Coated fabric with suede feel and manufacturing method thereof

A technology for coating fabrics and manufacturing methods, applied in textiles and papermaking, chemical instruments and methods, coatings, etc., can solve the problems of resin peeling, adhesives not environmentally friendly, affecting the quality of suede-like coated fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

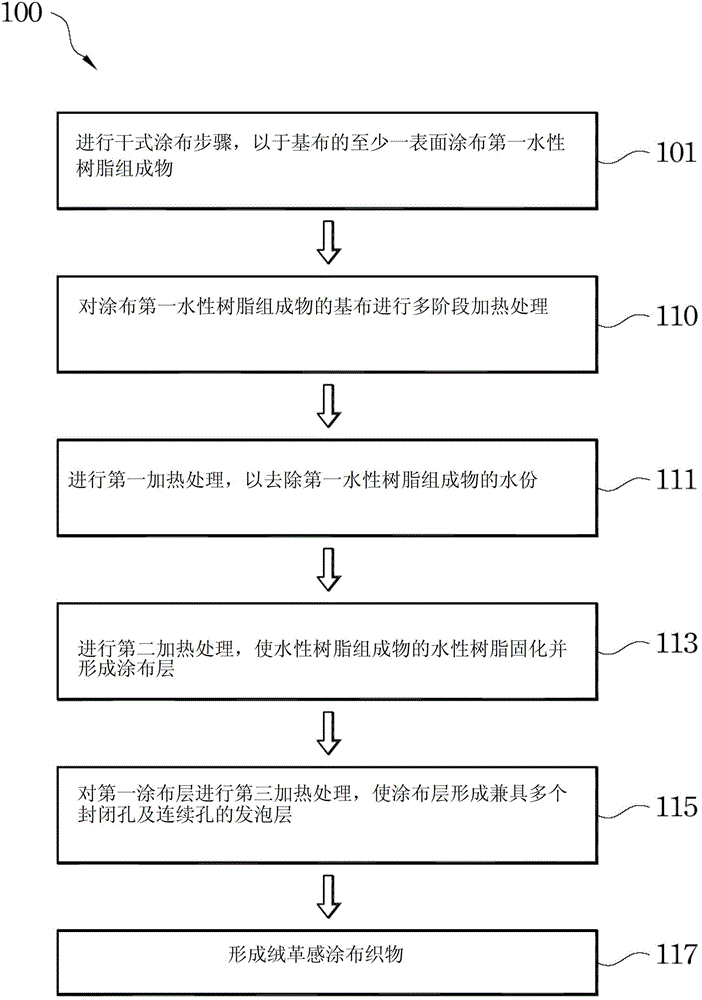

Method used

Image

Examples

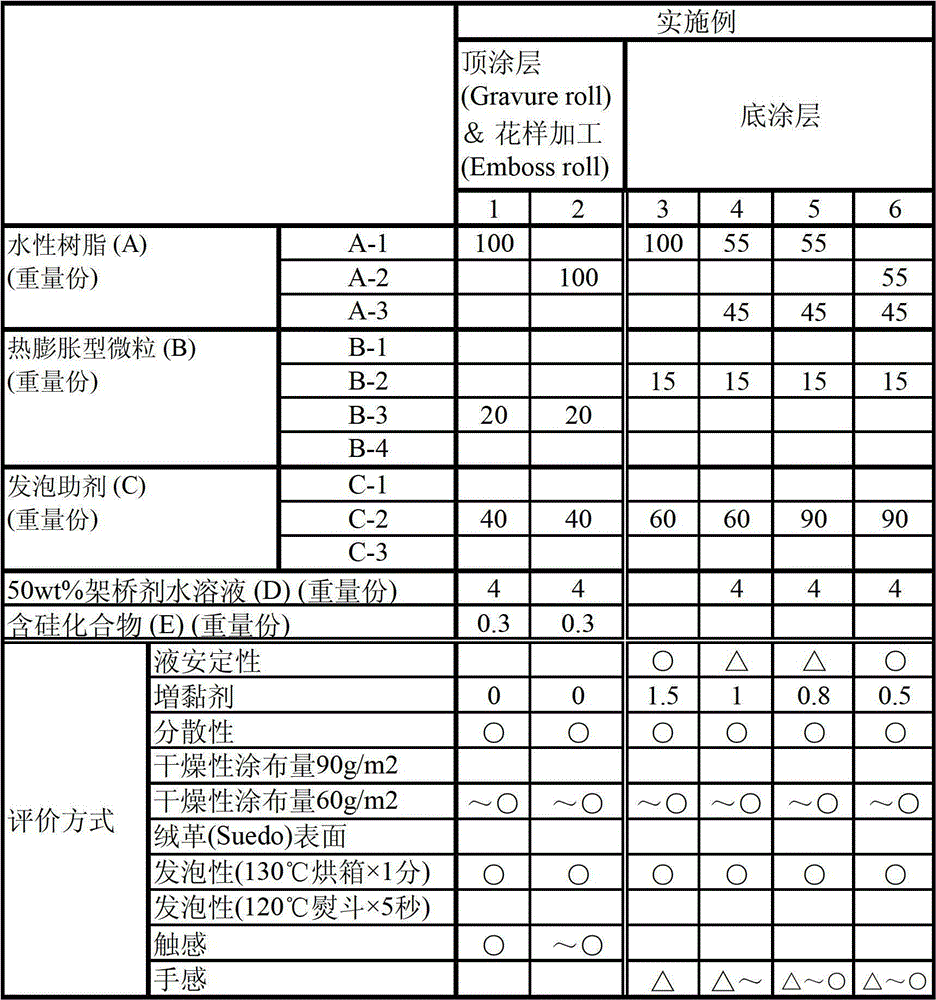

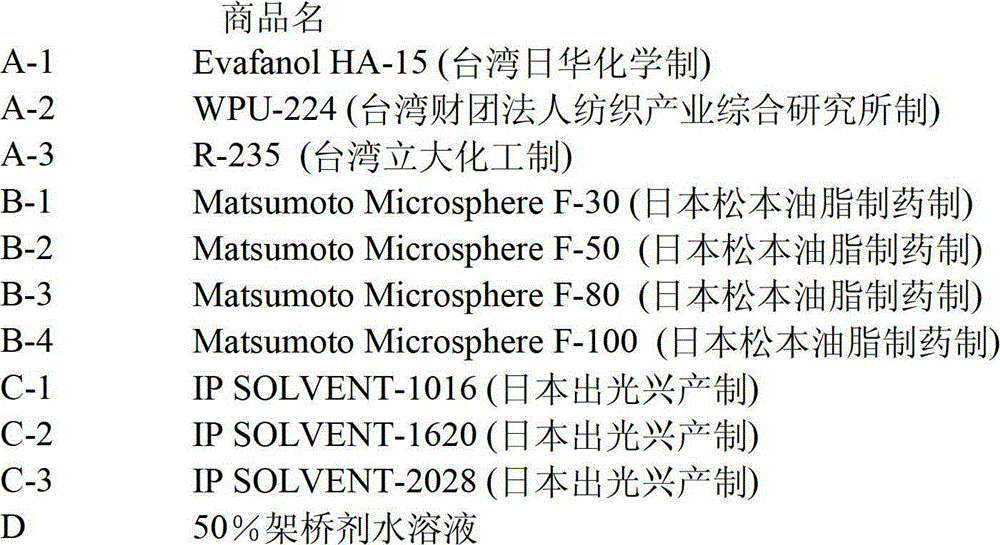

Embodiment 1

[0091] In this embodiment, 20 parts by weight of Microsphere F-80 (B-3) (manufactured by Matsumoto Oil Pharmaceutical Co., Ltd.), 40 parts by weight of IPSOLVENT1620 (C-2) (manufactured by Idemitsu Kogyo), 4 parts by weight of 50wt% frame The bridge agent aqueous solution (D) and 0.3 parts by weight of silicone (E) were uniformly dispersed in 100 parts by weight of Evafanol HA-15 (A-1) (manufactured by Rihua Chemical, Taiwan), and its dispersibility was tested. Next, the water-based resin composition for top coating was applied at 60 g / m 2 The coating amount is evenly coated on the surface of the base fabric. Then, place the substrate coated with the above-mentioned water-based resin composition in an oven at about 90° C. for about 5 minutes to remove the moisture of the water-based resin composition. Next, at a temperature of 100° C. to 120° C., the Evafanol HA-15 (A-1) was cured to form a coating layer. After that, treat the base fabric with the coating layer at 130°C for ...

Embodiment 2

[0093] Same as the manufacturing method of the suede-feel coated fabric in Example 1, the difference lies in that the type and usage amount of raw materials are changed in Example 2, and its formula and test results are shown in Table 1.

Embodiment 3

[0095] In this embodiment, 15 parts by weight of Microsphere F-50 (B-2) (manufactured by Matsumoto Oil Pharmaceutical Co., Ltd.) and 60 parts by weight of IPSOLVENT1620 (C-2) (manufactured by Idemitsu Kogyo) were uniformly stirred and dispersed in 100 parts by weight Parts of EvafanolHA-15 (A-1) (manufactured by Taiwan Rihua Chemical Co., Ltd.), and its solution stability, dispersibility, etc. were tested. Next, the water-based resin composition for the primer was applied at 60 g / m 2 The coating amount is evenly coated on the surface of the base fabric. Then, place the substrate coated with the above-mentioned water-based resin composition in an oven at 80° C. to 100° C. to remove moisture from the water-based resin composition. Next, at a temperature of 100° C. to 120° C., the Evafanol HA-15 (A-1) was cured to form a coating layer. After that, treat the base fabric with the coating layer in an oven at 130°C for 1 minute, so that the aforementioned coating layer forms a foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com