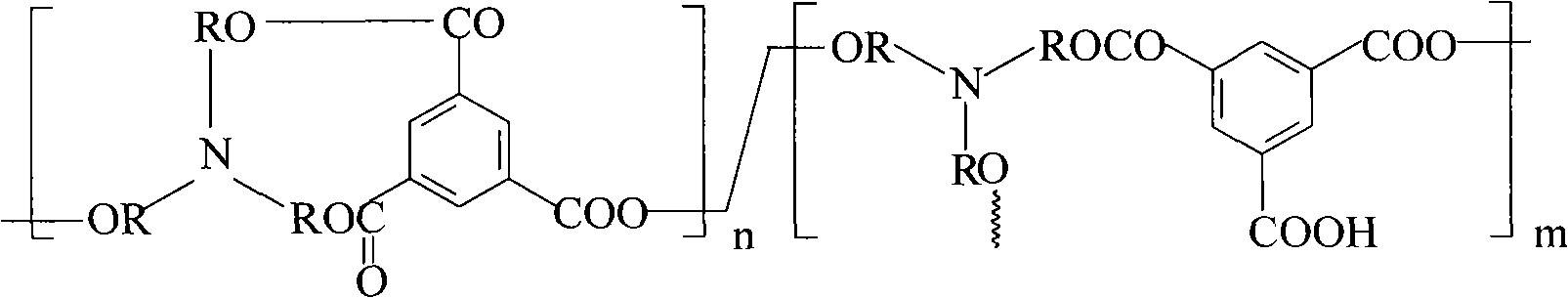

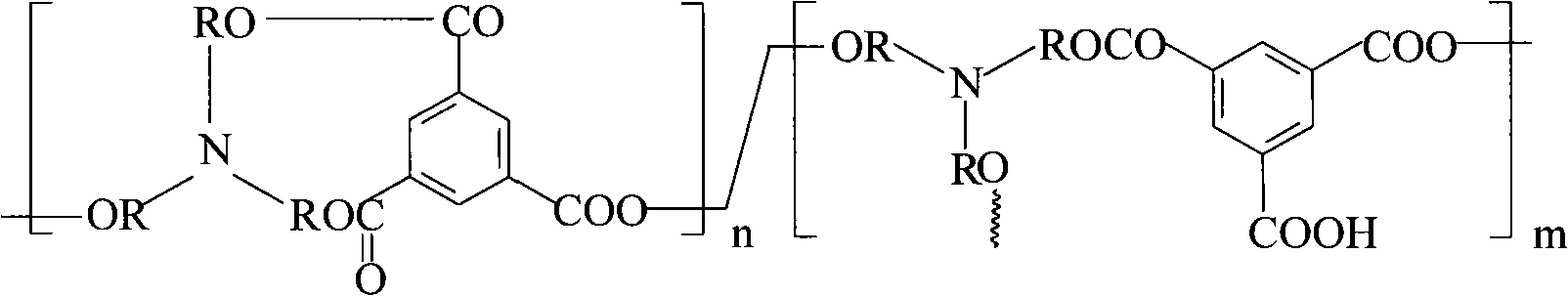

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

A technology of composite nanofiltration membrane and polysulfone ultrafiltration membrane, which is applied in the field of polyester composite nanofiltration membrane and its preparation, can solve the problems of unsatisfactory flux and rejection rate of polyester composite membrane, and achieve a good industrial production basis, Broad application prospects and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

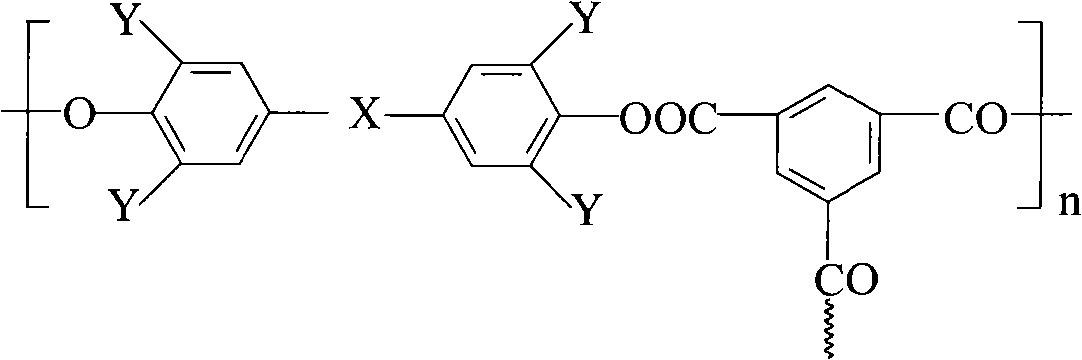

Method used

Image

Examples

Embodiment 1-3

[0032] A polysulfone ultrafiltration membrane with a molecular weight cut-off of 20,000-30,000 was selected as the supporting membrane.

[0033] Immerse the wet polysulfone support membrane into the concentration of triethanolamine is 5 ~ 7wt / v%, sodium lauryl sulfate is 0.3wt / v%, NaOH / Na 2 CO 3 (mass ratio 1: 2) was in the aqueous solution of 0.6wt / v% for 30 minutes, after taking it out, roll the surface of the supporting film with a rubber roller, squeeze it dry and carry out Interfacial polymerization was carried out for 35 minutes. After the composite film was naturally dried in air for 1 minute, it was heat-treated in an oven at 60°C for 30 minutes. After being rinsed several times with deionized water, the polyester composite nanofiltration membrane is obtained. The prepared composite membrane was stored in water, and its desalination performance was tested under the condition of 5mmol / L magnesium sulfate aqueous solution and operating pressure of 0.6MPa.

[0034] Th...

Embodiment 4-6

[0038] As in Example 1-3, according to the above method, the concentration ratio of triethanolamine is 5wt / v%, sodium lauryl sulfate is 0.3wt / v%, and NaOH / Na 2 CO 3 (mass ratio 1:2) 0.6wt / v% aqueous solution and trimesoyl chloride concentration 0.2-0.4wt / v% n-hexane solution carry out interfacial polymerization to prepare composite nanofiltration membrane. The prepared composite membrane was stored in water, and its desalination performance was tested under the condition of 5mmol / L magnesium sulfate aqueous solution and operating pressure of 0.6MPa.

[0039] These several examples are to investigate the effect of the concentration of trimesoyl chloride, a monomer in the organic phase, on the performance of the membrane.

[0040]

[0041] It can be seen from Examples 4-6 that the concentration of trimesoyl chloride has almost no effect on the membrane performance, so a lower concentration of trimesoyl chloride can be used to prepare this type of composite nanofiltration mem...

Embodiment 7-10

[0043] As in Example 1-3, according to the above method, the concentration of triethanolamine is 6wt / v%, sodium lauryl sulfate is 0.3wt / v%, NaOH / Na 2 CO 3 (Mass ratio 1:2) 0.6wt / v% aqueous solution and trimesoyl chloride concentration 0.2wt / v% n-hexane solution were interfacially polymerized to prepare a composite nanofiltration membrane. The prepared composite membrane was stored in water, and its desalination performance was tested under the condition of 5mmol / L brine solution and operating pressure of 0.6MPa.

[0044] These several examples are to investigate the desalination performance of polyester composite nanofiltration membranes to different salts.

[0045]

[0046] From Examples 7-10, it can be seen that this type of polyester composite nanofiltration membrane has a higher desalination rate for electrolyte solutions containing divalent anions, but a lower desalination rate for electrolyte solutions containing monovalent anions, so this type of polymer nanofiltratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com