Solid particle block tower-type solar pulse driven heat-exchange and heat-transmission system

A tower-type solar energy and solid block technology, which is applied in the field of solar thermal energy utilization, can solve the problems of limited use of molten salt heat storage, inability to realize heat transfer, and difficulty in transferring heat energy, and achieve high-efficiency collection and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

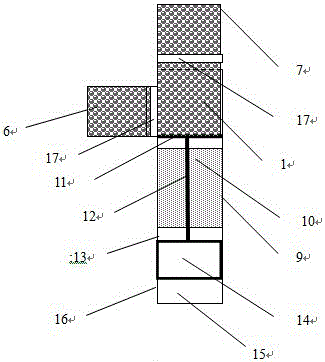

[0043] Embodiment 1, solid block pulsation drive pump

[0044] figure 1 It consists of a power device 13, a pulsation chamber 5, a push plate 11, a solid particle inlet 6, a solid particle outlet 7, an electronic control device, and a housing 16. The push plate is connected with the power device 13 through a connecting rod 12, and can be formed by The power device is driven to realize reciprocating motion in the pulsation chamber. The power device 13 is composed of a hydraulic cylinder 14 and a motor 15. The motor drives the hydraulic cylinder. The hydraulic cylinder pushes the connecting rod 12, drives the push plate 11, and the push plate pushes the solid particles to move. Granules 1 enter the pulsation chamber 5 from the inlet 6, and the power device 13 provides power to drive the push plate 11, and the push plate 11 pushes the solid particles 1, drives the solid granules 1 in the pulsation chamber 5, and flows out from the outlet 7 Outside the pulsation chamber 5, after th...

Embodiment 2

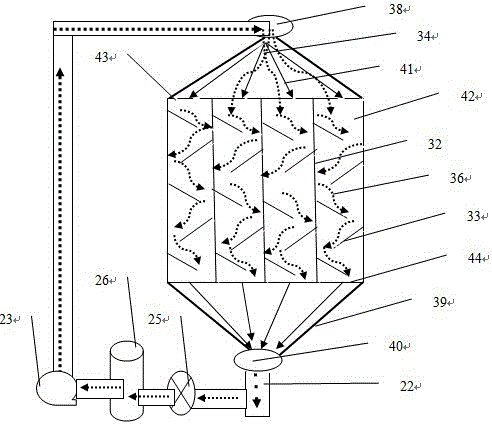

[0045] Embodiment 2. Solid block tower type solar heating transmission system

[0046] figure 2 The shown solid block tower solar heating and heat transfer system consists of a tower type solid block light-to-heat converter 22, a loading box 26, a pulsation pump 23, a solid block 1, a heat storage heat exchanger 5, and a valve or switch 17 , Uplink pipeline 19, downlink pipeline 20, heat storage heat exchanger 25, loading box 26, connecting pipeline 27 and other components. The light-to-heat converter 22 is at the focal point of the solar energy irradiation of the tower solar mirror, the upstream pipe 19 is connected to the inlet of the light-to-heat converter 22, and the down-going pipe 20 is connected to the outlet of the light-to-heat converter 22, and is arranged on the outside of the pipe. There is an insulation pipe 24, and the pulsation-driven pump is connected to the uplink pipeline 19 and then connected to the loading box 26 arranged on the ground. The solid particl...

Embodiment 3

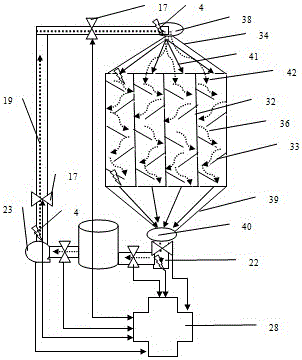

[0051] Embodiment 3. Solid block tower type solar heating heat transfer system

[0052] image 3 As shown, a switch 17 is provided at the inlet and outlet of the tower-type solar photothermal converter, a temperature sensor 4 is provided on the inner cavity of the photothermal converter, and a sensor 4 of solar light intensity and angle is provided on the housing; The electronic control device is arranged outside the thermal insulation layer of the light-to-heat converter, and the electronic control device collects the data of the temperature sensor 4, the solar light intensity and the angle sensor, and the sensor transmits the different data collected to the temperature control device 28, and realizes the process by using software. After the calculation, the temperature control device 28 sends the execution to the solid particle block pulsation drive pump 23, and the motor controls the quantity and speed of the solid particles 1 entering the cavity of the pulsation pump and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com