Process for producing wool-like polyester composite filament yarn

A composite filament and manufacturing method technology, applied to textiles, papermaking, yarn, etc., can solve the problems of poor wool-like effect of fabrics, and achieve good wool-like effect, good resilience, soft and delicate touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

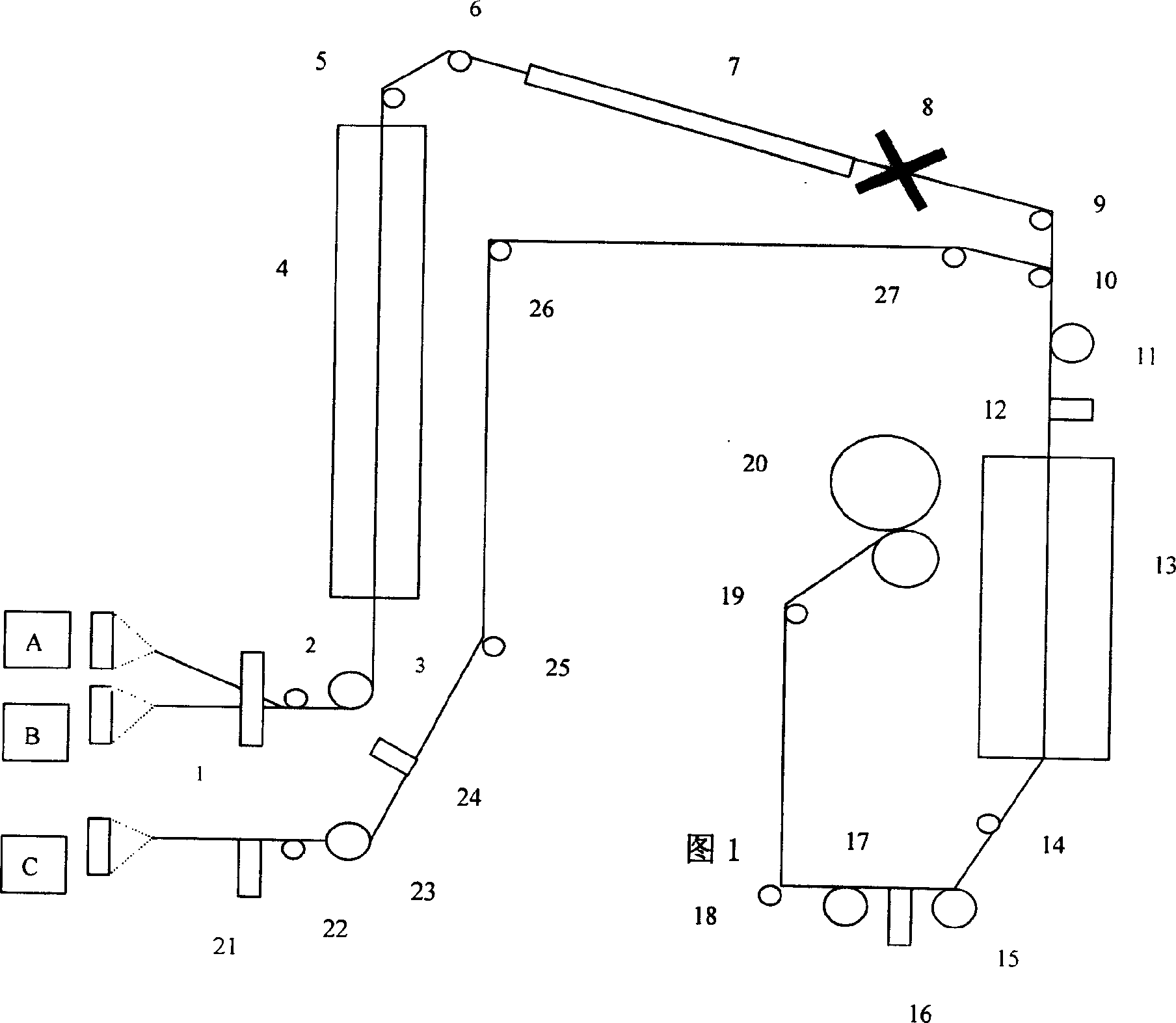

[0031]Produced on the Murata (MUTATEC) 33H (S+Z) machine, the sea-island yarn POY of 150dtex / 36f*37I specification is used as the first raw material yarn A, and the 150dtex / 36f round polyester cationic POY is used as the first raw material yarn B. The two bundles of filaments are drawn out from the original wire frame, separated and sequentially passed through the first double cutter 1, the first micro-moving filament guide 2, and the first wire feeding roller 3, and then enter the first hot box 4. The filament in the box 4 is subjected to 1.84 times the stretching of the second wire feed roller 11 (the draw ratio is generally 1.5-2.2) and The twisted deformation of the torsion transmitted from the false twister 8 has the characteristics of a textured yarn. Guided by the skid wire guides 5 and 6, the cooling plate 7 cools down to reduce the temperature of the filaments, and then enters the false twister 8 for false twisting. 115 degrees), the contact pressure of the apron is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com