Energy-saving air space capable of exhausting and foaming

A technology of air interlayer and exhaust hole, which is applied in energy-saving heating/cooling, shielding with air flow, space heating and ventilation, etc. It is difficult to recover a large proportion of exhaust air heat from fresh air heat recovery units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention is described in detail below in conjunction with the specific implementations of the embodiments in the accompanying drawings. Although the specific implementations of the embodiments of the present invention are shown in the drawings, the present invention should not be understood as limited by the specific implementations of the illustrated embodiments. Limitations, specific embodiments not shown or described in the figures are of the form well known to those skilled in the art.

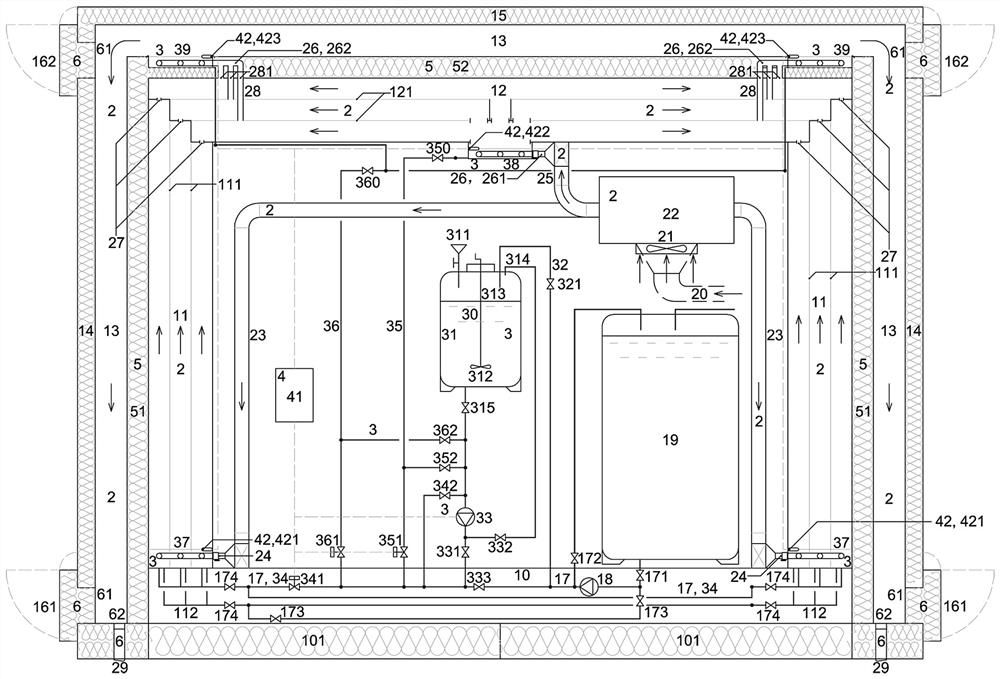

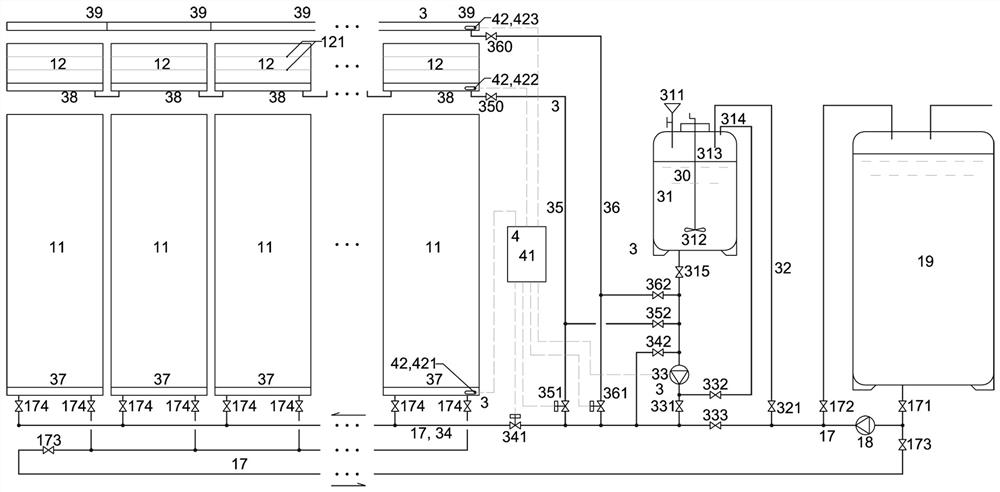

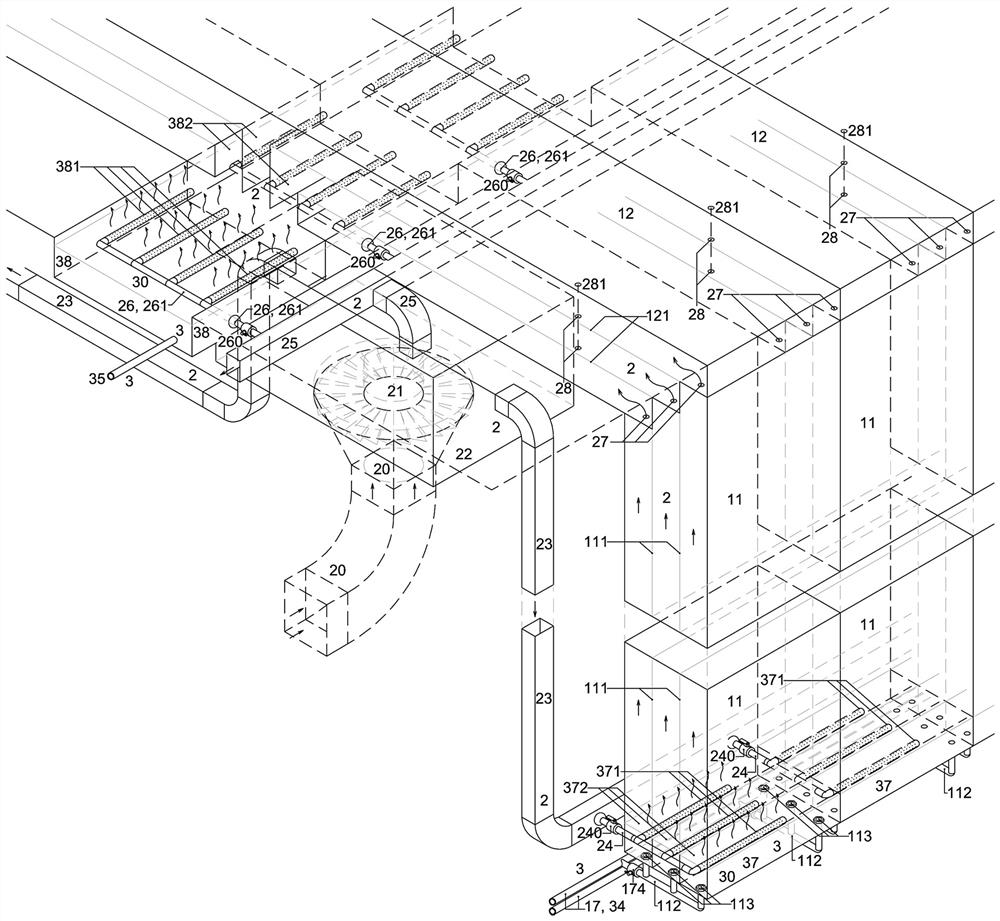

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the present invention proposes an energy-saving air space for venting and foaming, including: a wall module 11 and a top module 12 that can serve as an enclosure structure, can store water, and can form an air space inside after water release; The wall module 11 and the top module 12 also have a plurality of structural thin layers parallel to the indoor side surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com