Heliostat grouping control device in heliostat field of solar tower power plant

A technology of control device and heliostat, which is applied in the field of solar energy utilization, can solve the problems such as the unreported control method of mirror field grouping, and achieve the effects of reducing the cost of mirror field control, improving photoelectric conversion efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

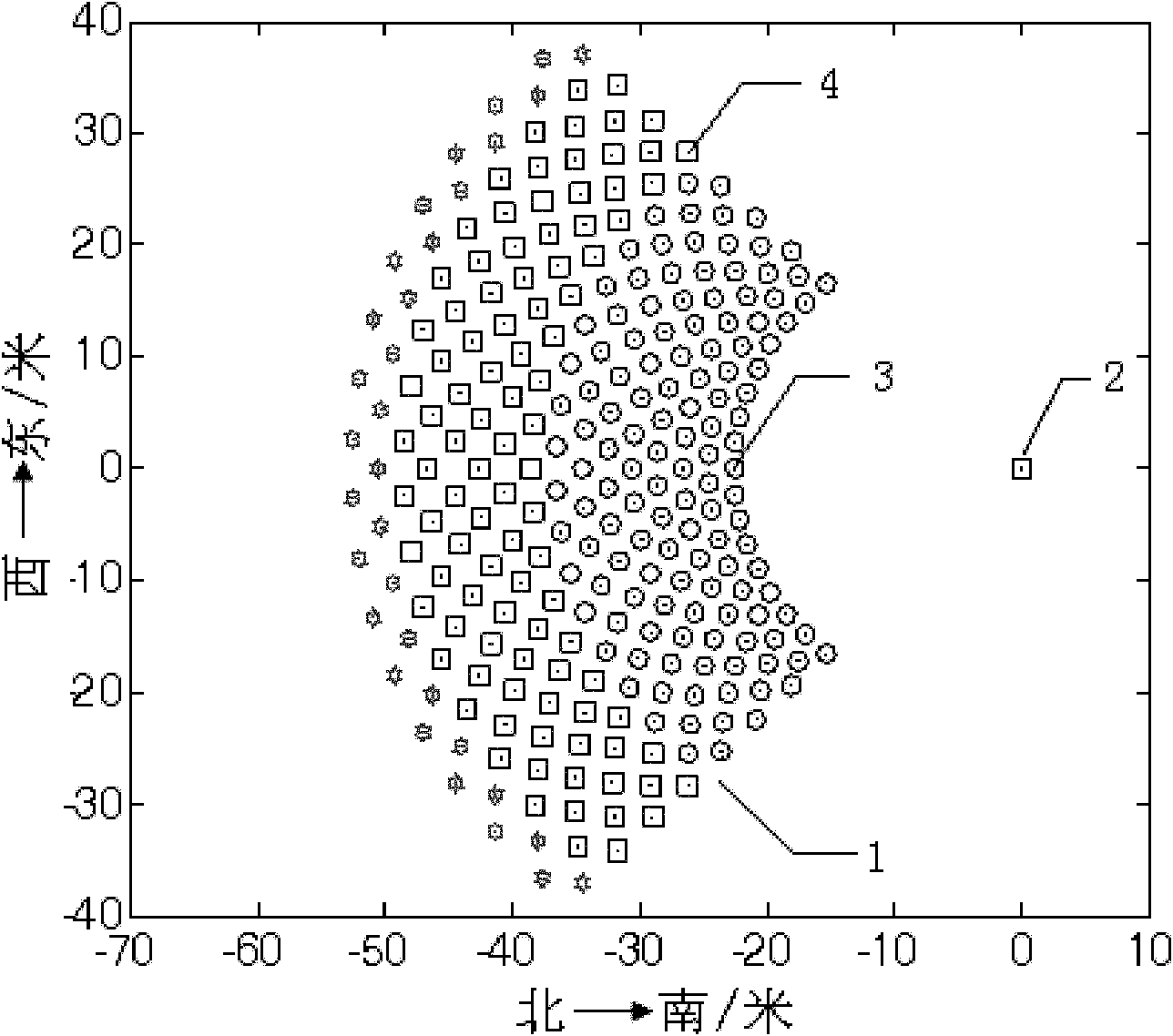

[0022] The solar tower power generation mirror field heliostat group control device of the present invention includes each heliostat azimuth control drive mechanism, each heliostat pitch transmission mechanism, and pitch control drive mechanism.

[0023] Such as Figure 4 As shown, the azimuth control drive mechanism can adopt a motor (not shown) fixed on the upper end of the support 13, which is movably connected with the apex of the heliostat through the pitch axis 12; the support 13 is vertically fixed on the ground . The motor rotates to drive the heliostat 11 to rotate around the axis of the bracket 13 through the pitch shaft 12 .

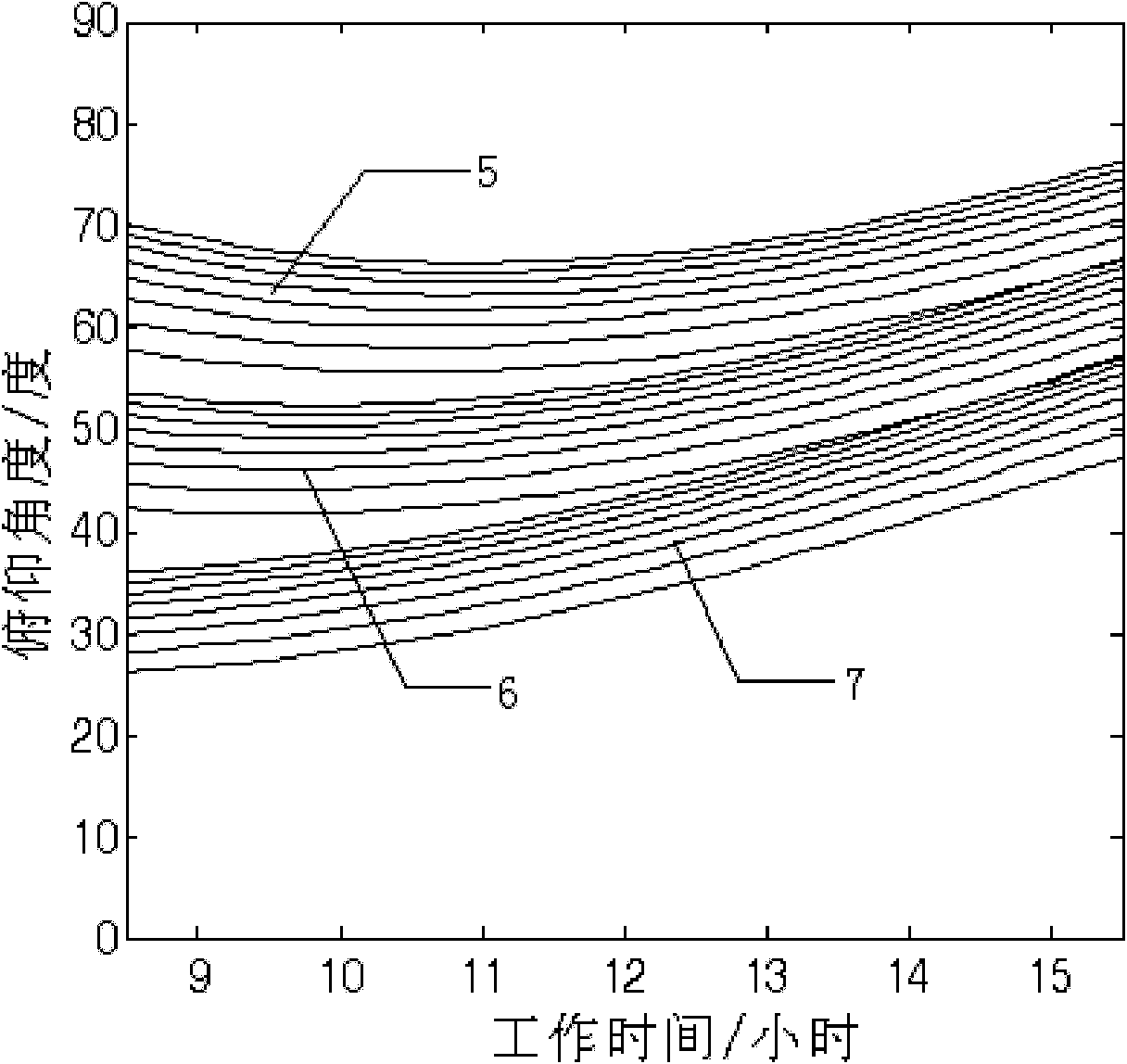

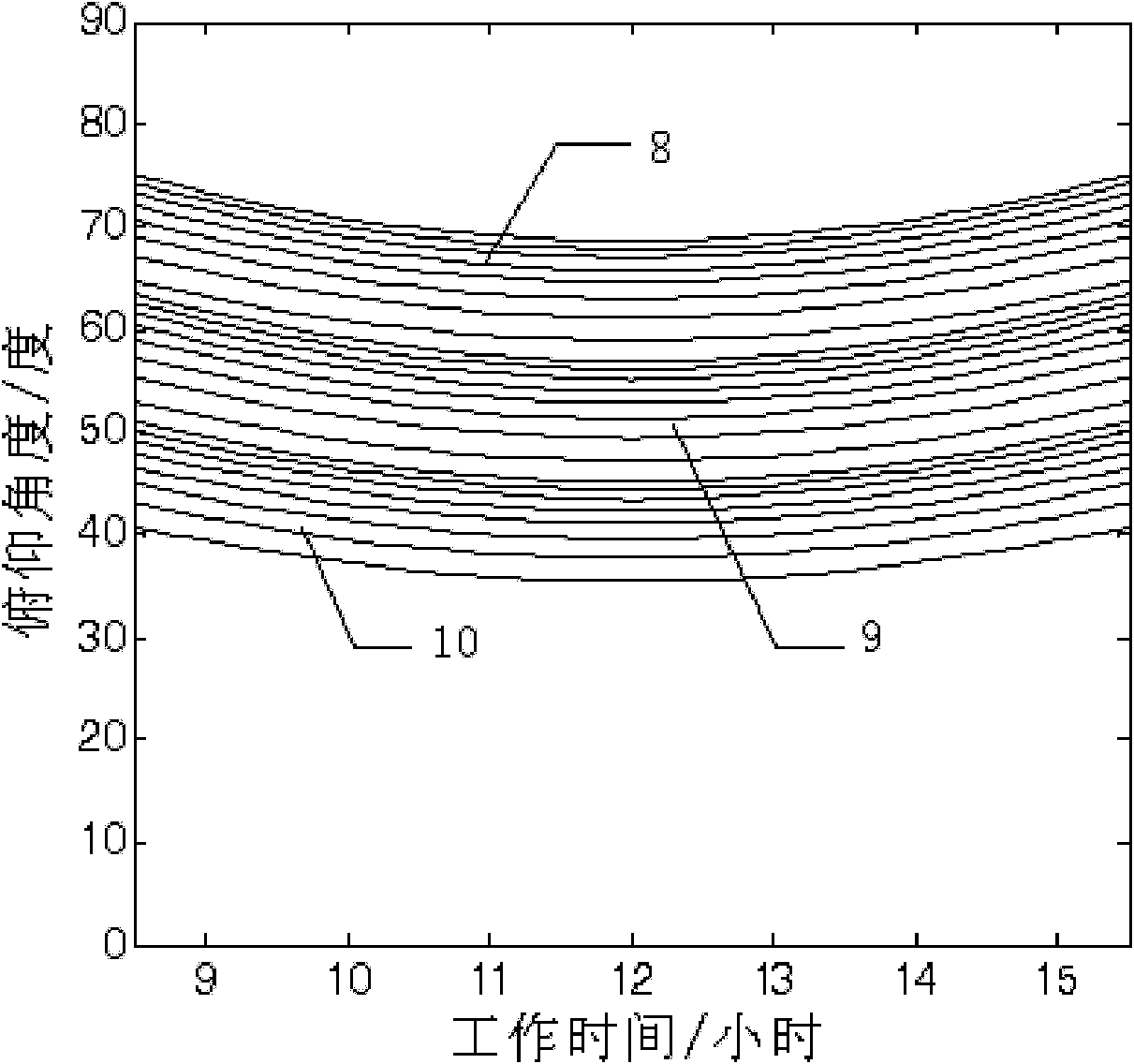

[0024] Such as Figure 4 , Figure 5a As shown, the pitch transmission mechanism of the heliostat includes a mirror body connecting rod 14, an arc-shaped slider 16, an arc-shaped guide rail 17, a vertically moving slider 21, a vertical guide rail 20, a slider connecting rod 18, and a rocker 19; One end of the connecting rod 14 is movably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com