Preparation method of dyeable polyester composite fiber of cationic dye

A technology of cationic dyes and composite fibers, which is applied in the field of preparation of cationic dye-dyeable polyester composite fibers, which can solve the problems of low curl, poor bulkiness, and prone to color difference in cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

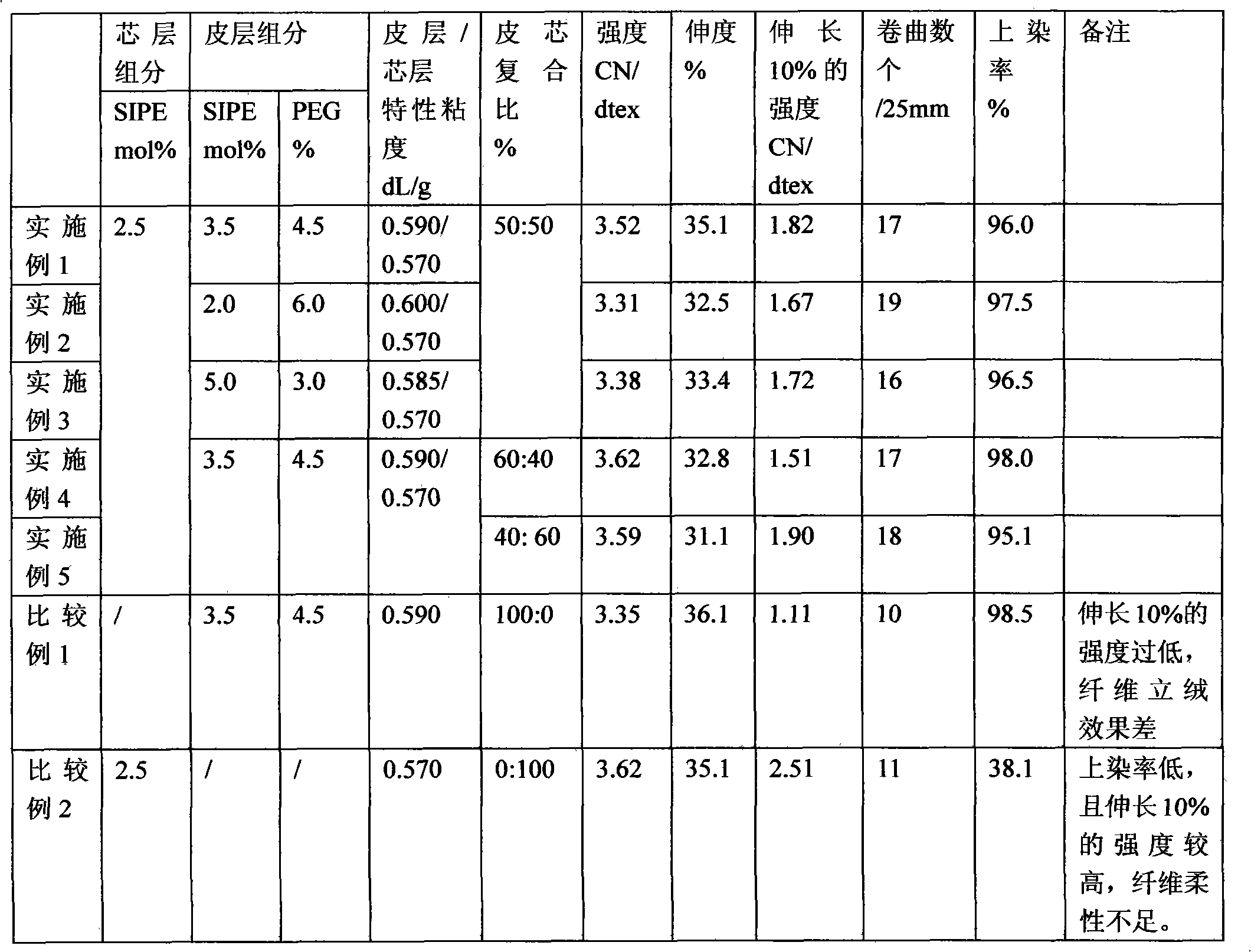

Examples

Embodiment 1

[0039] Preparation of modified polyester raw materials: on the semi-continuous polyester equipment, add purified terephthalic acid and ethylene glycol monomers into the slurry tank at a molar ratio of 1:1.20 for beating, and add catalyst ethylene glycol into the beating tank Alcohol antimony; the above slurry is continuously and stably transported to the esterification-I reactor, the pressure of the esterification-I reactor is controlled at 0.12MPa, the temperature is 250-258.0°C, the esterification rate is 98.2%, and the esterification product is sent to the esterification Chemical-II reactor.

[0040]Among them, the core layer component is to add 2.5mol% SIPE in the esterification-II reactor, control the temperature of the esterification-II reactor at 245-255°C, and the residence time of 30-50 minutes, and pump the homogeneously mixed esterified product to polycondensation In the section, according to the conventional polycondensation process, polycondensation is carried out...

Embodiment 2

[0045] The process steps of this example are basically the same as those of Example 1, the difference being that: the purified terephthalic acid and ethylene glycol monomers are added into the slurry tank at a molar ratio of 1:1.18 for beating. The skin component is produced by adding 2.0mol% SIPE and 6.0% PEG with a molecular weight of 1500 to the esterification-II reactor, and the prepared cationic dyeable polyester chip has an intrinsic viscosity of 0.600dL / g. The rest of the steps are the same.

[0046] The physical index of the fiber of this embodiment: fineness 3.2dtex, strength 3.31CN / dtex, elongation 32.5%, the strength when fiber elongation 10% is 1.67CN / dtex, crimp number 19 / 25mm, dye uptake rate 97.5% .

Embodiment 3

[0048] The process steps of this example are basically the same as those of Example 1, except that the purified terephthalic acid and ethylene glycol monomers are added into the slurry tank at a molar ratio of 1:1.25 for beating. The skin component is produced by adding 5.0mol% SIPE and 3.0% PEG with a molecular weight of 1500 in the esterification-II reactor, and the prepared cationic dyeable polyester chips have an intrinsic viscosity of 0.585dL / g. The rest of the steps are the same.

[0049] The physical index of the fiber of this embodiment: fineness 3.2dtex, intensity 3.38CN / dtex, elongation 33.4%, the strength when fiber elongation 10% reaches 1.72CN / dtex, crimp number 16 / 25mm, dye uptake rate 96.5% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com