Heliostat reflecting facula offset correction method

A heliostat and light spot technology, applied in position/direction control, non-electric variable control, instruments, etc., can solve the problems of being susceptible to interference and high price of heliostat correction technology, achieving low cost and strong ability to resist environmental interference , to meet the effect of industrial field application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

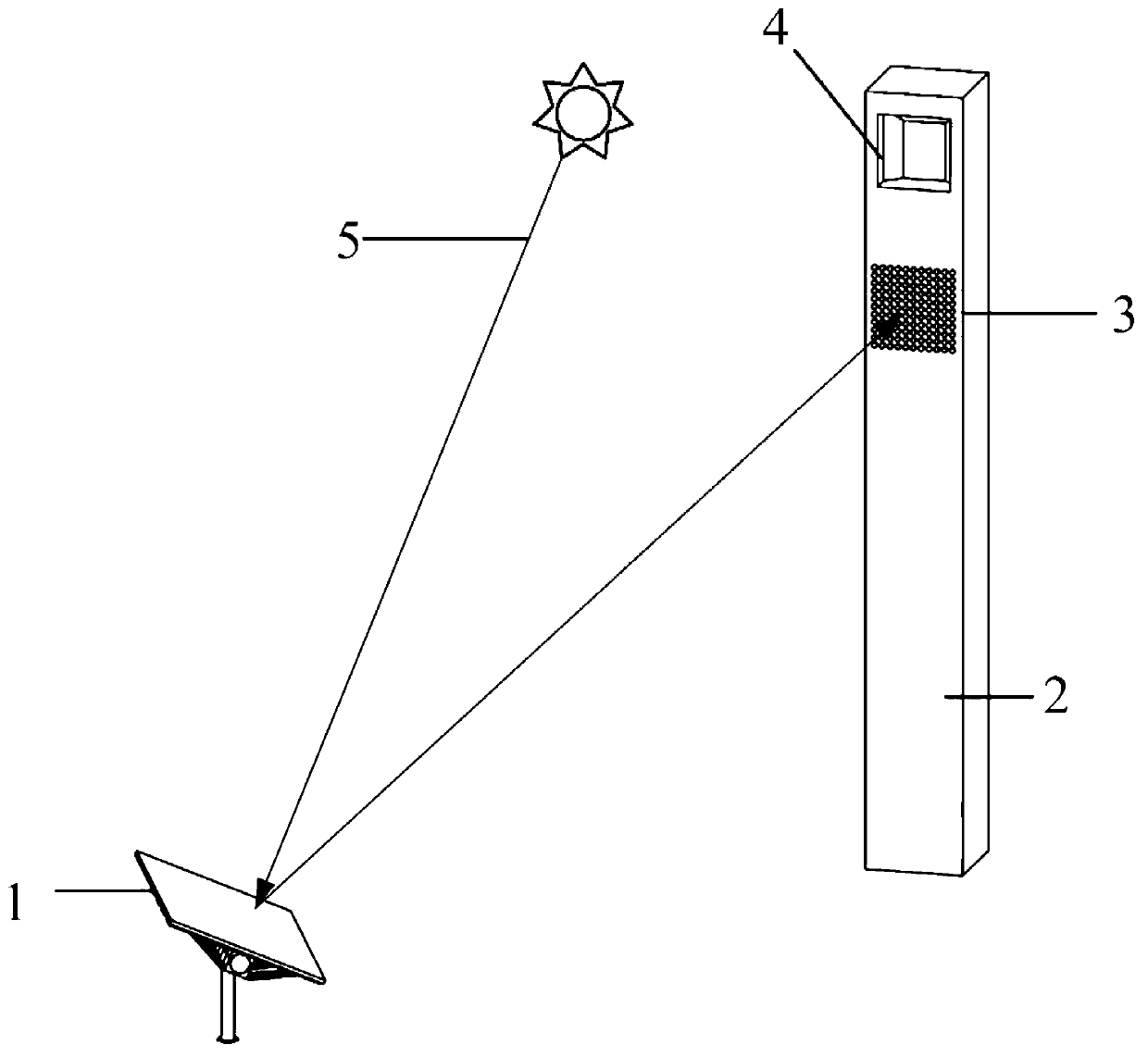

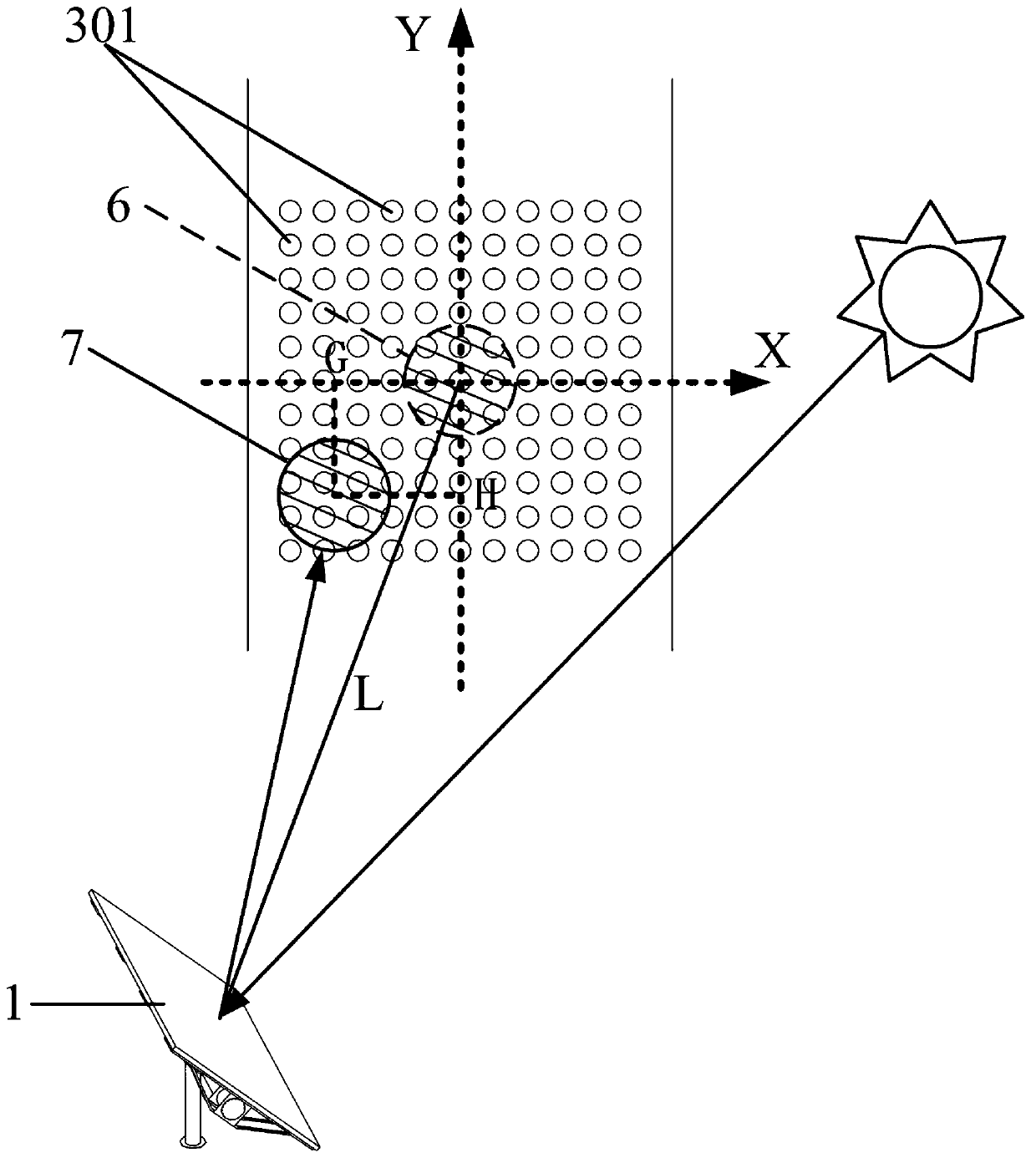

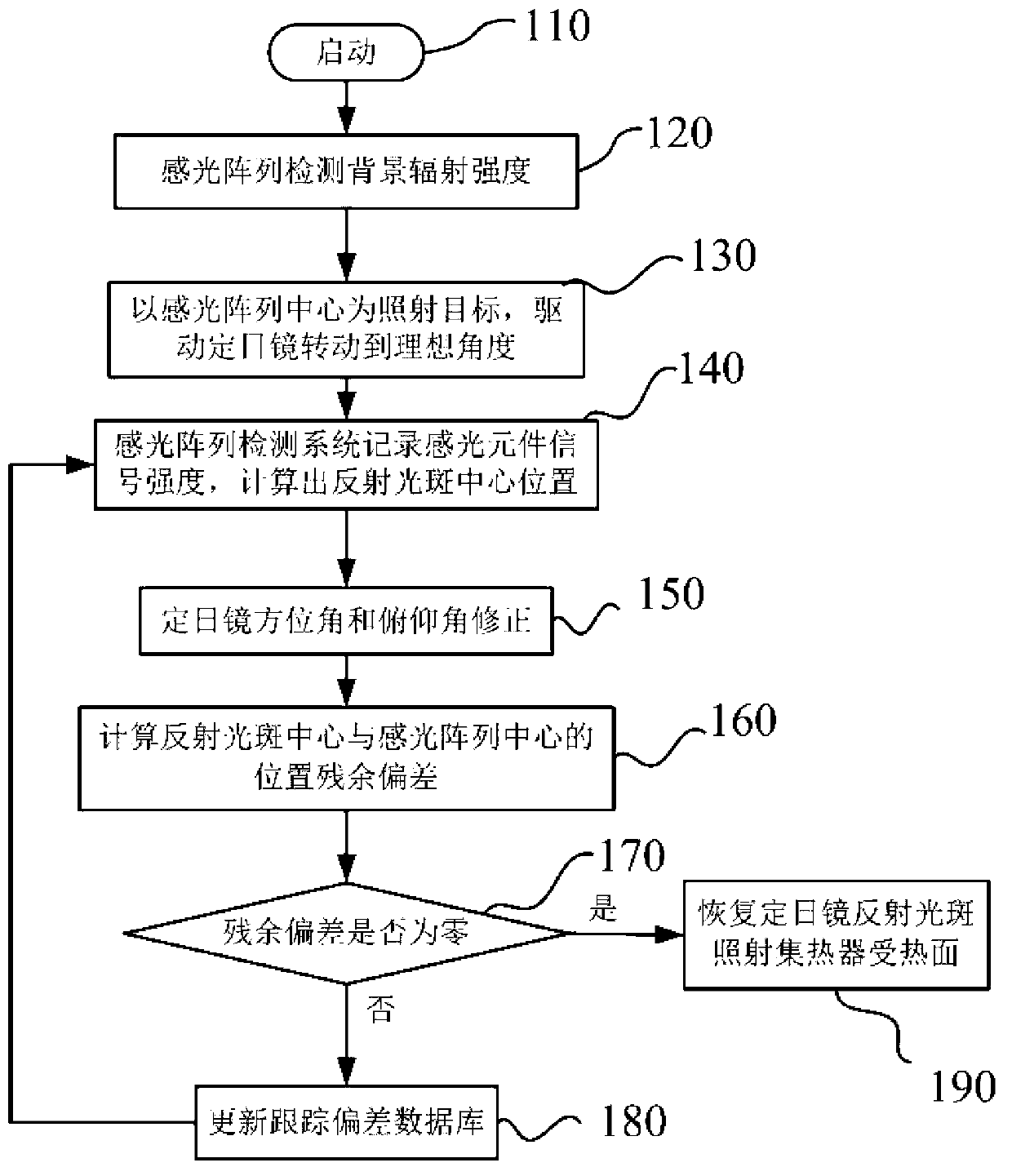

[0043] The heliostat reflection spot deviation correction device includes the heat collection tower 2 of the tower solar thermal power station, the heliostat field and the heliostat control system, the photosensitive array 3 and the photosensitive array detection system. figure 1 It is a schematic diagram of the optical path of the heliostat reflection spot deviation correction device used in the present invention. The heliostat 1 is the corrected heliostat in the heliostat field, the heat collector is placed on the top of the heat collection tower 2, and the photosensitive array 3 is placed on the The bottom of the heating surface 4 is installed on the heat collecting tower 2 in the same direction, the vertical centerline of the photosensitive array 3 coincides with the vertical centerline of the heat collector heating surface 4, the photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com