Polyester composite fiber and method for producing same

A technology for composite fibers, production methods, applied in the direction of fiber processing, conjugated synthetic polymer artificial filaments, filament/thread forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

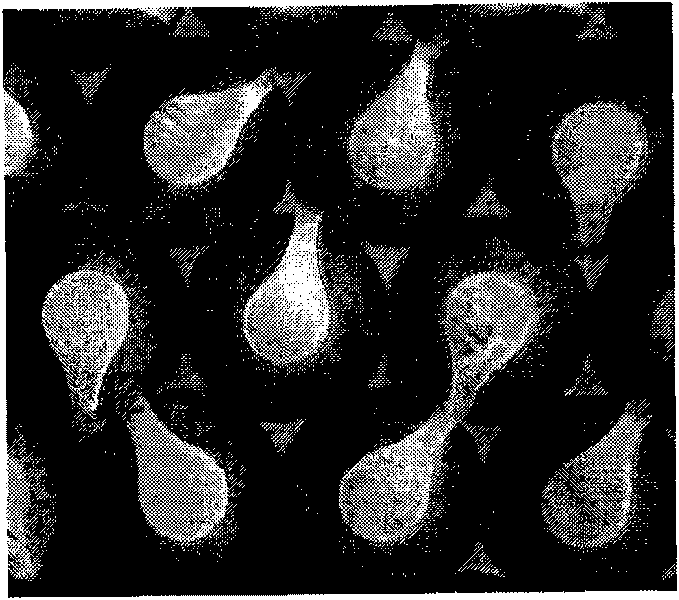

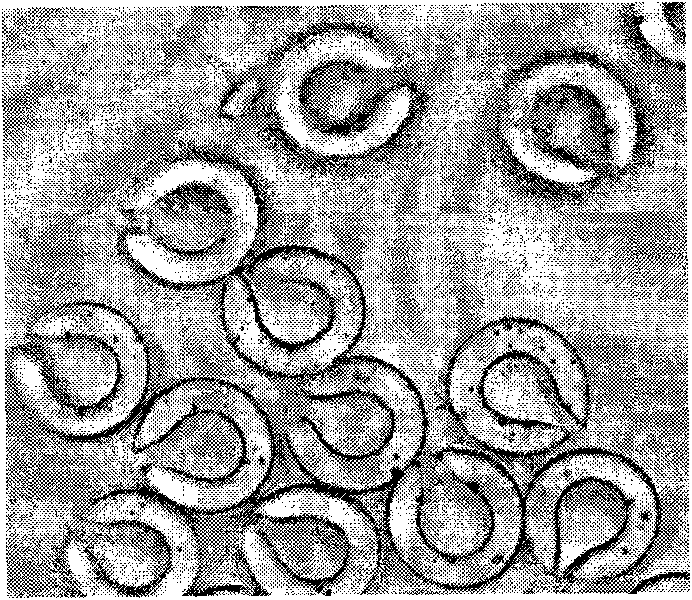

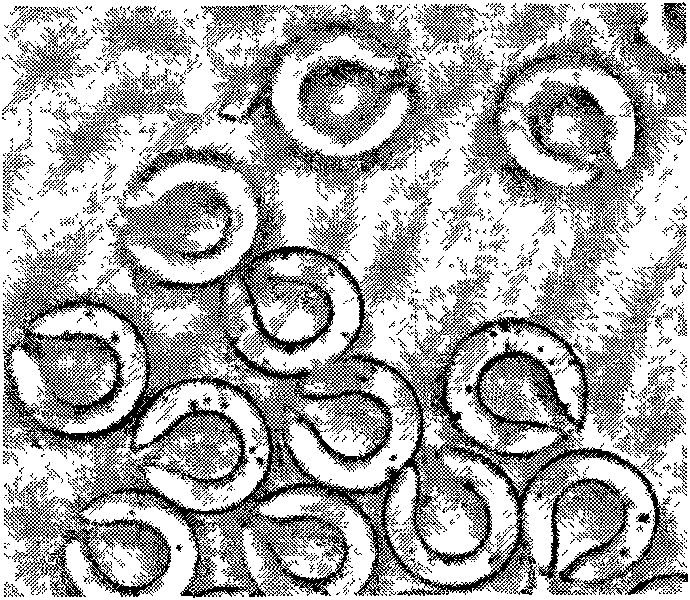

Image

Examples

Embodiment 1

[0030] The skin component polymer polyethylene terephthalate (PET) slices and the core component polymer alkali soluble copolyester (COPET) slices are dried to below 100ppm respectively, and the PET slices enter the A screw through the A silo at 290 Melting at ℃ temperature, the discharge volume is controlled by A metering pump, and the COPET chip enters the B screw through the B silo to be melted at 270°C, and the discharge volume is controlled by the B metering pump. The composite spinning assembly whose temperature is controlled by the spinning box under the condition of 290 ℃, spins the as-spun fibers, cools and solidifies them under the condition of the side blowing wind speed of 25m / min, and then oils the fibers evenly through the oiling nozzle to bundle the fibers and reduce them. For friction, the oil supply rate is 0.7%. The fibers that have been oiled and bundled pass through the spinning shaft, intertwine through the pre-interlacer, enter the first roller (1GR) at a...

Embodiment 2

[0033]The skin component polymer polyethylene terephthalate (PET) slices and the core component polymer alkali soluble copolyester (COPET) slices are dried to below 100ppm respectively, and the PET slices enter the A screw through the A silo at 290 Melting at a temperature of ℃, the discharge volume is controlled by the A metering pump, and the COPET chips enter the B screw through the B silo to be melted at a temperature of 270°C, and the discharge volume is controlled by the B metering pump. The composite spinning assembly whose temperature is controlled by the spinning box under the condition of 290 ℃, spins the as-spun fibers, cools and solidifies them under the condition of the side blowing wind speed of 25m / min, and then oils the fibers evenly through the oiling nozzle to bundle the fibers and reduce them. For friction, the oil supply rate is 0.7%. The fibers that have been oiled and bundled pass through the spinning shaft, intertwine through the pre-interlacer, enter th...

Embodiment 3

[0036] The skin component polymer polyethylene terephthalate (PET) slices and the core component polymer alkali soluble copolyester (COPET) slices are dried to below 100ppm respectively, and the PET slices enter the A screw through the A silo at 290 Melting at ℃ temperature, the discharge volume is controlled by A metering pump, the COPET chip enters the B screw through the B silo and melted at a temperature of 270°C, and the discharge volume is controlled by the B metering pump. The composite spinning assembly whose temperature is controlled by the spinning box under the condition of 290 ℃, spins the as-spun fibers, cools and solidifies them under the condition of the side blowing wind speed of 25m / min, and then oils the fibers evenly through the oiling nozzle to bundle the fibers and reduce them. For friction, the oil supply rate is 0.7%. The fibers that have been oiled and bundled pass through the spinning shaft, intertwine through the pre-interlacer, enter the first roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com