Solar tower type heat absorber with double-tube structure and design method for solar tower type heat absorber

A design method and heat sink technology, which are applied in the directions of solar thermal collectors, solar thermal collectors using working fluid, solar thermal energy, etc. cracking and other problems, to reduce stress, reduce wall temperature difference, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

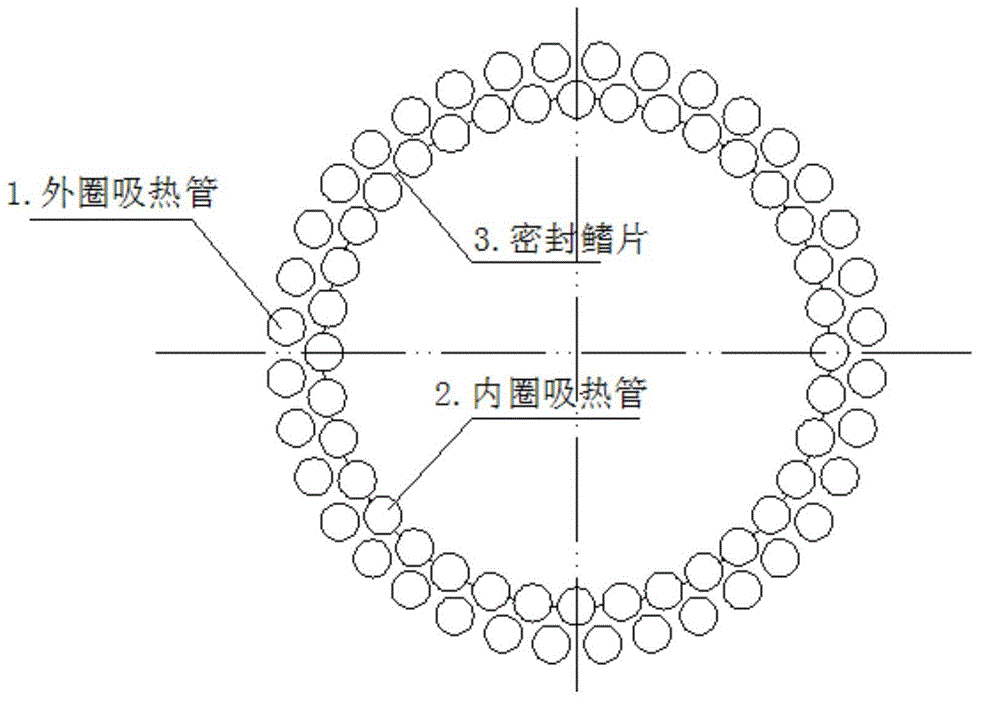

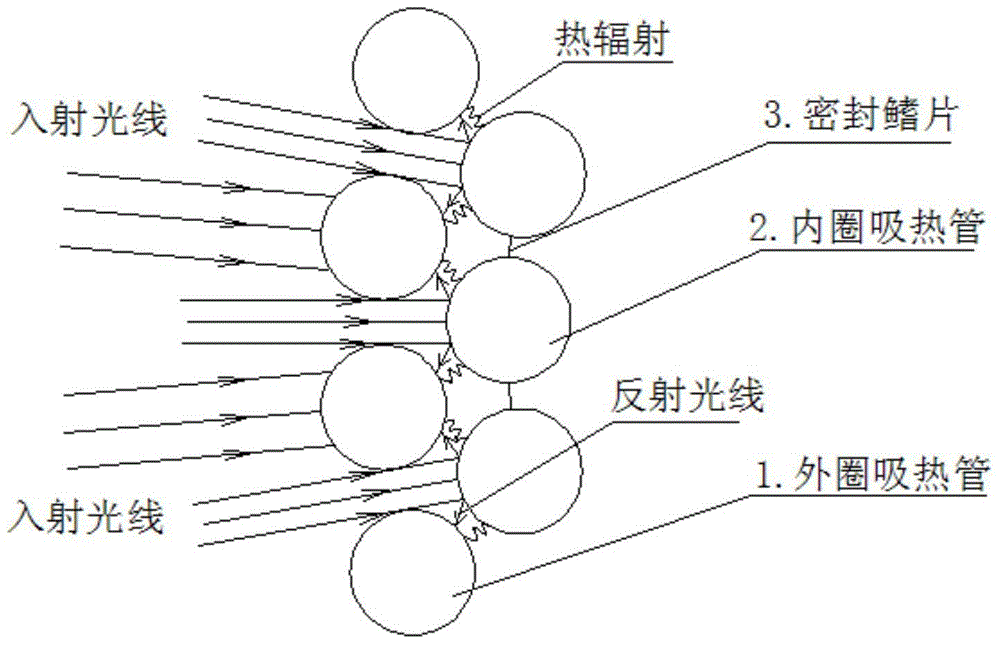

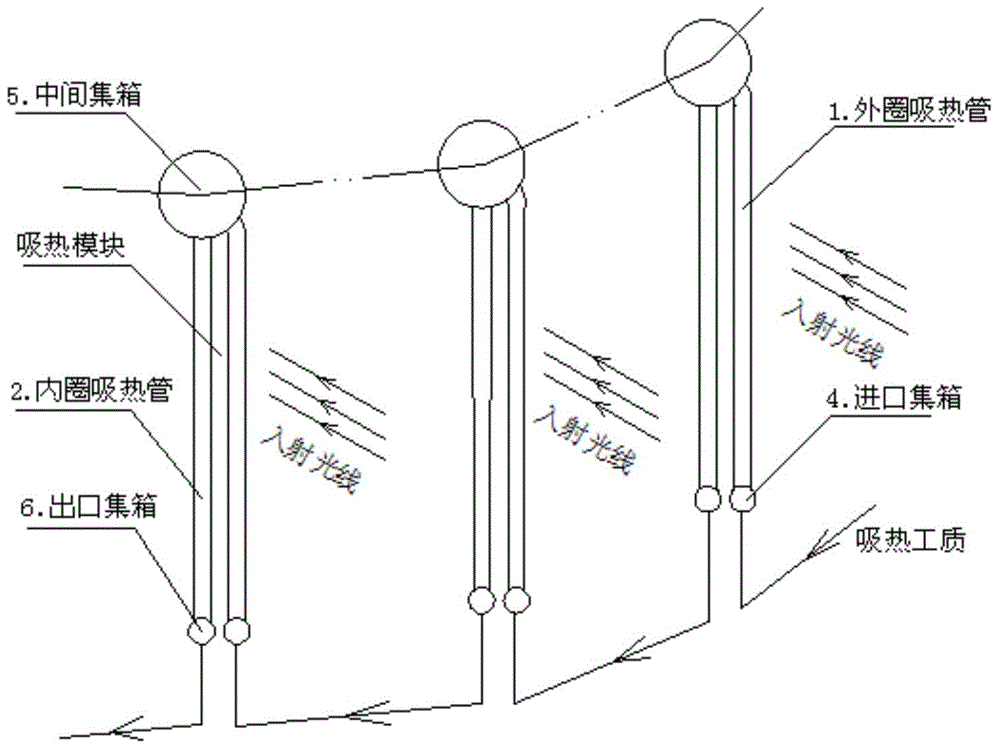

[0024] like image 3 As shown, the present invention includes an outer ring heat absorbing pipe 1, an inner ring heat absorbing pipe 2, a sealing fin 3 ( image 3 (not shown), inlet header 4, intermediate header 5, outlet header 6, etc. Due to the small size of the sealing fins 3 relative to the entire heat sink, the image 3 It is not drawn in the example of , the specific structure of the sealing fin 3 can refer to the figure 1 and figure 2 . In this example, in addition to the absorption and reflection of the incident light from the sun outside the heat sink, the working fluid flow is also briefly described.

[0025] In this example, the solar heat absorber of the double row tube structure is a multi-faceted prism and an external light receiving type structure. Each heat absorber includes a plurality of heat absorption modules, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com