Multistage coupling heat accumulating type solar heat-power cogeneration system

A technology of combined heat and power and solar energy, which is applied to solar thermal power generation, solar thermal installations, and mechanical power generation with solar energy, etc., can solve the problems of inability to form energy cascade utilization, lack of direct heat transfer coupling, and inability to perform combined heat and power supply, etc. To achieve the effect of facilitating large-scale production and popularization and application, improving use efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

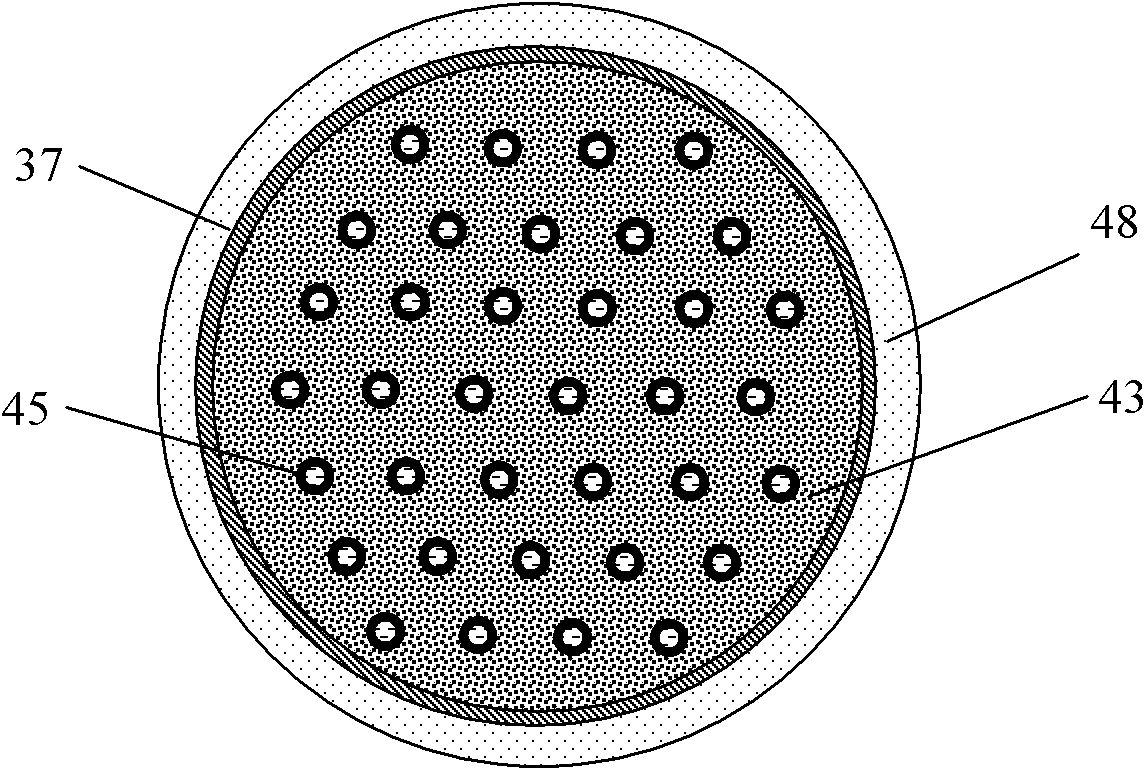

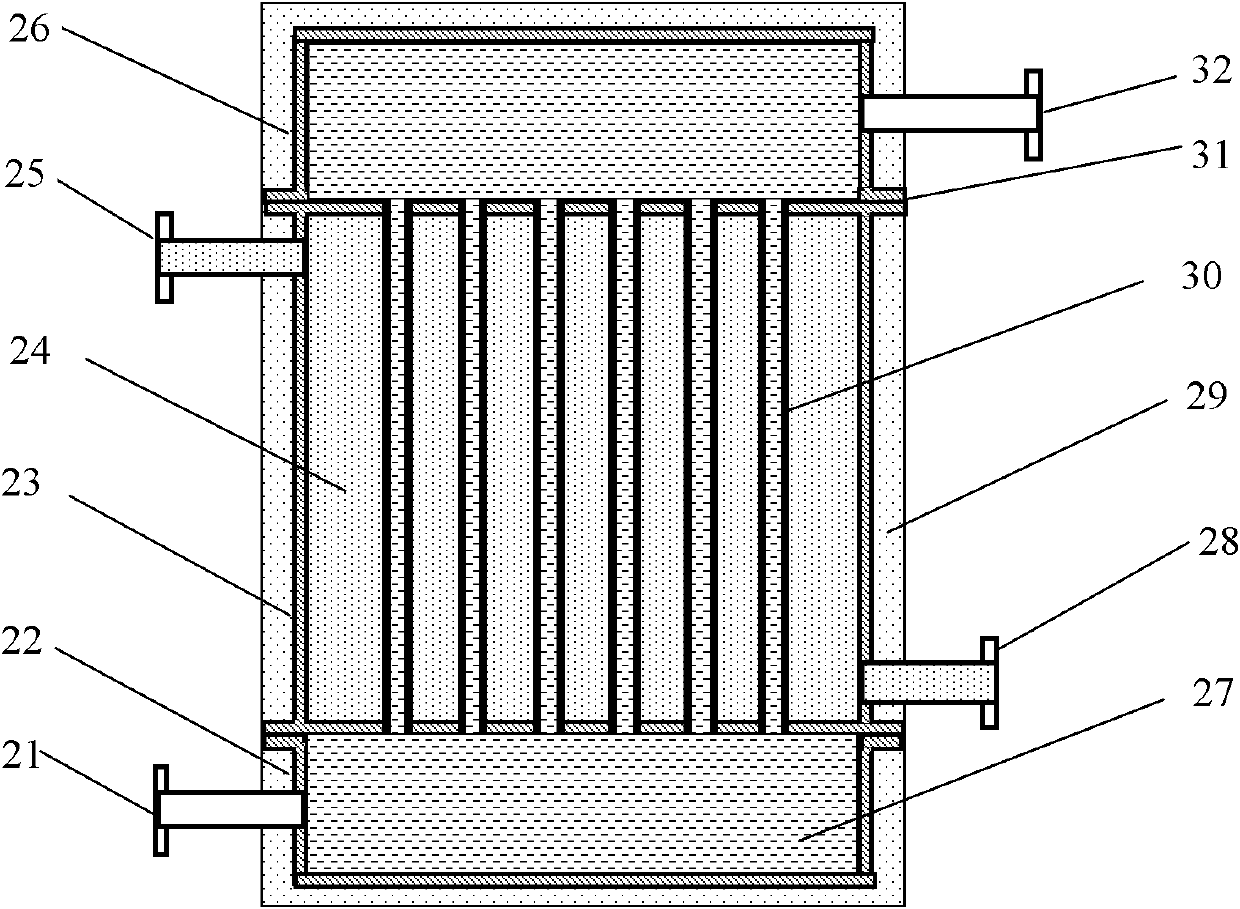

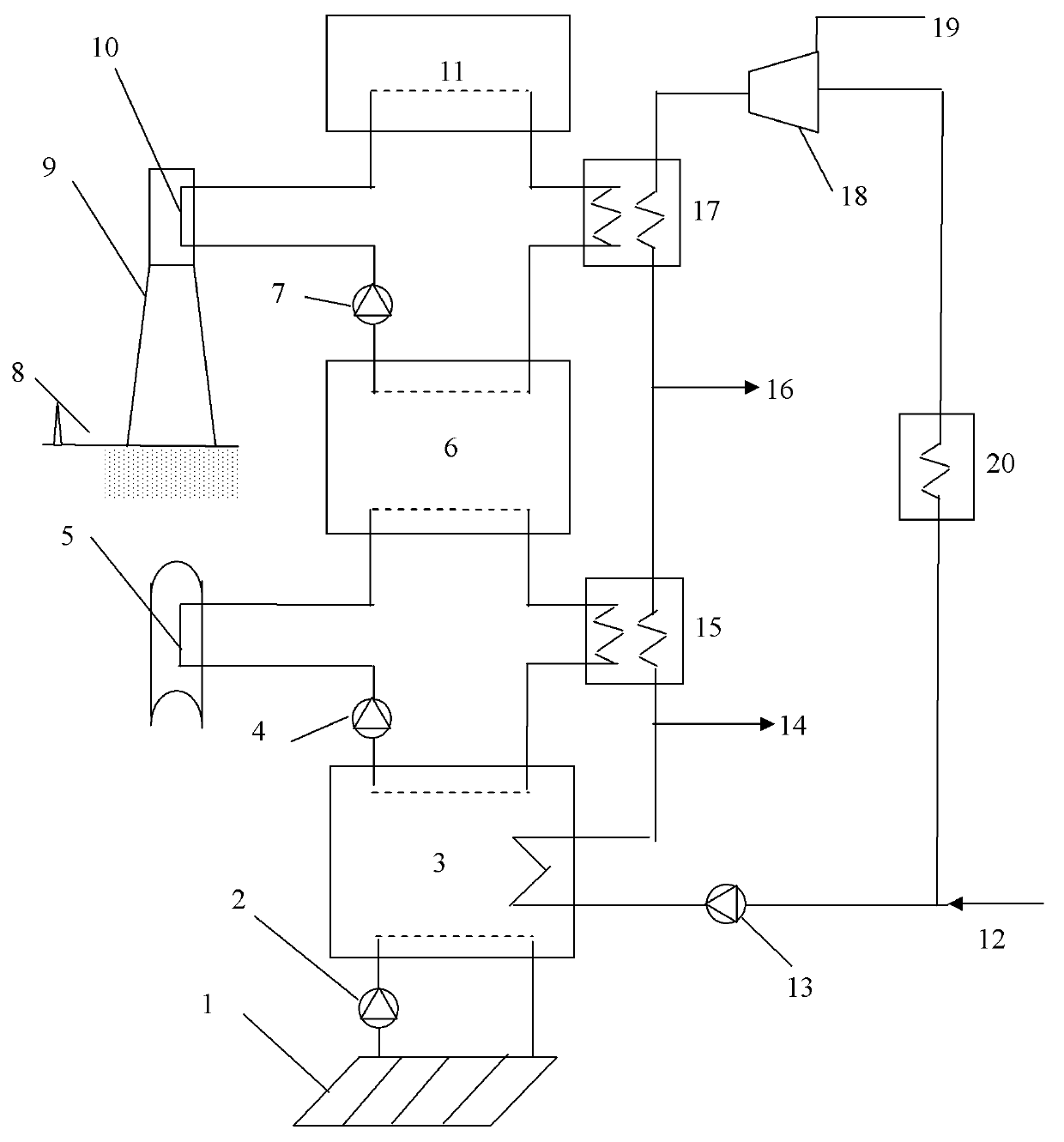

[0029] A multi-stage coupled regenerative solar heat and power cogeneration system, its structure is as follows figure 1 As shown, the tower-type heat absorption heat storage heat transfer subsystem includes a heliostat field 8, a concentrating tower 9, a heat absorber 10, a high temperature resistant pump 7, a high temperature heat accumulator 11 and pipelines. The working temperature of the high-temperature heat transfer and heat storage medium is 300°C-700°C, usually high-temperature mixed molten salt, liquid metal, etc. The trough heat absorption heat storage heat transfer subsystem includes a parabolic trough mirror field and a vacuum tube heat absorber 5, a pump 4, a medium temperature coupled heat accumulator 6 and pipelines. The working temperature of medium temperature heat transfer and heat storage medium is 100°C-400°C, usually high temperature resistant heat transfer oil, etc. The plate heat absorption heat storage heat transfer subsystem includes a plate heat col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com