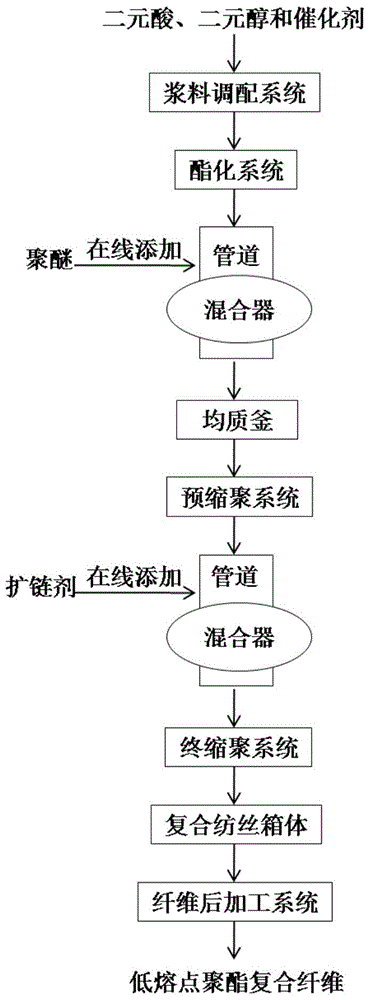

Method for preparing low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning

A low-melting polyester and composite fiber technology, applied in fiber processing, stretch spinning, conjugated synthetic polymer rayon, etc., can solve the problems of low production efficiency, difficult to guarantee product quality, high cost, and achieve molding Good, improve production efficiency, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. The slurry prepared by terephthalic acid, isophthalic acid, ethylene glycol and antimony series catalyst, the molar ratio of acid and alcohol in the slurry is 1:1.05;

[0040] 2. The obtained slurry is continuously and uniformly transported to the esterification system composed of the vertical first esterification kettle and the vertical second esterification kettle for esterification reaction. The reaction temperature of the first esterification kettle is 265°C and the reaction pressure is is 200kPa, the reaction temperature of the second esterification kettle is 270°C, and the reaction pressure is 120kPa. When the esterification rate of the esterified product reaches 96%, the terephthalic acid / isophthalic acid / ethylene glycol ternary oligomer is continuously and stably pumped out from the esterification kettle through the oligomer pump;

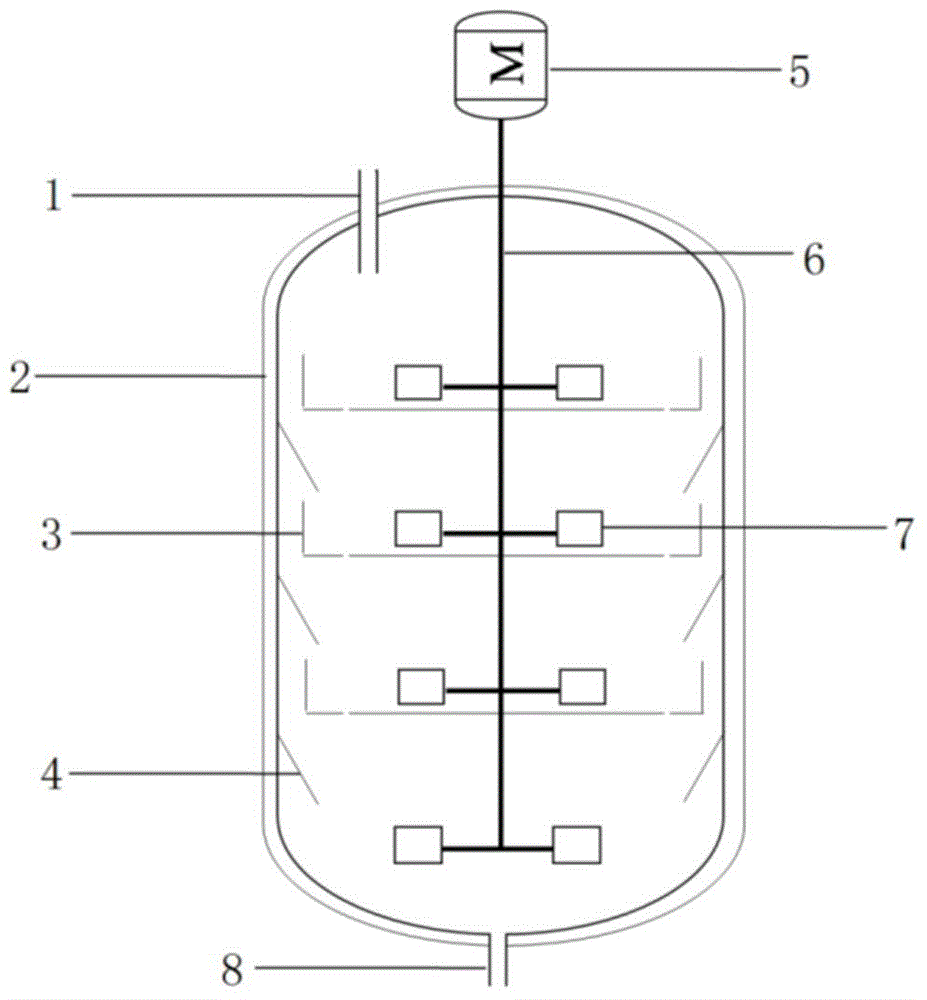

[0041] 3. The oligomer obtained in step 2 and the polyether component polyethylene glycol 100 injected into the oligomer pipelin...

Embodiment 2

[0049] 1. The slurry prepared by terephthalic acid, succinic acid, butanediol and titanium-based catalyst, the molar ratio of acid to alcohol in the slurry is 1:1.4;

[0050] 2. The obtained slurry is continuously and uniformly transported to an esterification system composed of a vertical esterification kettle for esterification reaction. The reaction temperature is 230°C and the reaction pressure is 300kPa. When the esterification rate of the esterified product reaches 96%, the terephthalic acid / succinic acid / butanediol ternary oligomer is continuously and stably pumped out from the esterification kettle through the oligomer pump;

[0051] 3. The oligomer obtained in step 2 and the polyether component polytetramethylene glycol 1000 injected into the oligomer pipeline are mixed evenly by the tubular static mixer arranged on the pipeline and then enter the homogenizer to carry out the transesterification reaction; wherein , the reaction temperature of the homogenizing kettle i...

Embodiment 3

[0059] 1. The slurry prepared by terephthalic acid, adipic acid, propylene glycol and titanium-based catalyst, the molar ratio of acid to alcohol in the slurry is 1:1.4;

[0060]2. The obtained slurry is continuously and uniformly transported to the esterification system composed of the vertical first esterification kettle and the horizontal second esterification kettle for esterification reaction. The reaction temperature of the first esterification kettle is 250°C and the reaction pressure is is 200kPa, the reaction temperature of the second esterification kettle is 255°C, and the reaction pressure is 100kPa. When the esterification rate of the esterified product reaches 95%, the terephthalic acid / adipic acid / propylene glycol tertiary oligomer is continuously and stably pumped out from the second esterification kettle through the oligomer pump;

[0061] 3. The oligomer prepared in step 2 and the polyether component polypropylene glycol 5000 injected into the oligomer pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com