Method for adjusting heliostat array synchronous traction

A technology for synchronous tracking and heliostats, applied in the field of solar energy applications, can solve the problems of high cost, complex debugging of heliostat arrays, and high power consumption, and achieve the effects of low cost, easy promotion and application, and reduced power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

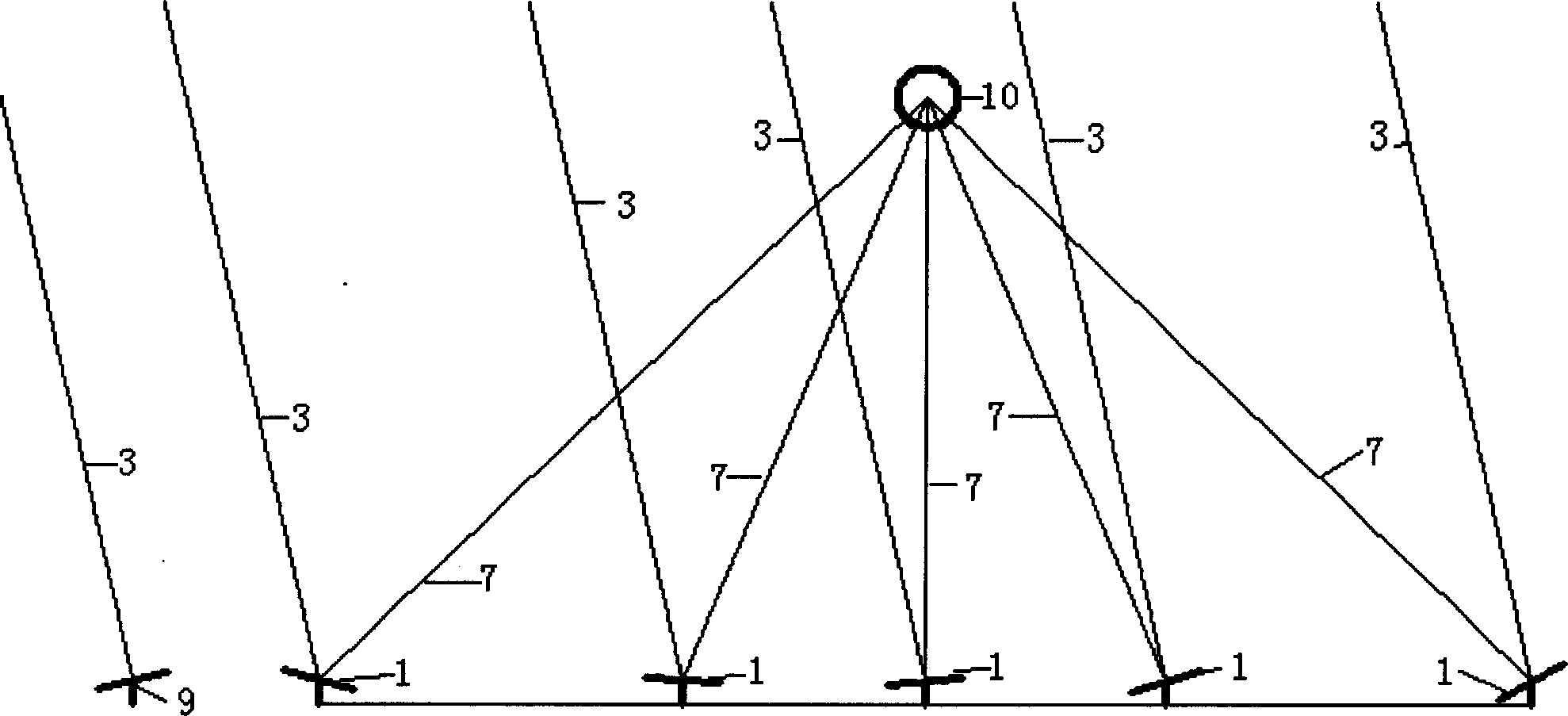

[0036] exist figure 2 In the implementation schematic diagram of controlling the synchronous tracking of the heliostat array, the precision sun tracker 9 works in the state of accurately tracking the sun, and controls the tracking drive motor of each heliostat in the heliostat array. Due to the relative motion of the sun, when the deviation error of the incident light from the sun exceeds the allowable value, the precision sun tracker 9 starts the tracking drive motor of itself and each heliostat in the heliostat matrix to correct the deviation error of the incident light from the sun, When the deviation error of the sun's incident light is eliminated, the precision sun tracker closes itself and the tracking drive motor of each heliostat in the heliostat array stops rotating, and completes a control cycle. When the sun's incident light deviation error occurs next time, the above control process is repeated to realize the synchronous tracking of the controlled heliostat array....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com