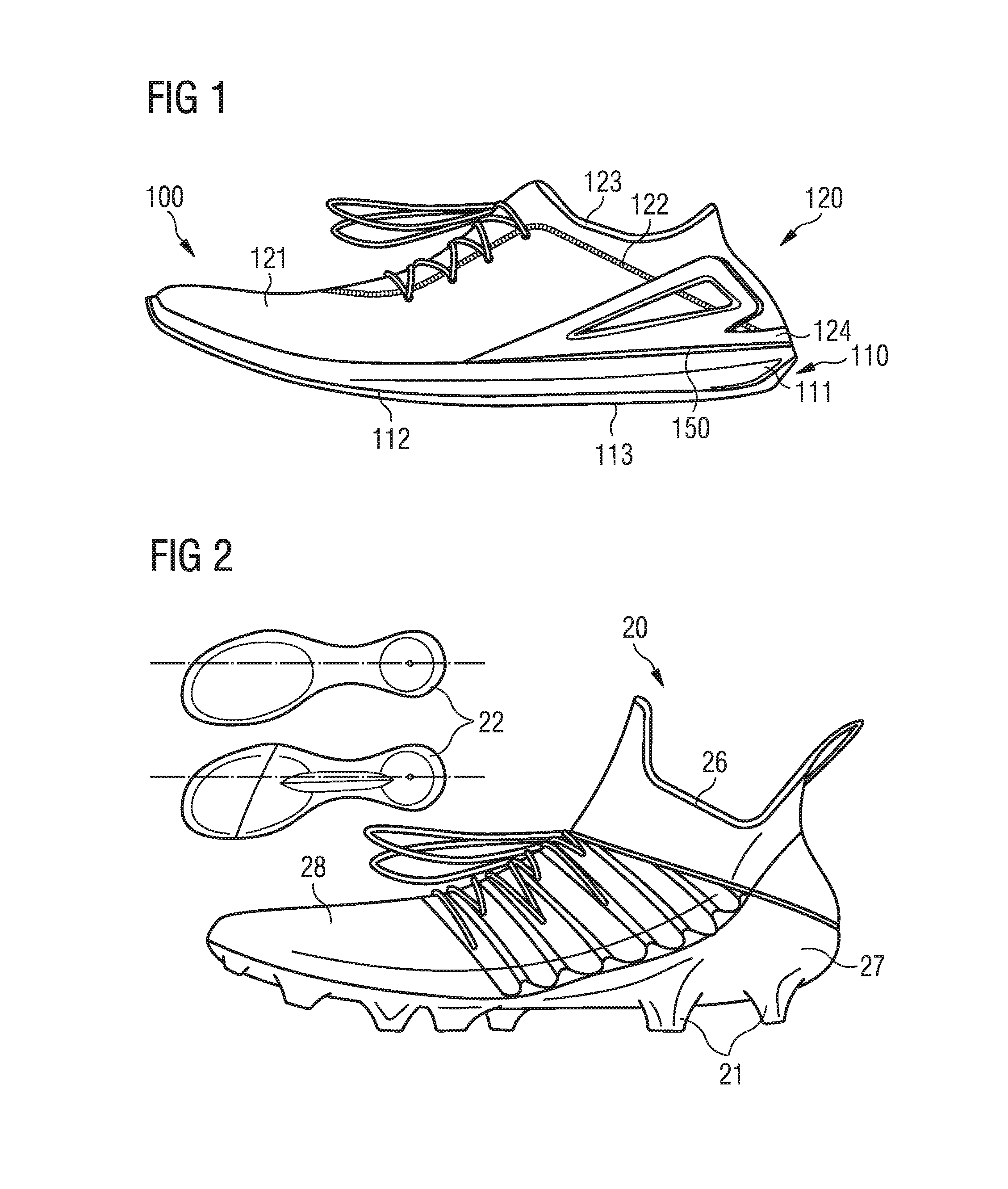

[0095]Shoe, in particular sports shoe, comprising:

[0096]an upper (120), wherein a majority by weight of the upper is made from a thermoplastic base material;

[0097]a sole (110), wherein a majority by weight of the sole is made from the same thermoplastic base material;

[0098]wherein the sole (110) and the upper (120) are individually fabricated and joined to each other; and

[0099]wherein the thermoplastic base material is selected from one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

example 2

[0100]Shoe according to Example 1, wherein the thermoplastic base material is adapted to be recycled in a joint recycling process for the upper (120) and the sole (110) so that it can serve as a base material for the manufacture of a further upper and / or sole.

example 3

[0101]Shoe according to Example 1 or Example 2, wherein the thermoplastic base material is a PA selected from one of the following materials: PA6, PA66, PA11, PA1010, PA612, PA610, PA1012, PA410, PA12 or polyether block amide PEBA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| physical property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com