High temperature heat absorber used in solar tower-type thermal power station

A heat absorber and power station technology, applied in solar thermal power generation, solar collectors, solar thermal energy and other directions, can solve problems such as poor thermal response capability and safety, high energy consumption of working fluid circulation power equipment, and complex control system. , to achieve the effect of high working temperature and operational reliability, high working reliability and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

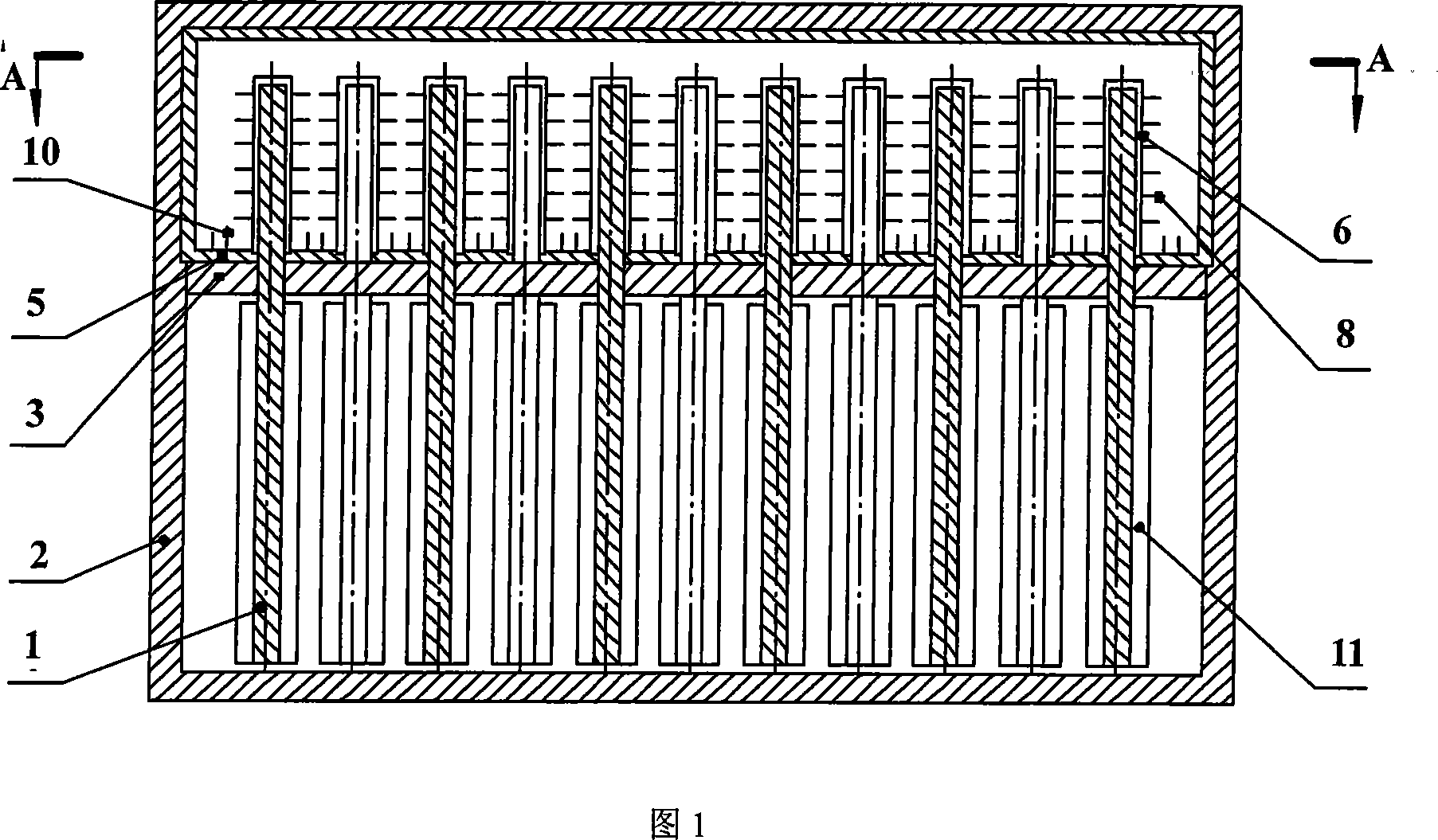

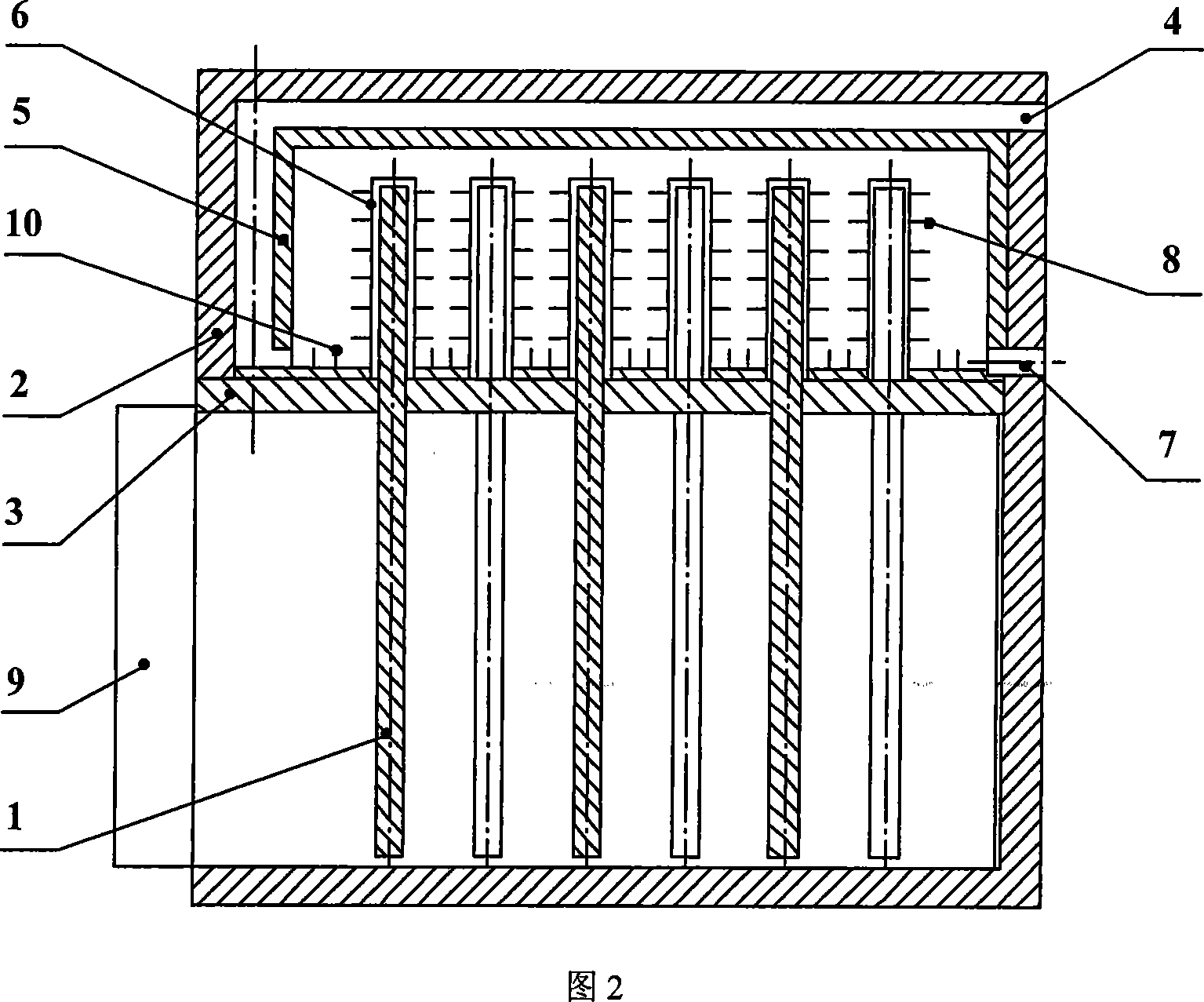

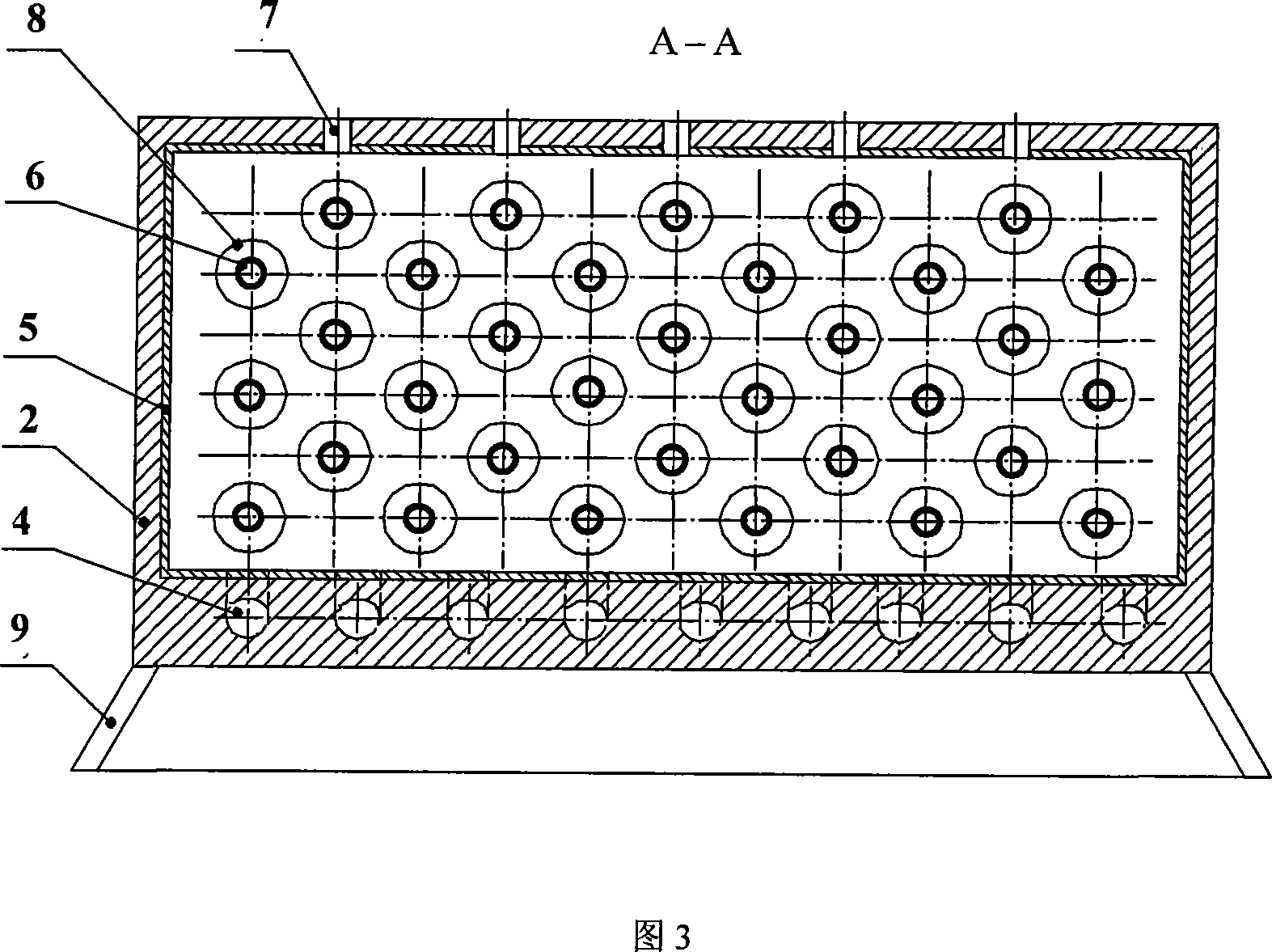

[0015] Fig. 1 is a front view of a solar high temperature heat absorber according to a specific embodiment of the present invention. The overall structure of the heat absorber is cavity type. The heat pipe 1 is installed in the heat-absorbing cavity, and is located at the lower part of the cooling channel 5 . Except for the opening, the heat-absorbing cavity is equipped with a heat-resistant insulation layer on all sides to reduce the heat loss of the heat absorber. The condensing section of the heat pipe 1 is inserted into the liner 6 of the cooling channel 5 . Fins 8 are installed on the outer surface of the liner 6 , that is, on the side facing the inside of the cooling flow channel, to enhance heat exchange with the working fluid in the cooling flow channel 5 . The outer surface of the evaporation section of the heat pipe 1 is equipped with fins 11, and the fins 11 are straight fins facing the incident energy flow. The outer surface of the evaporation section of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com