In-cavity self-adaptive optical beam purification system and method

An adaptive optics and purification system technology, applied in optics, optical components, instruments, etc., can solve the problem of shortening the time-consuming of beam purification in the cavity, and achieve strong anti-interference ability, shortening time-consuming, and low computing speed requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

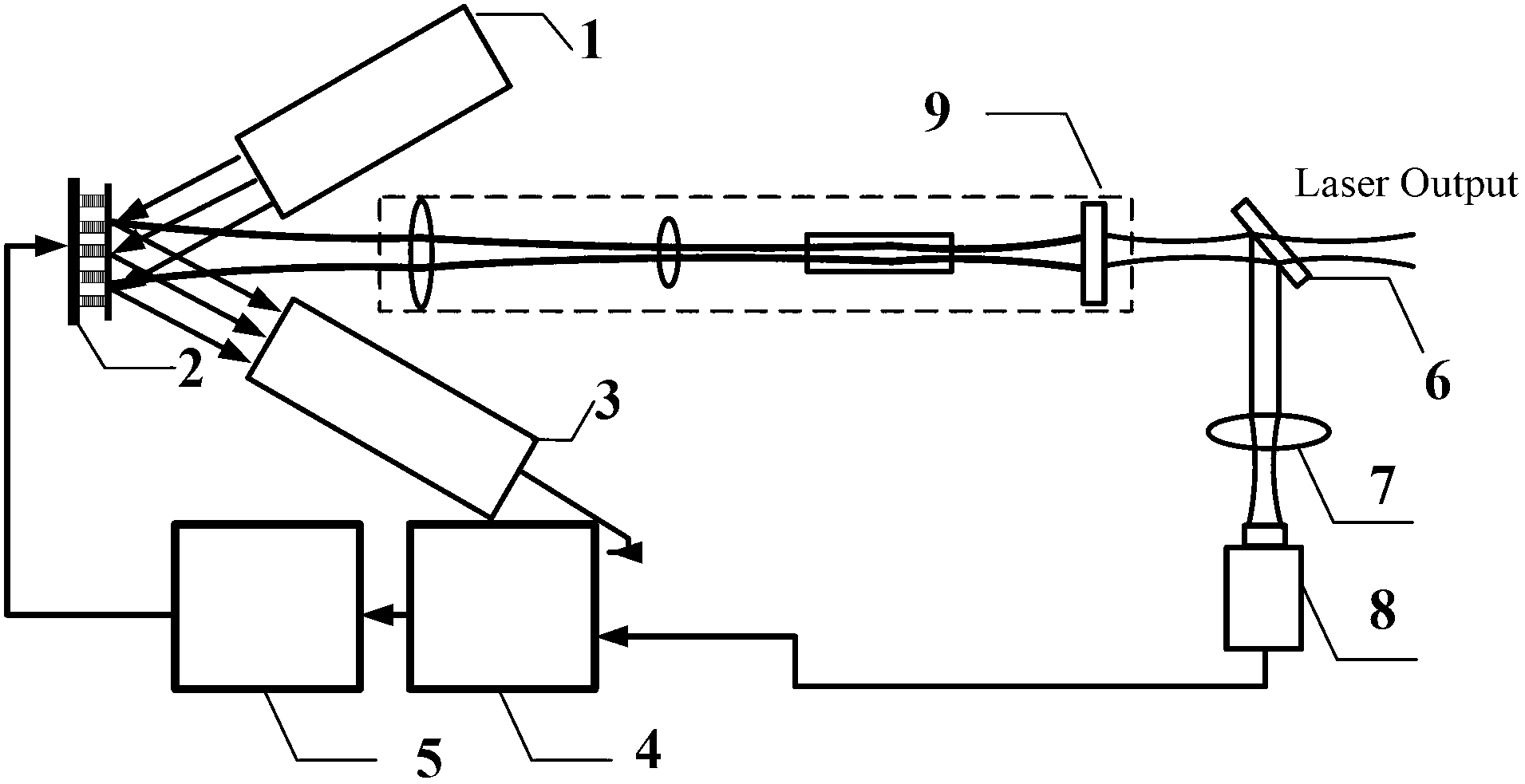

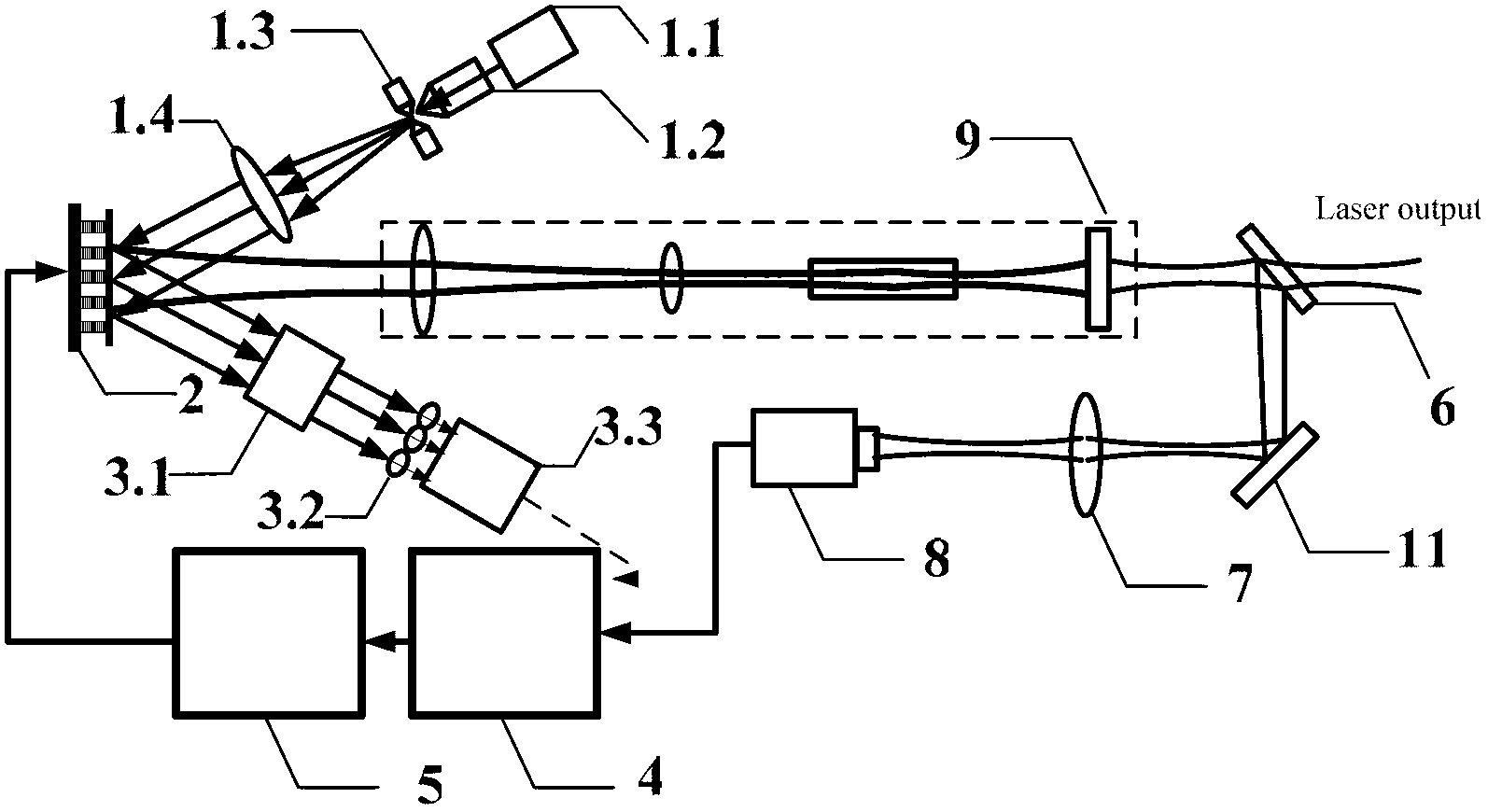

[0025] Such as figure 2 As shown, a schematic diagram of the optical path of an implementation example of the intracavity adaptive optical beam purification system, a parallel light source 1 composed of a 650nm semiconductor laser 1.1, a microscopic objective lens 1.2, a pinhole 1.3, and a collimating lens 1.4, a deformable mirror 2, and a beam shrinker Hartmann sensor 3 composed of device 3.1, microlens array 3.2, camera 3.3, data acquisition and control computer 4, high-voltage amplifier 5, beam splitter 6, focusing lens 7, beam quality diagnostic camera 8, and laser 9.

[0026]A parallel light source composed of a 650nm semiconductor laser 1.1, a microscopic objective lens 1.2, a pinhole 1.3 and a collimating lens 1.4 emits a parallel light beam with uniform light intensity and enters the deformable mirror 2 at 22°. The beam shrinker 3.1 is located about 300 mm behind the deformable mirror, with an aperture of 50 mm, and is coaxial with the 650 nm parallel beam reflected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com