Patents

Literature

247results about How to "Unnecessary to provide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

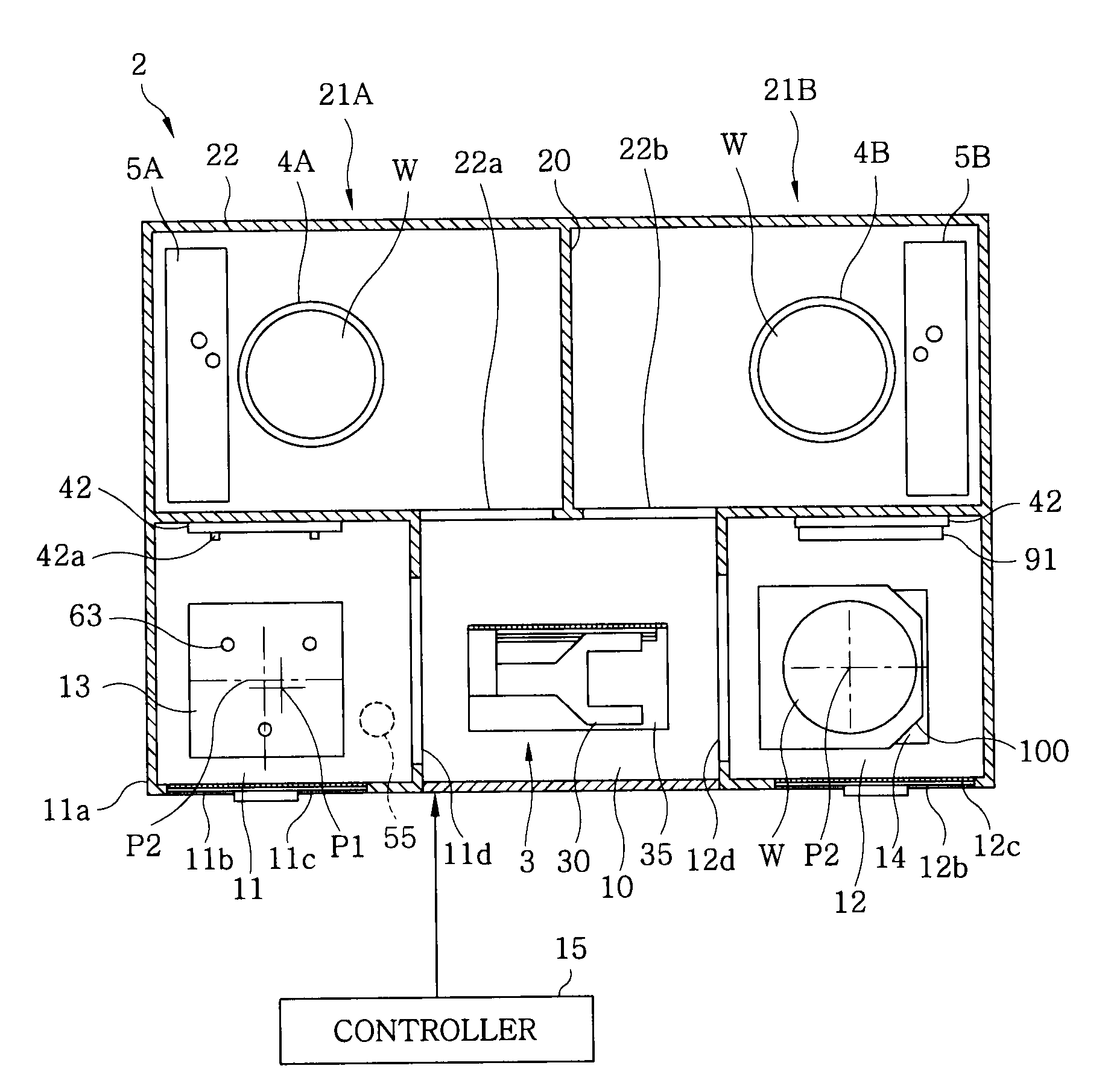

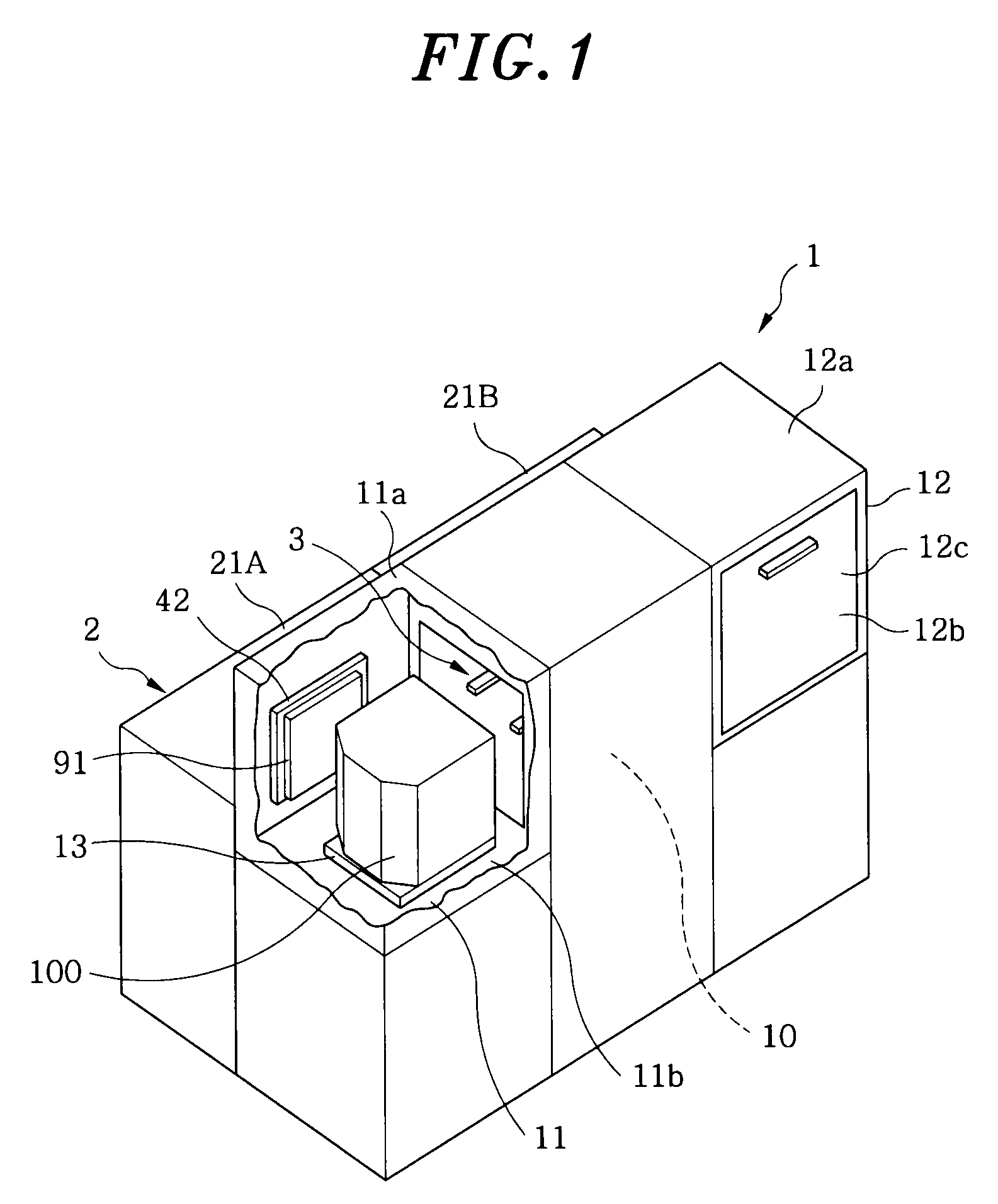

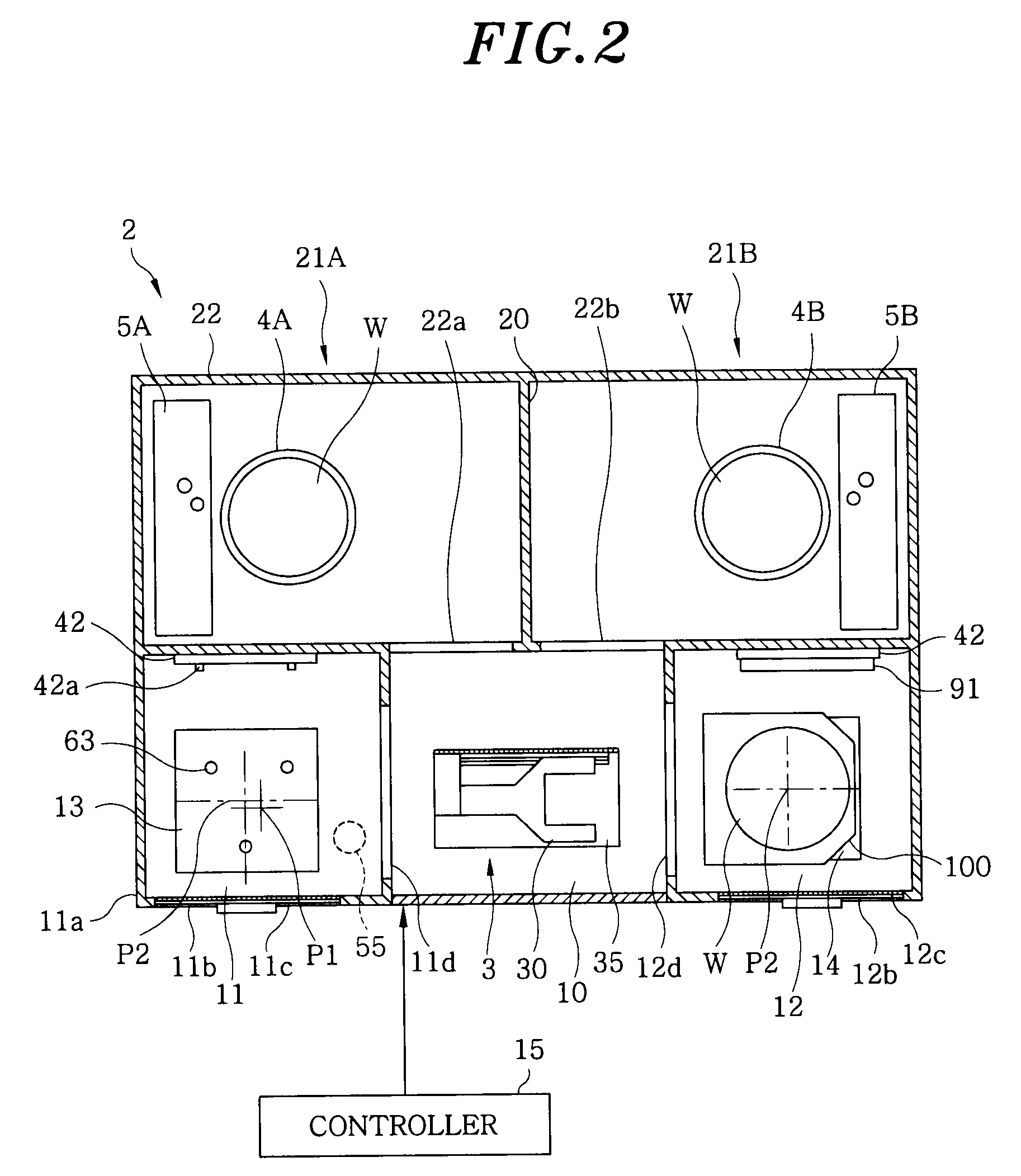

FOUP opening/closing device and probe apparatus

ActiveUS8267633B2Assure great degree of freedomEfficient comprehensive utilizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalFOUP

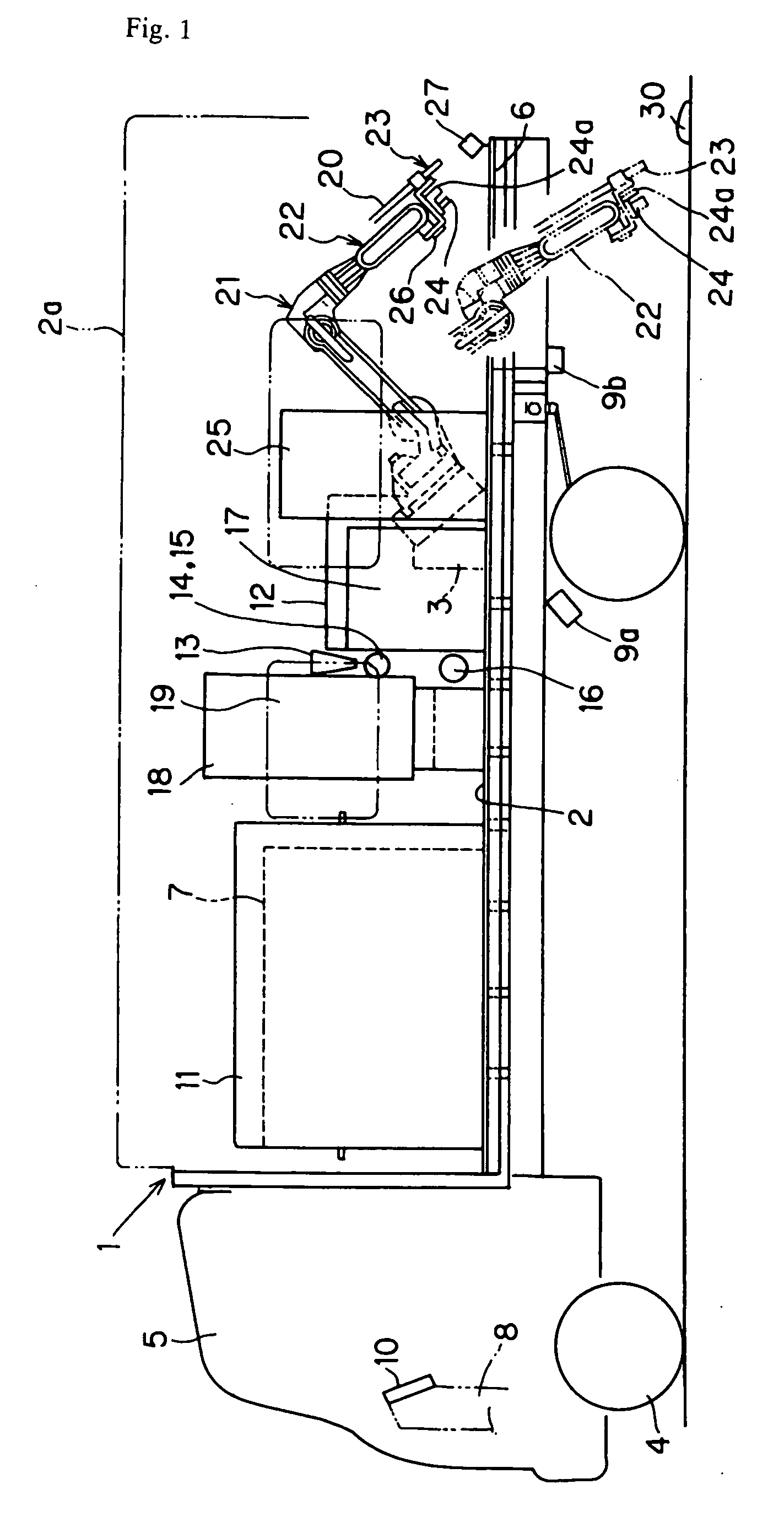

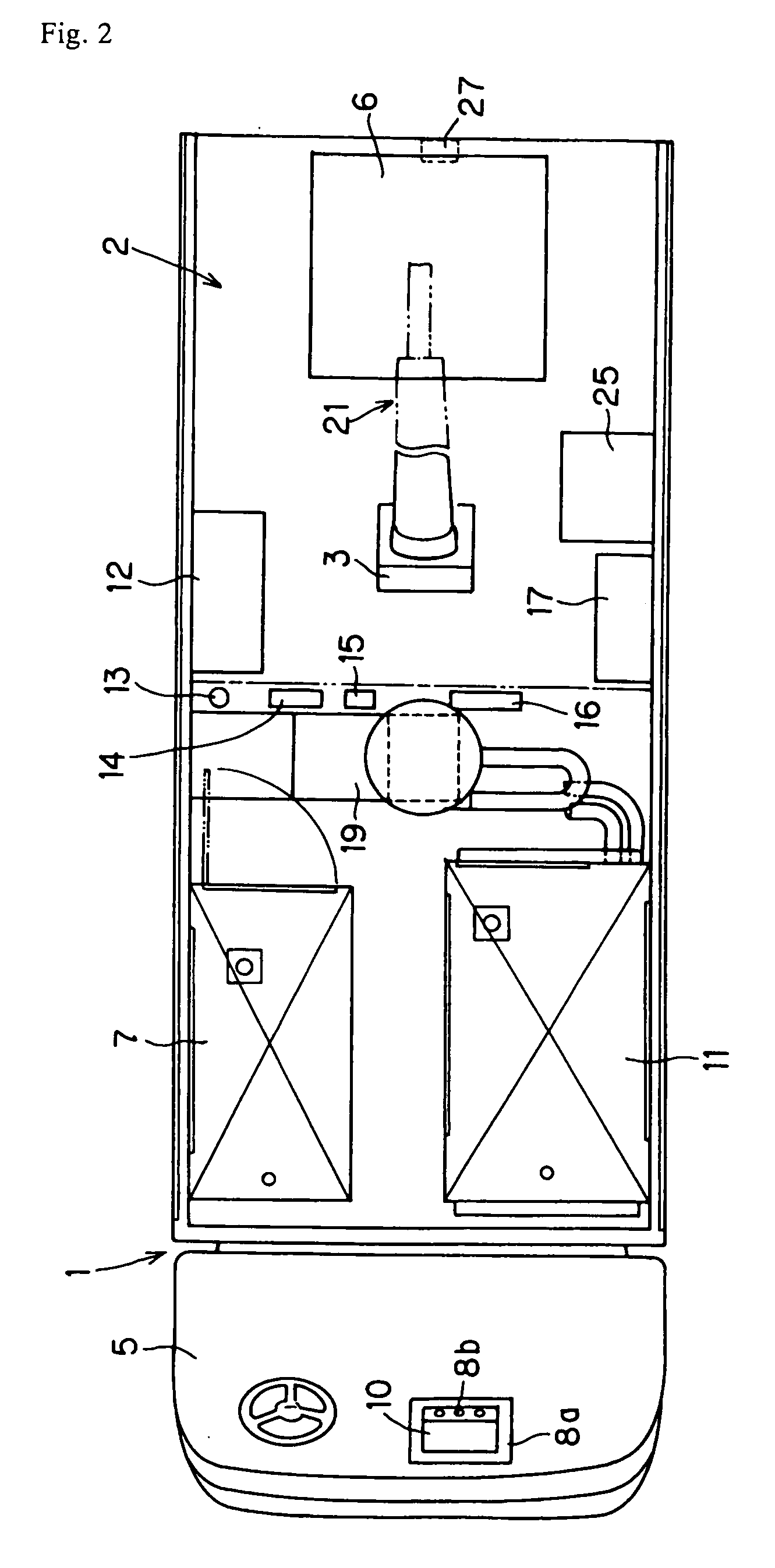

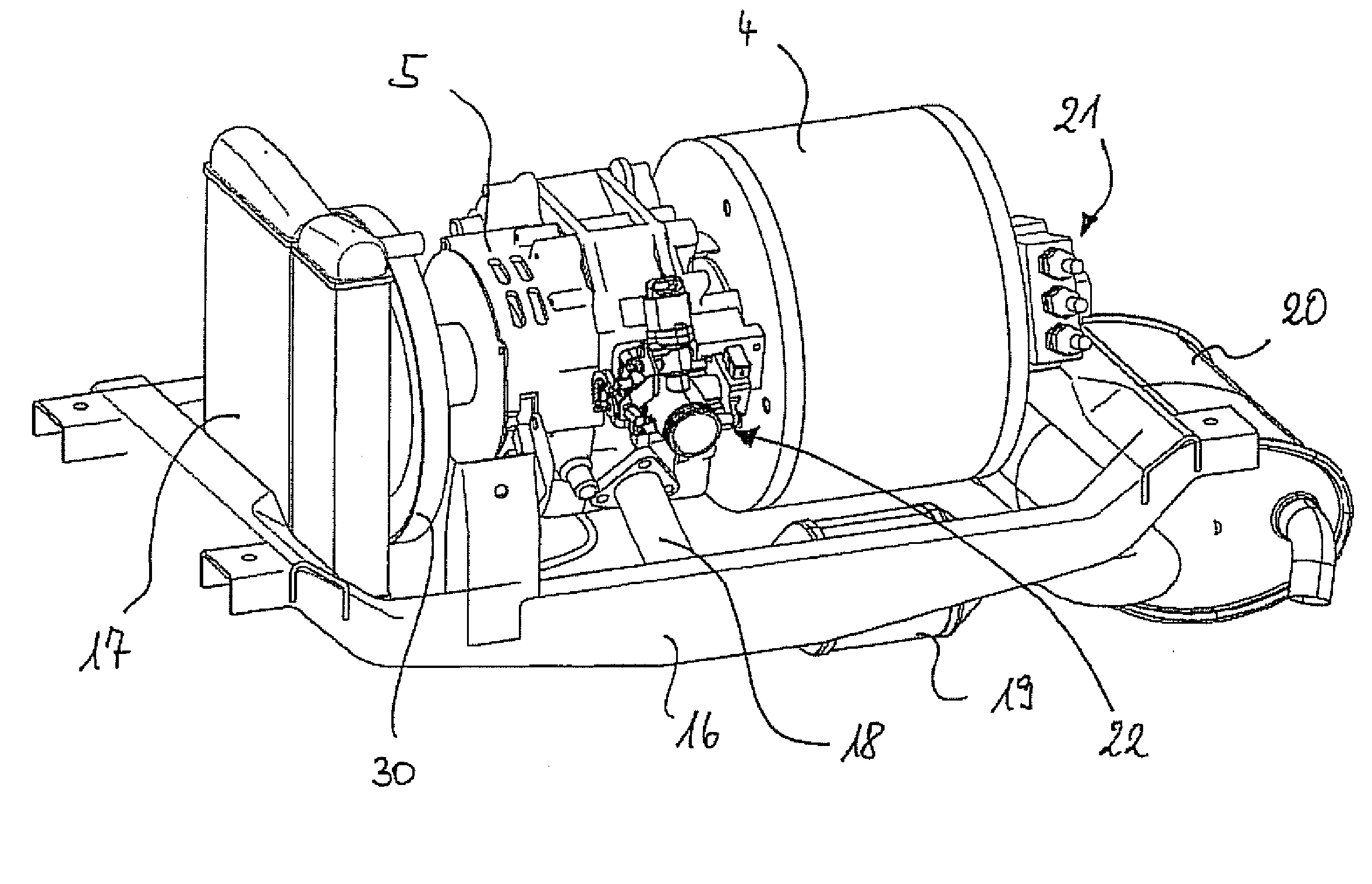

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

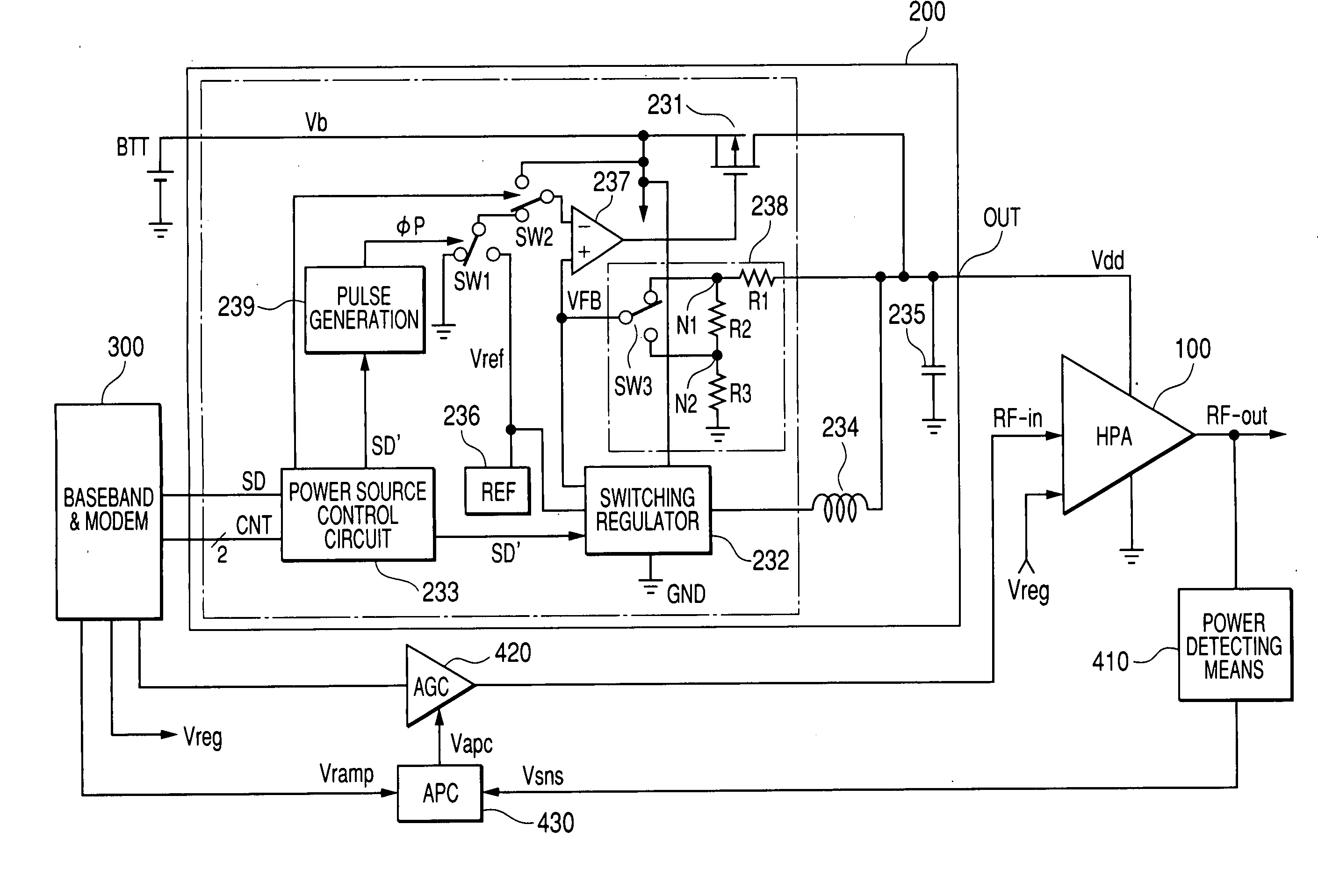

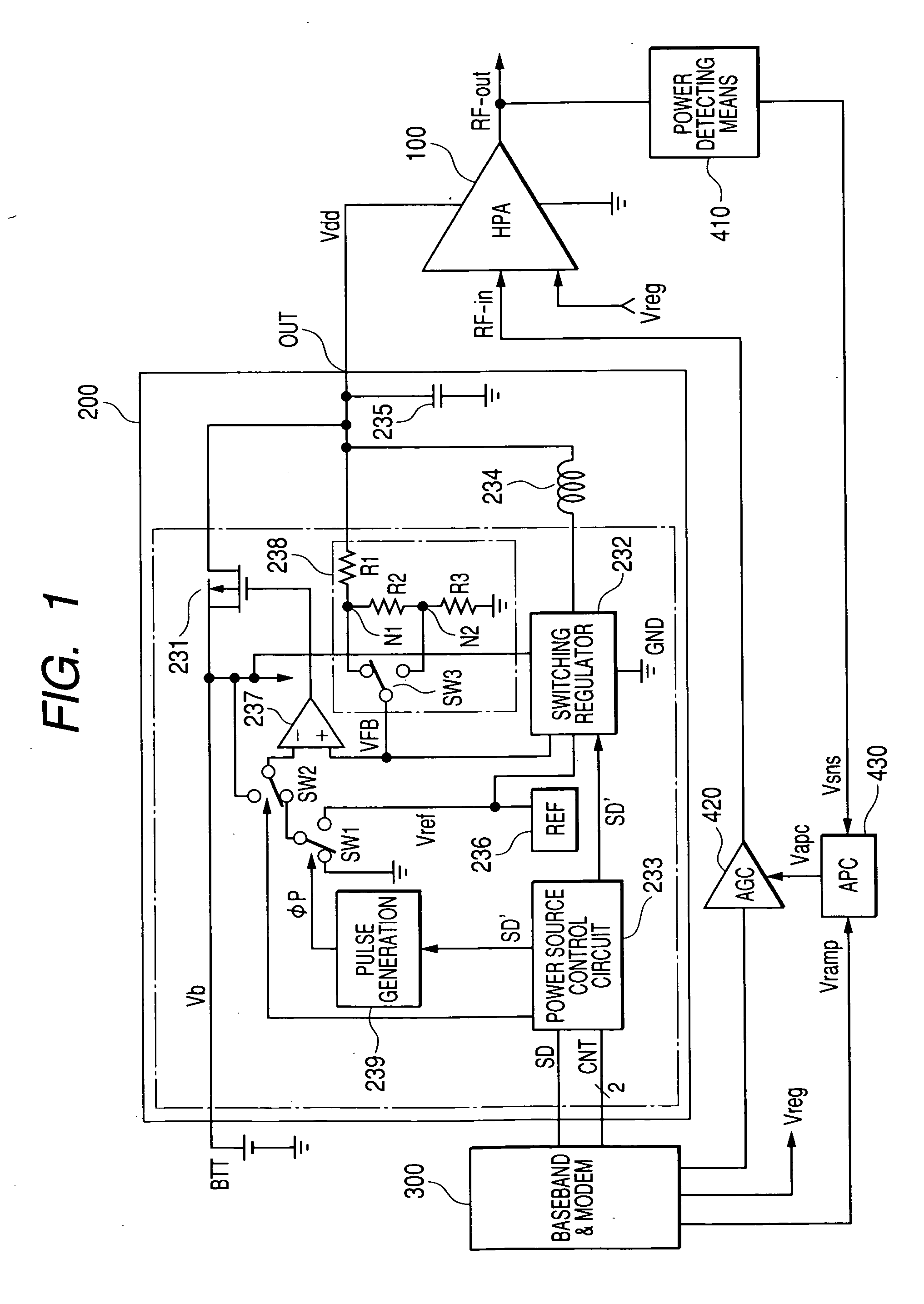

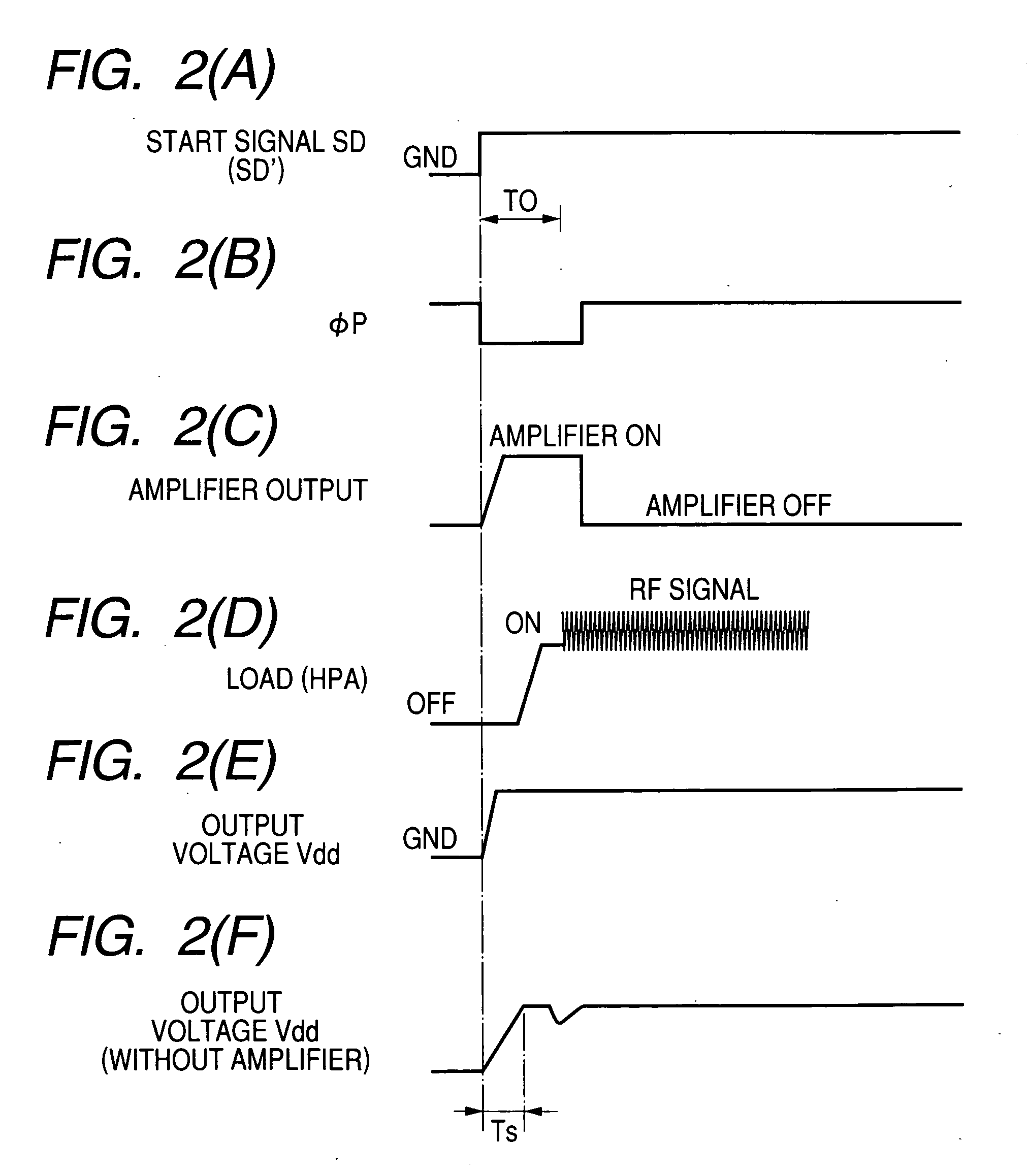

Power source circuit for high frequency power amplifying circuit and semiconductor integrated circuit for power source and electronics component for power source

InactiveUS20050122171A1Function increaseSmall sizeAmplifier modifications to raise efficiencySupply voltage varying controlHigh frequency powerGSM

The invention realizes a power source circuit for a high frequency power amplifying circuit, which achieves excellent responsiveness of output voltage, can be used for a portable telephone of the GSM or WCDMA and a portable telephone capable of performing communications in two or more communication systems such as the GSM and CDMA and, moreover, has high power efficiency. A power source circuit for a high frequency power amplifying circuit is constructed by using both a first direct current power source circuit such as a series regulator whose power efficiency is not high but which becomes the high level quickly, and a second direct current power source circuit such as a switching regulator, which does not become the high level quickly but whose power efficiency is high. When the power source voltage has to become the high level at high speed, both of the series regulator and the switching regulator are simultaneously operated. When the output power source voltage reaches a predetermined level, the operation of the series regulator is stopped.

Owner:RENESAS TECH CORP

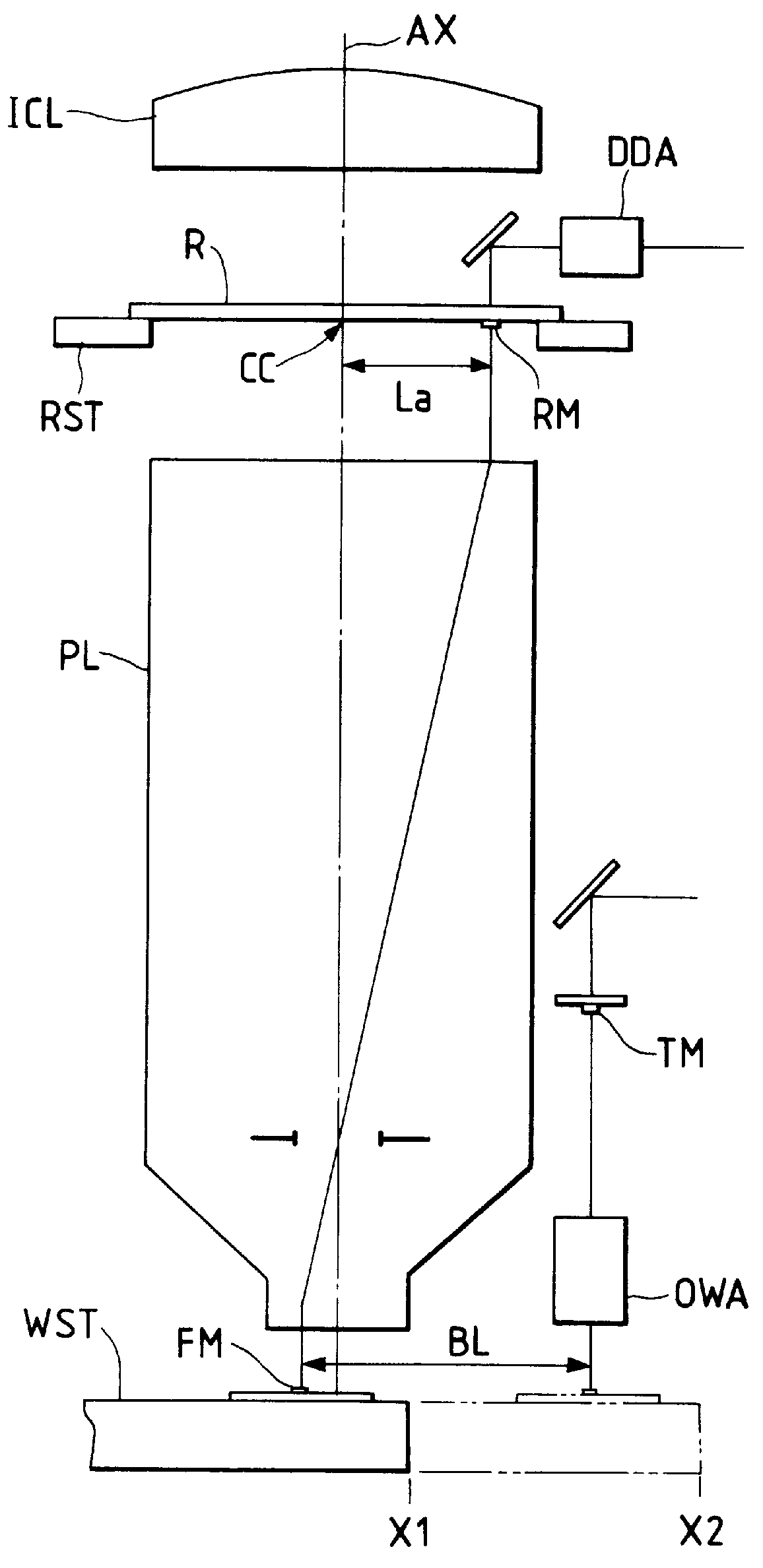

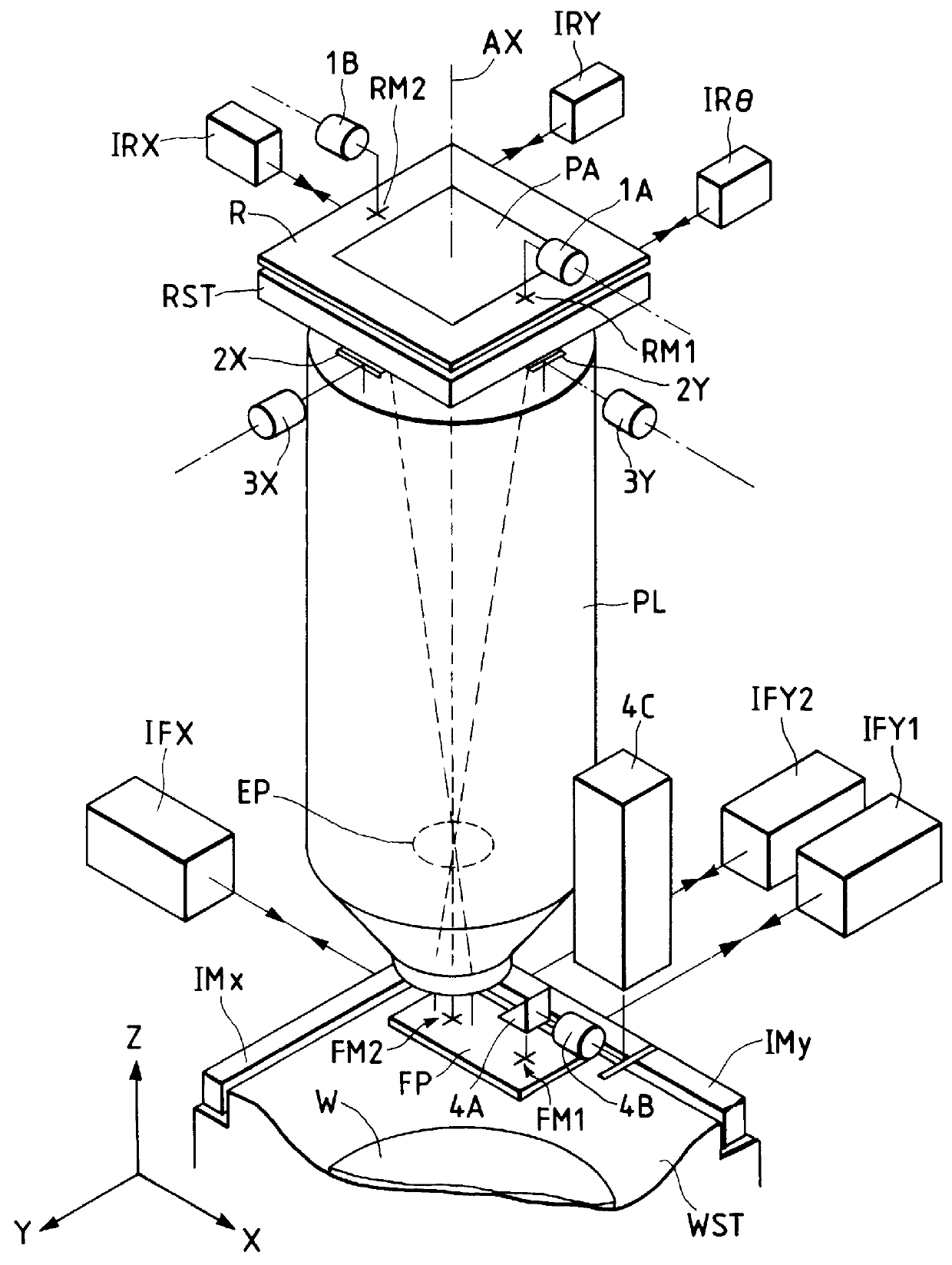

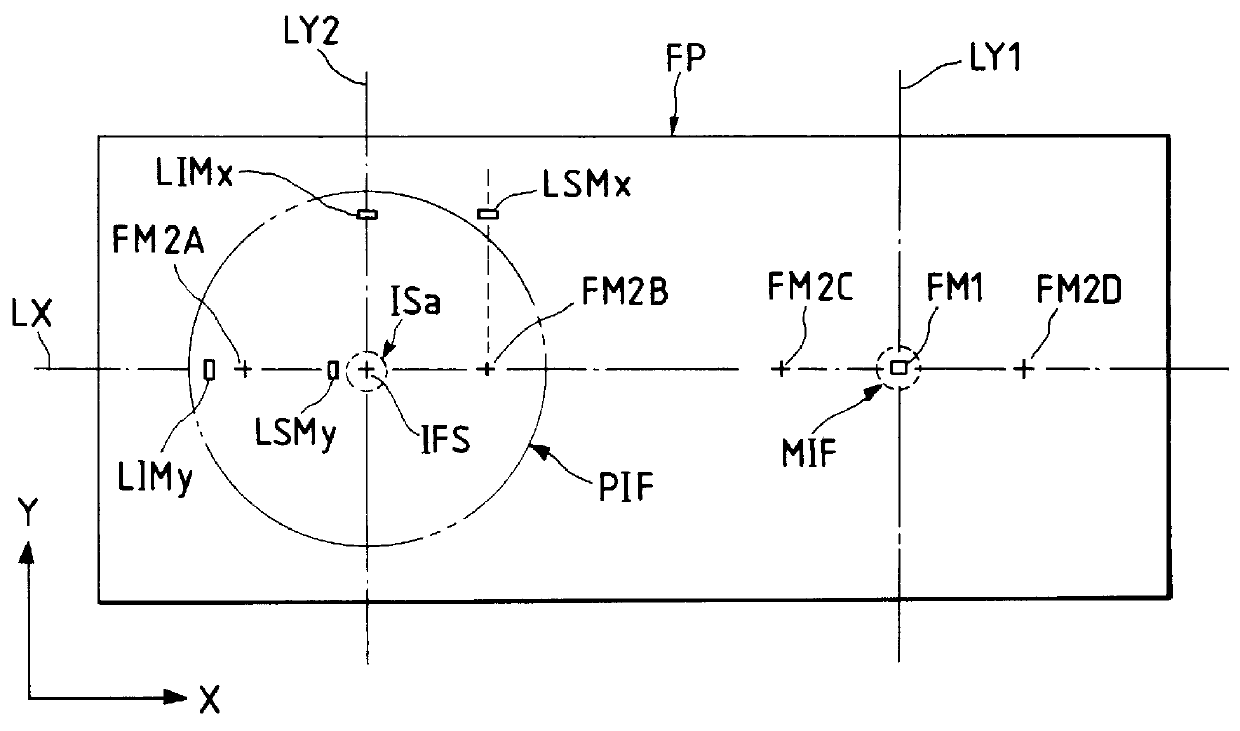

Projection exposure apparatus having an off-axis alignment system and method of alignment therefor

InactiveUSRE36730E1Unnecessary to provideIncrease speedInvestigating moving sheetsUsing optical meansOptoelectronicsProjection lens

An exposure apparatus for exposing mask patterns on a sensitive plate comprises a set (for X and Y direction) of a laser interferometer for measuring a position of a wafer stage and satisfying Abbe's condition with respect to a projection lens and a set (for X and Y direction) of the laser interferometer and satisfying Abbe's condition with respect to off-axis alignment system. When a fiducial mark on the wafer stage is positioned directly under the projection lens, a presetting is performed so that measuring values by the two sets of laser interferometers are equal to each other.

Owner:NIKON CORP

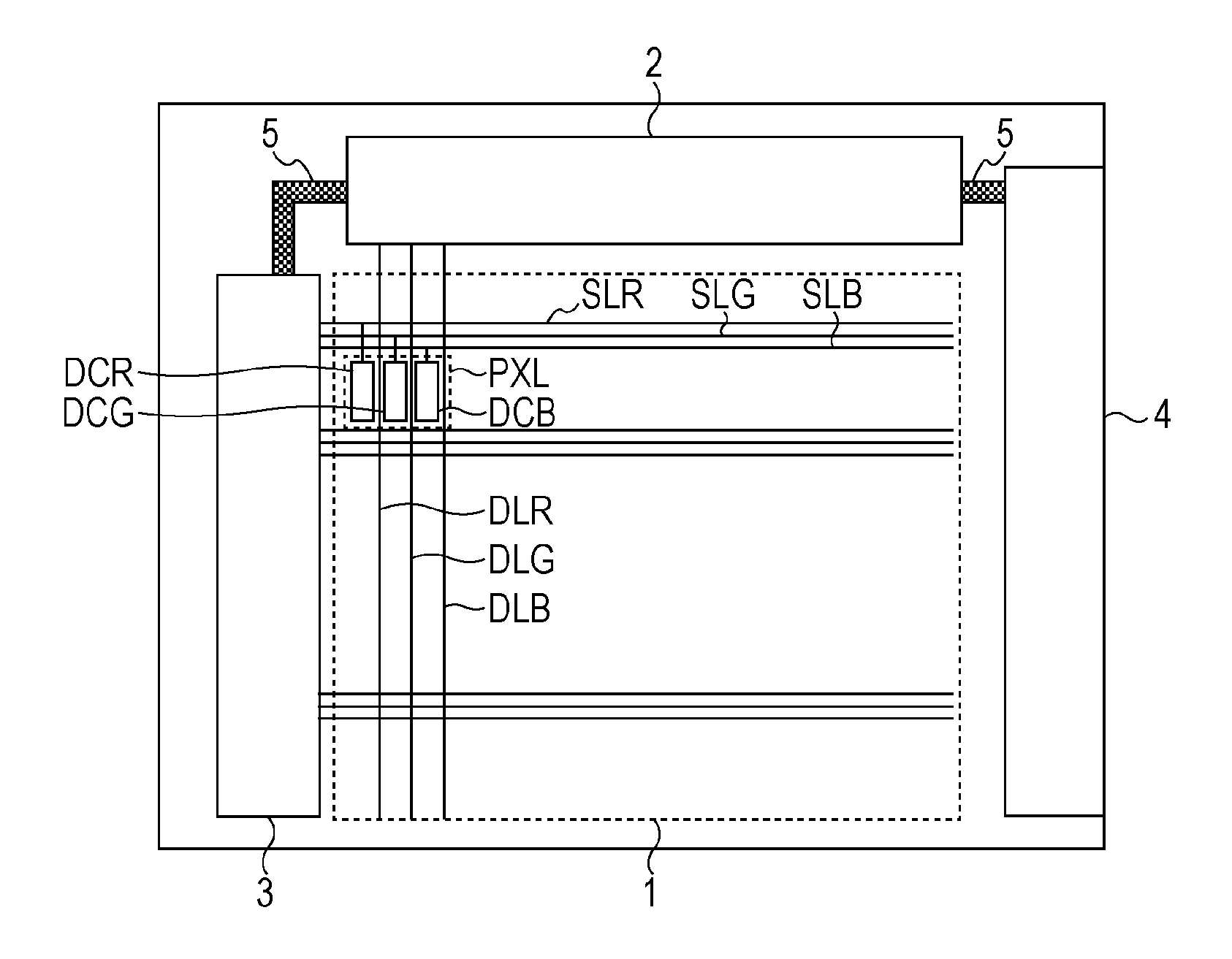

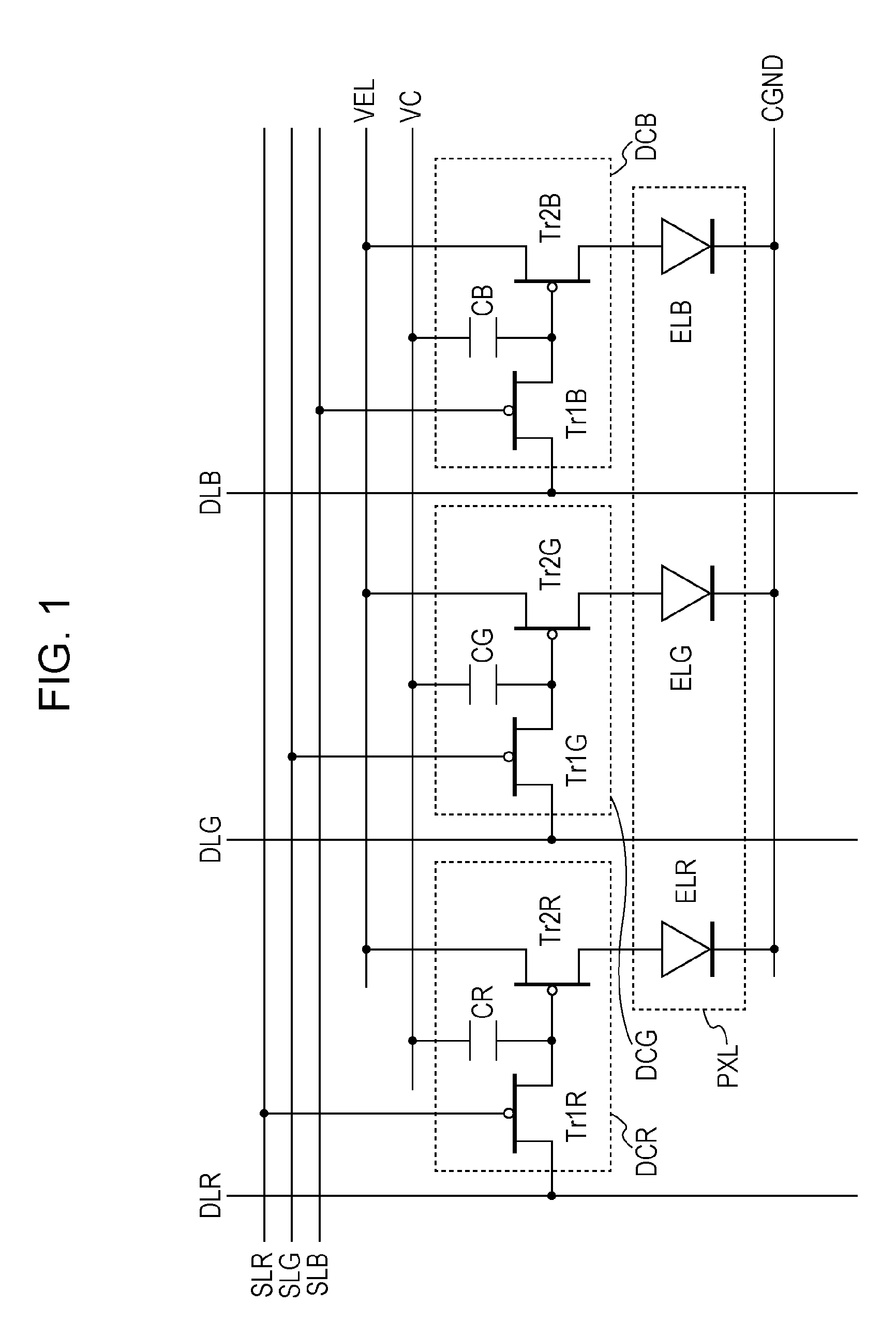

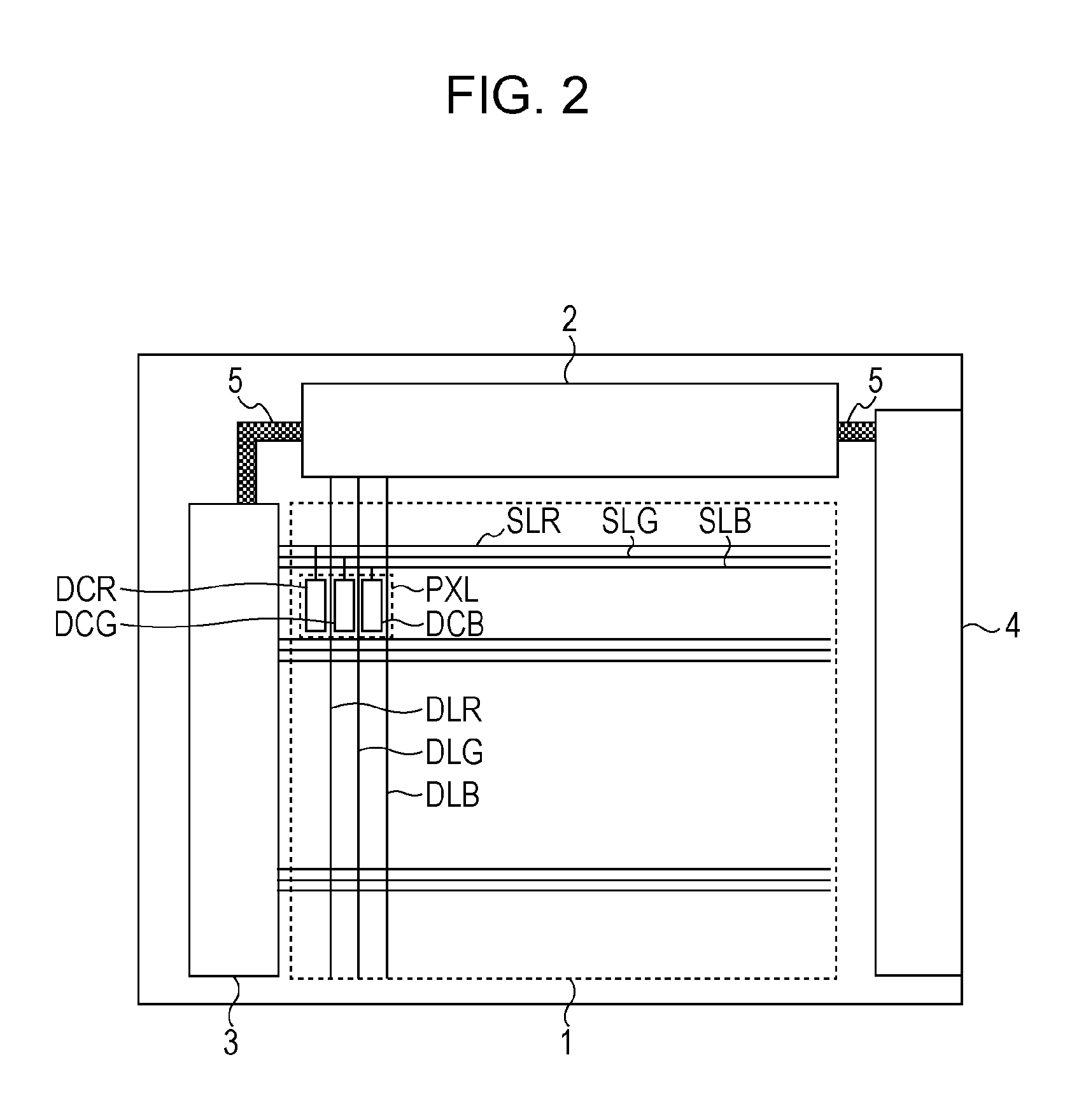

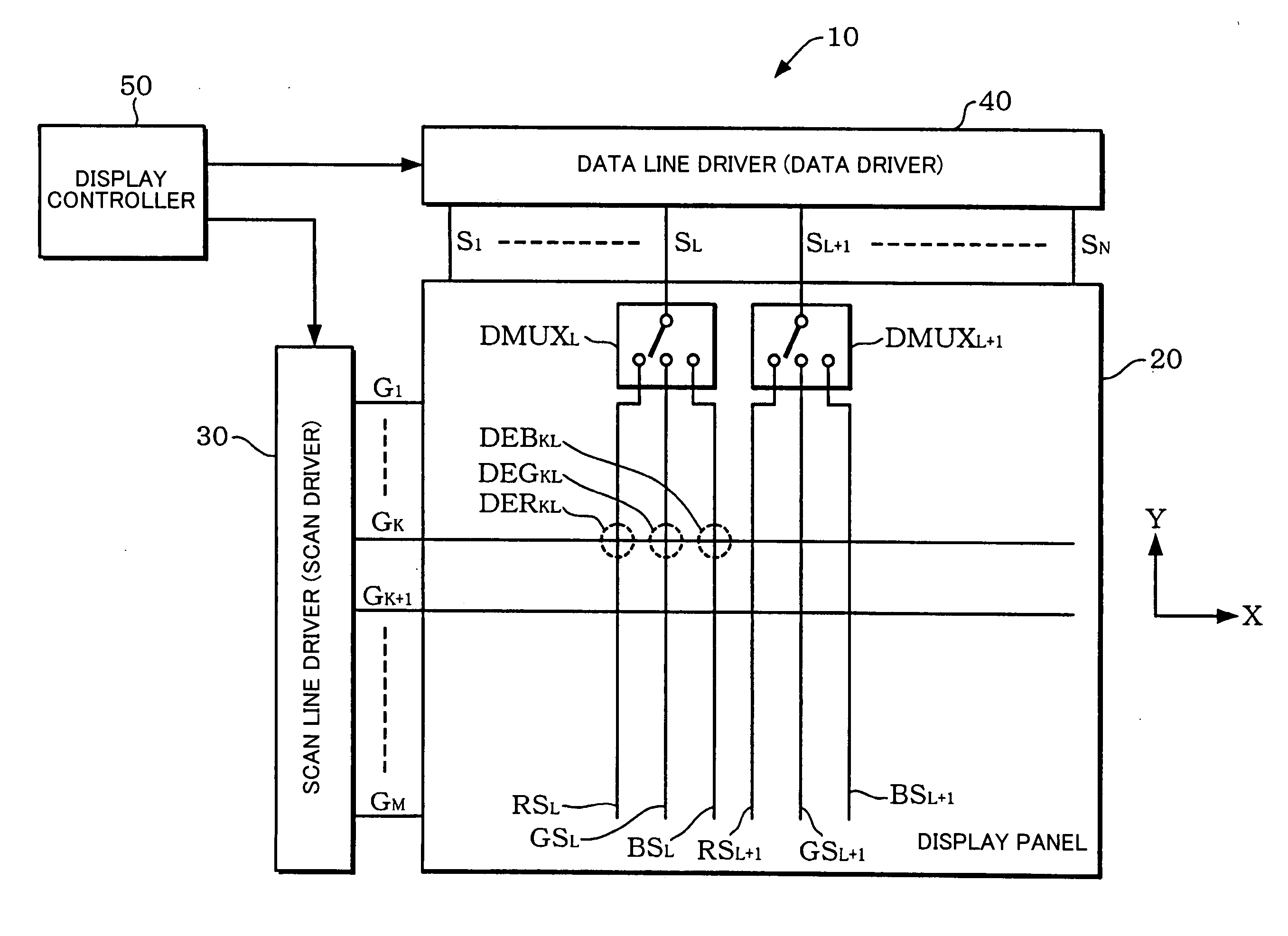

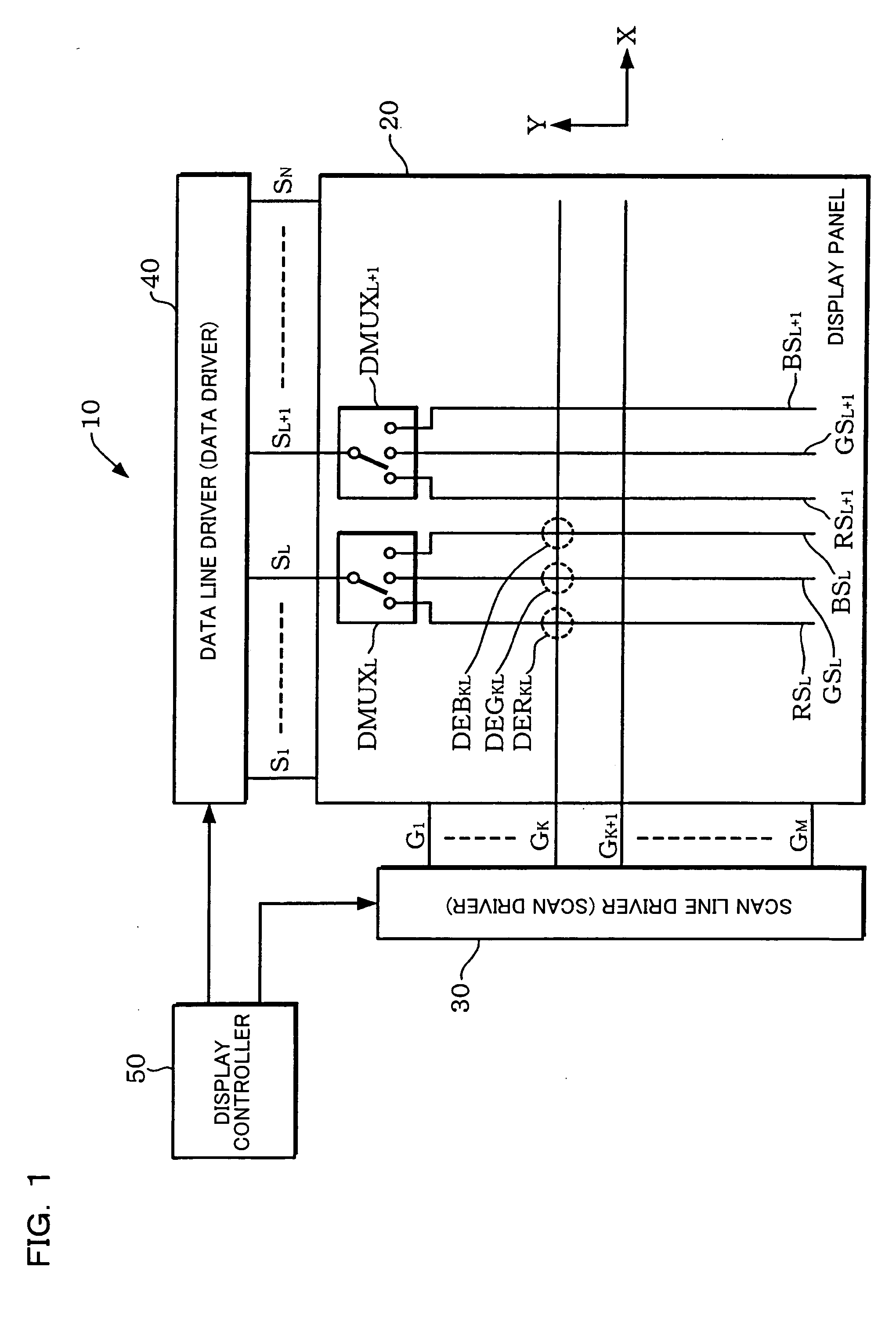

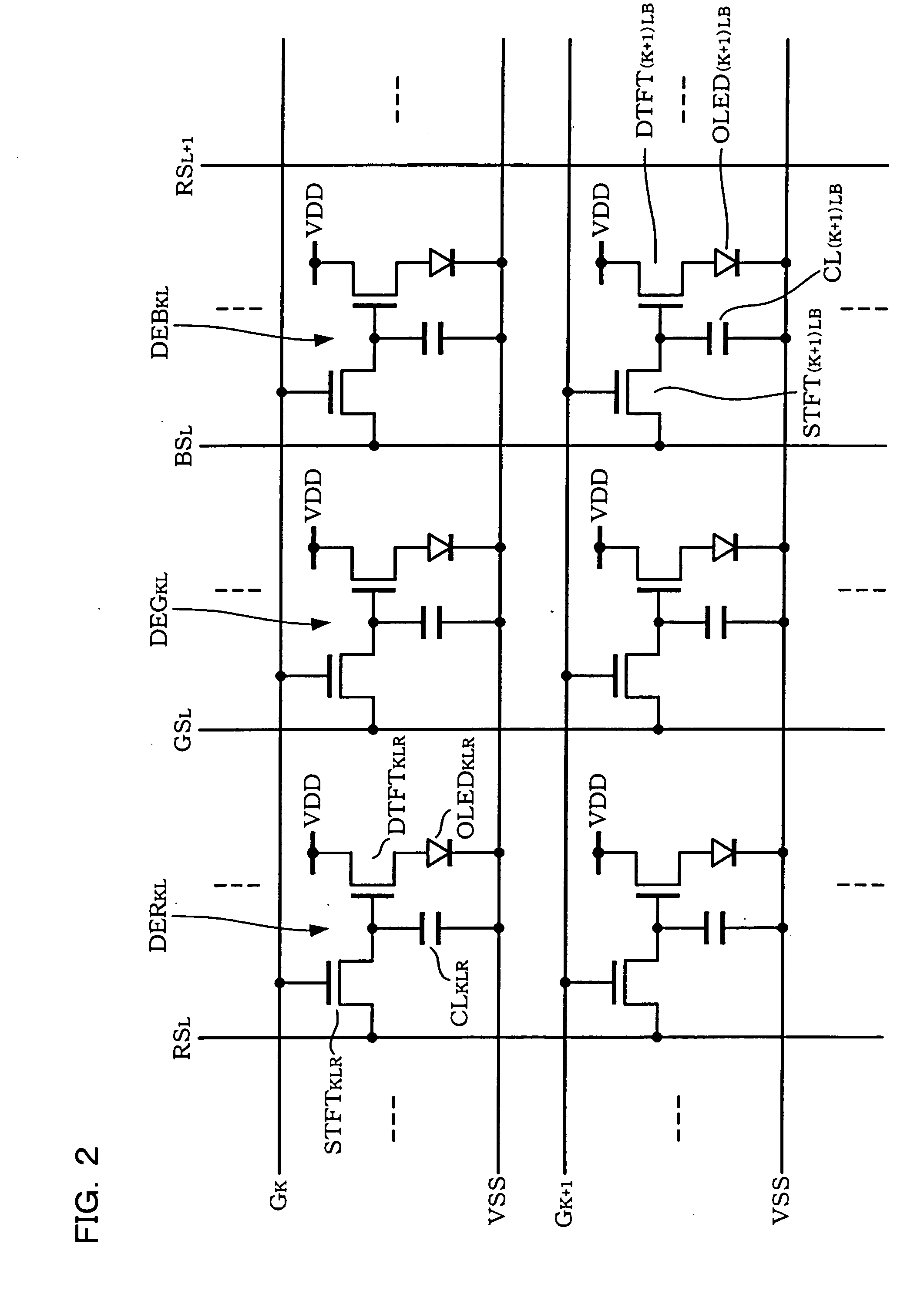

Display apparatus

InactiveUS20120320101A1Unnecessary to provideCathode-ray tube indicatorsInput/output processes for data processingEngineeringData lines

An exemplary embodiment of the present invention is a display apparatus. In the display apparatus, each row has as many row selection lines as the number of colors of light emitting elements, and row selection signals are supplied via the row selection lines such that a first row selection signal and a second row selection signals are supplied to driving circuits of light emitting elements of each color in first and second periods alternately and a plurality of times at different intervals in each frame. In the first period, light-emission or no-light-emission data signals are supplied over data lines. In the second period, only no-light-emission data signals are supplied. One of the first and second row selection signals is supplied with the same timing for all colors, while the other one of the row selection signals is supplied with timing different among the colors.

Owner:CANON KK

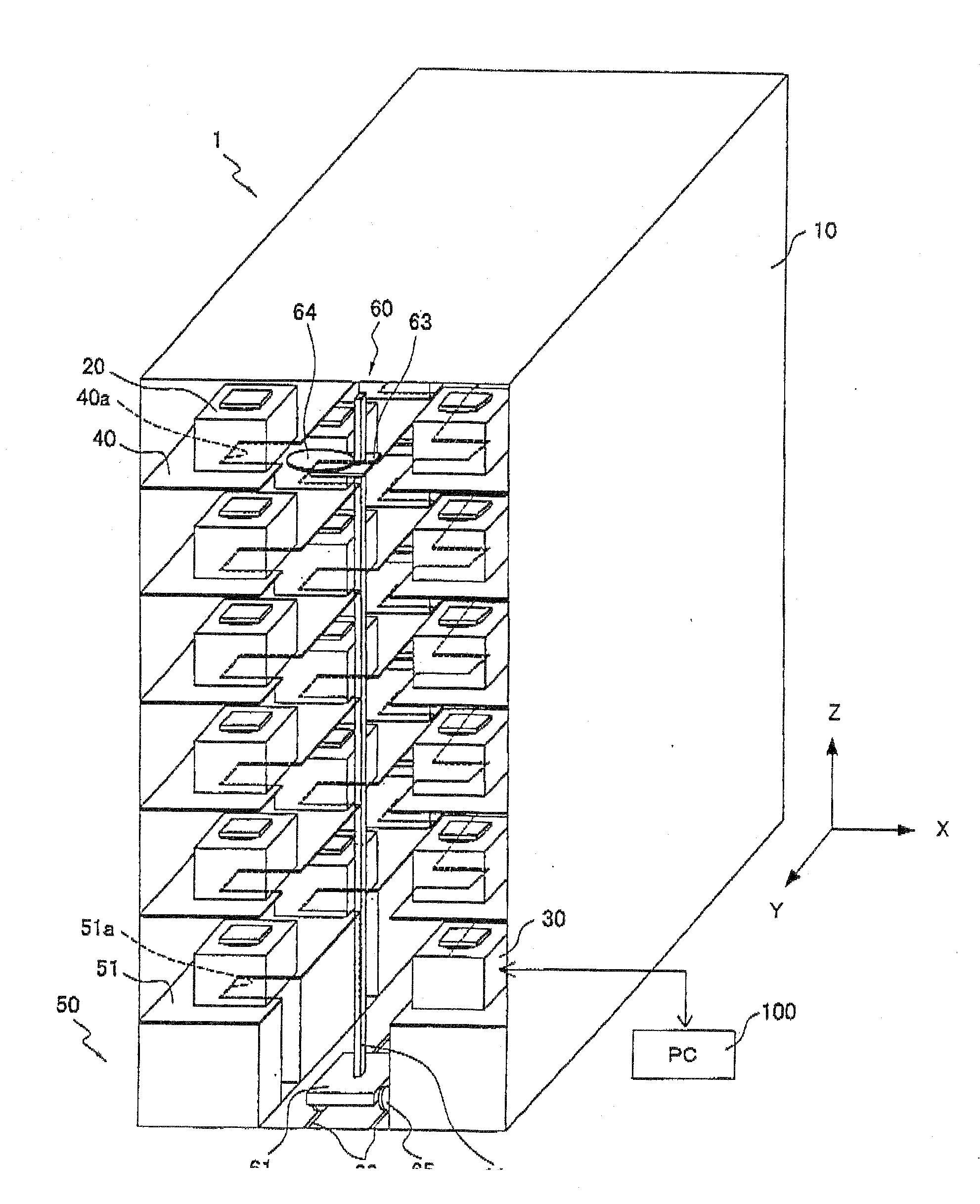

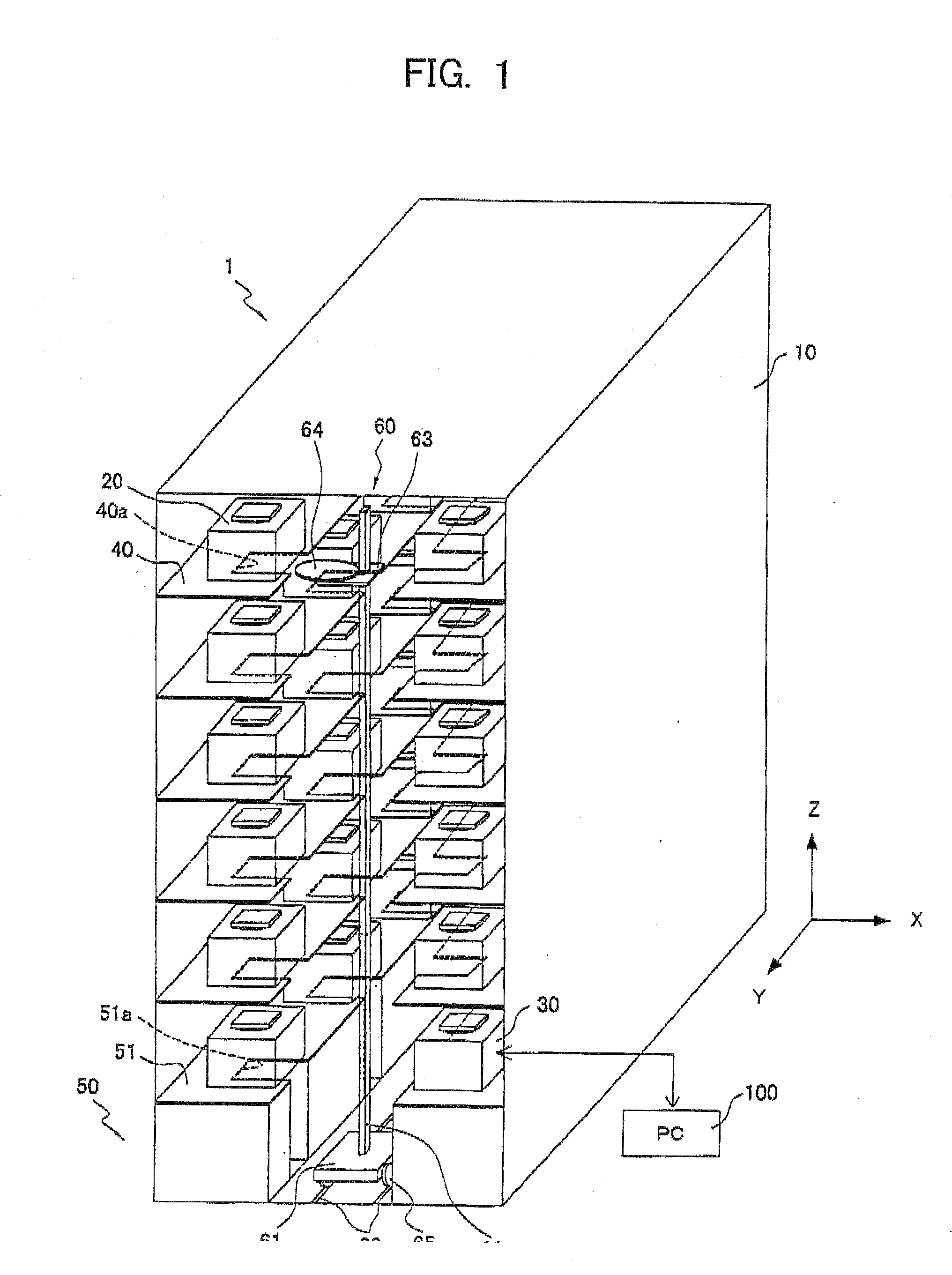

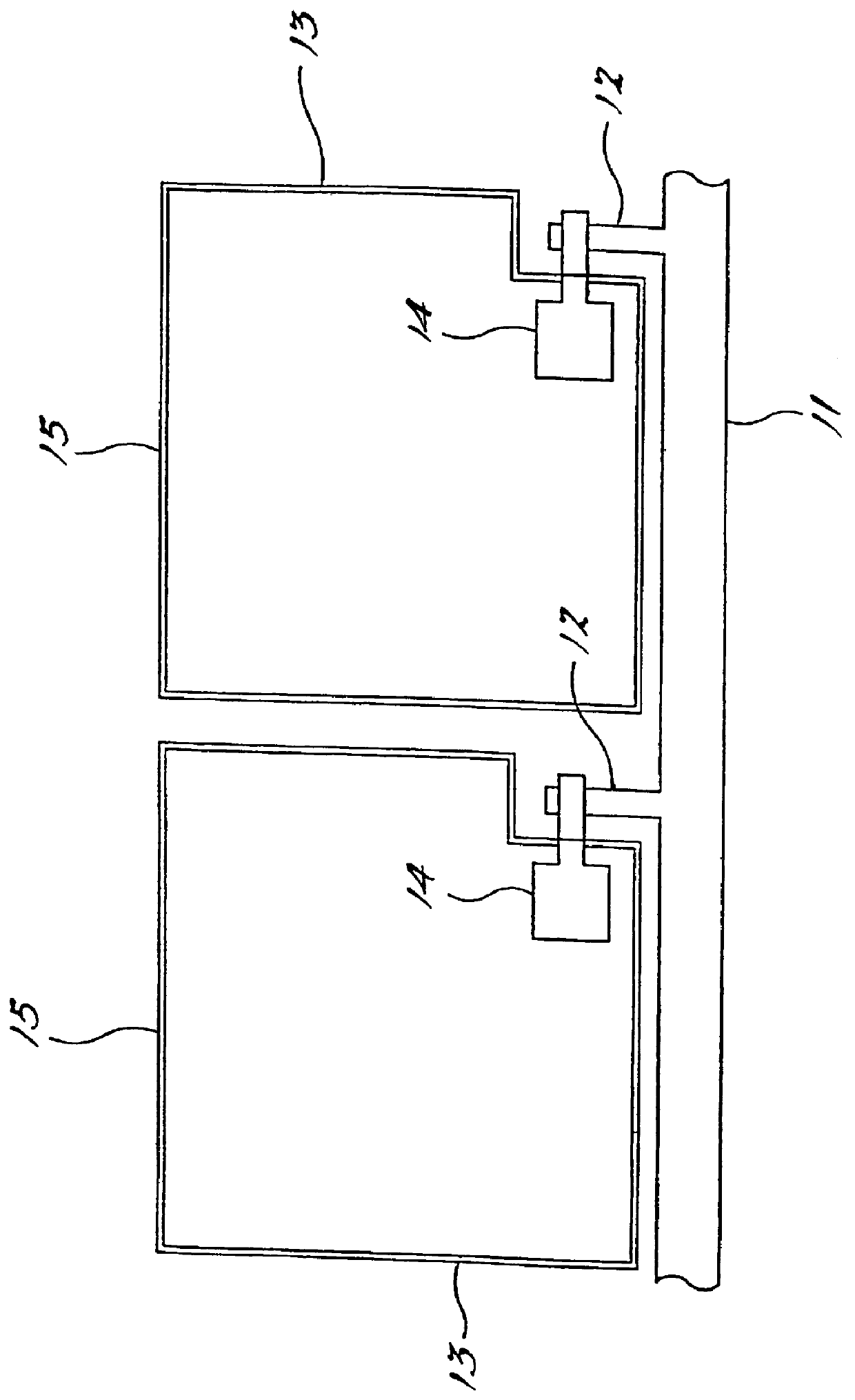

Container transport system and measurement container

ActiveUS20080156069A1Low costSave spaceDetection of fluid at leakage pointTesting/calibration apparatusTransport systemProcess engineering

A stocker 1 includes a storage FOUP 20, plural purge units 50, a measurement FOUP 30 and a stacker crane 60. The storage FOUP 20 stores a semiconductor wafer inside. The measurement FOUP 30 includes a flow meter inside. The purge unit 50 includes a purge shelf 51 having plural purge tables 54 for placing the storage FOUP 20, and a nitrogen gas is supplied into the storage FOUP 20 placed on the purge table 54. The stacker crane 60 transports the storage container 20 onto the purge table 54, and the measurement FOUP 30 is transported between the plural purge tables 54.

Owner:MURATA MASCH LTD

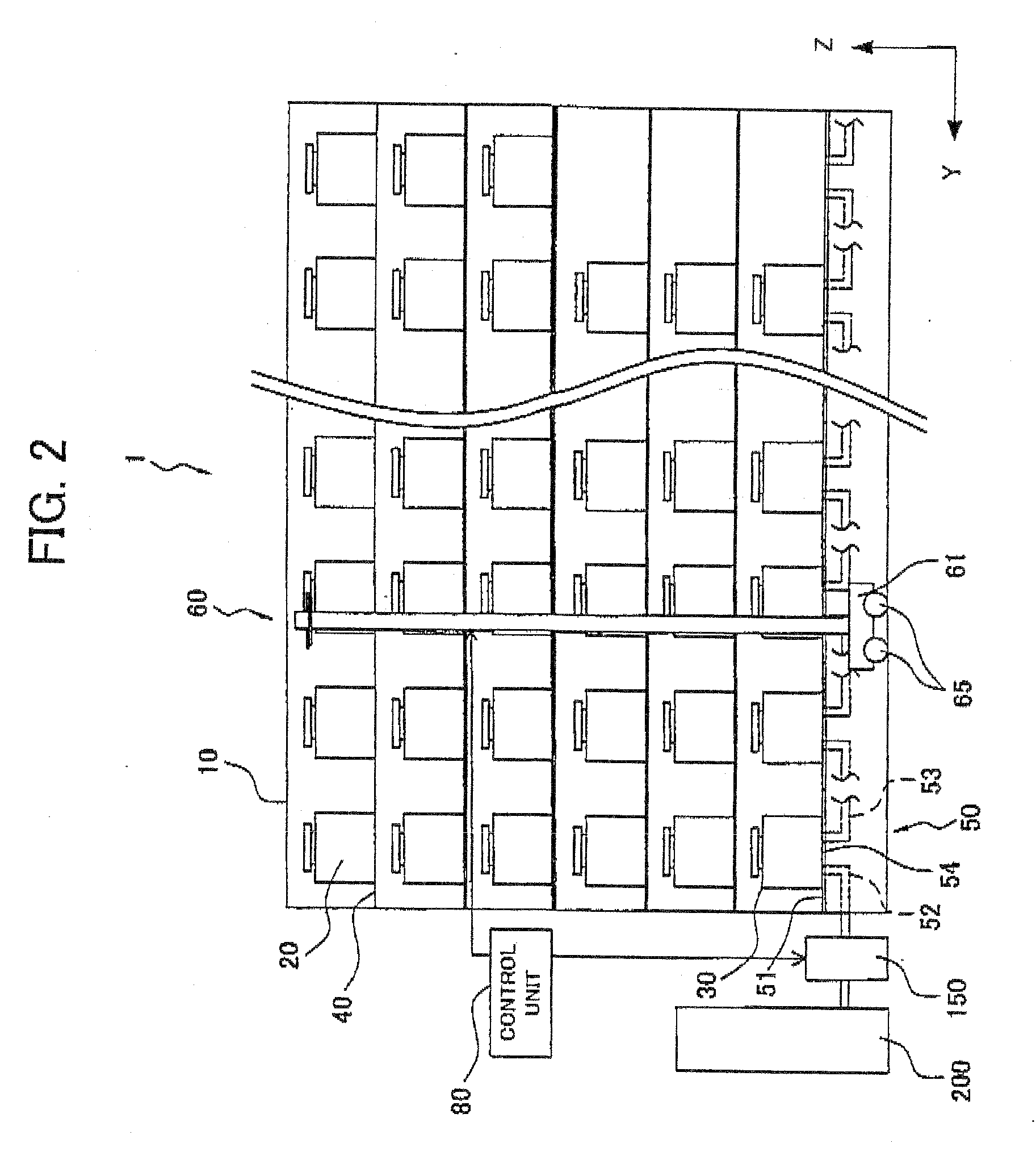

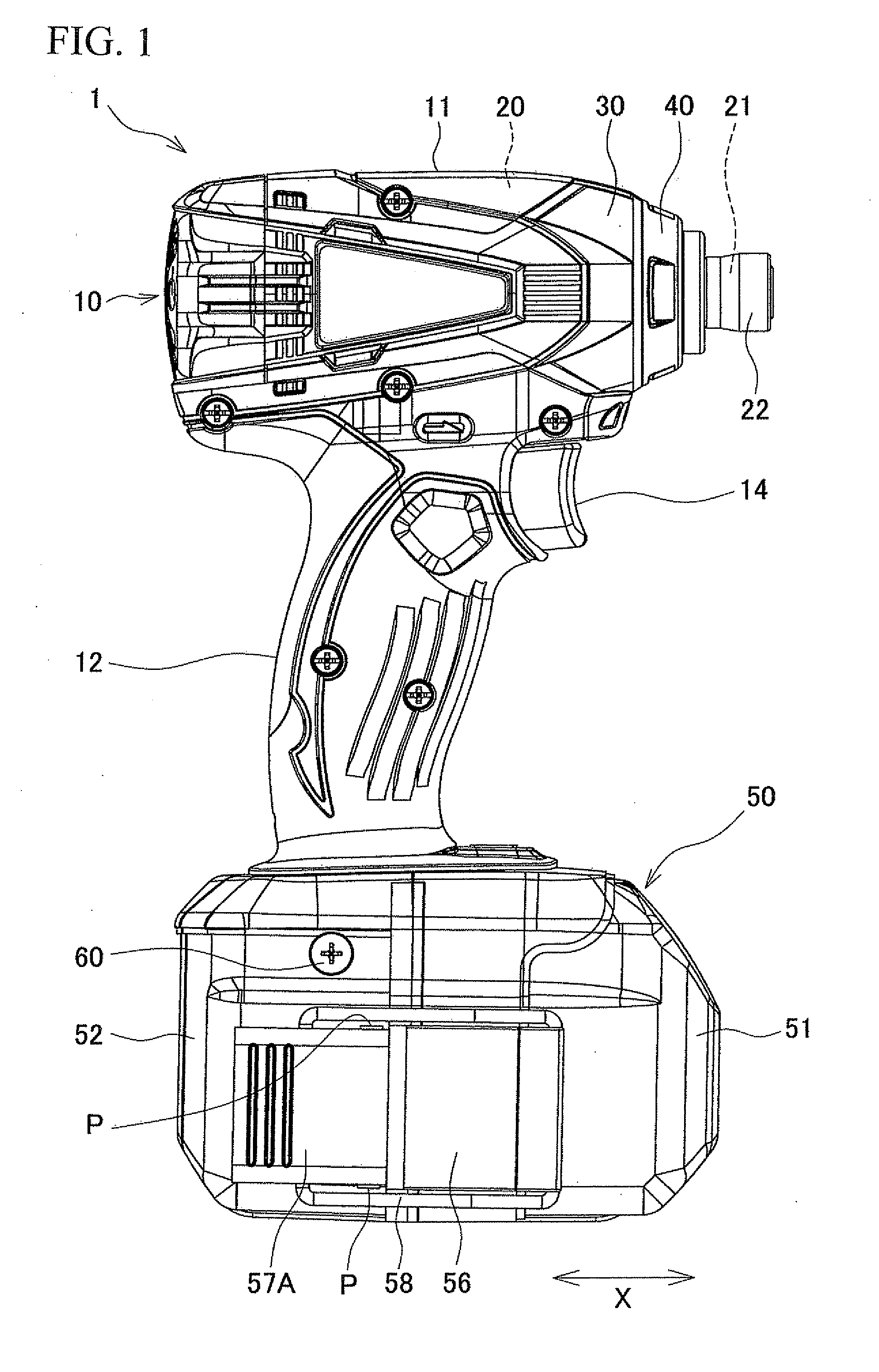

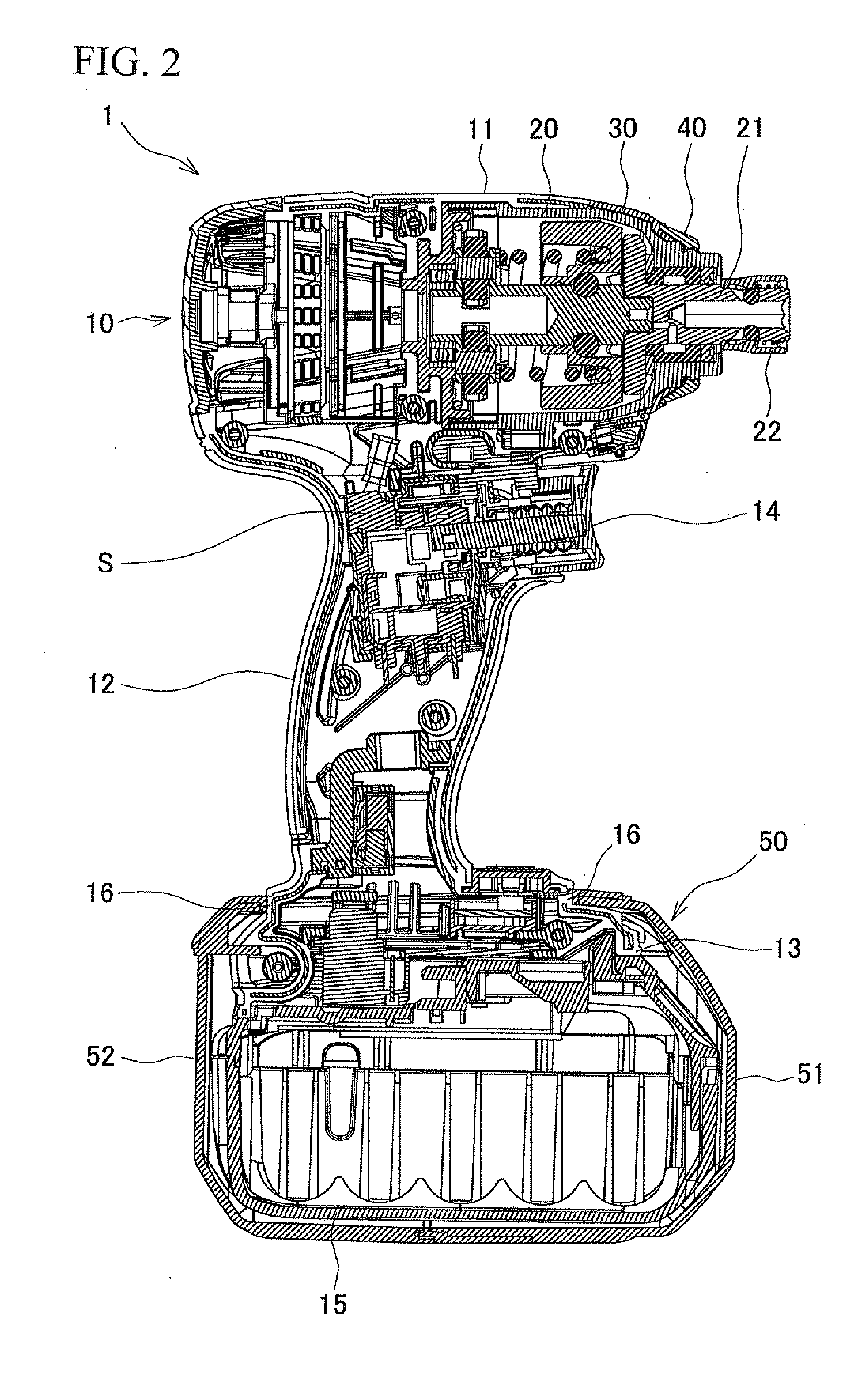

Rechargeable electric tool

ActiveUS20120061117A1Improve waterproof performanceUnnecessary to provideDrilling rodsConstructionsCouplingBattery pack

The present invention provides a rechargeable electric tool in which a battery pack as a power supply slides in a battery holder formed in an end part of a housing. A bag-shaped waterproof cover covering the battery pack including a coupling part between the battery holder and the battery pack is formed by two divided covers which are separated to the front and rear sides in a slide attachment direction of the battery pack. Between the two divided covers, a coupling mechanism can be arbitrary operated in a coupling position or a coupling cancelling position. The coupling position is a position in which the divided covers are coupled to each other in an attached state where the coupling part and the battery pack are covered. The coupling cancelling position is a position in which coupling of the divided covers is cancelled.

Owner:MAKITA CORP

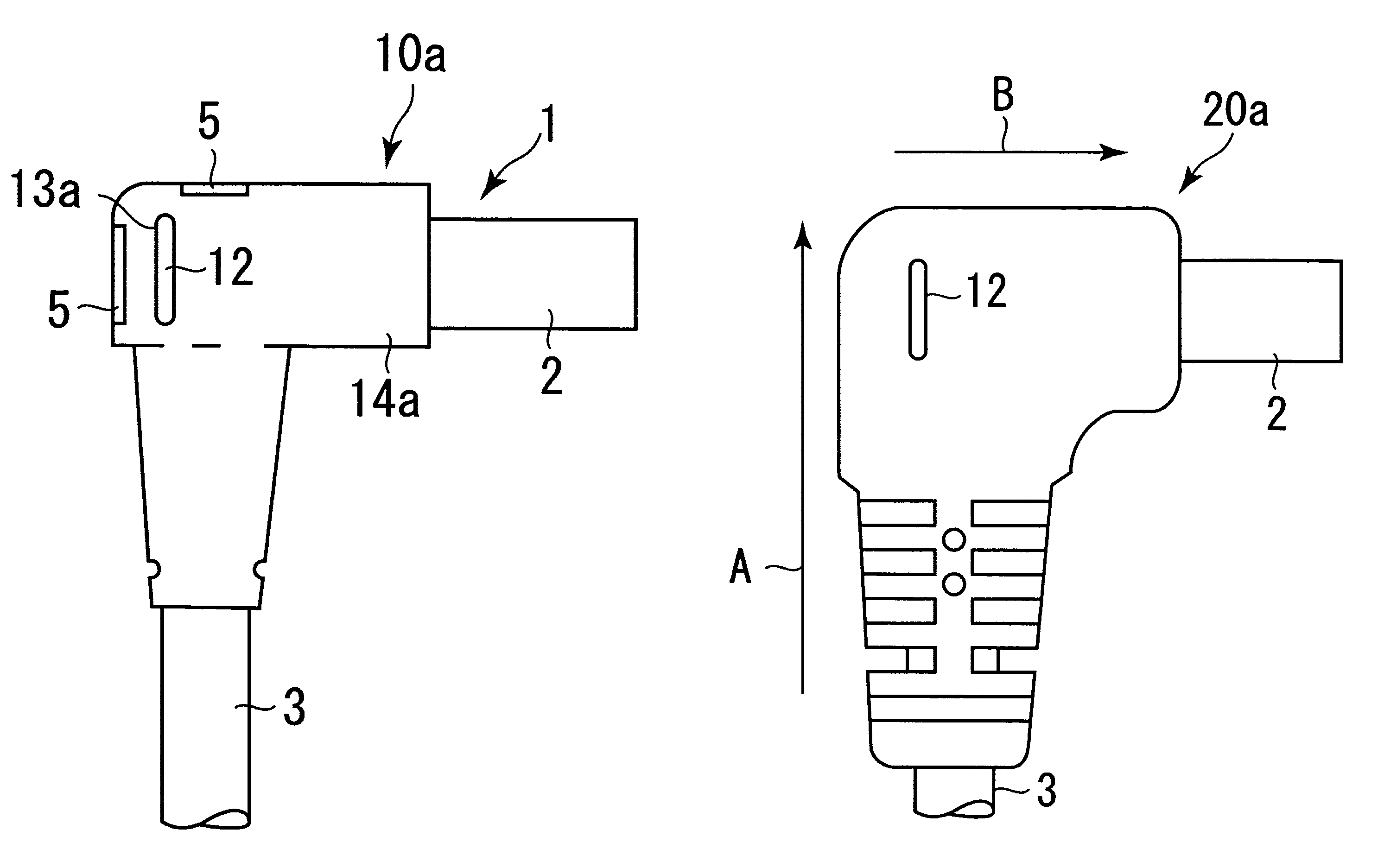

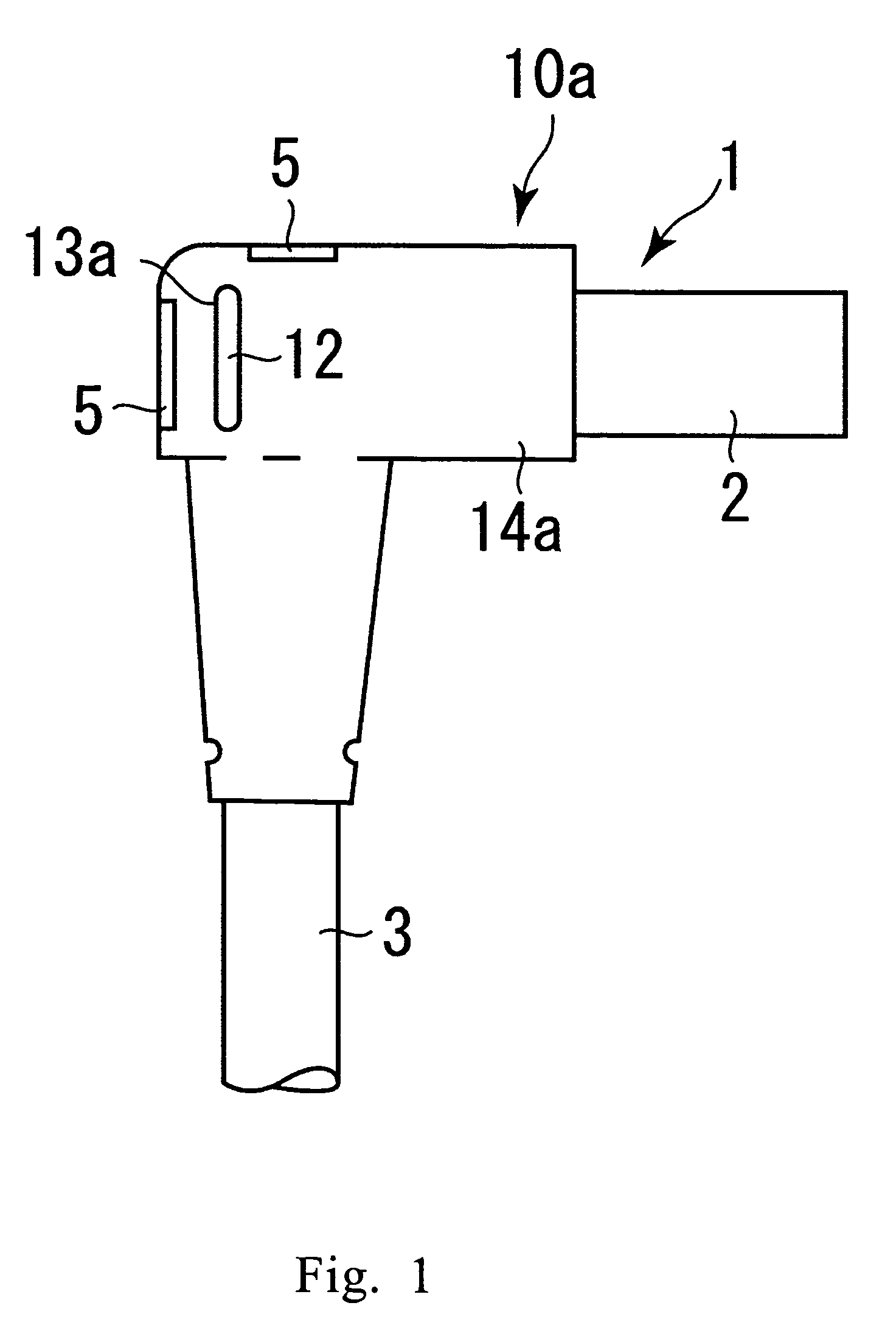

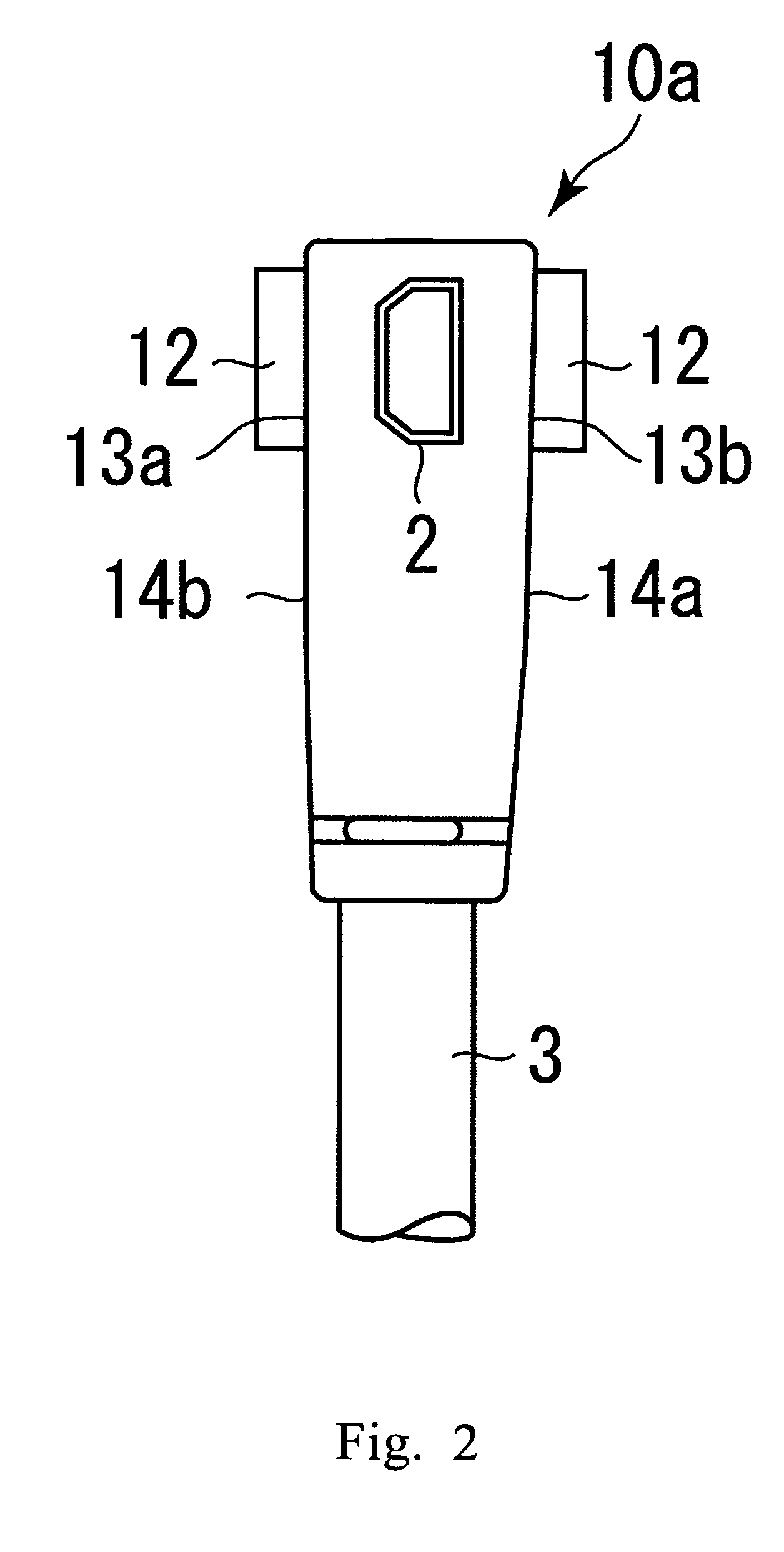

Connector with resin molded portion

InactiveUS7018236B2Avoid misalignmentAvoid problemsRelieving strain on wire connectionContact member assembly/disassemblyShell moldingEngineering

A connector includes a connector main body 1 having a metallic electrical connecting portion 2, an inner molded portion 10a provided outside the connector main body and having a pair of protrusions 12 which are integrally formed on the opposite surfaces of the inner molded portion 10a, and an outer molded portion 20a provided outside the inner molded portion so that the protrusions 12 are partially exposed on the outer surface of the outer molded portion 20a. The pair of protrusions 12 protrude toward a pair of metal molds for molding the outer molding portion, respectively.

Owner:MITSUMI ELECTRIC CO LTD

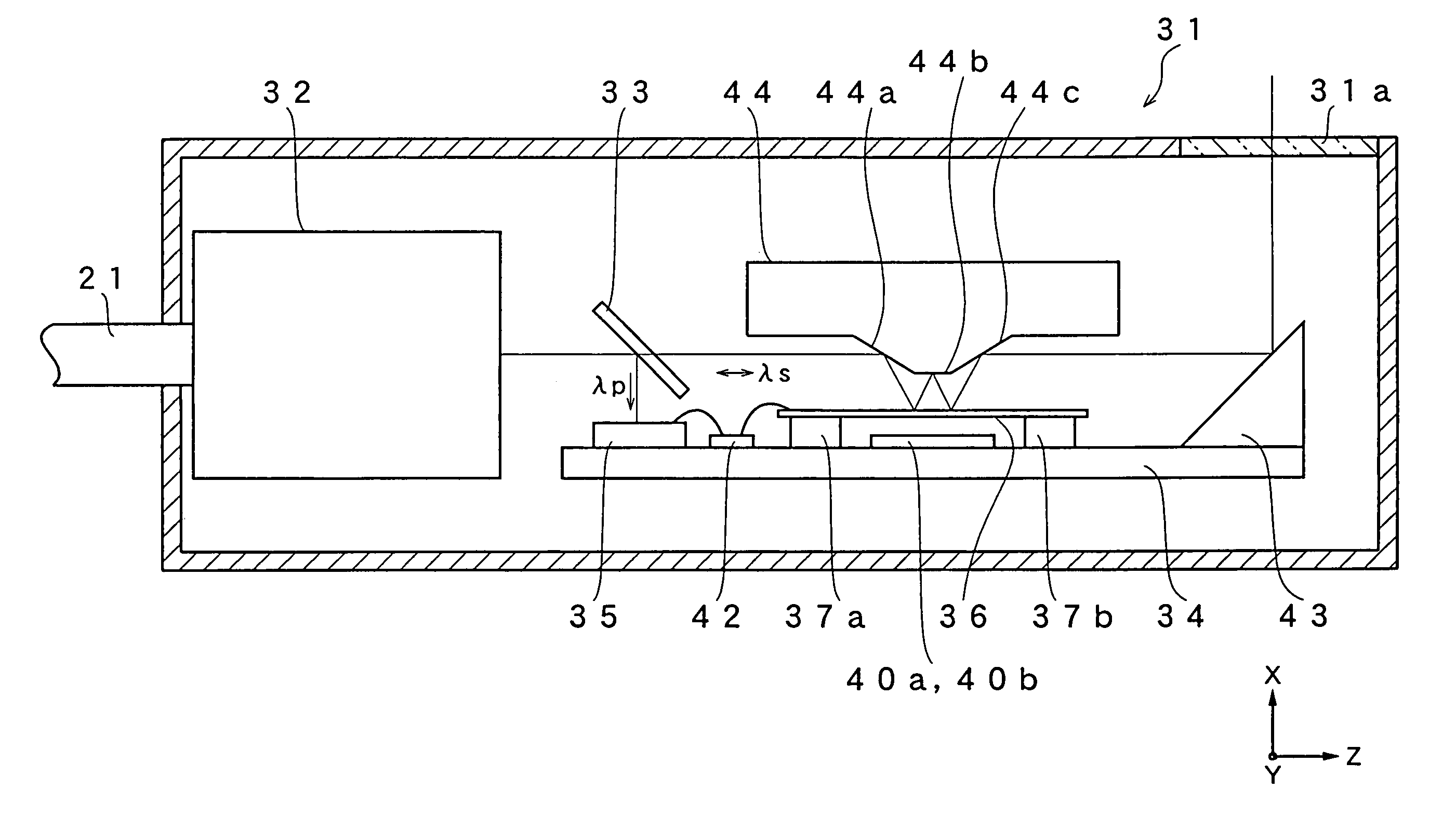

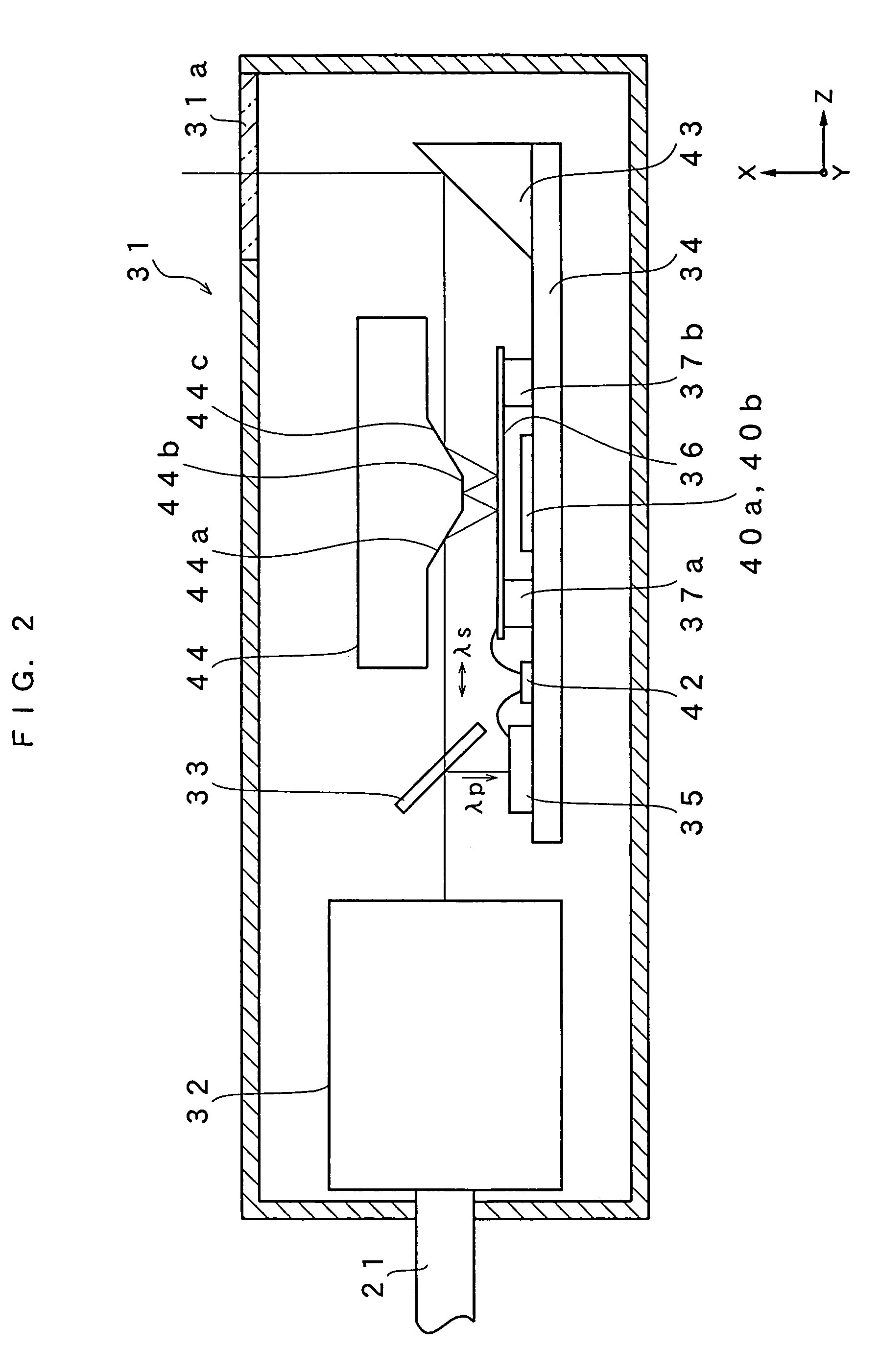

Optical deflection probe and optical deflection probe device

ActiveUS7323680B2Simple configurationReduce manufacturing costRadiation pyrometryBeam/ray focussing/reflecting arrangementsSignal lightActuator

An optical fiber transmits signal light and the excitation light for driving an actuator each having a different wavelength to a probe. In the probe, the signal light and excitation light are separated from each other by an optical filter and the excitation light is irradiated to a photo diode. The signal light is supplied to a MEMS mirror unit. Then, the MEMS mirror unit is driven by an electromotive force obtained by the photo diode. In this manner, by modulating intensity of the excitation light, the signal light can be deflected.

Owner:SANTEC

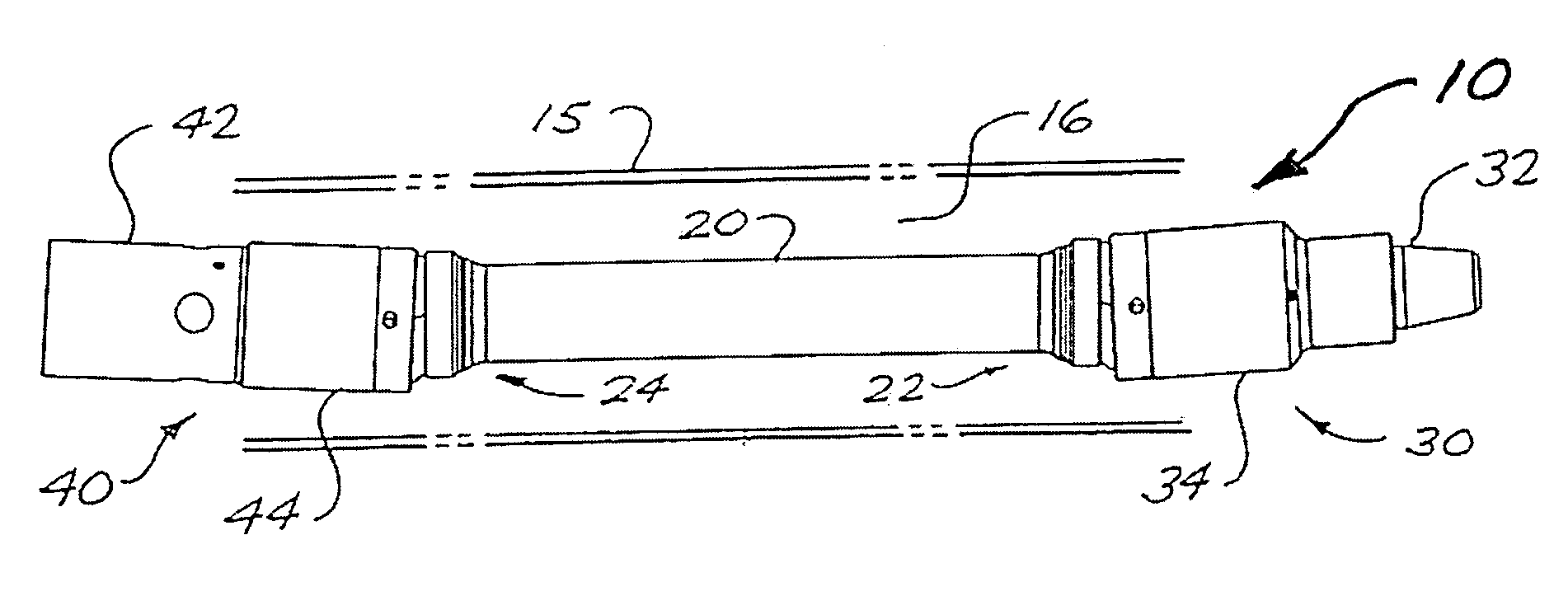

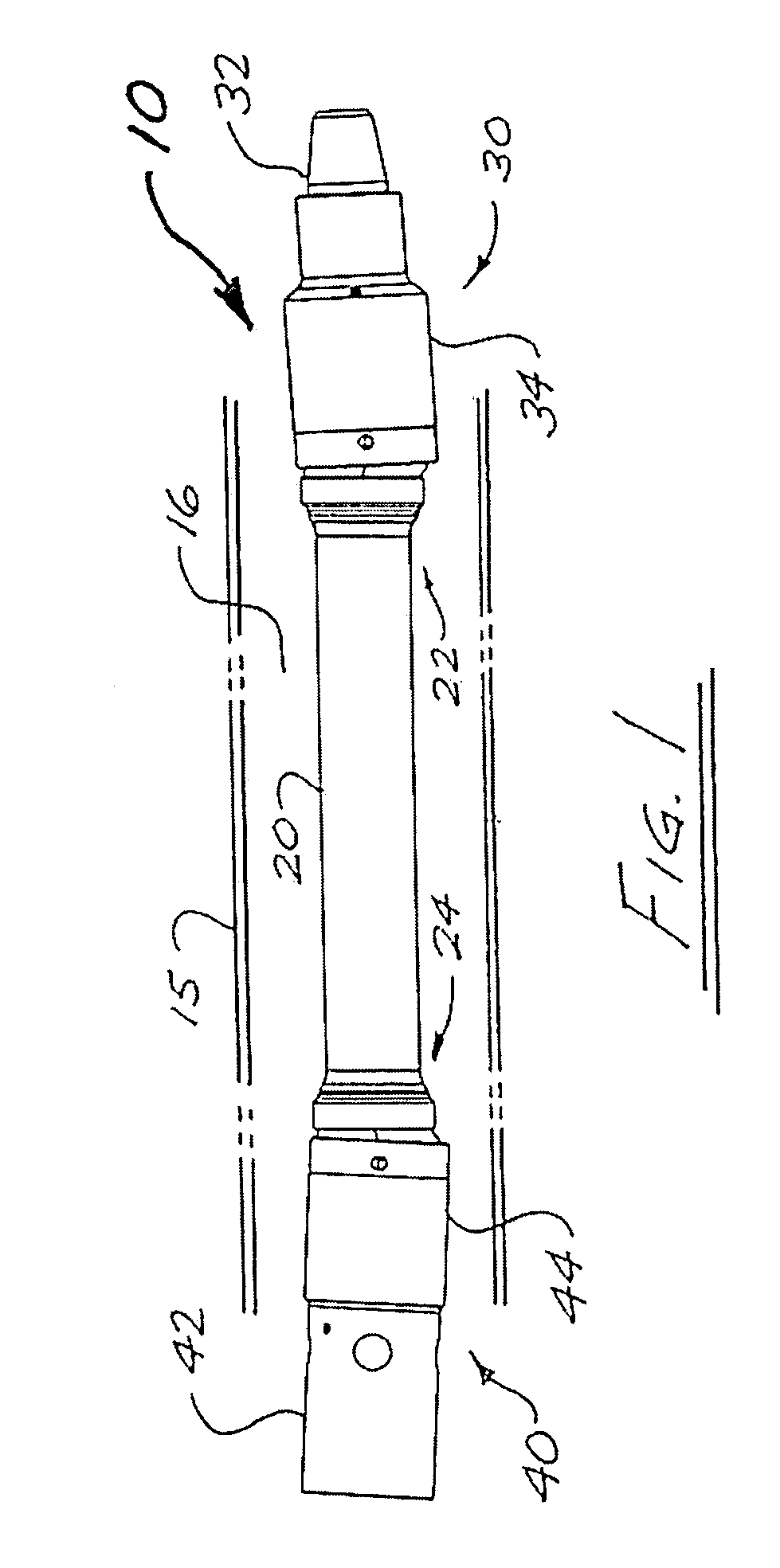

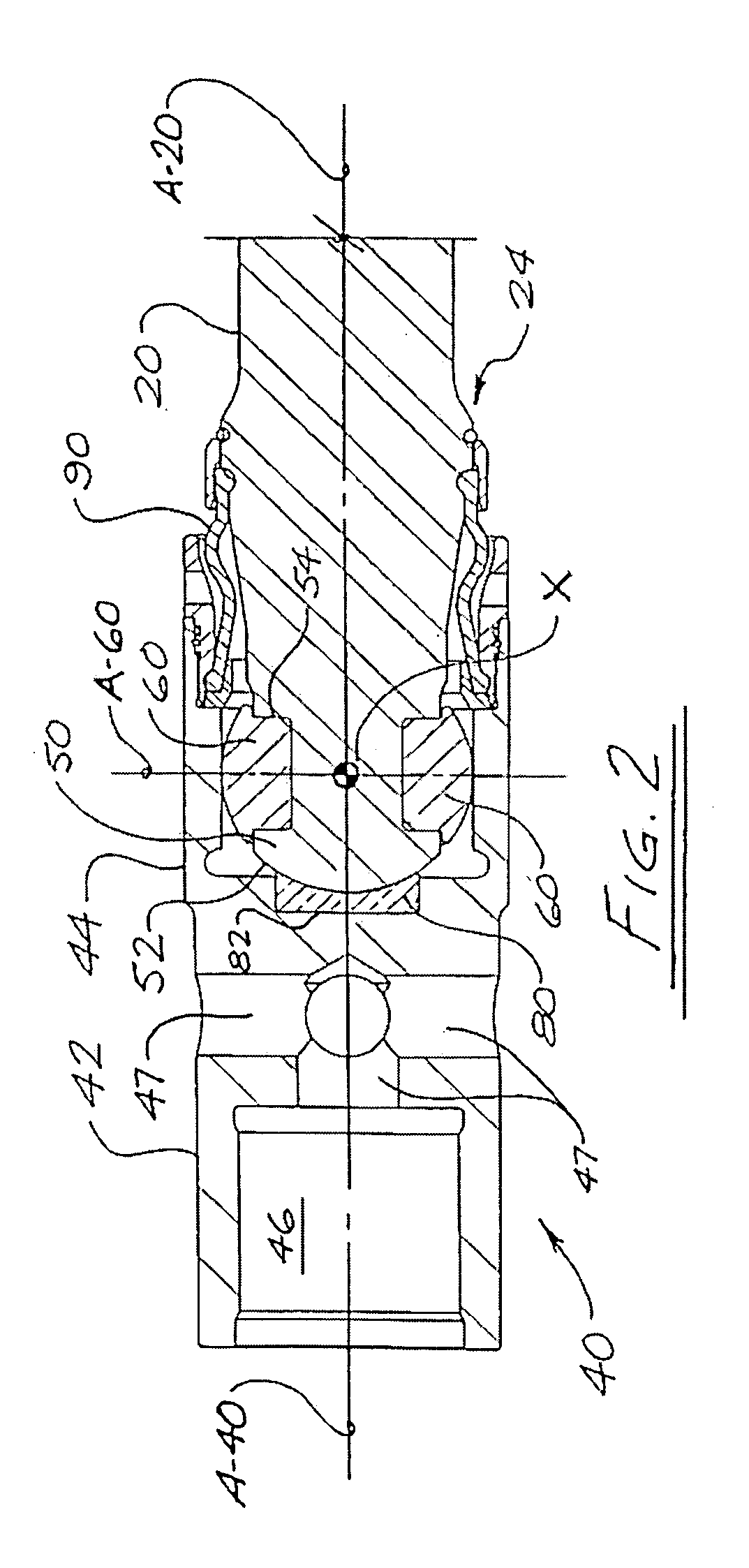

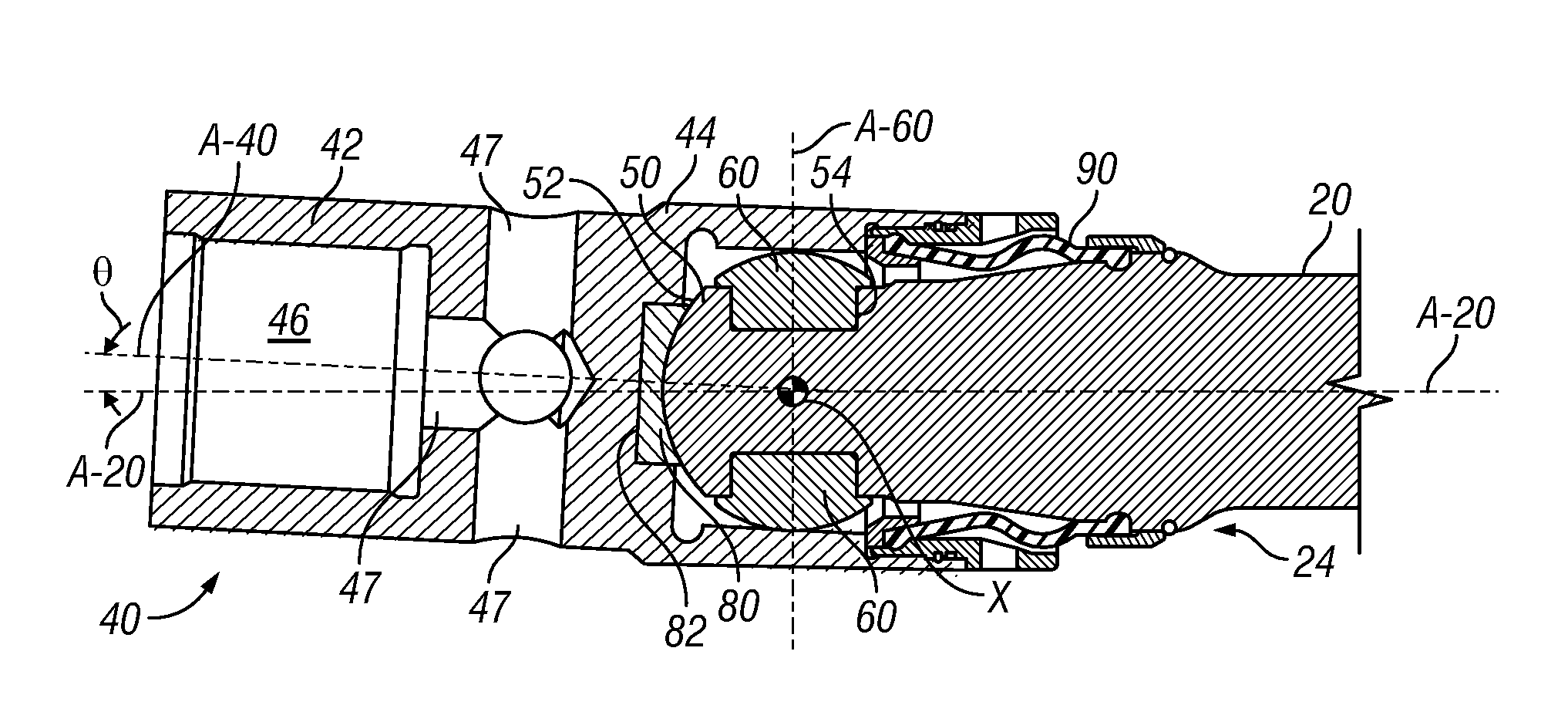

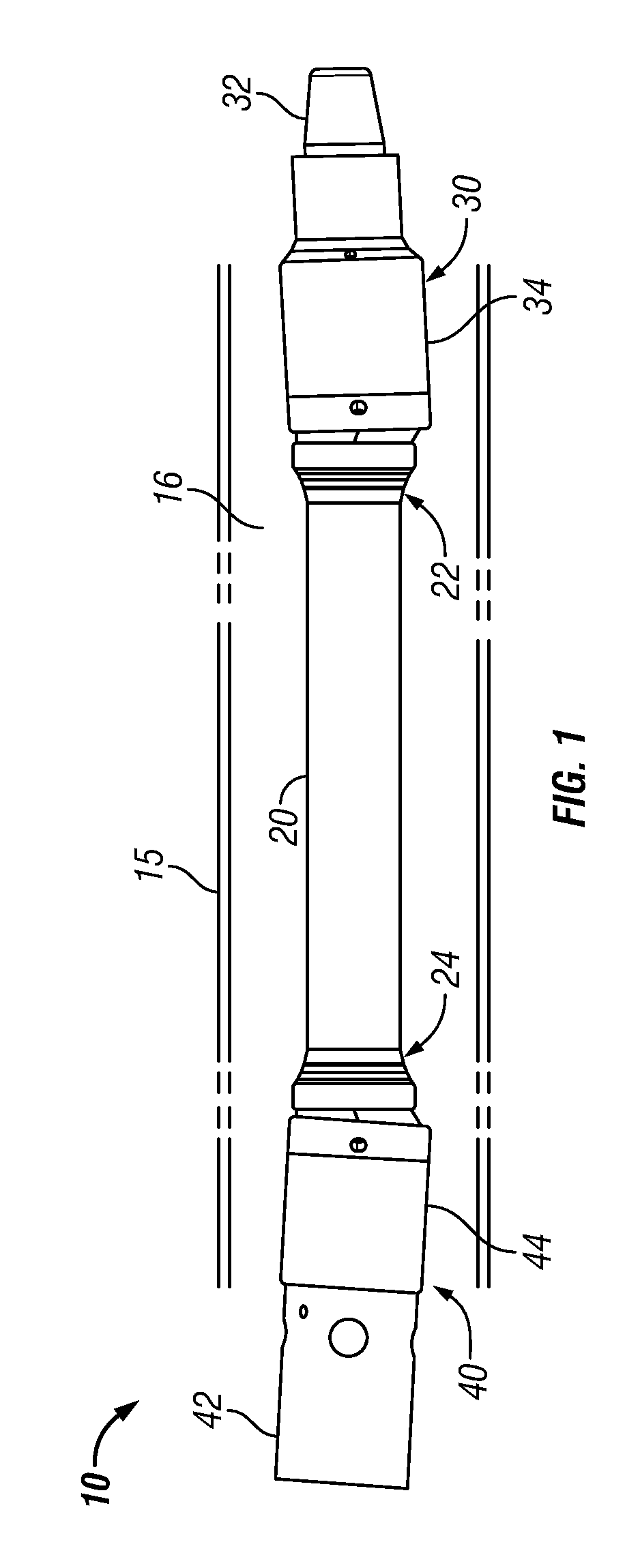

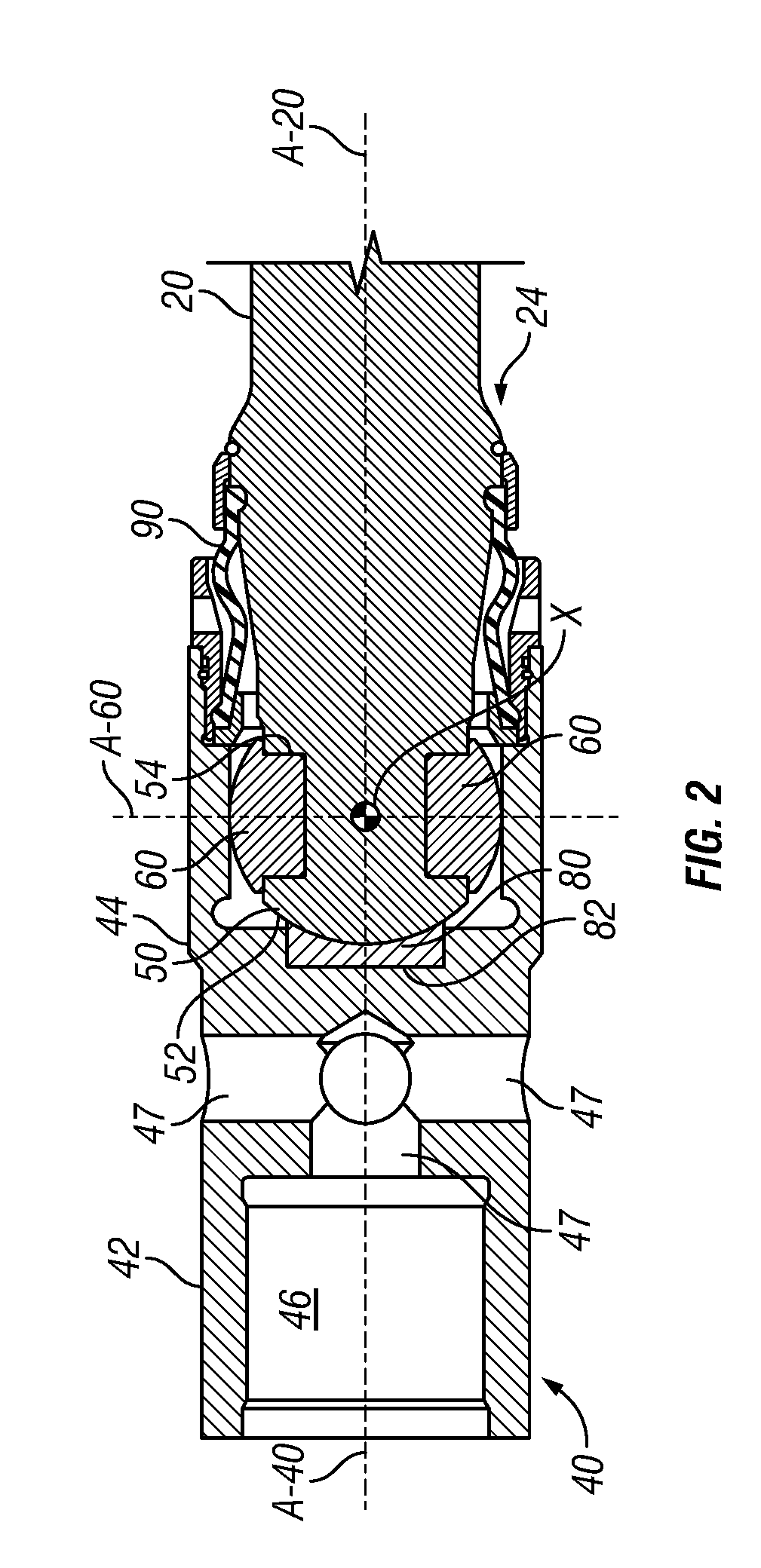

Drive shaft assembly for a downhole motor

ActiveUS20090275415A1Improve pronunciationIncrease capacityYielding couplingDrilling rodsRotational axisSpherical bearing

A drive shaft assembly for a downhole motor includes a drive shaft formed with convexly spherical bearing surfaces on each end, and end housings with concavely spherical bearing surfaces for mating contact with the spherical bearing surfaces of the drive shaft, thereby facilitating omni-directional articulation between the drive shaft and the end housings while transferring axial thrust loads between the drive shaft and end housings across the interface of the mating spherical bearing surfaces. Torque is transferred between the drive shaft and end housings through two or alternatively four swivelling drive keys mounted to each end of the drive shaft and engageable with complementary drive key slots in the end housings. Full and constant torque-transferring contact is thus provided between the swivelling drive keys and the end housings irrespective of any angular offset between the drive shaft and the end housings, resulting from omni-directional articulation of the drive shaft relative to the end housing. The omni-directional center of rotation at each end of the drive shaft coincides with the geometric centerpoint of the corresponding convexly spherical bearing surface, which corresponds to the intersection of the drive shaft's rotational axis, the end housing's rotational axis, and the drive key swivel axis.

Owner:DRECO ENERGY SERVICES ULC

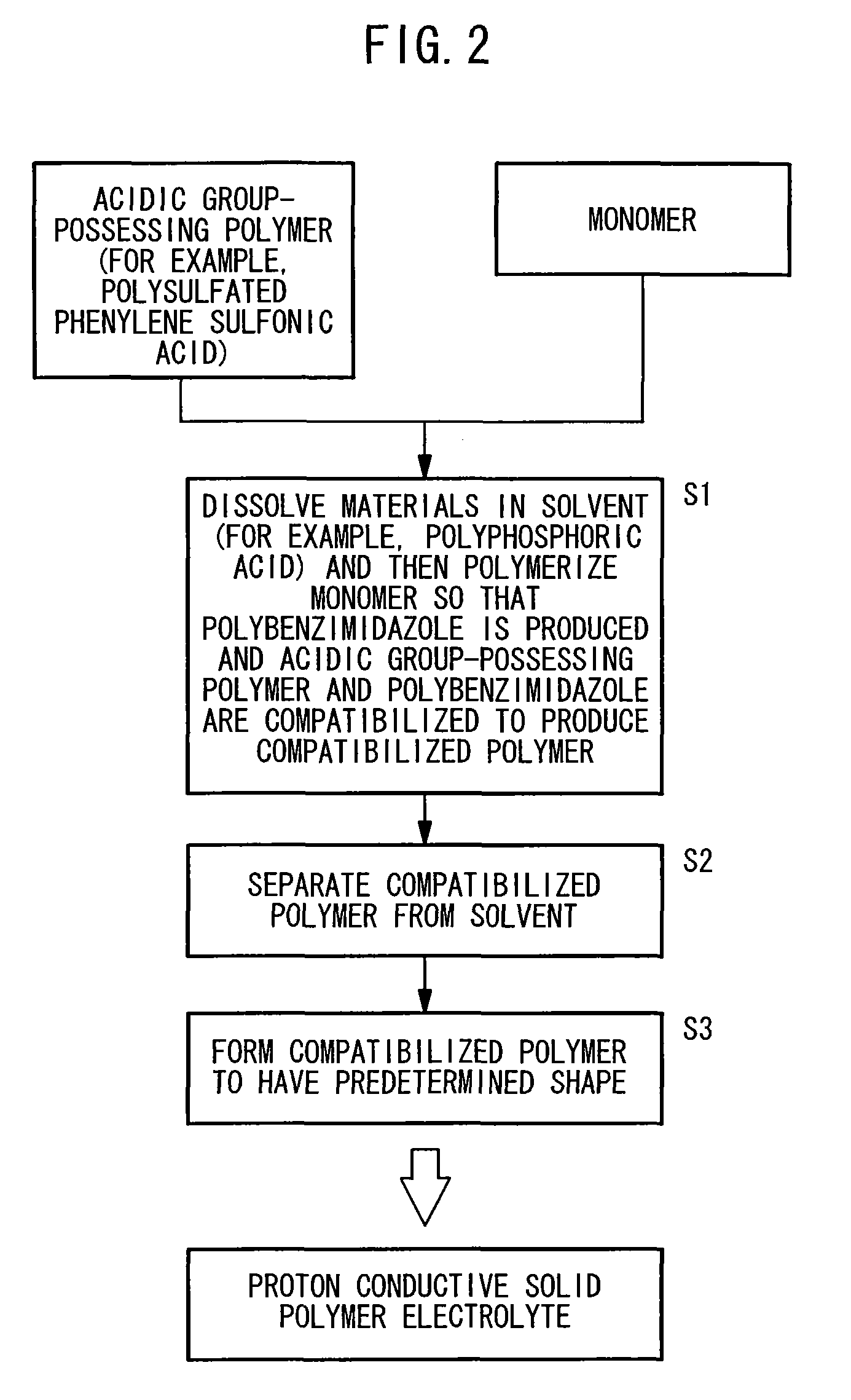

Proton conductive solid polymer electrolyte and method for producing the same

InactiveUS7045241B2Excellent abilitySecure characteristicSolid electrolytesFinal product manufacturePhosphoric acidPoly(benzimidazole)

A monomer to produce polybenzimidazole is dissolved in polyphosphoric acid. For example, polysulfated phenylene sulfonic acid (acidic group-possessing polymer) is further dissolved in this solution. In this procedure, the acidic group-possessing polymer and the monomer are adsorbed to one another in accordance with the acid-base interaction. When the monomer is polymerized, for example, by means of dehydration polymerization in this state, then polybenzimidazole is synthesized, and the polybenzimidazole and the acidic group-possessing polymer are compatibilized with each other to produce a compatibilized polymer. When the compatibilized polymer is deposited as a solid, and the solid is separated from polyphosphoric acid, then the compatibilized polymer is obtained. A proton conductive solid polymer electrolyte as a final product is manufactured by forming the compatibilized polymer to have a predetermined shape.

Owner:HONDA MOTOR CO LTD

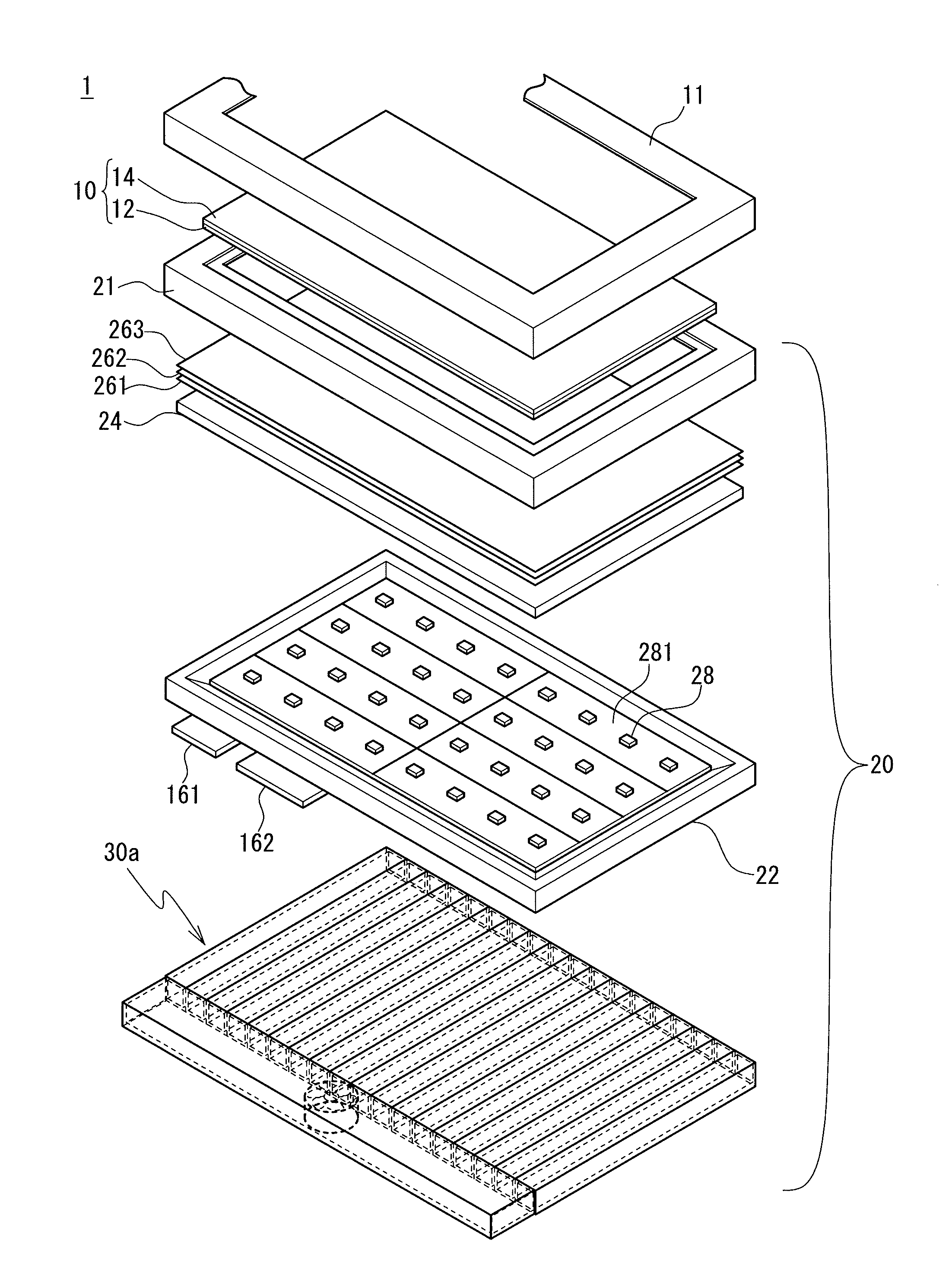

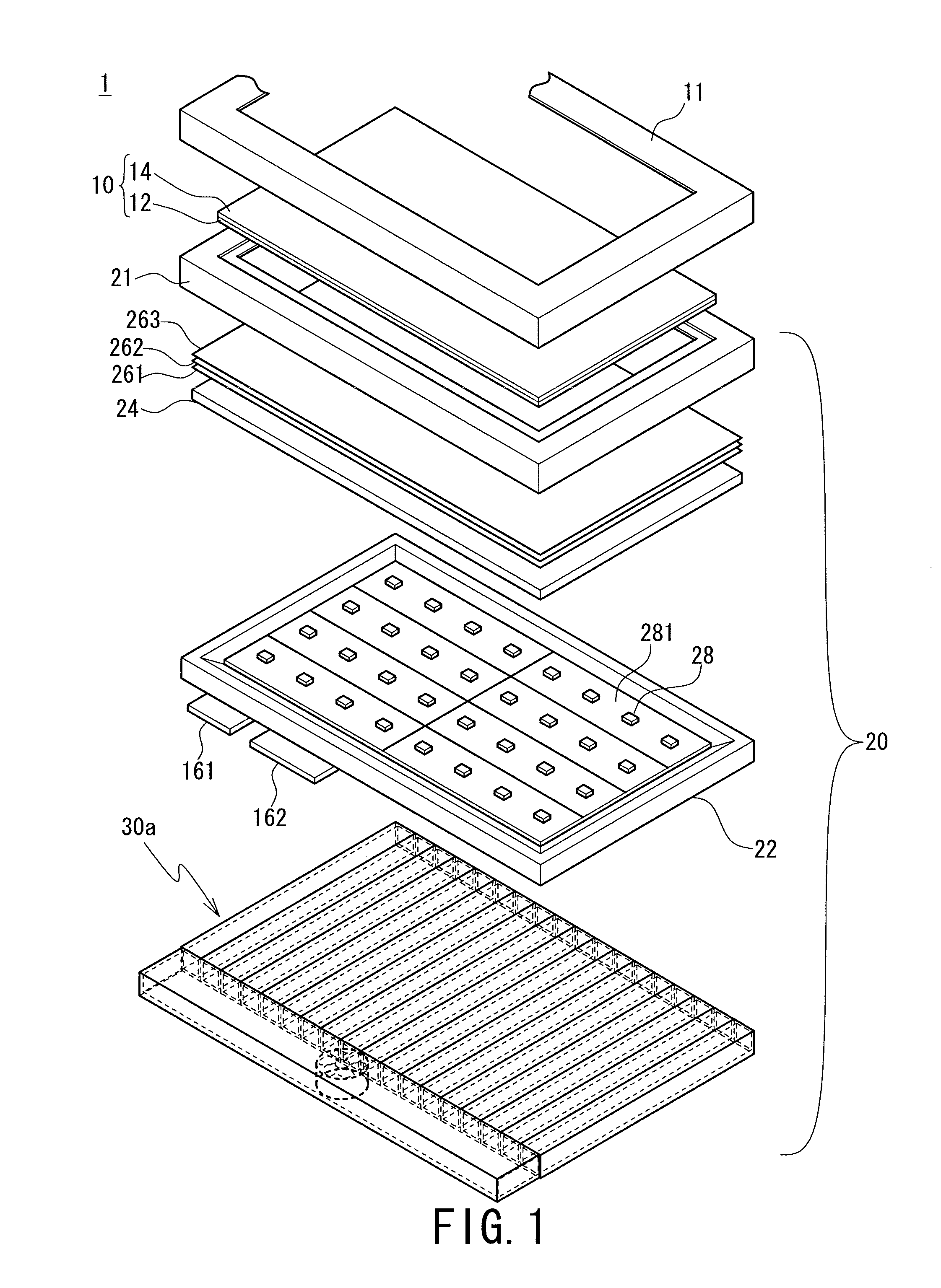

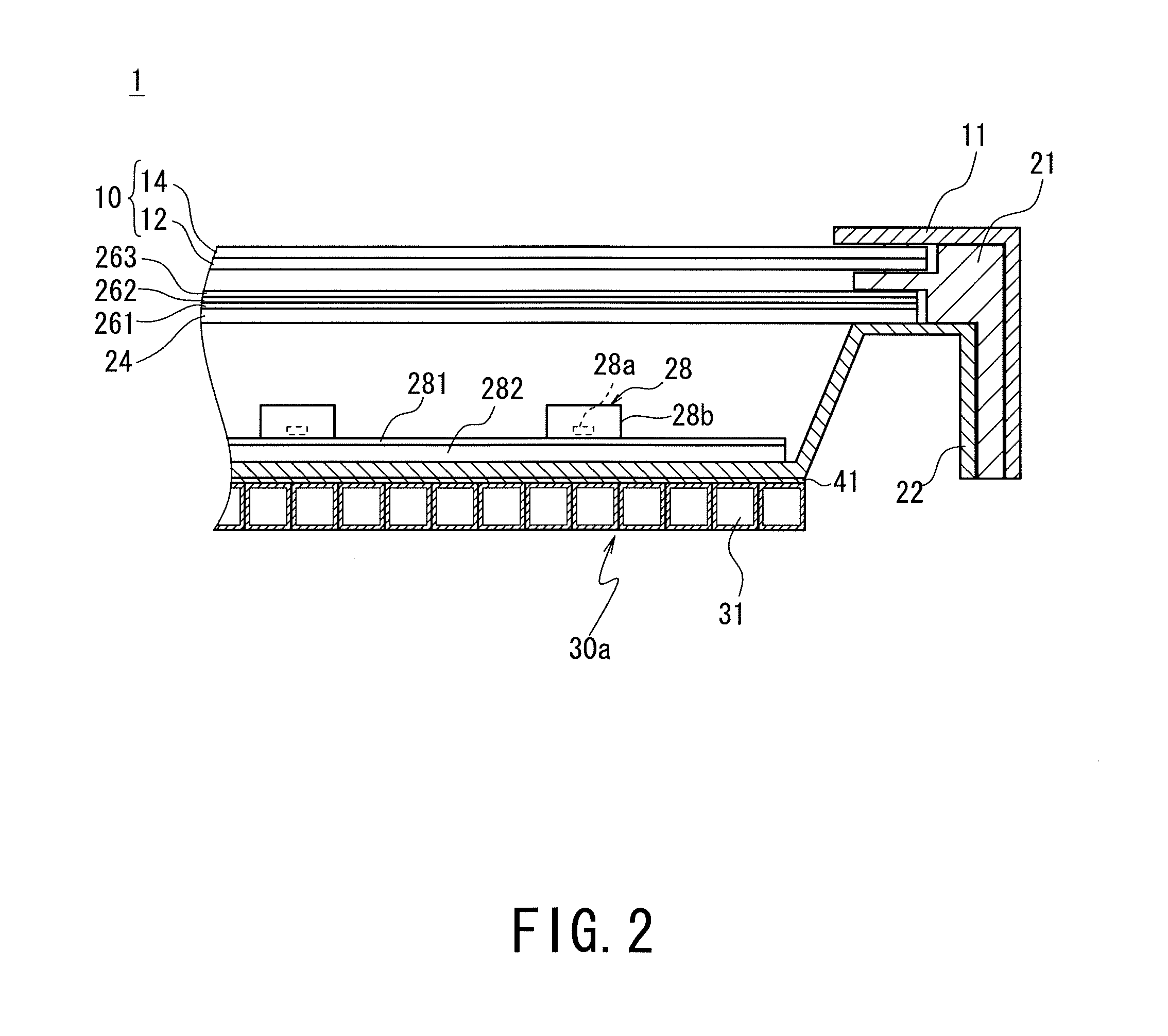

Liquid crystal display device, and LED backlight unit

InactiveUS20120320566A1Improve cooling effectUnnecessary to provideLighting heating/cooling arrangementsIlluminated signsLiquid-crystal displayEngineering

Provided is a liquid crystal display device and a backlight unit that are of high quality and have a simple configuration that a mechanism cooling a cooling medium is not included. Included are a liquid crystal display panel and an LED backlight unit including an LED light source emitting light toward the panel, and a chassis plate on which the light source is disposed, the plate including a through flow path for cooling air dissipating heat from the light source, wherein the path includes a main duct introducing the cooling air and disposed along one side of the panel, and a branch duct branching off from the main duct, aligned along a disposed direction of the light source, and including an exhaust port disposed at an end of the branch duct and discharging the cooling air to outside of the device.

Owner:SHARP KK

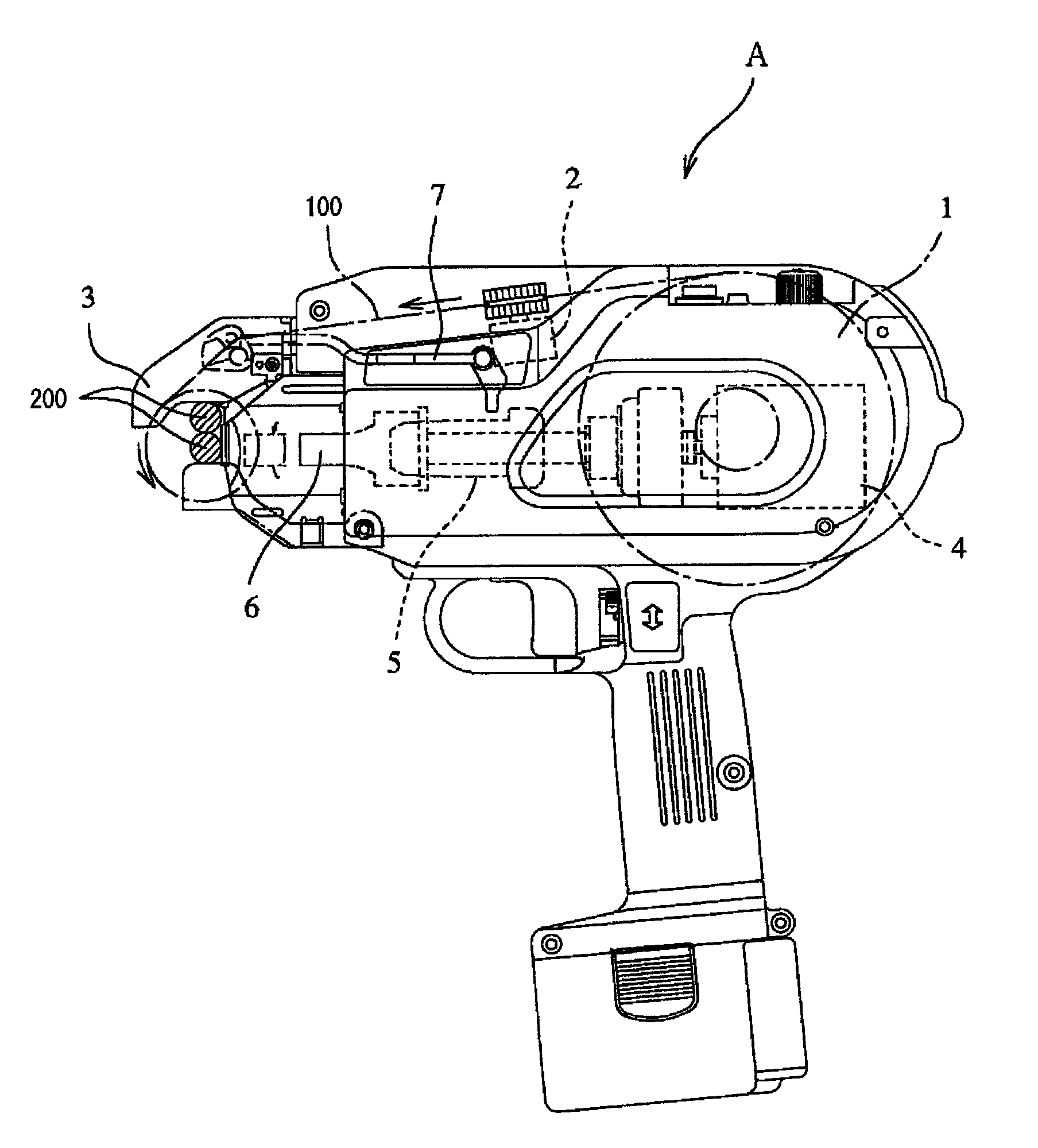

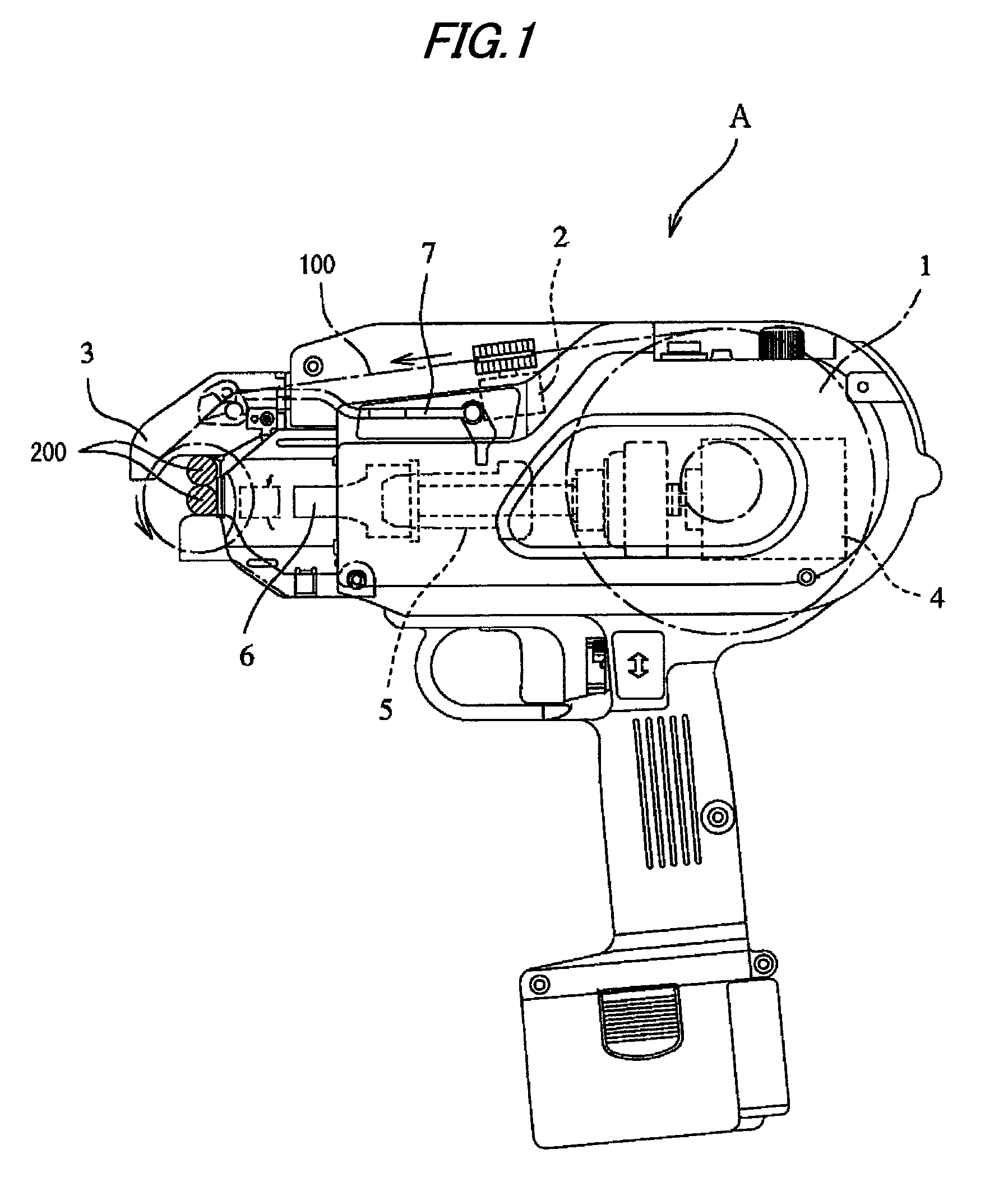

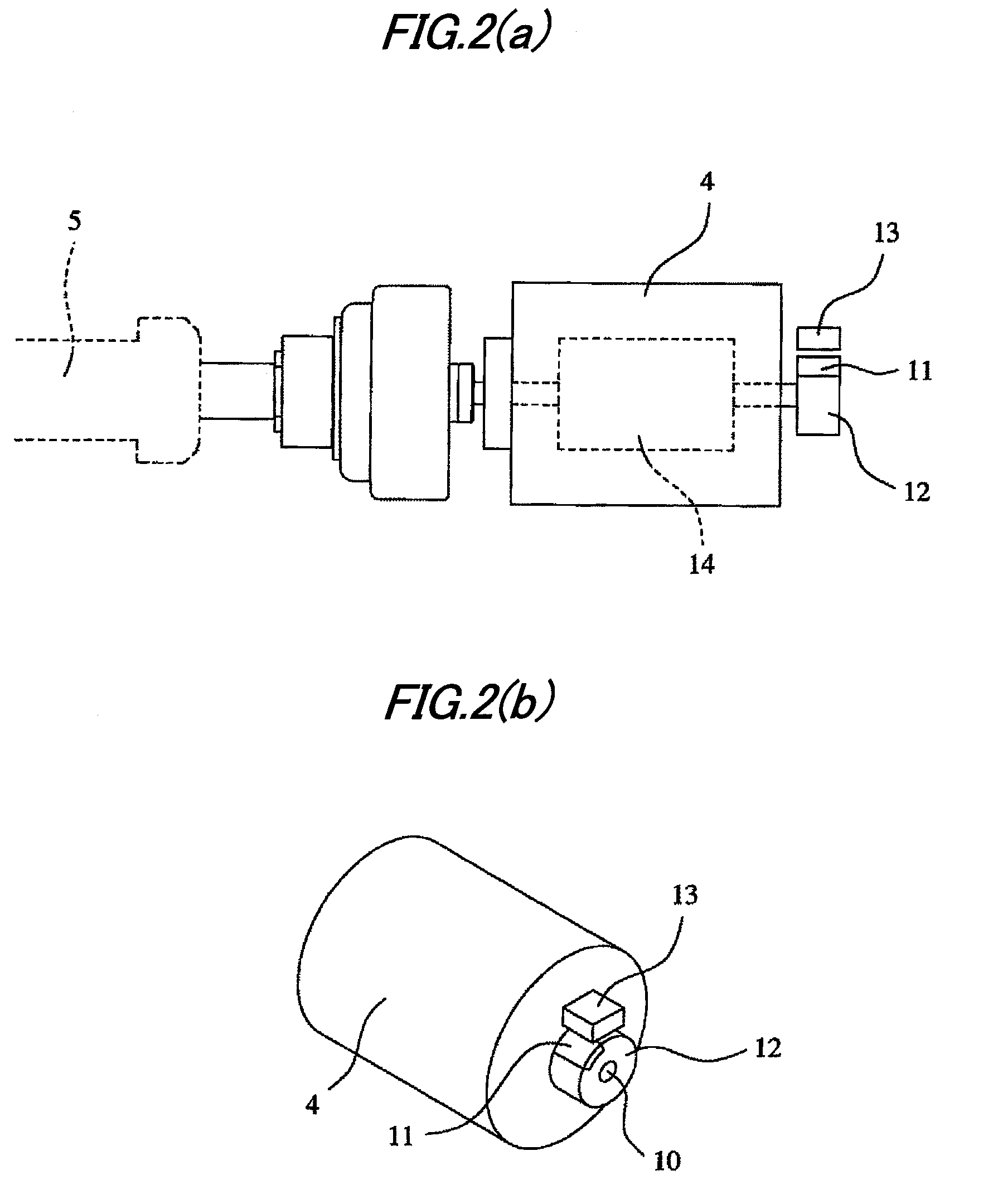

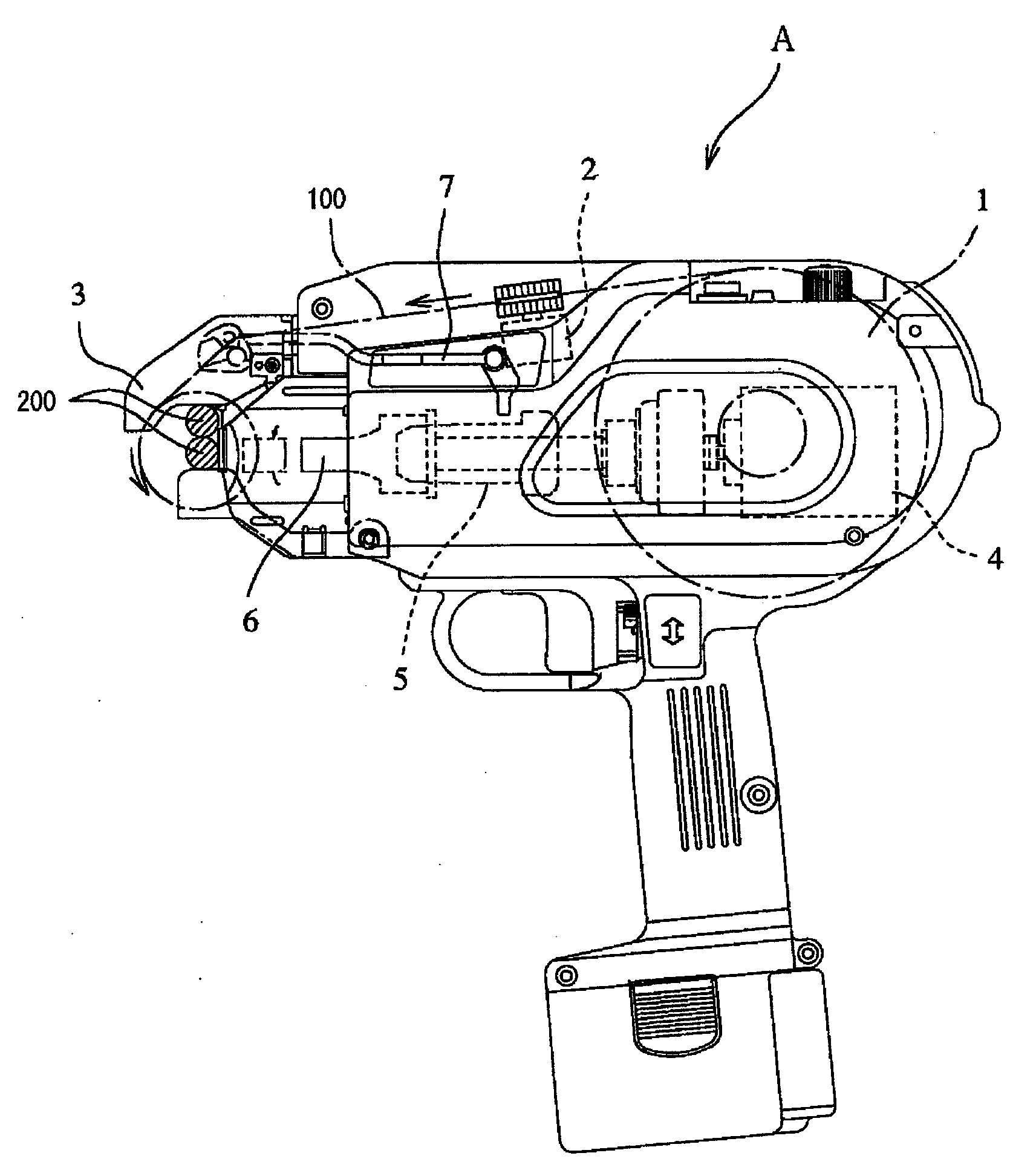

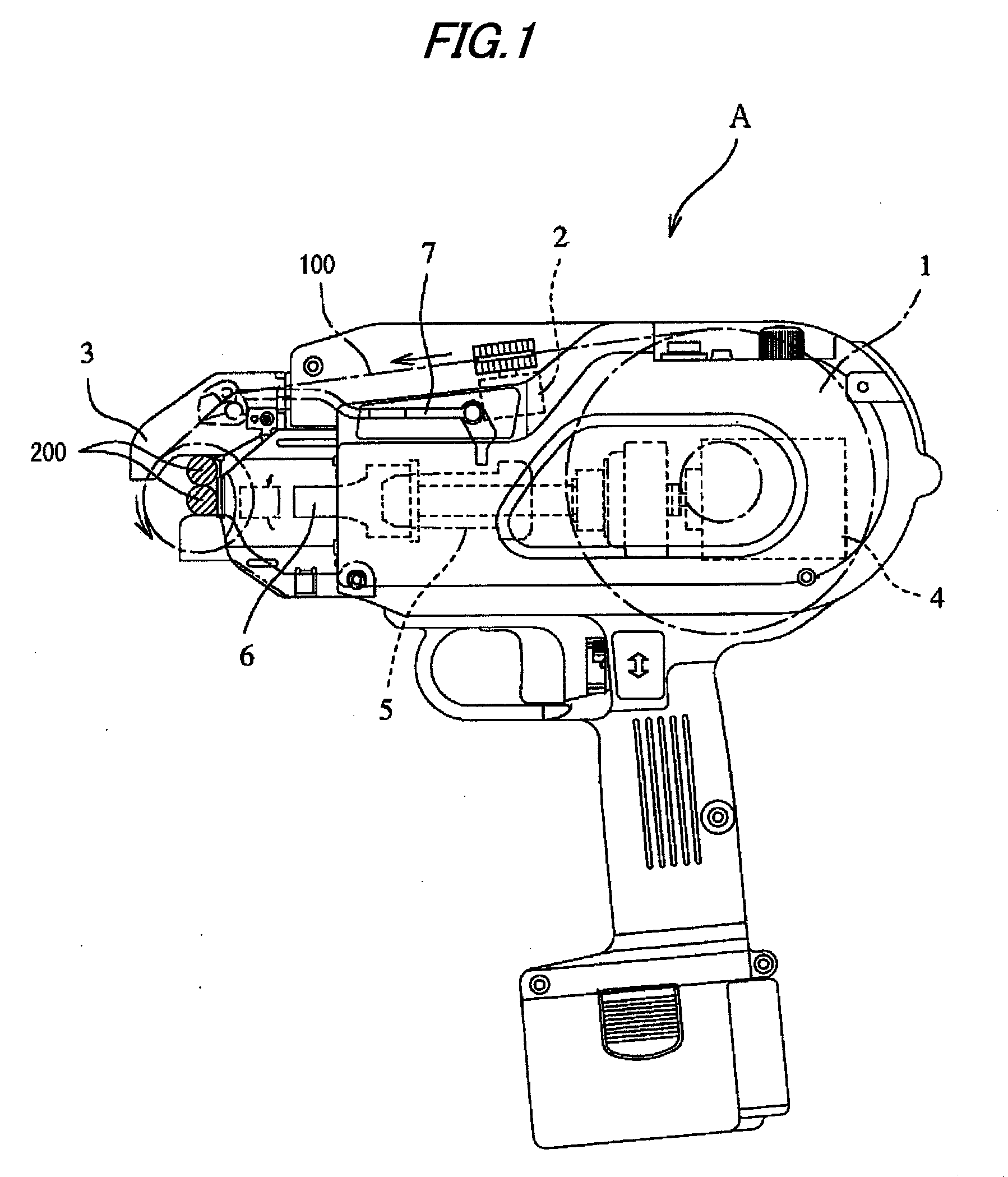

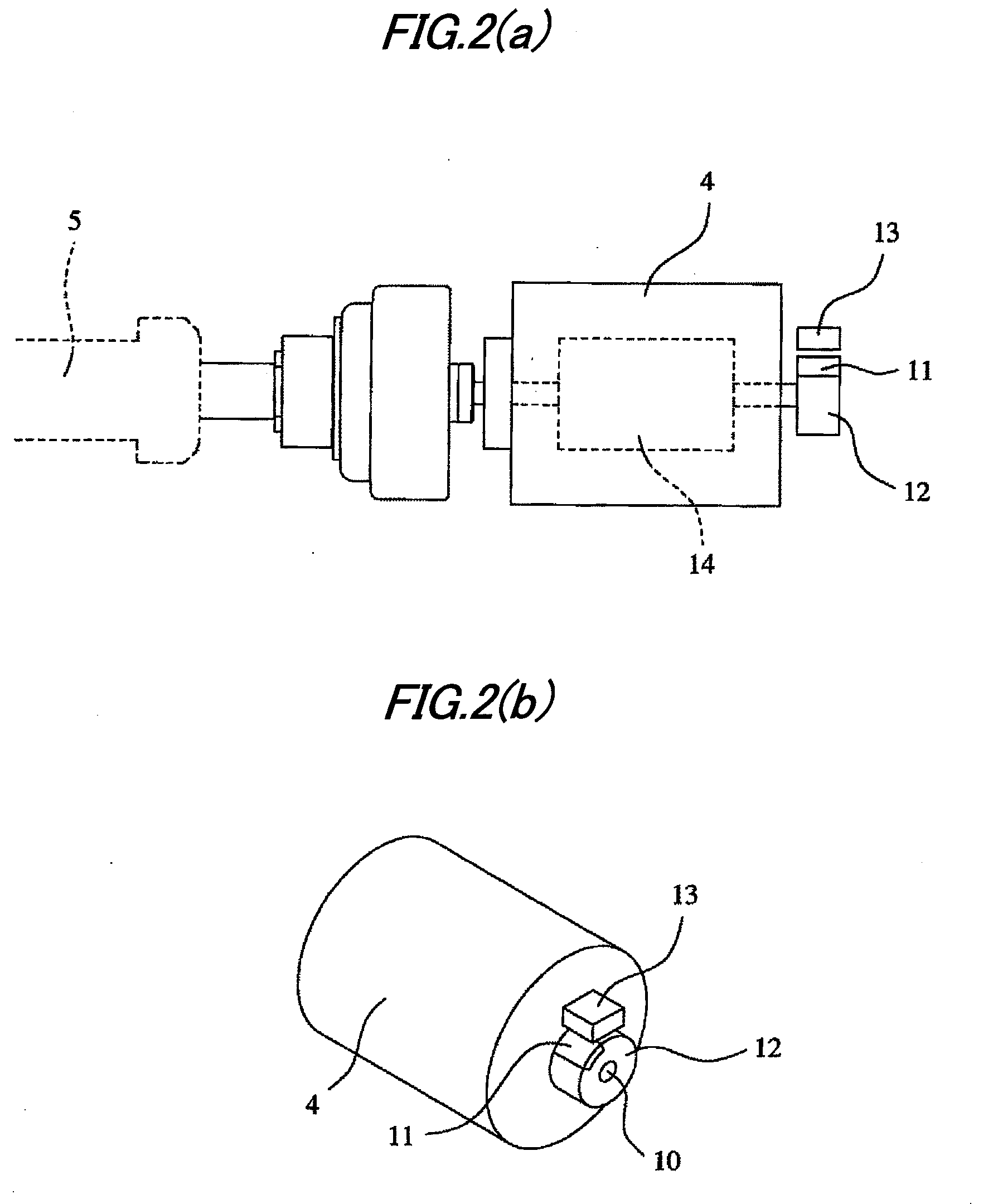

Electric power tool

ActiveUS8198839B2Free from loadReduce in quantitySynchronous motors startersDC motor speed/torque controlBrushless motorsElectric power system

An electric power tool “A” operates a working part 5 by repeating rotation of a motor 4 in a normal direction and in a reverse direction one or more times. The motor 4 includes a brushless motor. Sensors H for detecting a position of a rotor 15 are provided on the motor 4 so as to be advanced by an electrical angle of 30°±θ° from an intermediate position between respective stator teeth 16 in a direction of the normal rotation of the rotor 15. A control part 20 for controlling the rotation of the motor 4 controls a driving signal of the motor 4 based on the results of detection by the sensors H. Moreover, the control part 20 selects a detection signal of the sensors H so that relation between the rotor 15 and the detection signal of the sensors H is equivalent in either of the normal rotation and the reverse rotation of the rotor 15.

Owner:MAX CO LTD

Drive shaft assembly for a downhole motor

ActiveUS8033917B2Improve pronunciationIncrease capacityYielding couplingDrilling rodsRotational axisSpherical bearing

Owner:NOV CANADA ULC

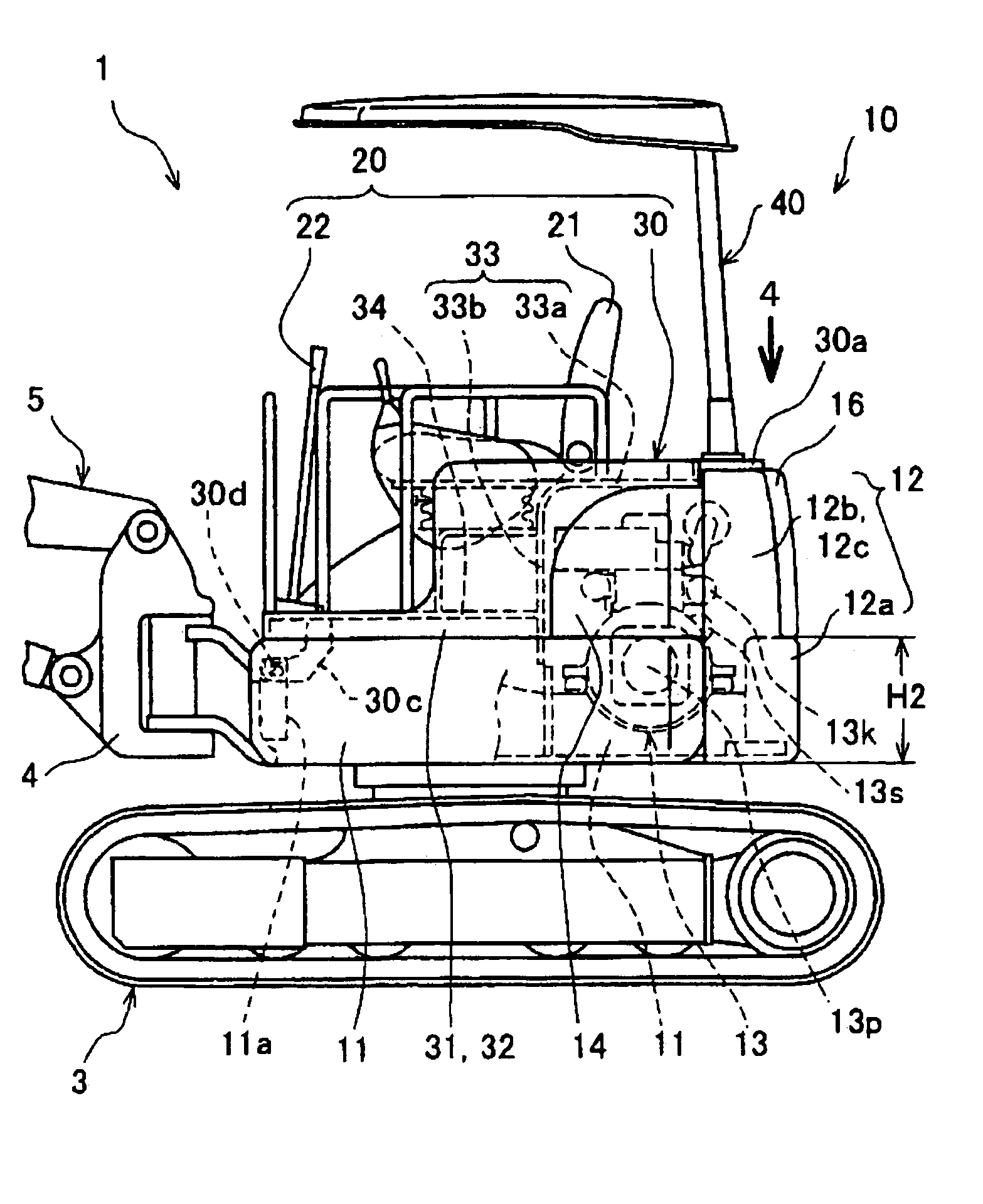

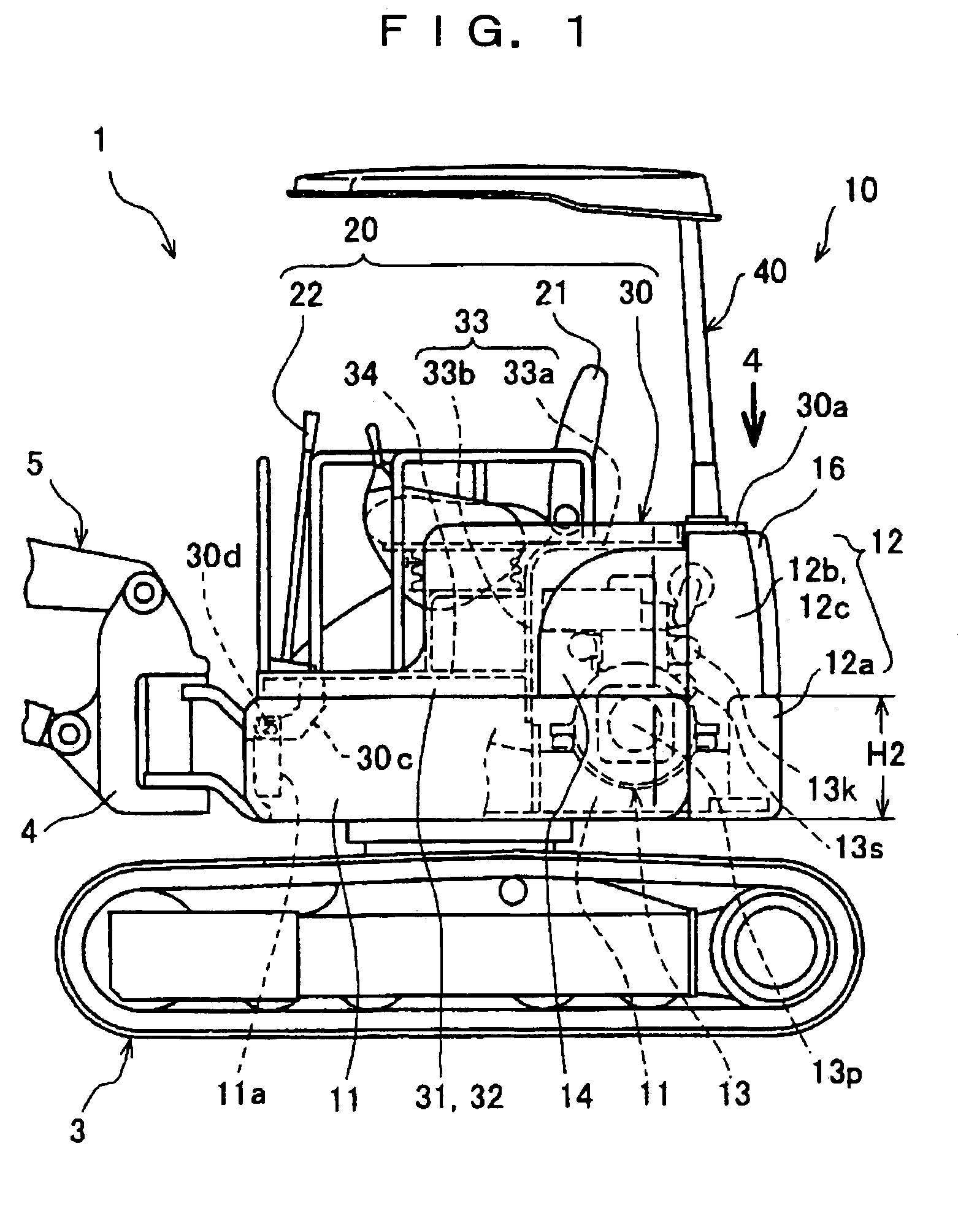

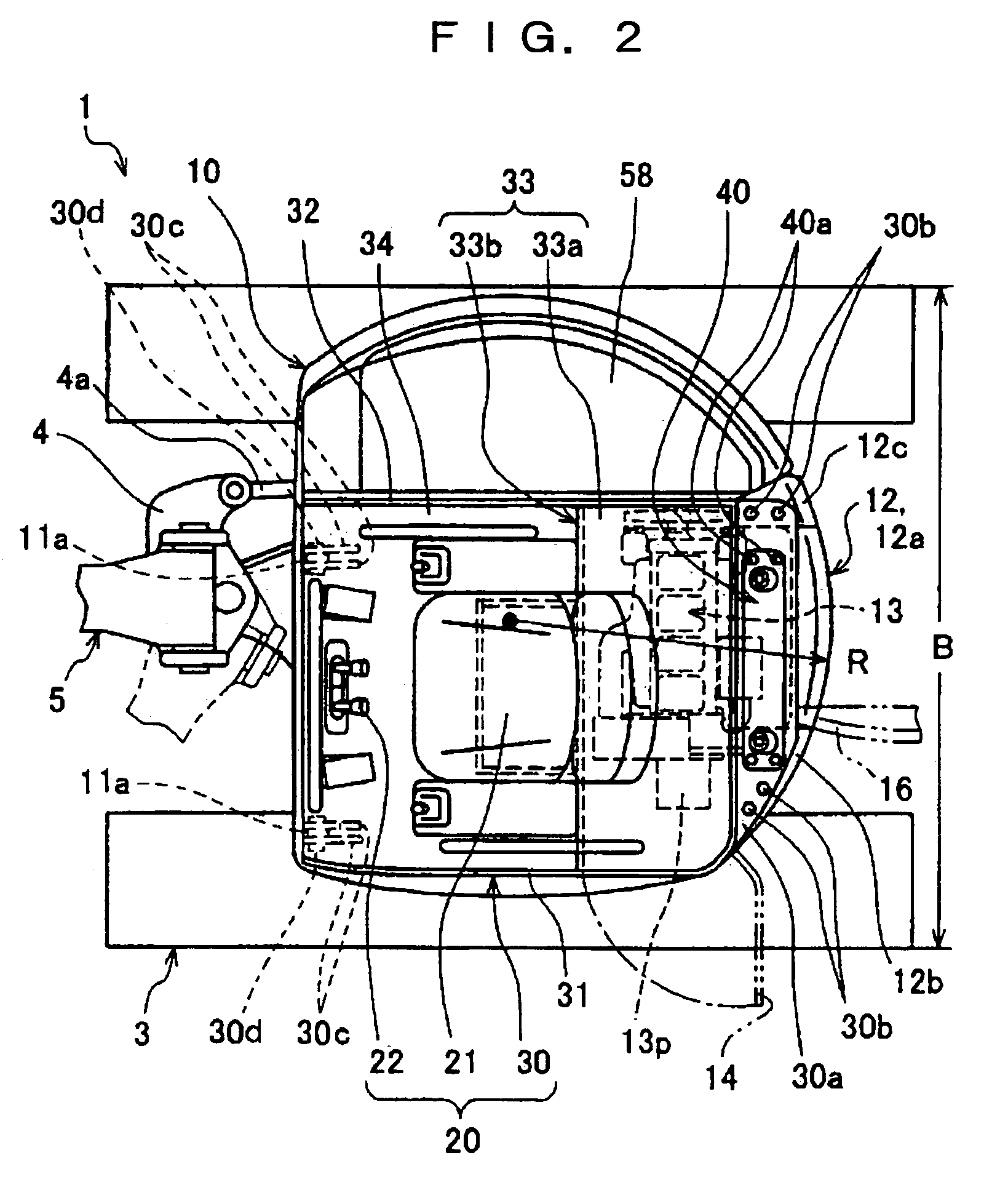

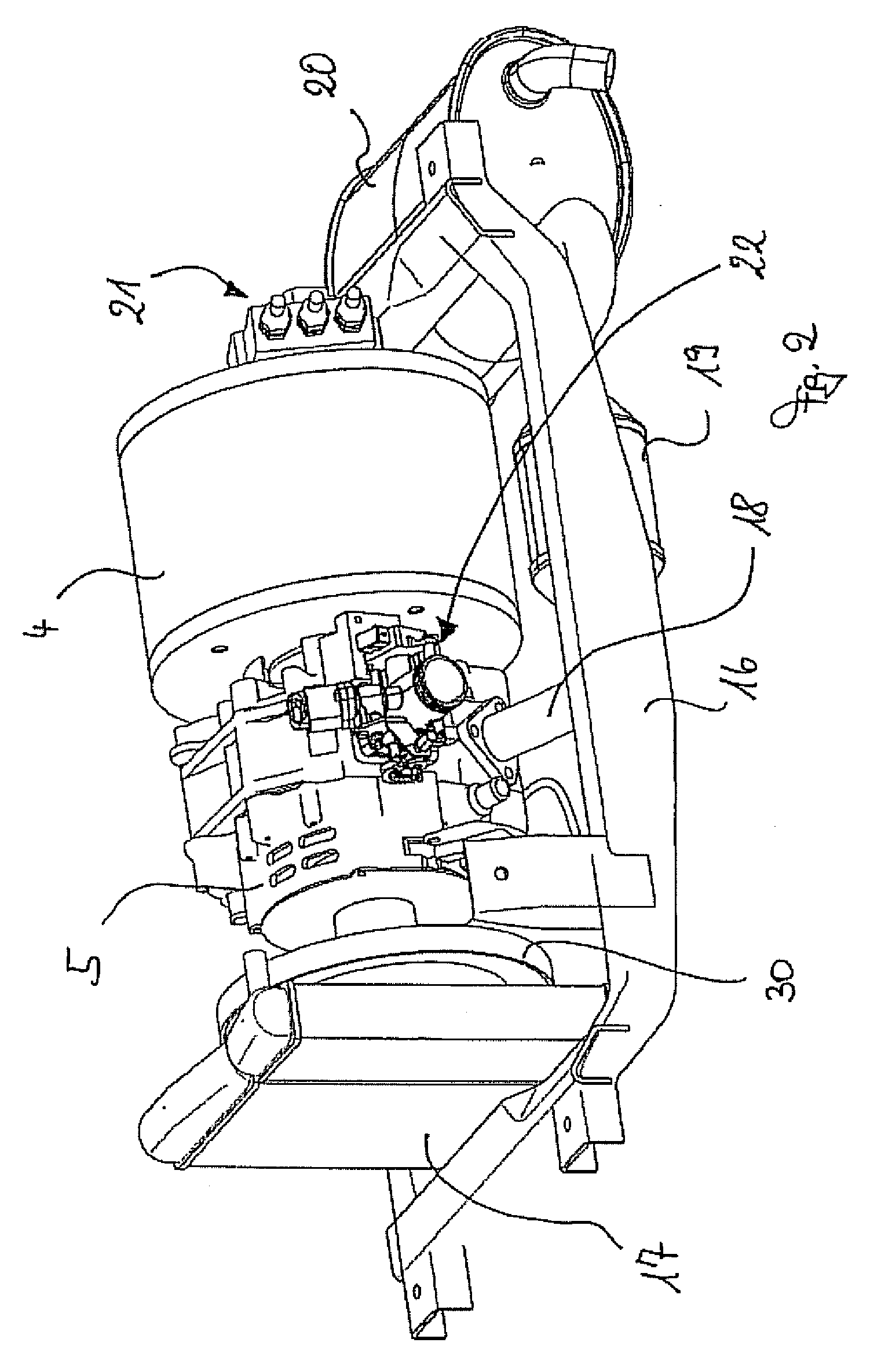

Counterweight for hydraulic shovel

InactiveUS7188865B2Simple structureQuality improvementElectric propulsion mountingGas pressure propulsion mountingEngineeringShovel

A counterweight for a hydraulic shovel, which is applicable to a compact to large-sized hydraulic shovels, and is capable of realizing favorable engine maintainability and assurance of sufficient mass, is provided. For this purpose, supporting column portions (12b, 12c) are vertically provided at left and right of a counterweight (12). The left and right supporting column portions are constituted as an increase amount of mass of the counterweight. At least one of a floor frame (30), a canopy (40), outer casings (14, 16) and engine partition walls (33a, 33b) is supported at the left and right supporting column portions. Further, an engine (13) is placed at a position fronting to between the left and right supporting column portions.

Owner:KOMATSU LTD

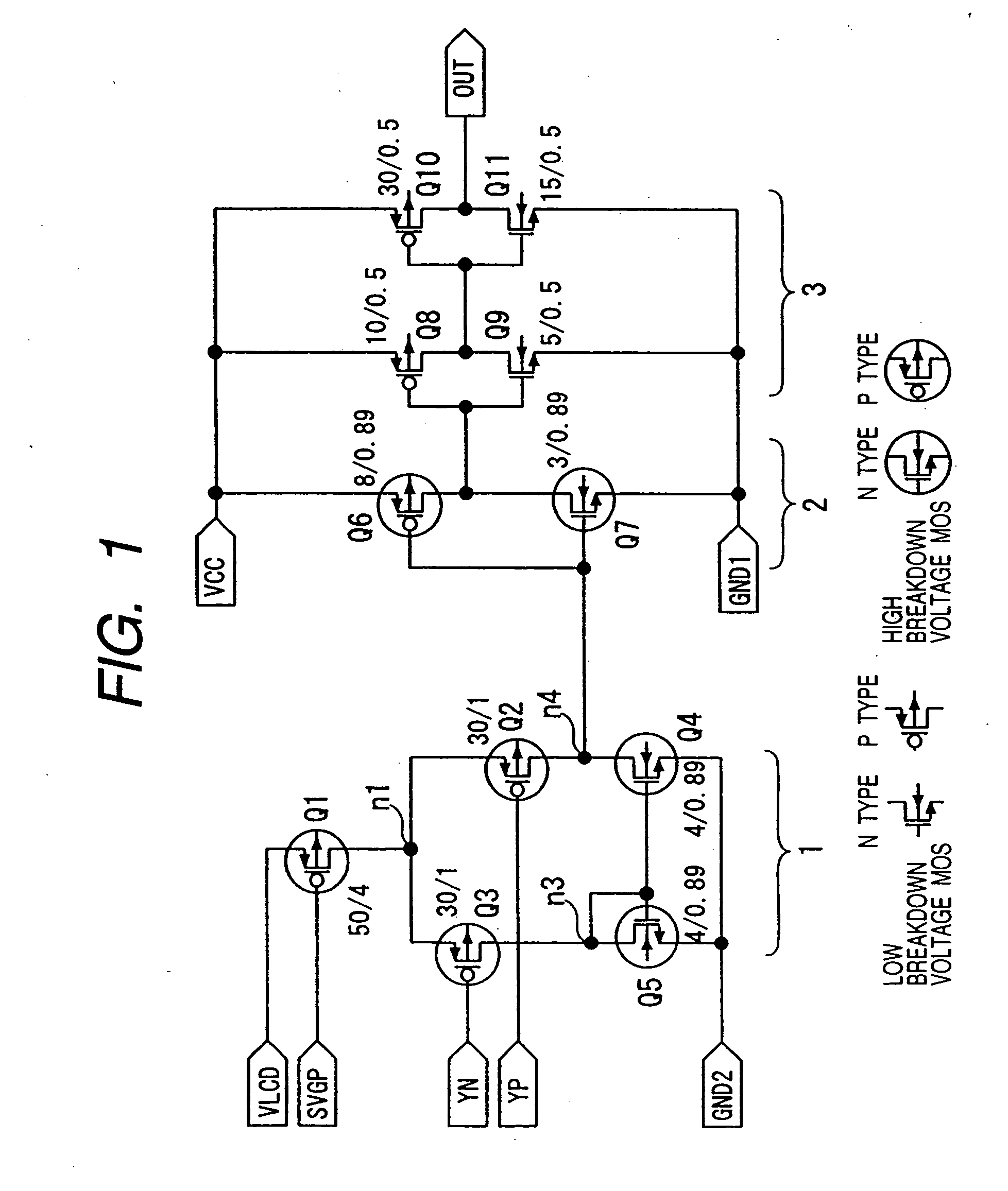

Reference voltage generation circuit, data driver, display device, and electronic instrument

InactiveUS20050207249A1Unnecessary to provideQuick responseAnalogue/digital conversionElectric signal transmission systemsDisplay deviceElectronic instrument

A reference voltage generation circuit includes a gamma correction resistor circuit which outputs reference voltages generated by resistively dividing voltages of two opposite ends of a resistor circuit to resistive division nodes, and high-potential-side-voltage and low-potential side-voltage supply circuits which supply a high-potential-side voltage and a low-potential-side voltage to the two opposite ends, respectively. The high-potential-side-voltage and low-potential side-voltage supply circuits supply the high-potential-side voltage and the low-potential-side voltage to the two opposite ends, respectively, by switching the high-potential-side voltage and the low-potential-side voltage for each of color components which form one pixel, the high-potential-side voltage and the low-potential-side voltage being provided for each of the color components. The gamma correction resistor circuit supplies the reference voltages switched for each of the color components to reference voltage signal lines to be selected as inputs of driver sections which drive data lines of an electro-optical device.

Owner:SEIKO EPSON CORP

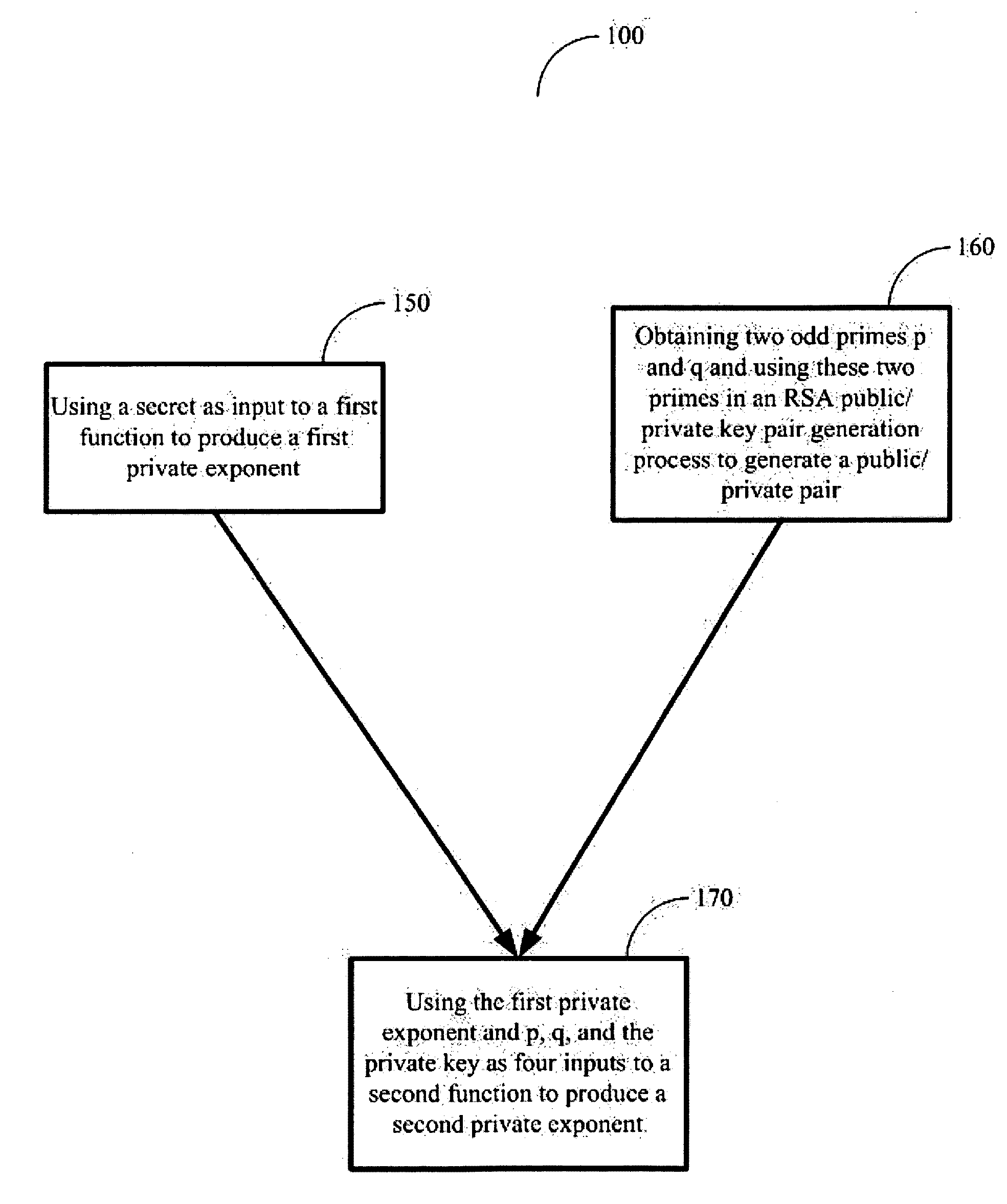

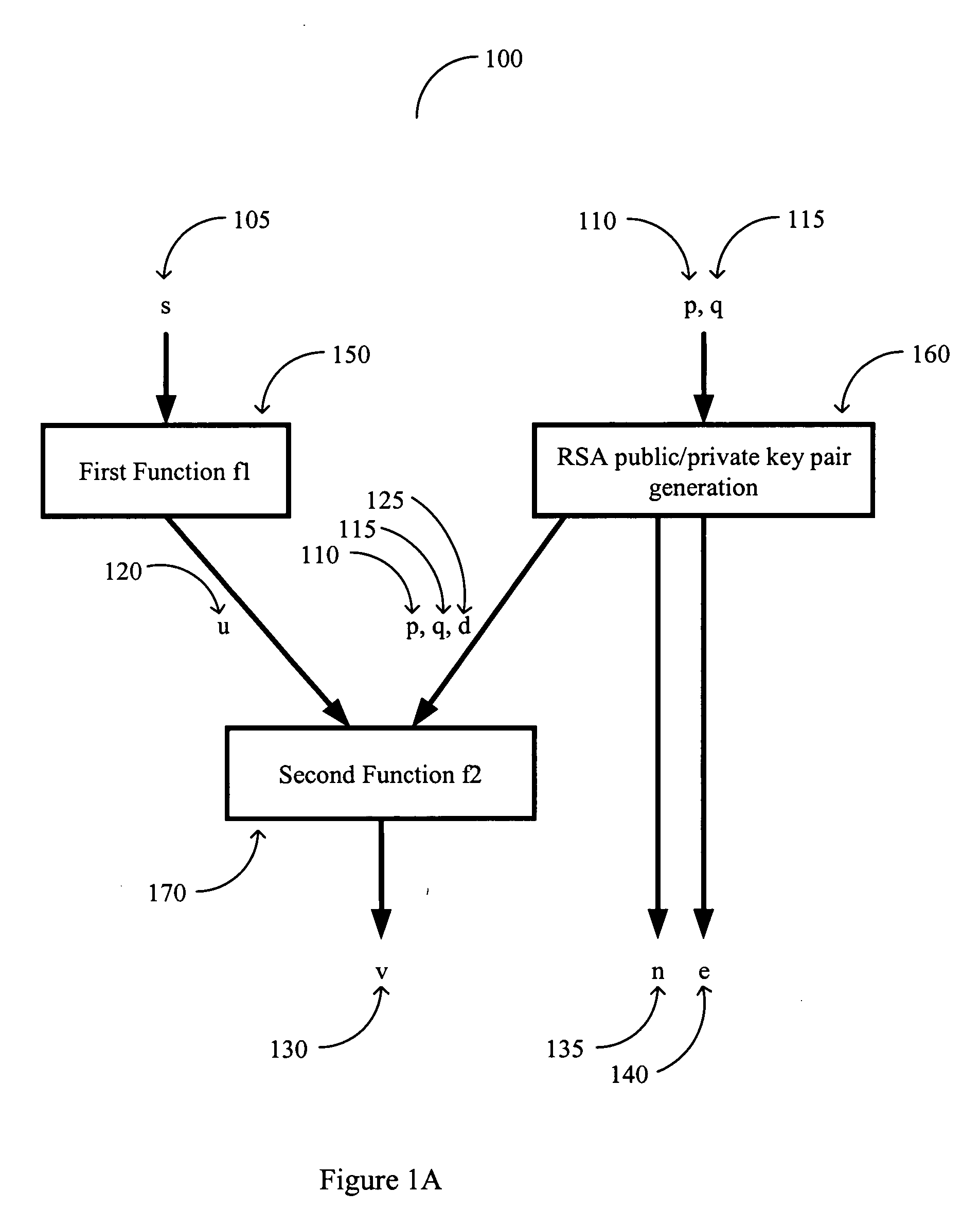

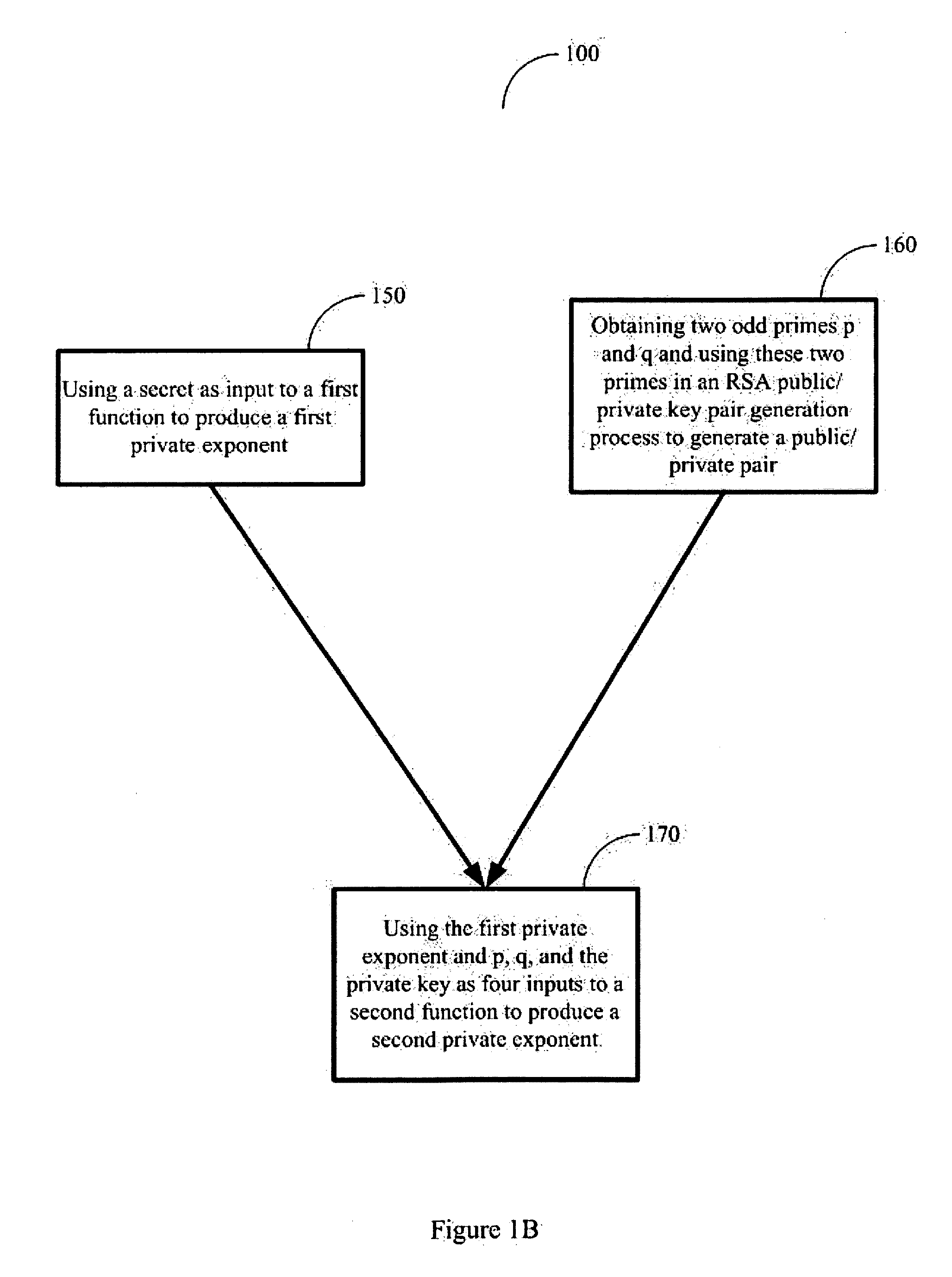

RSA with personalized secret

InactiveUS20060083370A1Improve confidentialityUnnecessary to provideSecret communicationSecuring communicationPersonalizationCryptographic key generation

The present invention creates flexibility into the RSA cryptography. The goal is achieved by allowing a user to select a personalized secret such as a password to derive an exponent that functions like a leading part of the RSA private key, and by further allowing the user to discretionarily change the selection without resorting to a regeneration of the public / private key pair. The invention also includes methods and cryptosystems of using a personalized secret and a crypto-key trio to produce and validate a digital signature. Exchanging a symmetric crypto key between two communication parties is one further application utilizing the devised techniques for the crypto-key generation, update, and validation.

Owner:CHANG GUNG UNIVERSITY

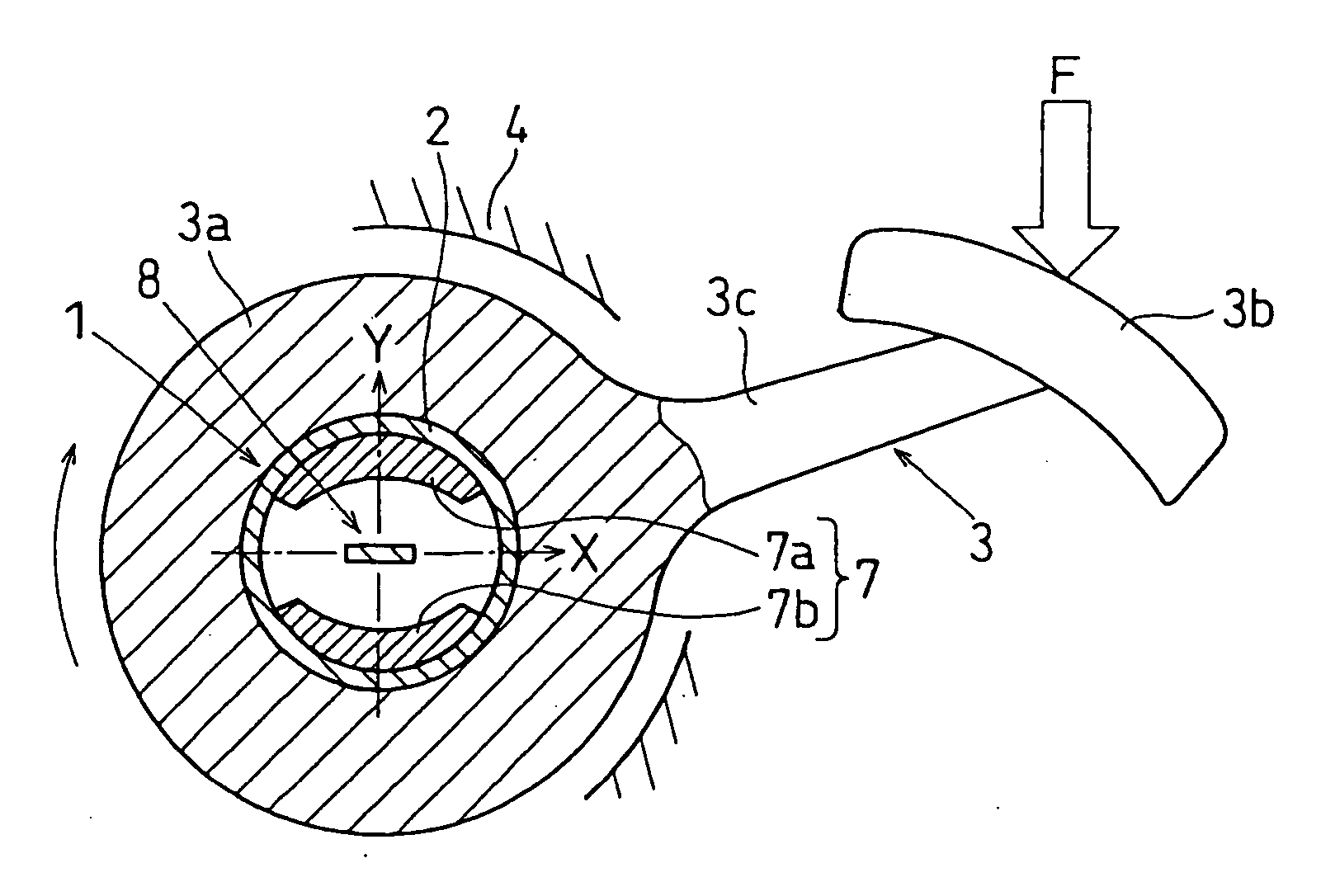

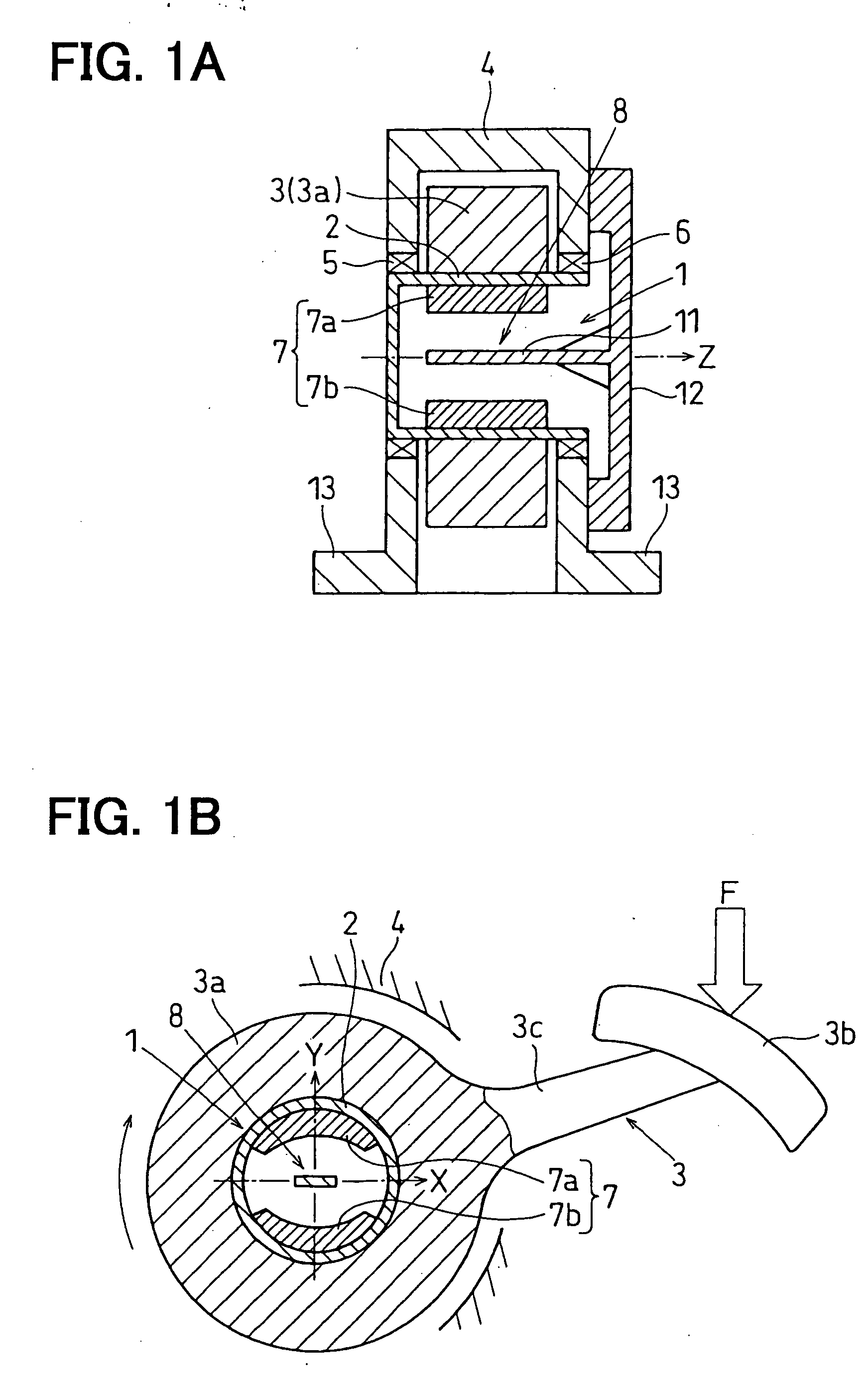

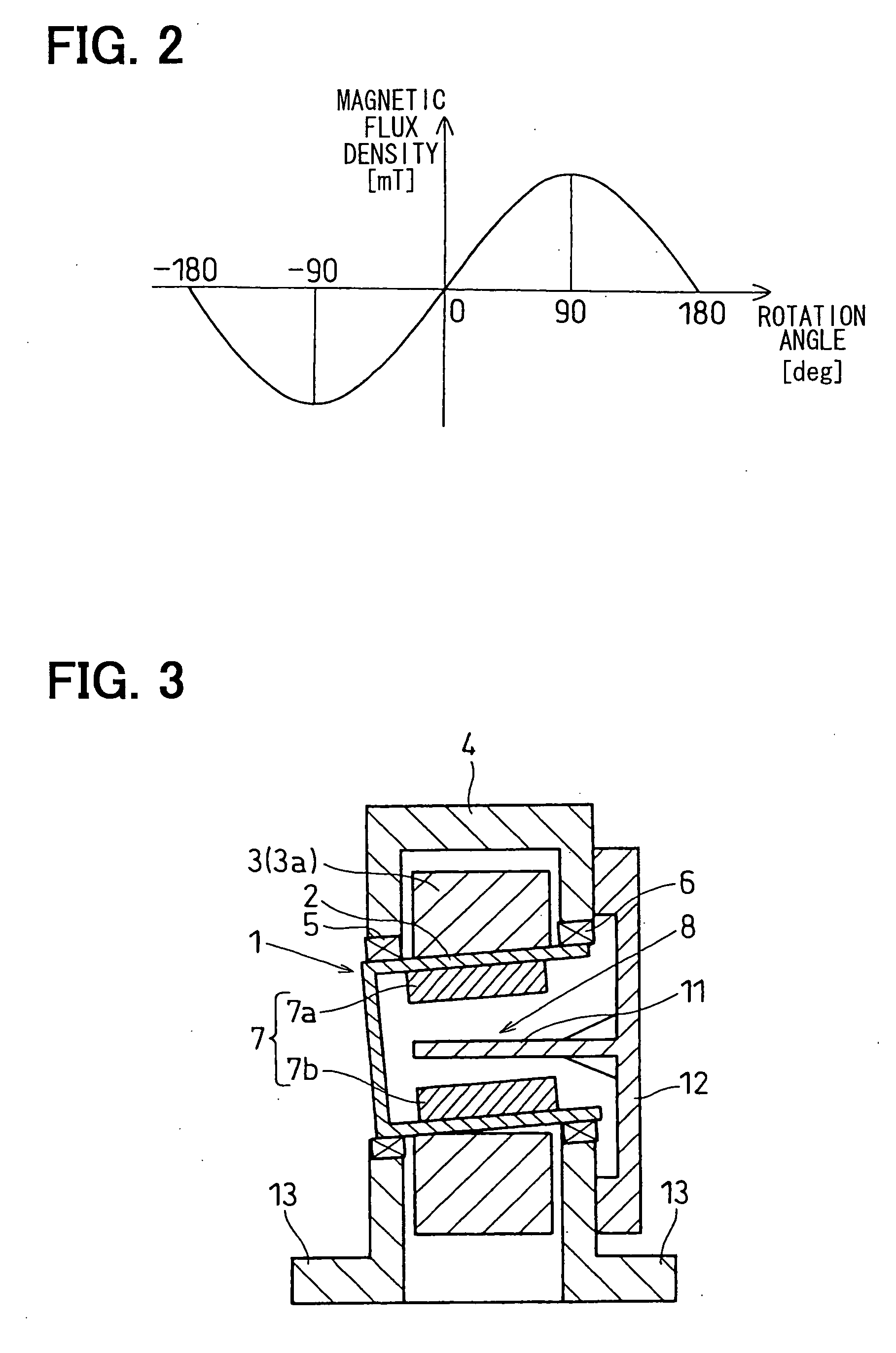

Rotation angle detection device

InactiveUS20070103149A1Deterioration can be suppressedLow costControlling membersSolid-state devicesMagnetic tension forceEngineering

A rotation angle detection device for detecting a rotation angle of an object has a substantially cylinder-shaped yoke, a magnetism generation unit which is fixed to an inner surface of the yoke, a magnetism detection member which is arranged substantially in a center axis of the yoke, at least one bearing which rotatably supports the yoke, and a support member which holds the bearing. The yoke is made of a magnetic metal, and fixedly mounted at the object to be rotatable integrally with the object. The magnetism generation unit generates a magnetic field substantially perpendicular to the center axis of the yoke. The magnetism detection member generates an output corresponding to a variation of the magnetic field to detect the rotation angle of the object relative to the magnetism detection member.

Owner:DENSO CORP

Electric power tool

ActiveUS20090160373A1Free from loadReduce in quantityAC motor controlDC motor speed/torque controlBrushless motorsElectric power system

An electric power tool “A” operates a working part 5 by repeating rotation of a motor 4 in a normal direction and in a reverse direction one or more times. The motor 4 includes a brushless motor. Sensors H for detecting a position of a rotor 15 are provided on the motor 4 so as to be advanced by an electrical angle of 30°±θ° from an intermediate position between respective stator teeth 16 in a direction of the normal rotation of the rotor 15. A control part 20 for controlling the rotation of the motor 4 controls a driving signal of the motor 4 based on the results of detection by the sensors H. Moreover, the control part 20 selects a detection signal of the sensors H so that relation between the rotor 15 and the detection signal of the sensors H is equivalent in either of the normal rotation and the reverse rotation of the rotor 15.

Owner:MAX CO LTD

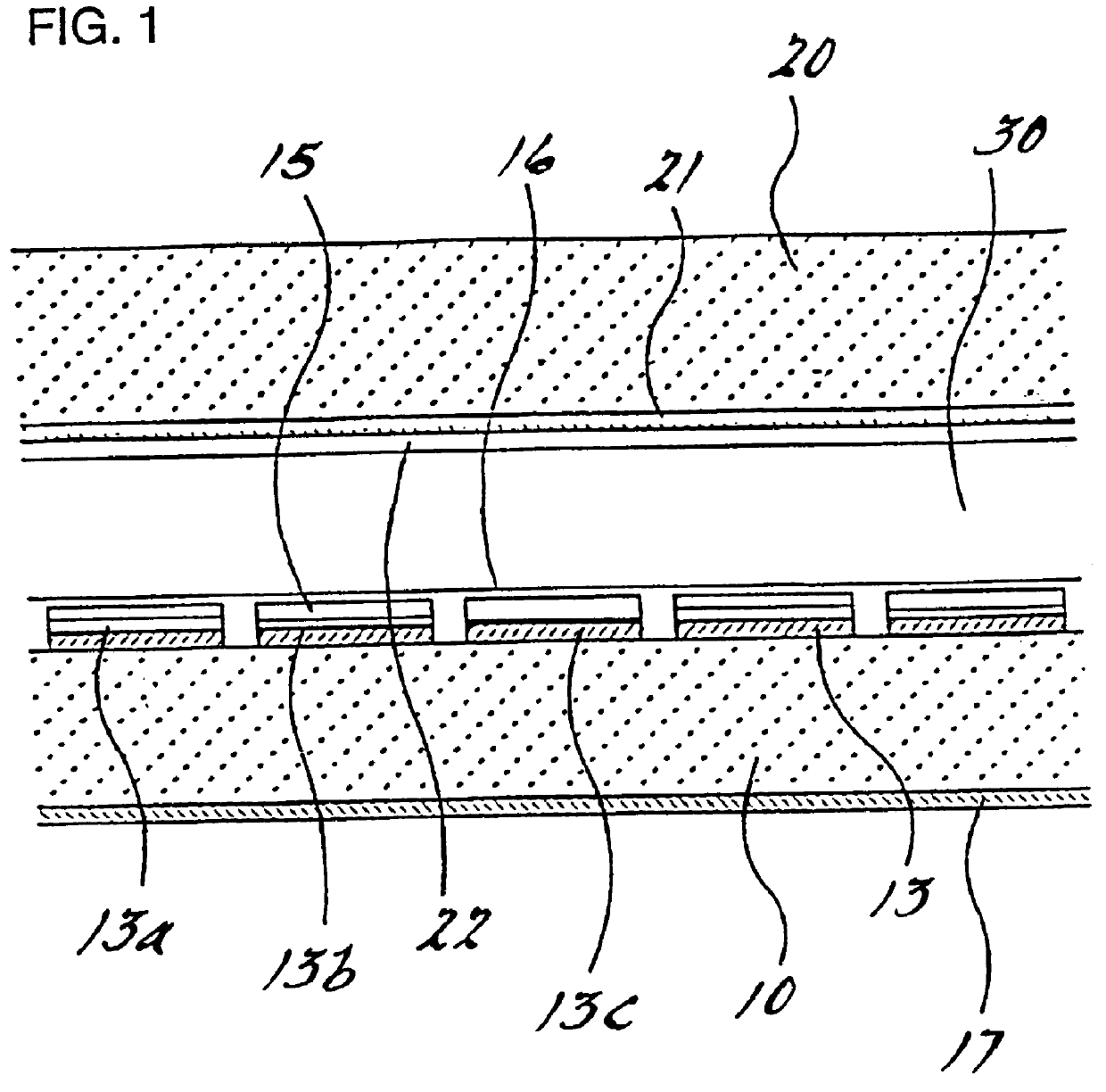

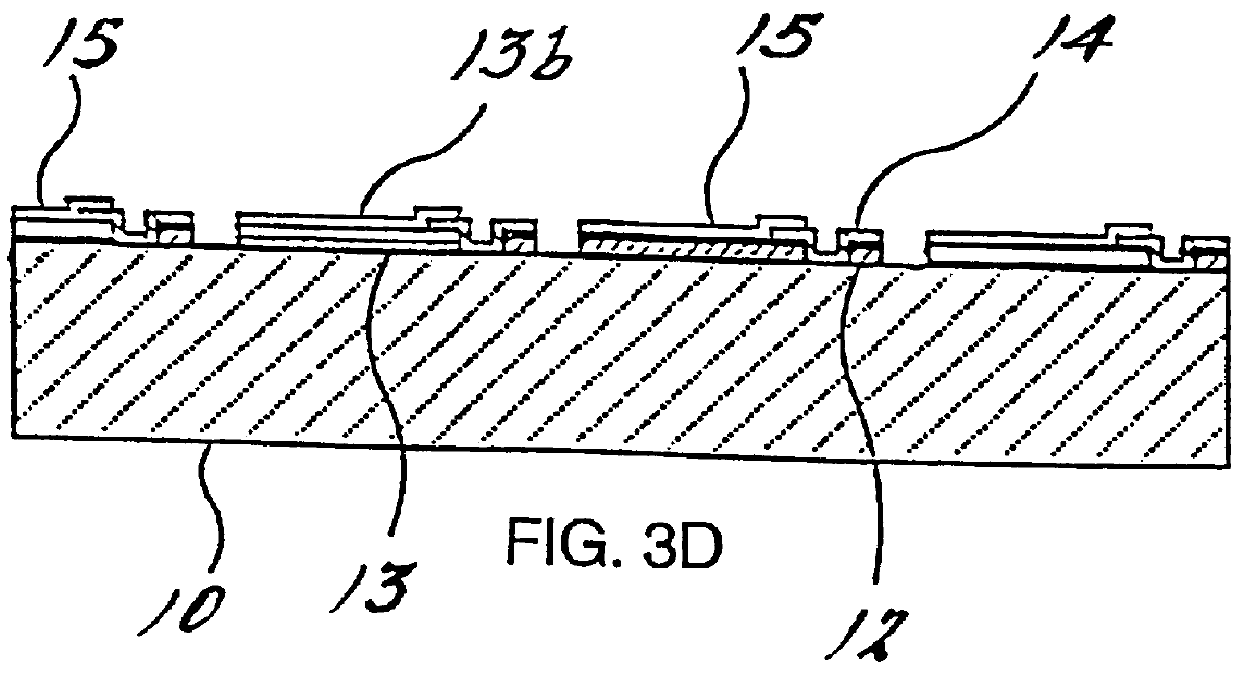

Liquid-crystal display unit, and process for manufacturing the same

InactiveUS6104459AExpansion quantityEasy to manufactureNon-linear opticsLiquid-crystal displayEngineering

PCT No. PCT / JP97 / 02426 Sec. 371 Date Mar. 10, 1998 Sec. 102(e) Date Mar. 10, 1998 PCT Filed Jul. 11, 1997 PCT Pub. No. WO98 / 02775 PCT Pub. Date Jan. 22, 1998The present invention provides a liquid-crystal display device and a process for manufacturing the same, wherein the unit achieves an inhibition of reduction in the displaying brightness even when used for a color reflection-type liquid-crystal display device, and a restriction of variation in the color tone which varies depending on the quantity of incident light. For each of the pixel regions, a pixel reflective layer 13 is formed with Ta. On the surface of each of a plurality of the pixel regions, three anodic oxide films 13a, 13b and 13c are formed with mutually different thicknesses. The thicknesses of the anodic oxide films are determined such that light reflected by the pixel reflective layer 13 is colored into three different colors.

Owner:SEIKO EPSON CORP

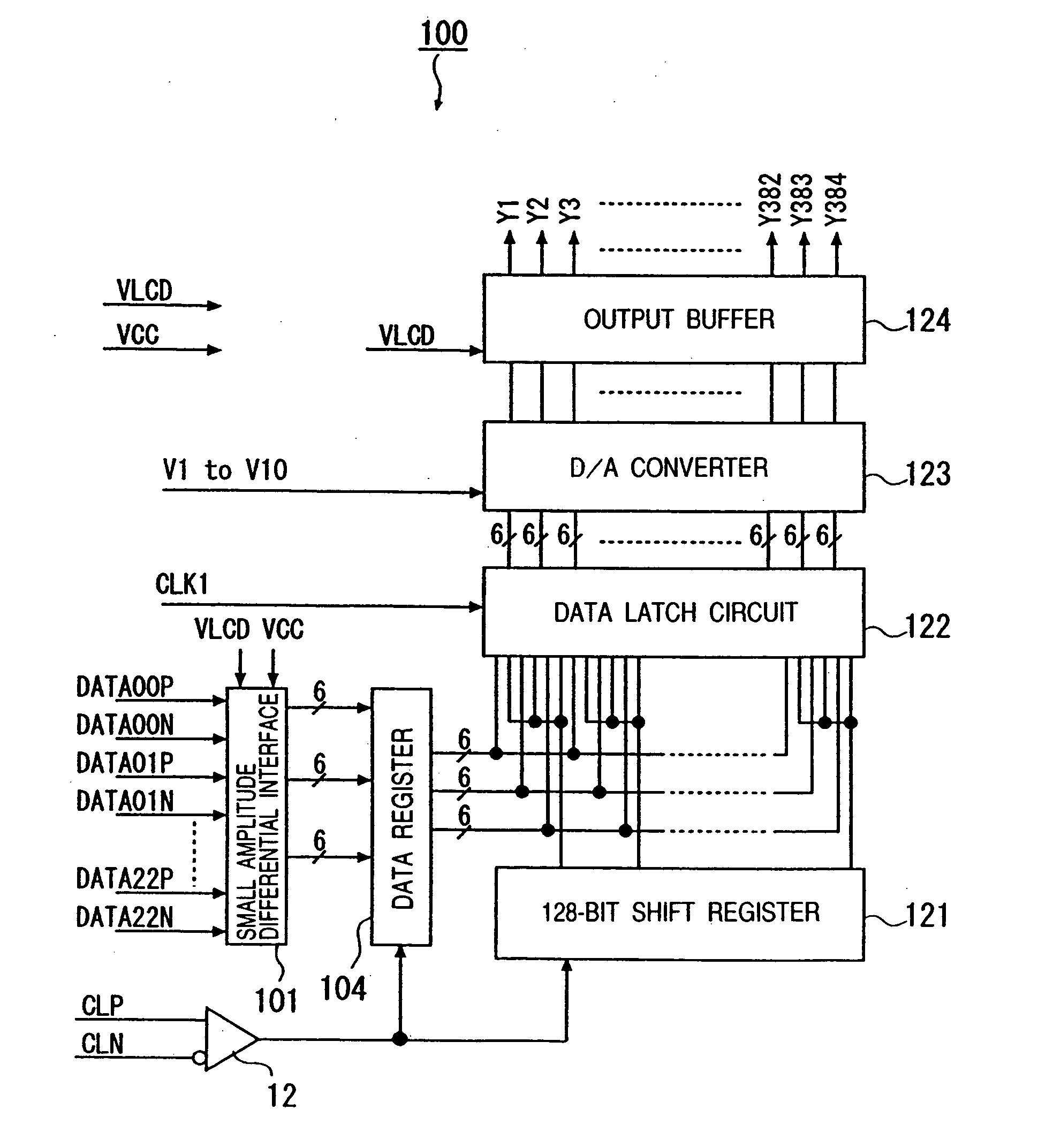

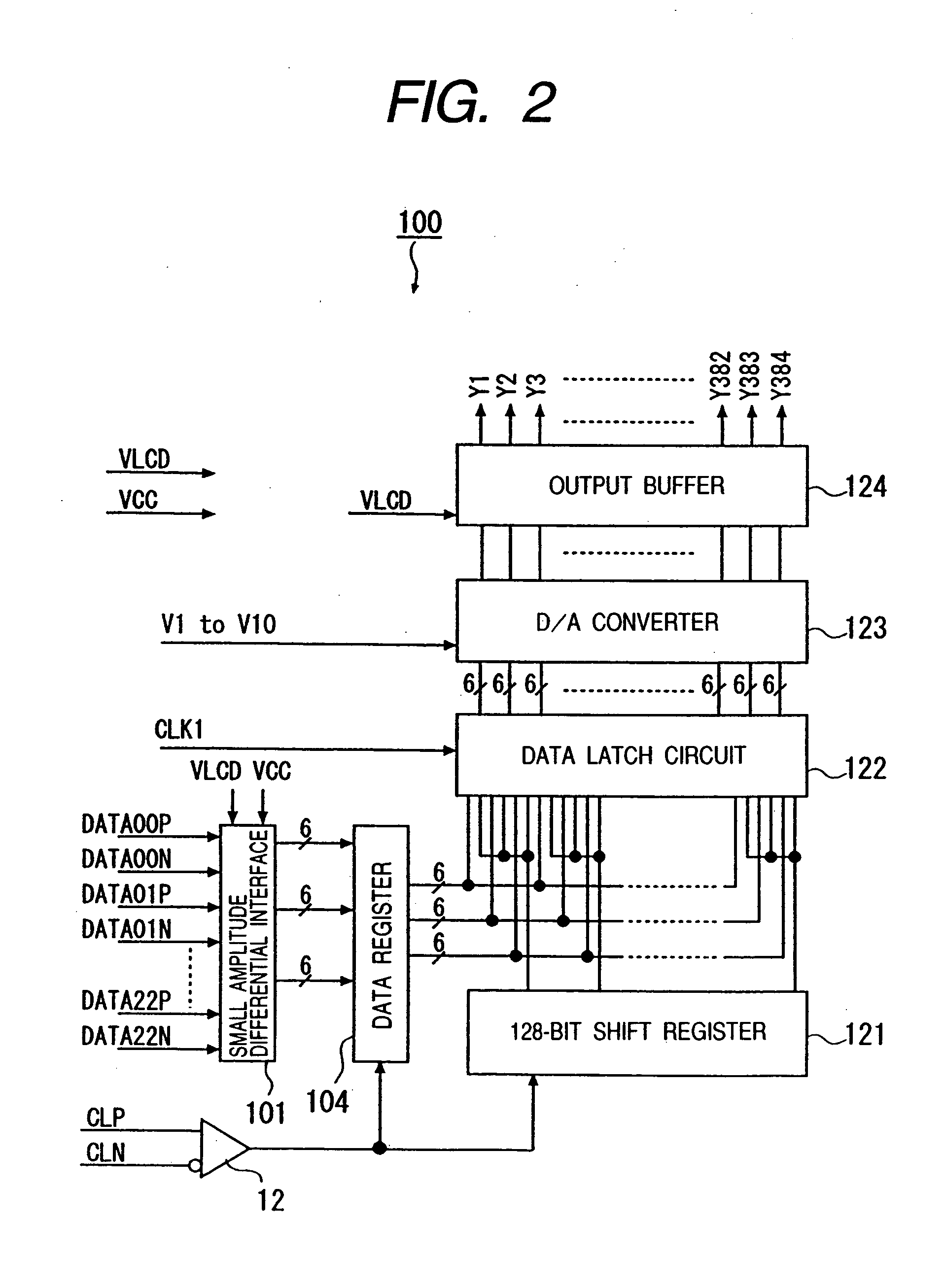

Semiconductor integrated circuit, liquid crystal drive device, and liquid crystal display system

InactiveUS20050146493A1Easy to adjustReduce impactCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displaySignal on

A liquid crystal drive device having a differential-type input circuit including a differential amplification stage for receiving a differential signal and a buffer stage for generating an output signal on the basis of an output of the differential amplification stage, the liquid crystal drive device for receiving a signal of display data via the input circuit and outputting a signal for driving a liquid crystal panel on the basis of the display data, wherein a liquid crystal driving voltage VLCD larger than a power supply voltage VCC for logic to be supplied to the operation voltage buffer stage is supplied to the differential amplification stage of the input circuit. A standby function of interrupting an operation current of the differential amplification stage in a period where no display data is received is provided.

Owner:RENESAS ELECTRONICS CORP +1

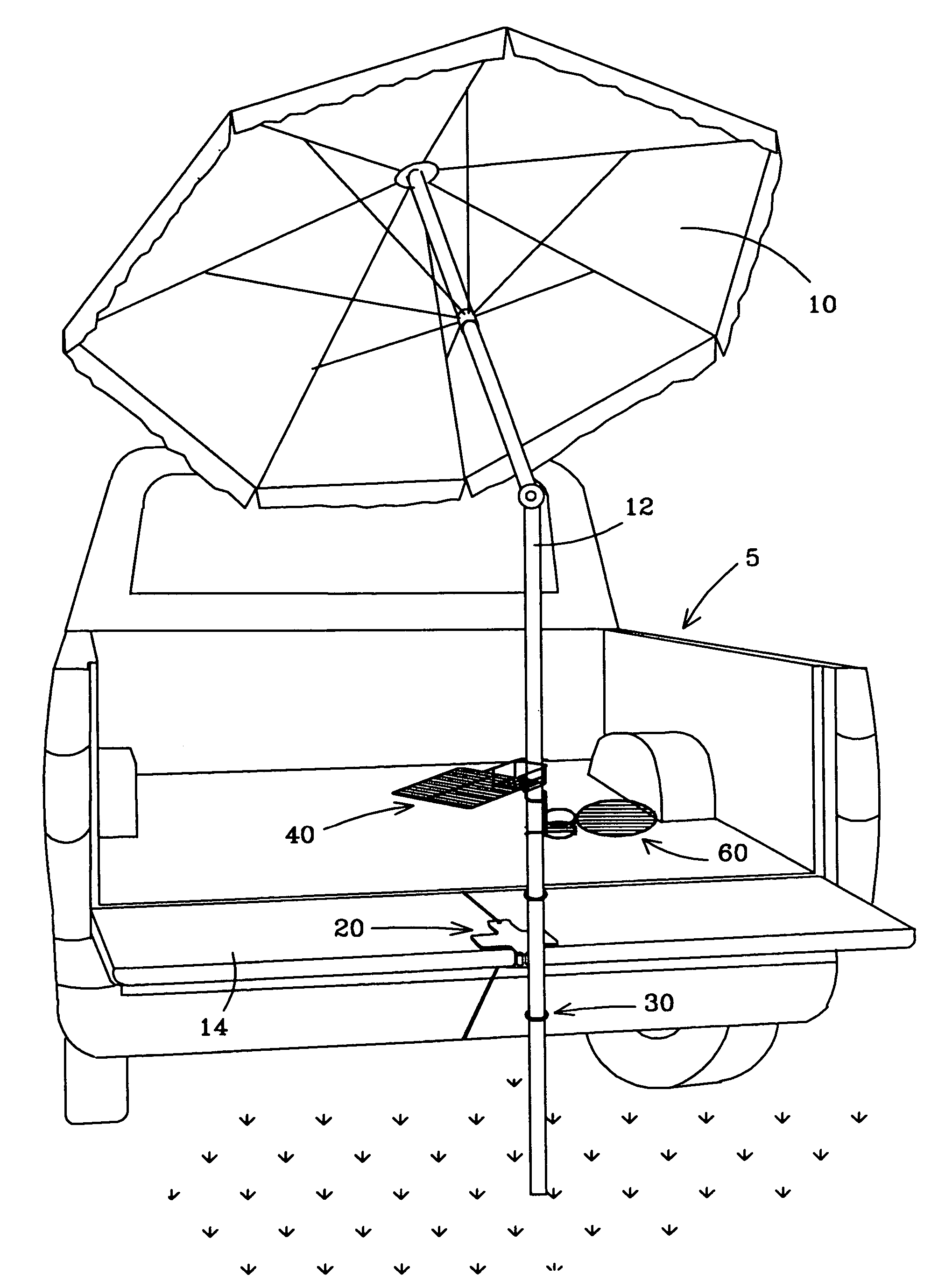

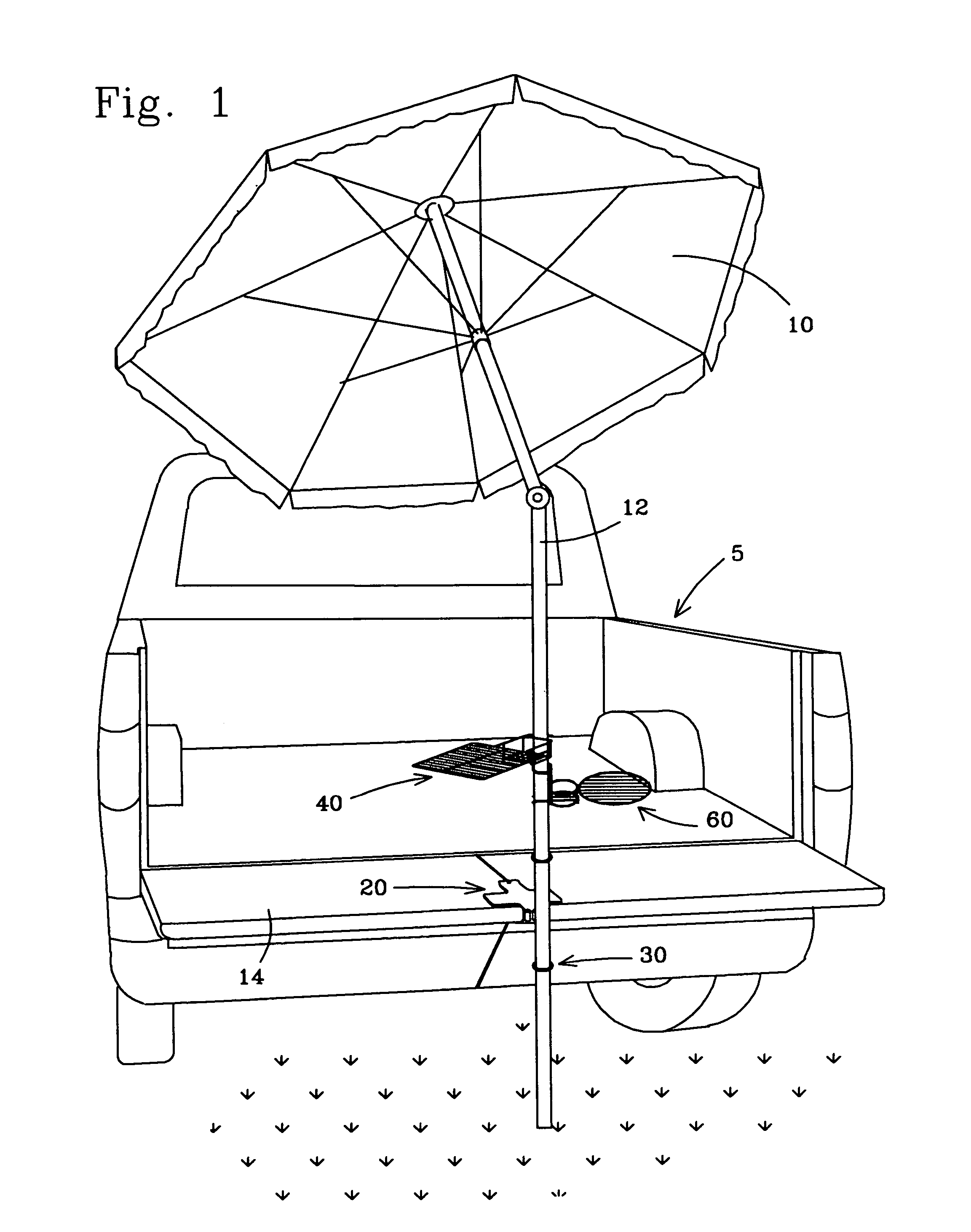

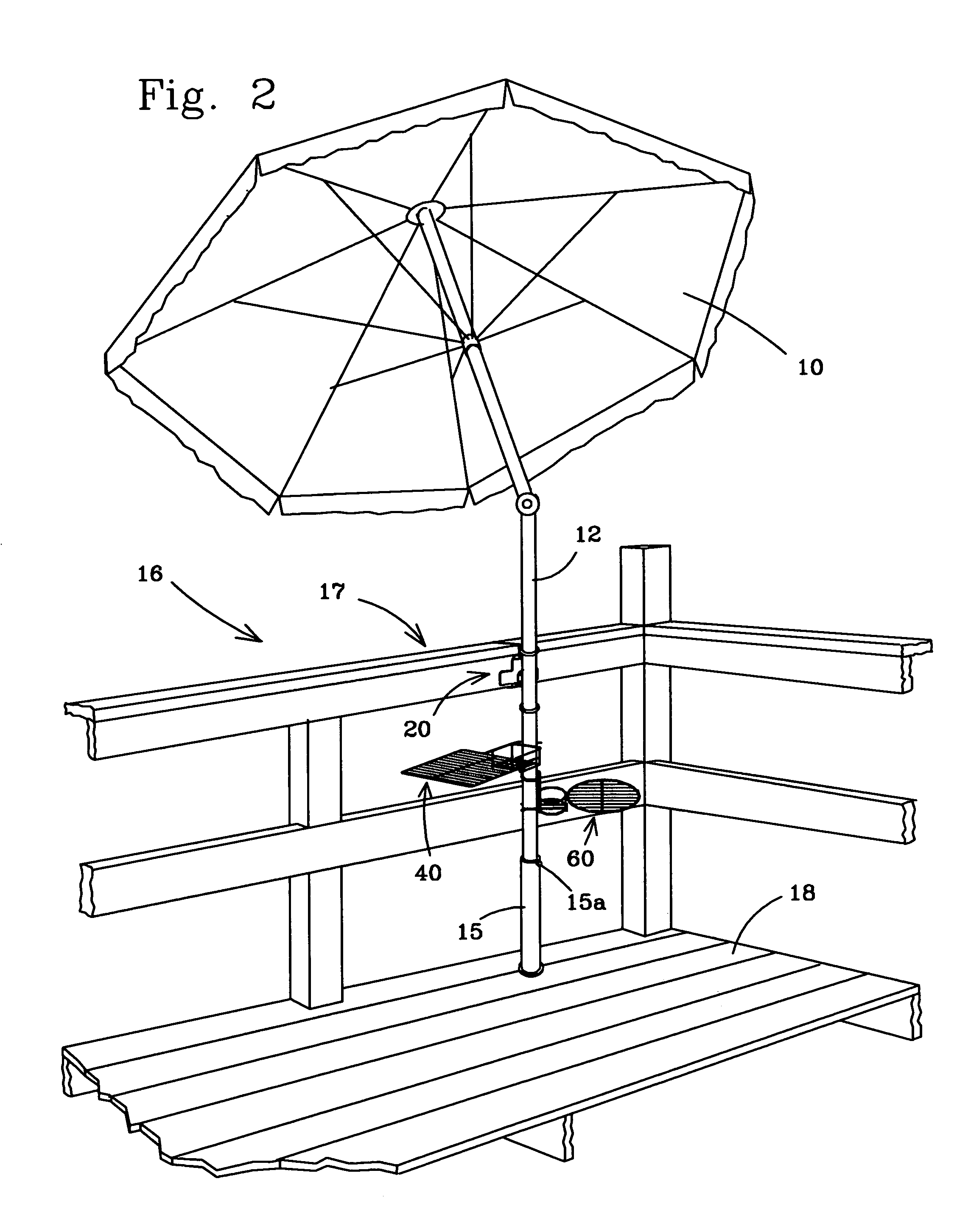

Umbrella support device and serving trays

InactiveUS7334593B2Provide protectionUnnecessary to provideCandle holdersLighting support devicesEngineeringMechanical engineering

The present invention provides a support device associated with an object such as a vehicle tailgate or a residential deck for holding an umbrella with an umbrella pole supporting at least one serving tray to provide shade from the sun for a user occupying a portion of the object. The support device comprises a bent plate support in contact with the object. At least one retainer strap with a hook at each end holds the bent plate in contact with the object. An umbrella pole support is connected to the bent plate support to receive and help hold the umbrella pole. At least one support collar is welded to the bent plate to receive and support the umbrella pole support. Additional accessories and applications are also realized within the scope of this invention including a fishing pole holder, a bowl holder and a light assembly for night use.

Owner:AVERY BRYAN K

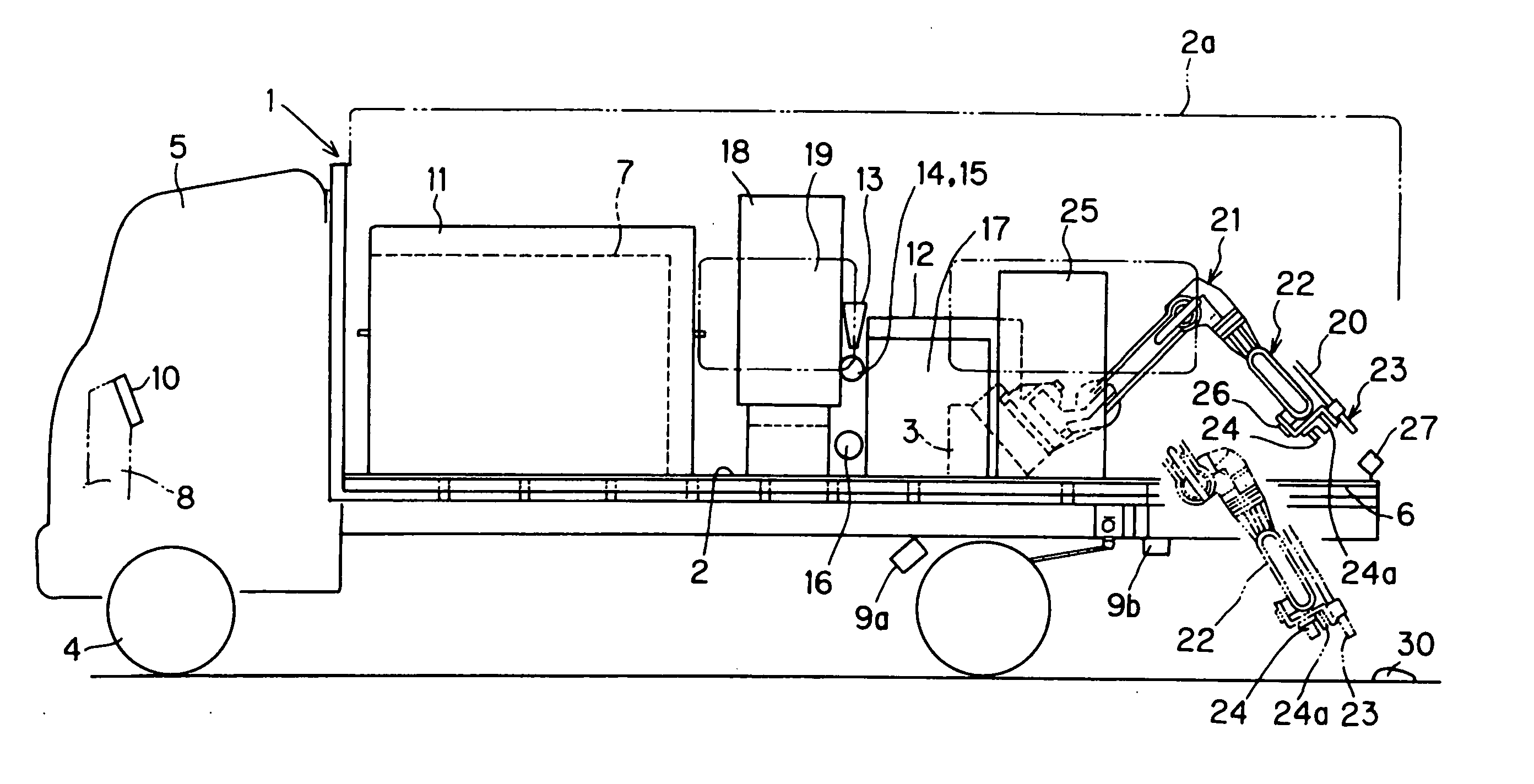

Method and system for cleaning

ActiveUS20070037484A1Environmental loading can be suppressedImprove propertiesGrinding feed controlTraffic signalsRoad surfaceEngineering

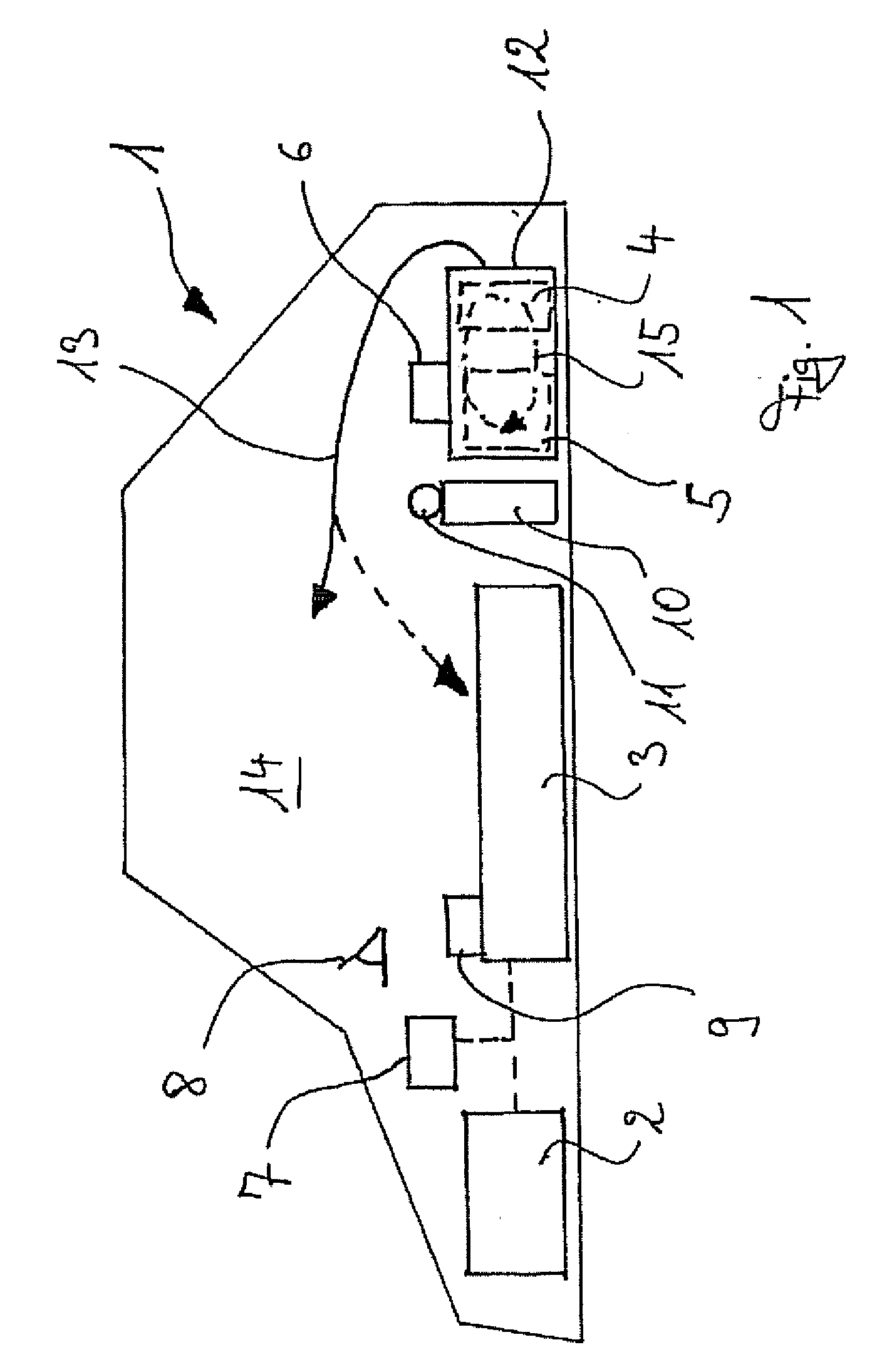

A method and a system for cleaning the glass surface of an object, such as a surface light, a run way guide light, or a reflector, installed on various pavements or roads, by propelling a cleaning agent from a blast nozzle to the glass surface. The blast nozzle is installed on the front end of an arm of a working robot mounted on a truck. A truck mounted with a cleaning agent blaster and a working robot (21) provided with a blast nozzle (23) and a CCD camera (24) at the forward end of a manipulator is stopped at a specified position in the vicinity of an object to be cleaned, i.e. surface light or a reflection mirror (30). Based on an image of the object taken by the CCD camera (24), dimensions are recognized from distance information through processing by a vehicle-mounted computer, the image shape of the object is collated with a stored shape and recognized, and then positional information of the recognized object is searched. Cleaning agent is propelled from the blast nozzle (23) at the forward end of the manipulator (22) toward the object while measuring the extent of cleaning, brightness or light intensity of the cleaned object is determined by the CCD camera, and automatic cleaning is performed.

Owner:SANKI ENG CO LTD

Electric vehicle with increased range

InactiveUS20100147606A1Increase rangeOperational safety is enhancedOperating modesPropulsion using engine-driven generatorsElectric vehicleSupply energy

The present invention relates to a drive mechanism of an electric vehicle that is realized only by means of one or more electric motors that are connected to at least one storage battery, wherein a generator is provided that can be connected for supplying energy to the drive mechanism, wherein the generator is coupled to a Wankel engine that drives only the generator when needed, but delivers no driving power as torque to the drive train of the electric motor or motors of the drive mechanism. A method for operating an electric vehicle is also presented.

Owner:FEV MOTORENTECHN GMBH

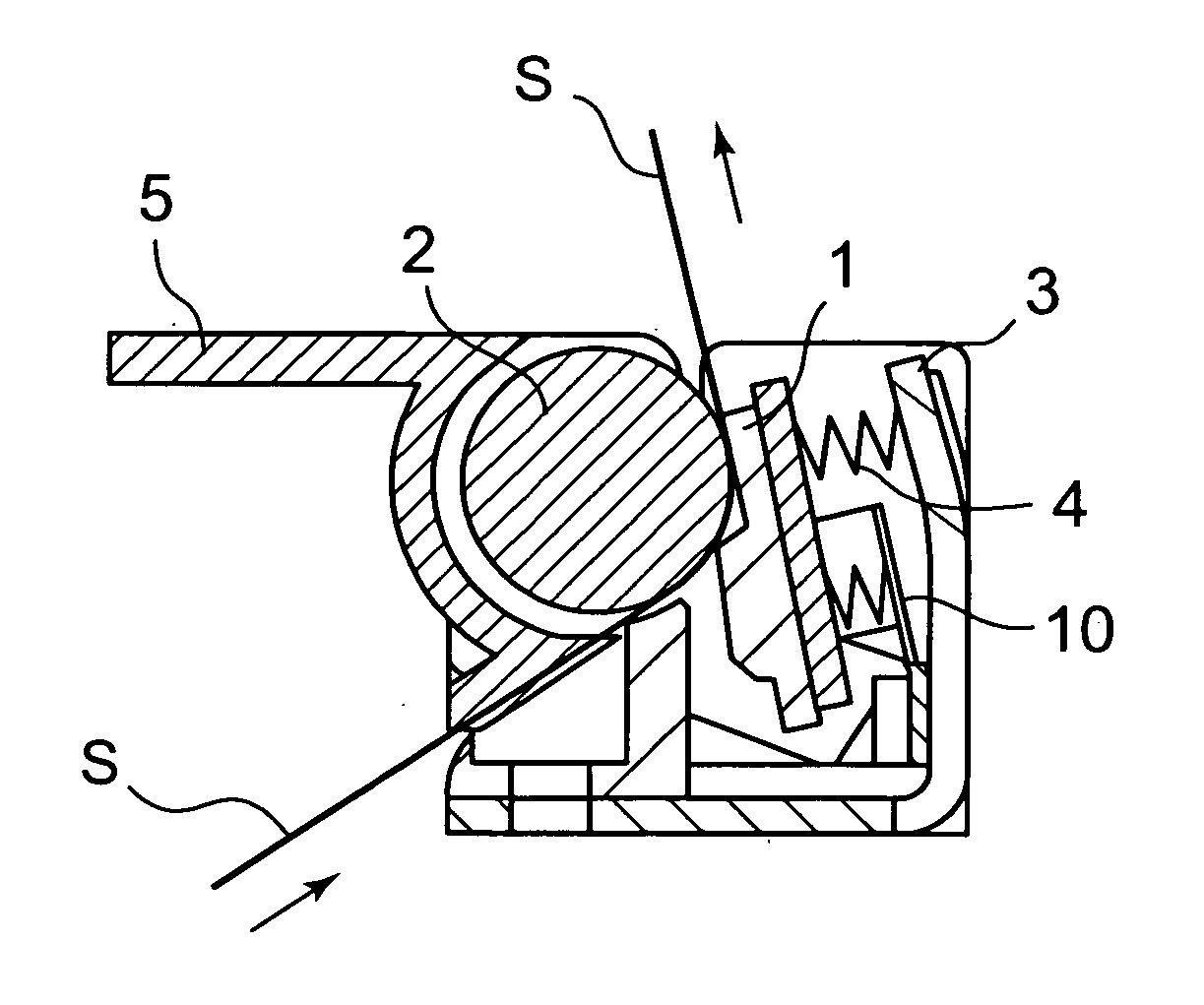

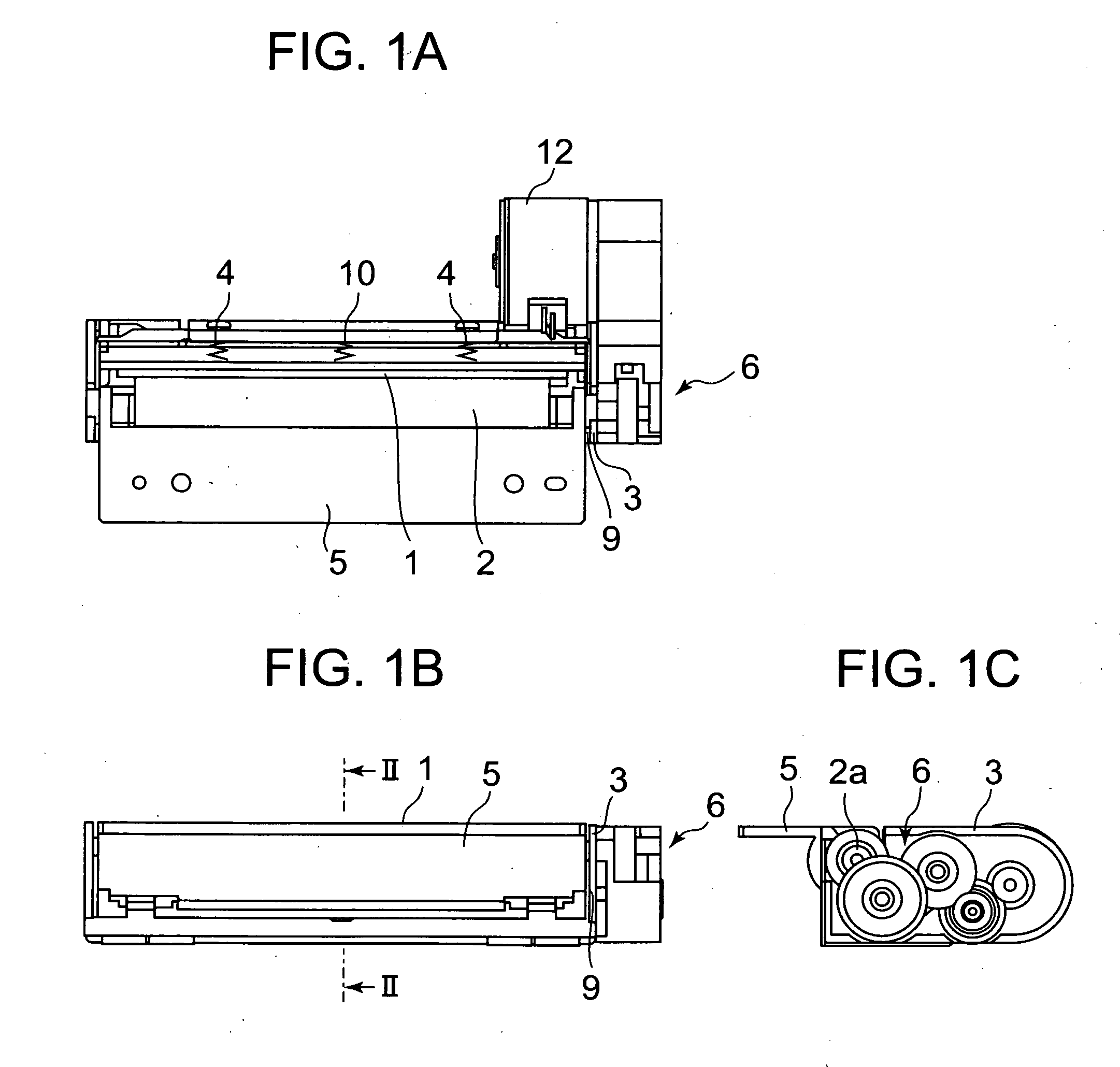

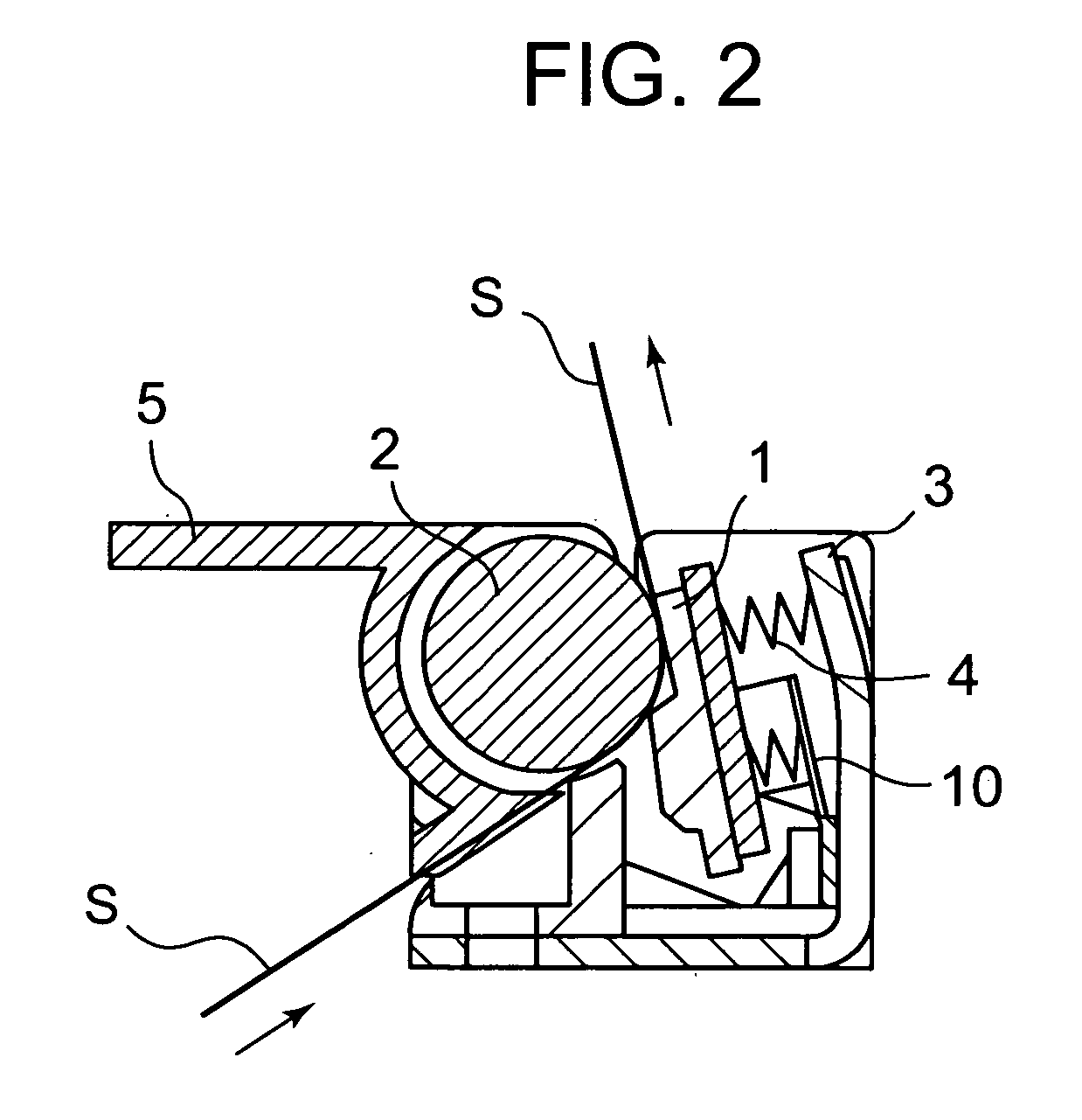

Platen retaining structure and recording unit

InactiveUS20080180468A1Unnecessary to provideRecording apparatusInking apparatusSpring forceEngineering

A shaft portion 2a of a platen roller 2 is inserted into an elongated hole-like recess 5a of a platen frame 5 so as to be movable therein. A release arm 9 having an engagement portion 9b engaged with a shaft portion 2a is swingably provided and is urged by a spring member 10. A switch 11 has an intercept 11a which can be contacted / separated to / from the release arm 9. When a thermal head 1 is moved against a spring force of a spring member 4, the release arm 9 follows the thermal head 1 to be allowed to swing by the spring member 10, thereby moving the shaft portion 2a in the recess 5a. When the switch 1 detects movement of the release arm 9, it is determined that recording is impossible since the thermal head 1 and the platen roller 2 are spaced apart from each other.

Owner:SEIKO INSTR INC

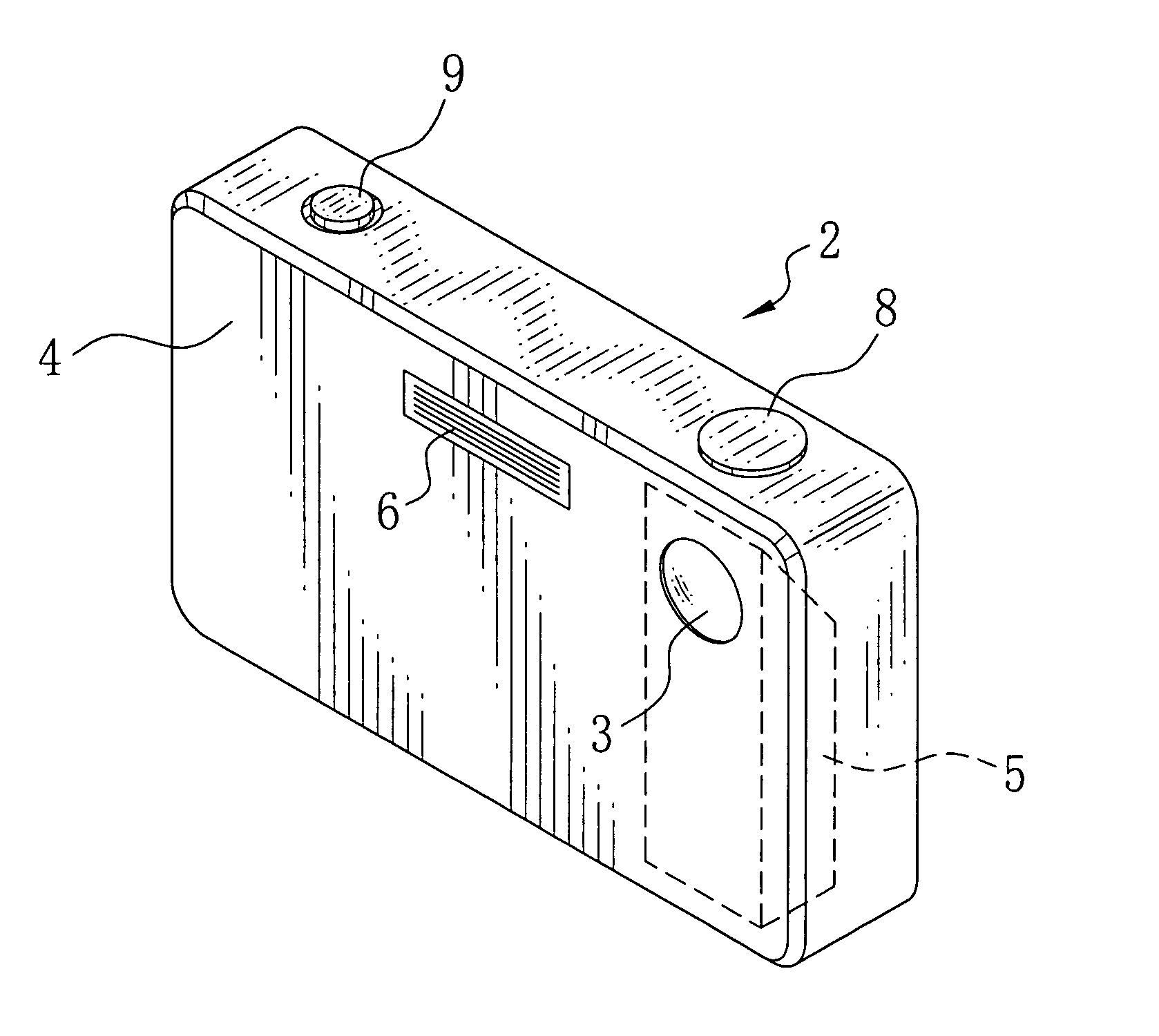

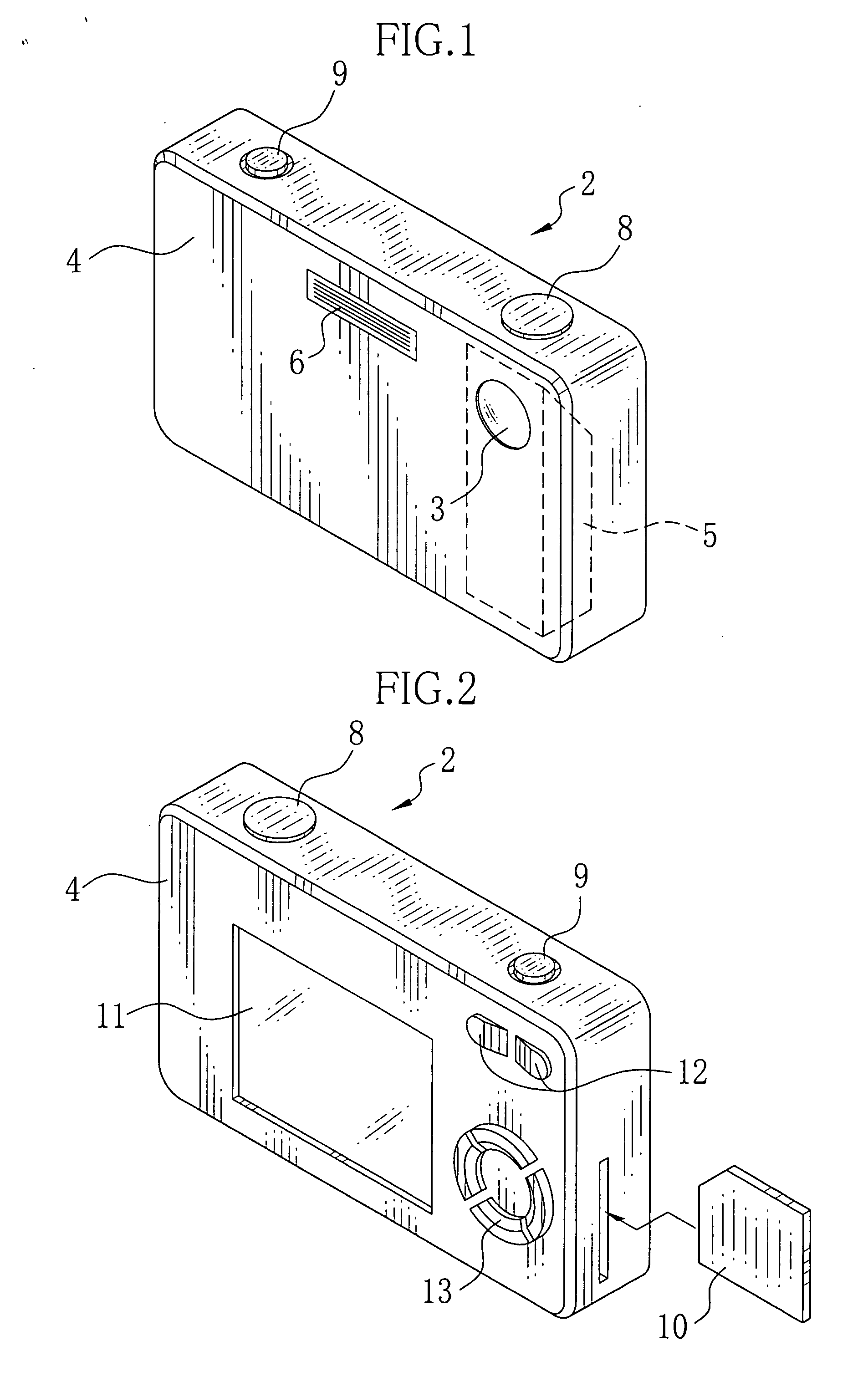

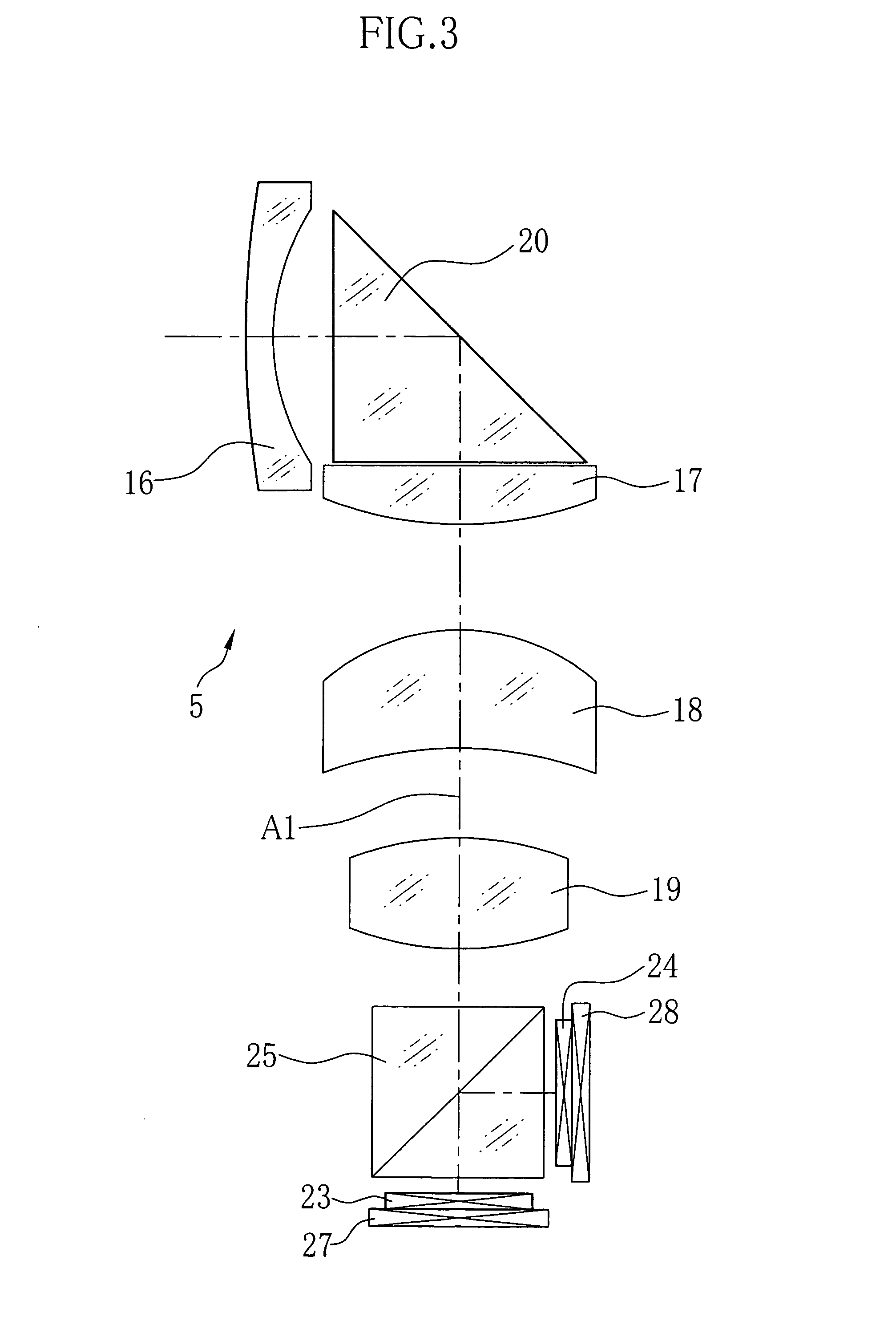

Imaging apparatus

InactiveUS20060177208A1Low costSmall sizeTelevision system detailsCamera body detailsOptical axisDichroic prism

A lens unit is provided with two CCD image sensors and a color-separation prism for separating subject light into green light (G light), and a mixture of red light (R light) and blue light (B light). The color-separation prism allows the G light to enter into one of the CCD image sensors, and the mixture of the R and B light to enter into the other CCD image sensor. Sensor moving mechanisms drive the CCD image sensors individually in a plane perpendicular to an optical axis when camera shake is detected, thereby preventing the image from blurring.

Owner:FUJIFILM CORP +1

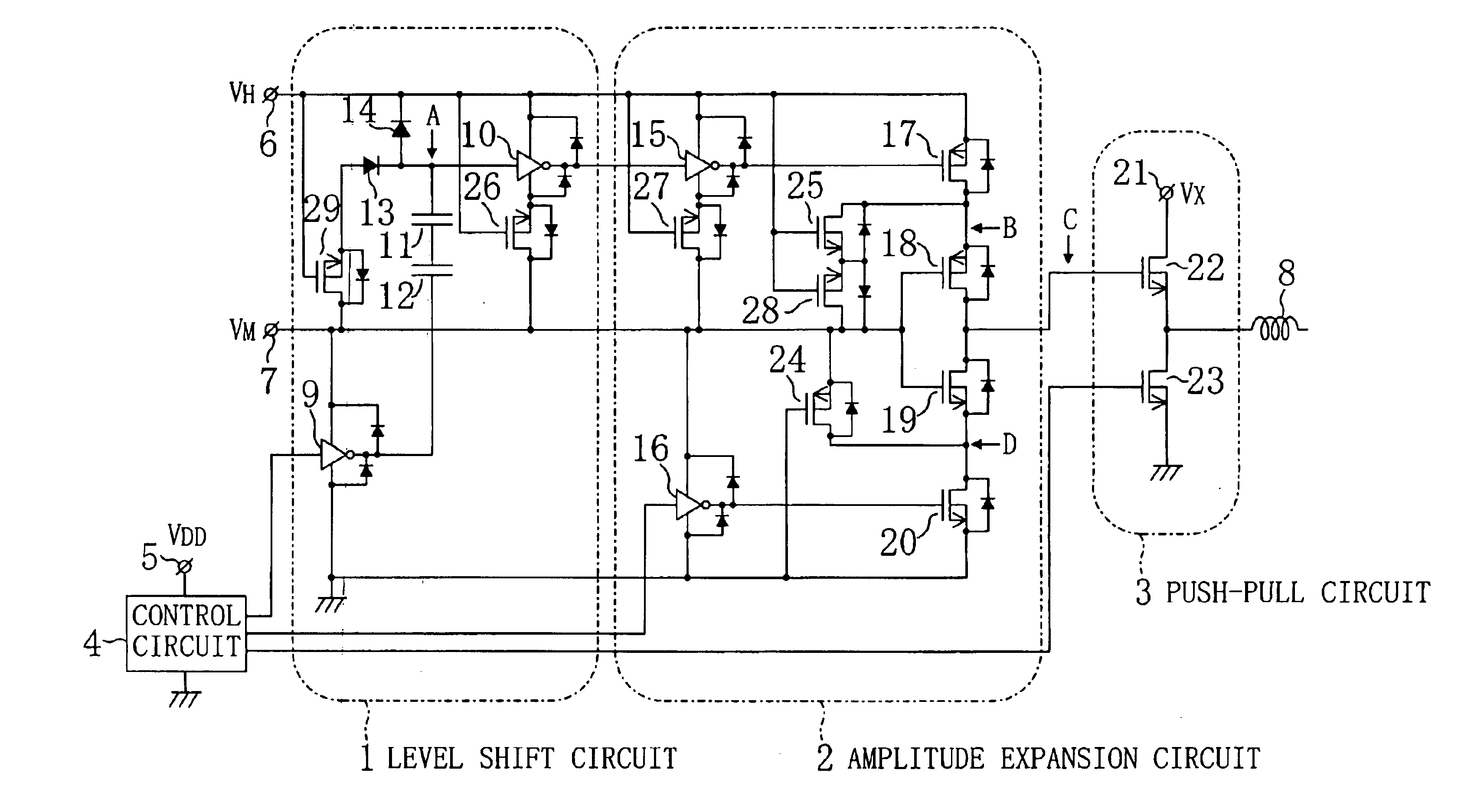

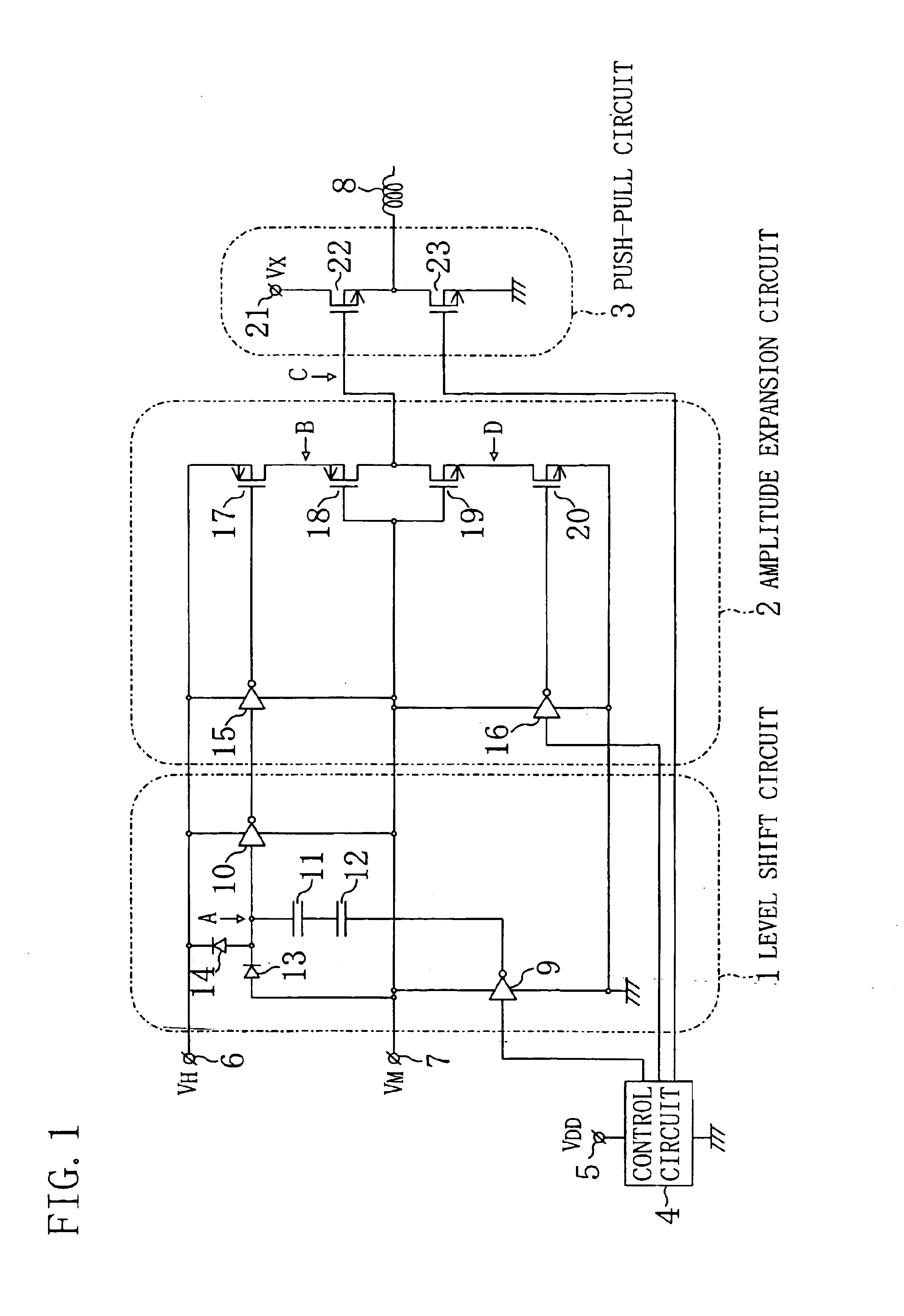

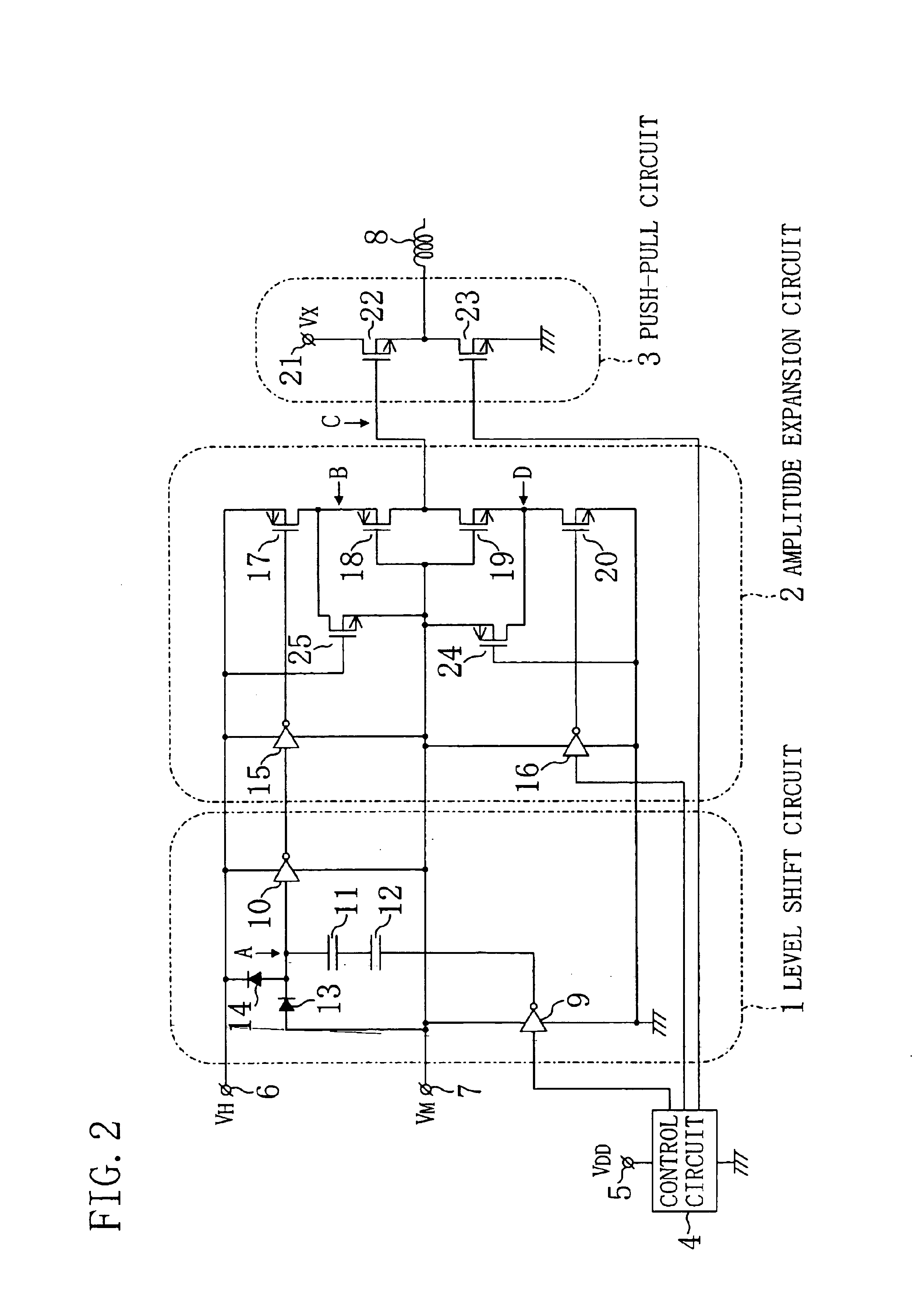

Drive circuit

The amplitude expansion circuit as a main part of a drive circuit includes: a VM DC power supply line to which a voltage VM is applied; a VH DC power supply line to which a voltage VH roughly twice as high as the voltage VM is applied; an inverter circuit receiving a pulse signal oscillating between the ground voltage and the voltage VM; another inverter circuit receiving a pulse signal oscillating between the voltage VM and the voltage VH in correspondence with the oscillation of the voltage level of the above pulse signal; a p-channel MOSFET having a gate receiving an output from the inverter circuit; another p-channel MOSFET having a gate connected to the VM DC power supply line; an n-channel MOSFET having a gate connected to the VM DC power supply line; and another n-channel MOSFET having a gate receiving an output from the other inverter circuit. A common connection node of the p-channel MOSFET and the n-channel MOSFET works as the output terminal of the amplitude expansion circuit.

Owner:PANASONIC CORP

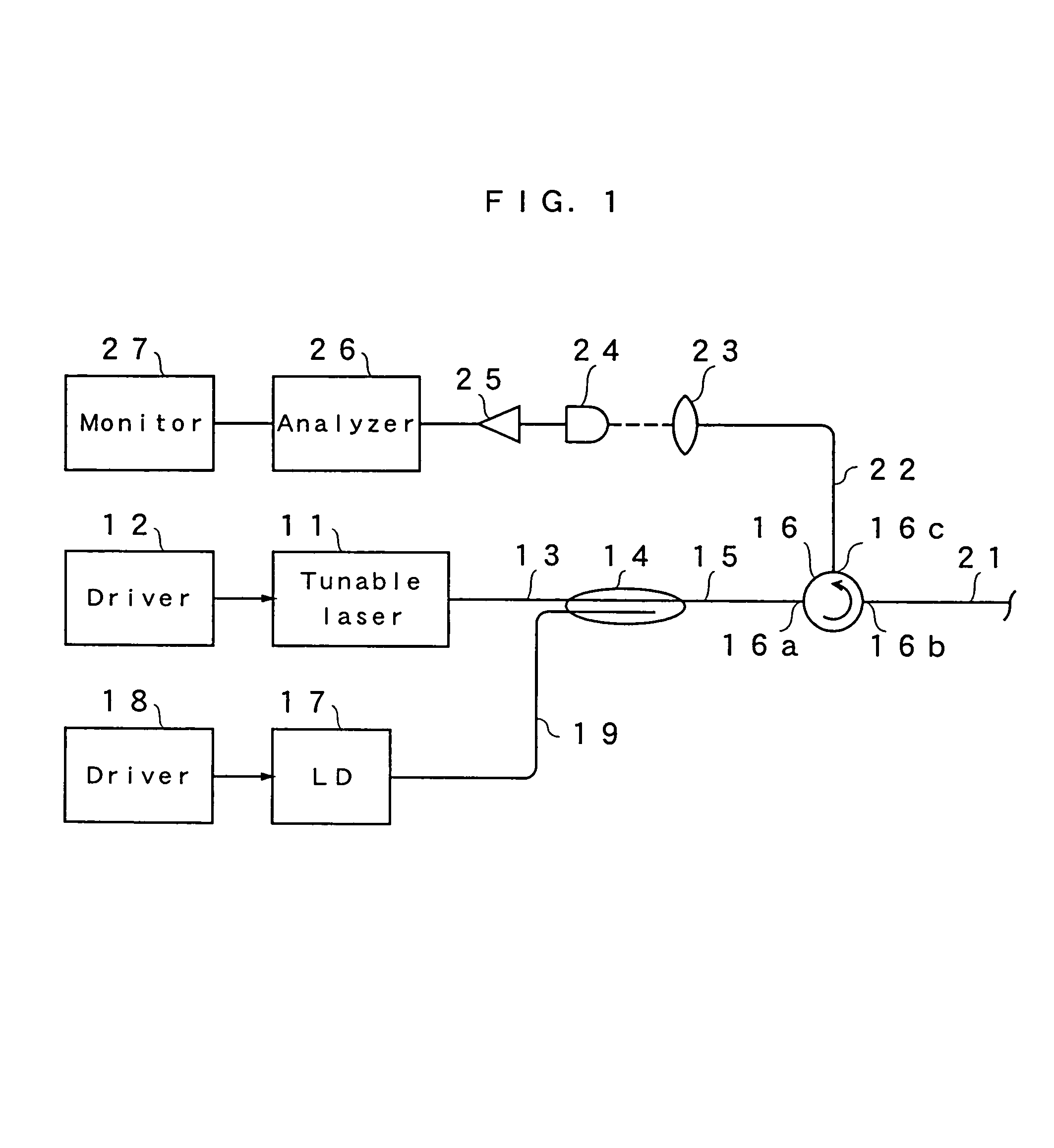

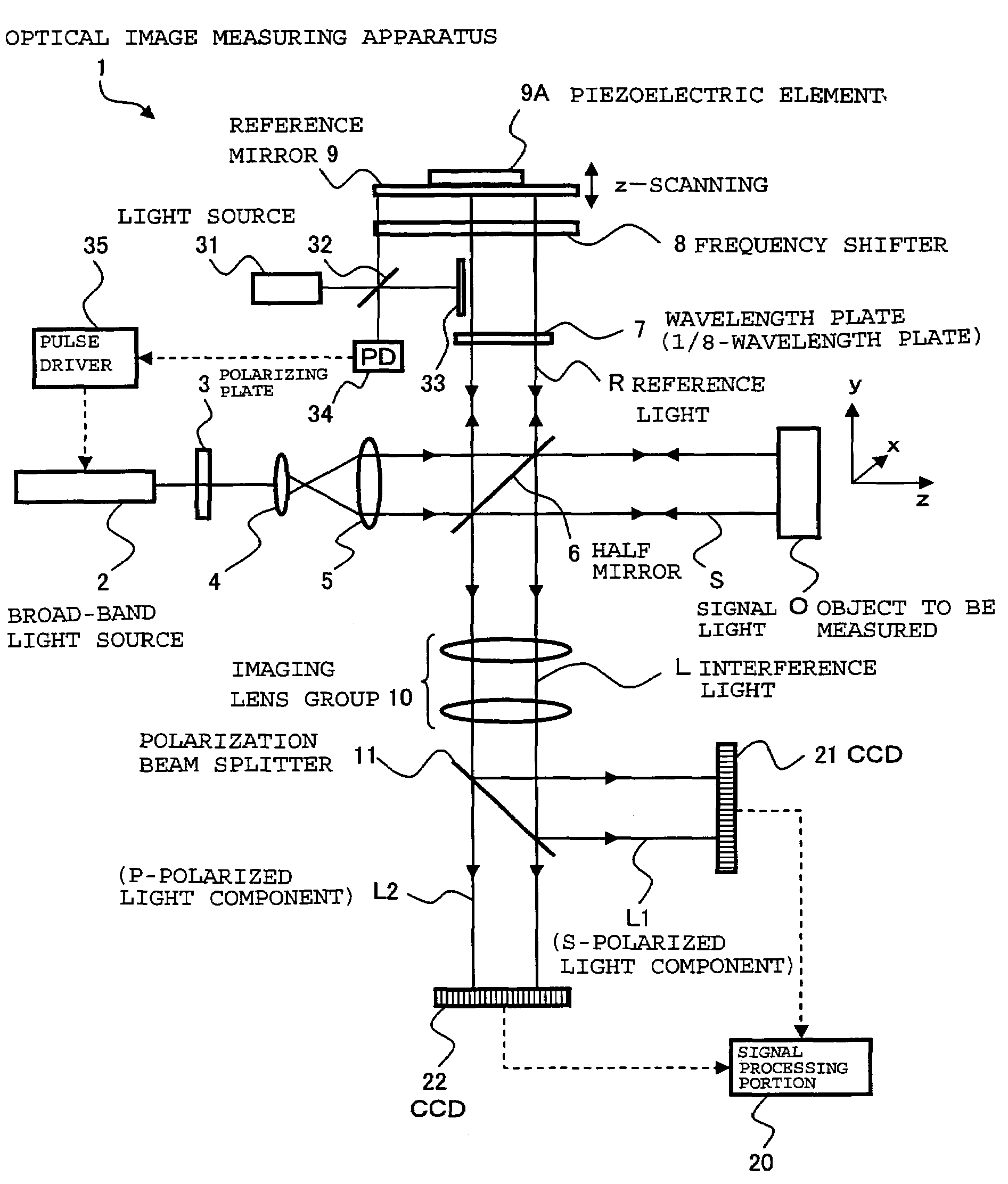

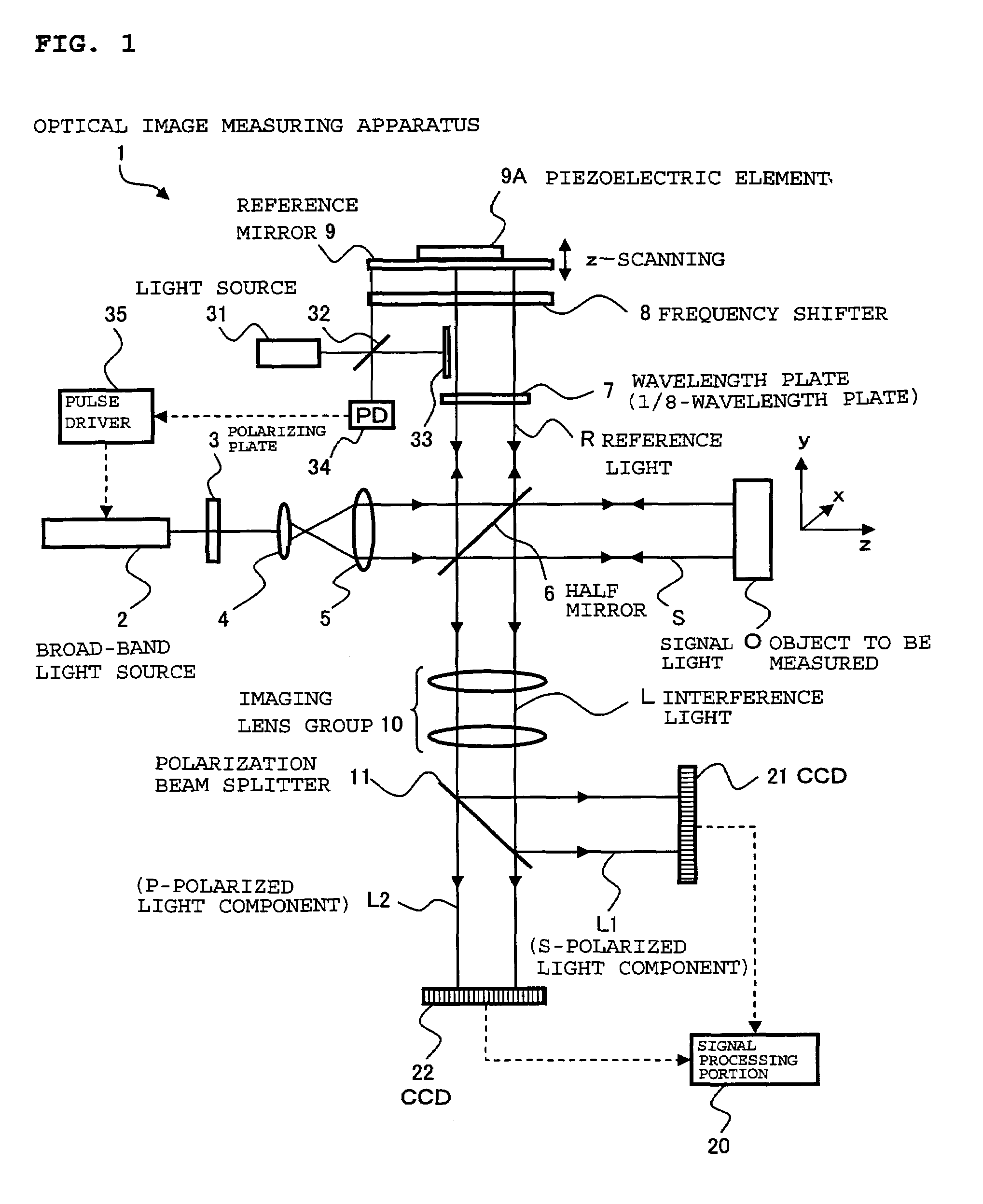

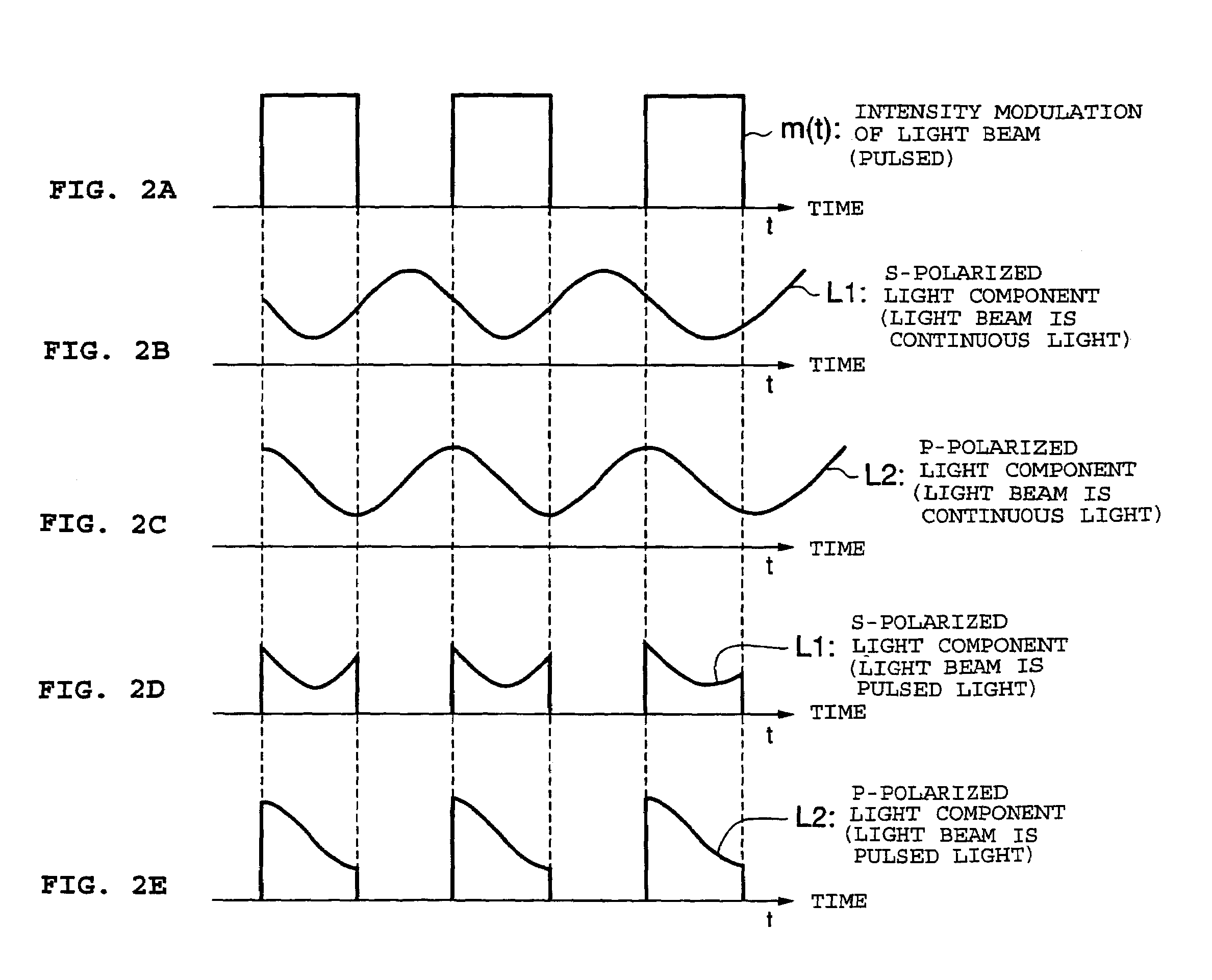

Optical image measuring apparatus and optical image measuring method

InactiveUS7307733B2High detection sensitivityImprove accuracyInterferometersUsing optical meansSignal lightOptoelectronics

Owner:KK TOPCON

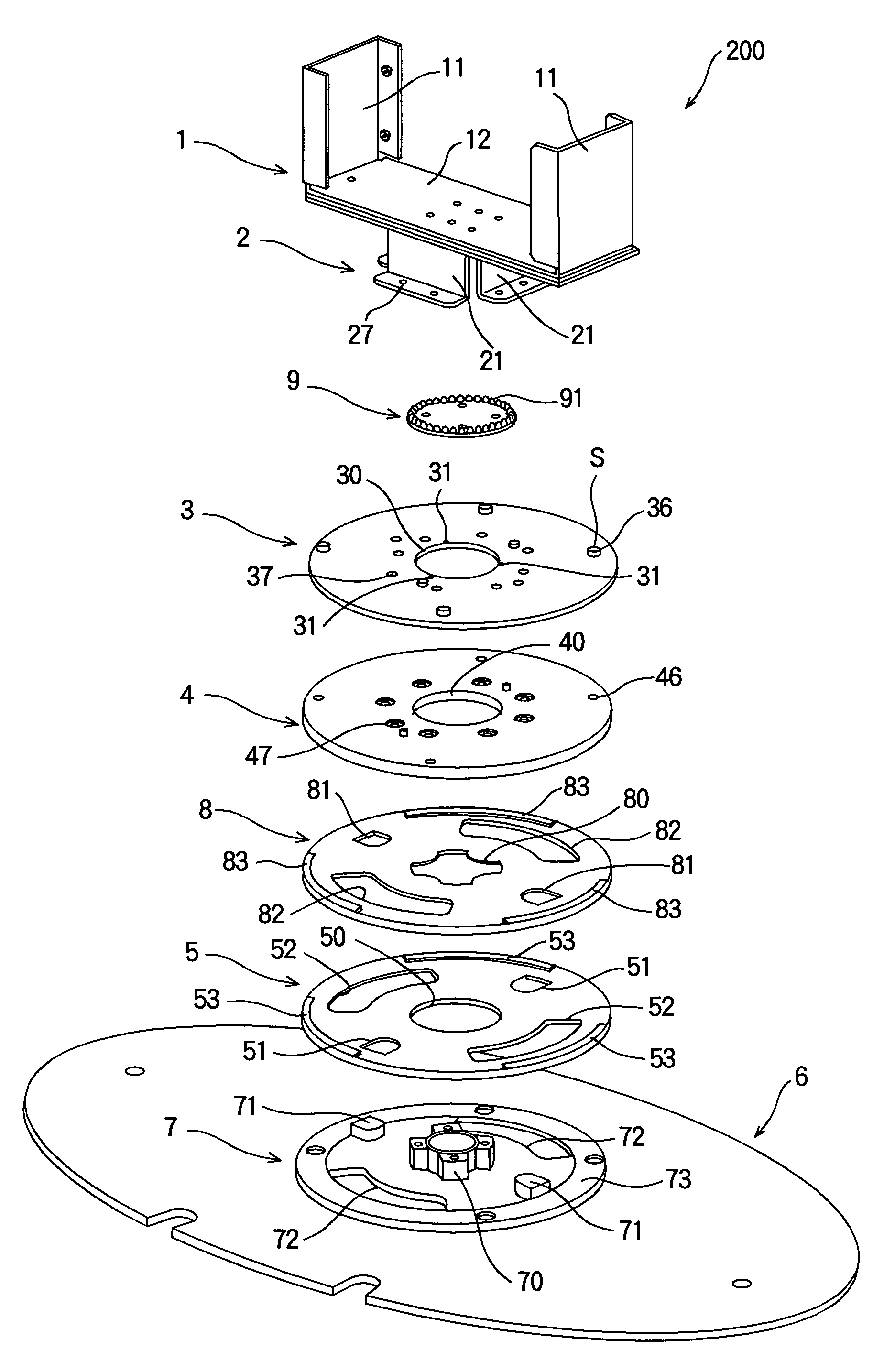

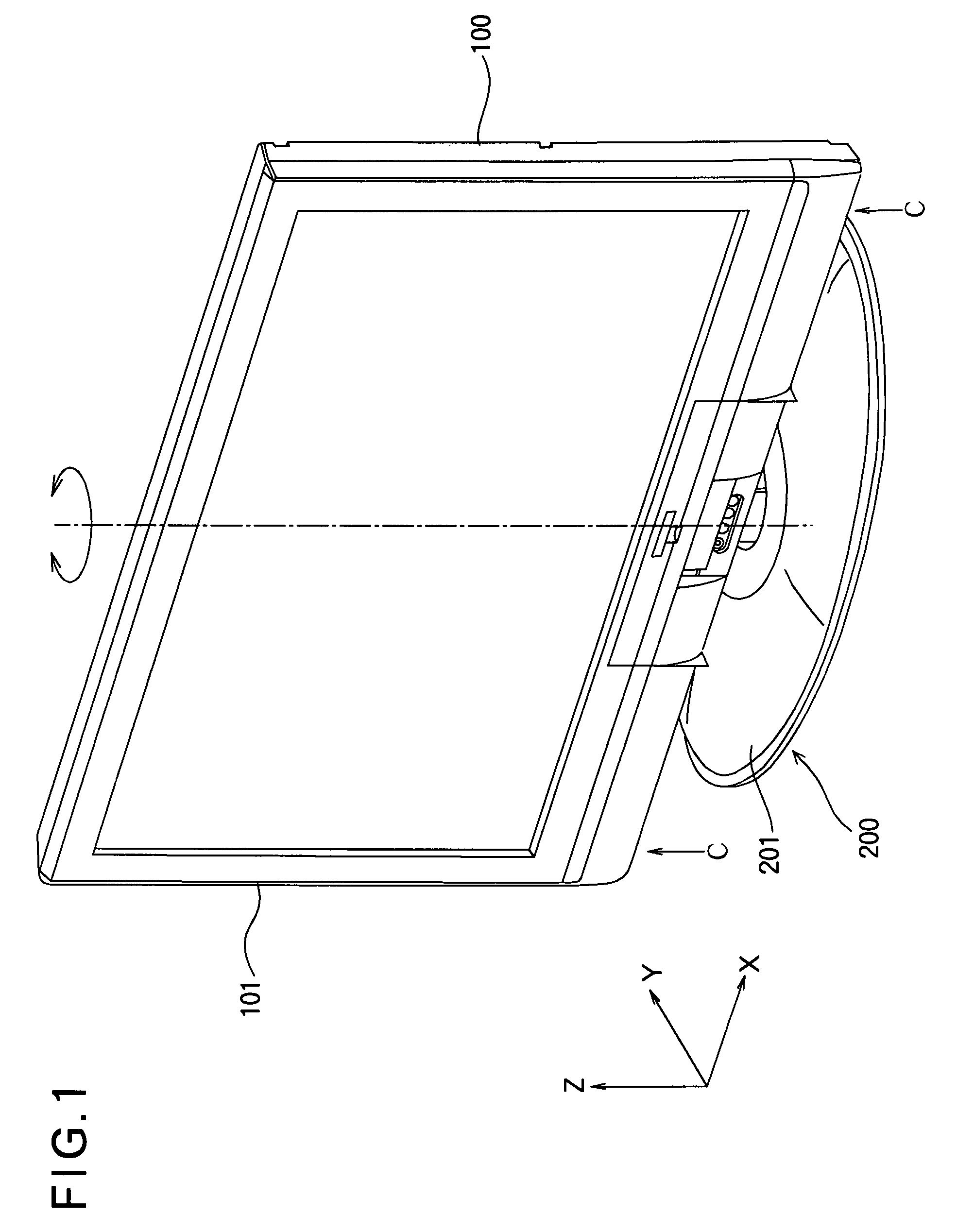

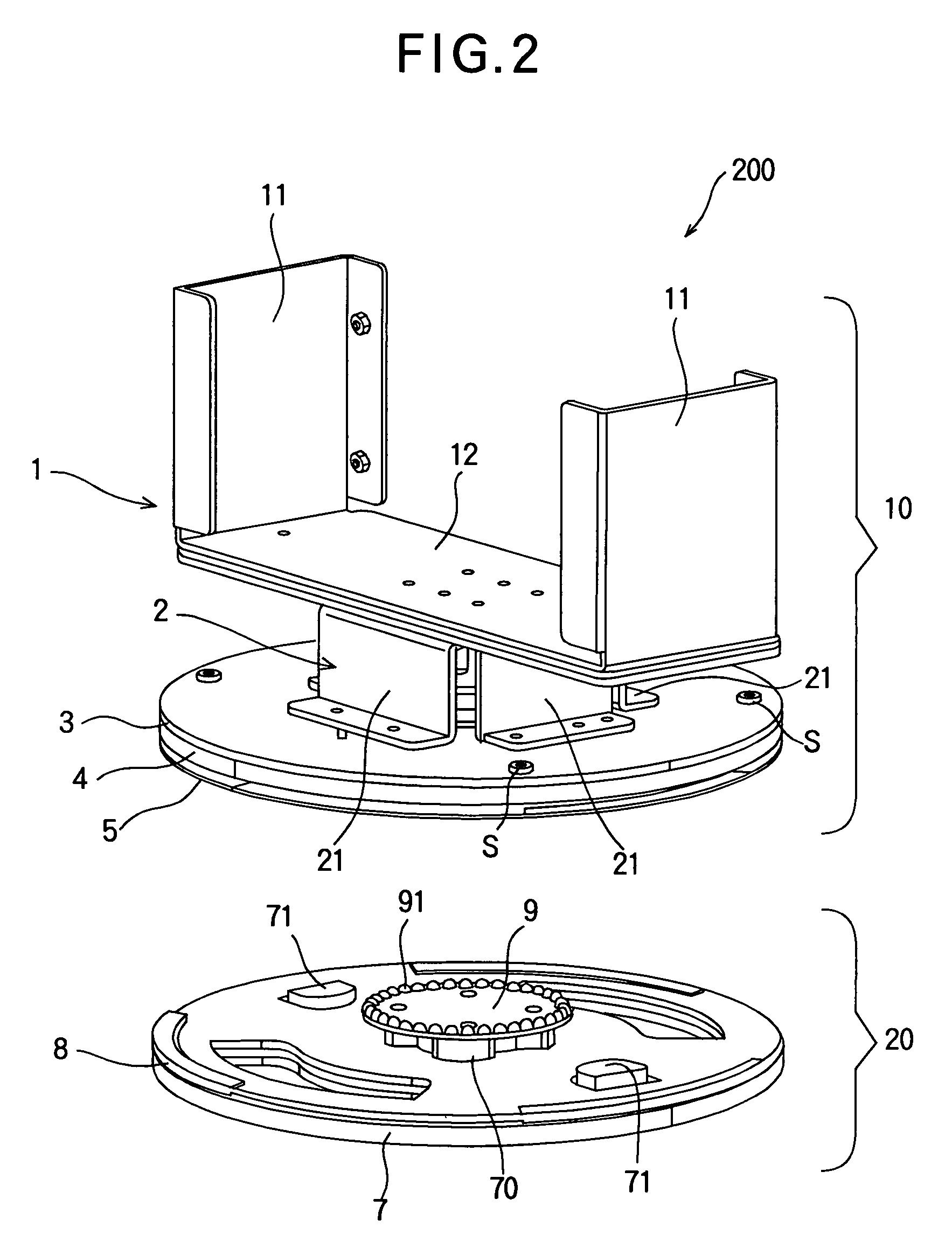

Turntable and display apparatus

InactiveUS7708239B2Smooth rotationReduce variationStands/trestlesKitchen equipmentSliding contactEngineering

A turntable includes a rotatable member rotatable together with a display portion about a predetermined axis line, a fixed member disposed on one side of the rotatable member in a direction of the axis line, a first friction plate whose rotation about the axis line is restricted by the rotatable member (and movable relative to the rotatable member in a direction of the axis line), and a second friction plate whose rotation about the axis line is restricted by the fixed member (and movable relative to the fixed member in a direction of the axis line). The first friction plate and the second friction plate are disposed between the fixed member and the rotatable member in a direction of the axis line. At least, a sliding contact portion between the fixed member and the first friction plate, a sliding contact portion between the first friction plate and the second friction plate, and a sliding contact portion between the second friction plate and the rotatable member are provided.

Owner:MITSUBISHI ELECTRIC CORP

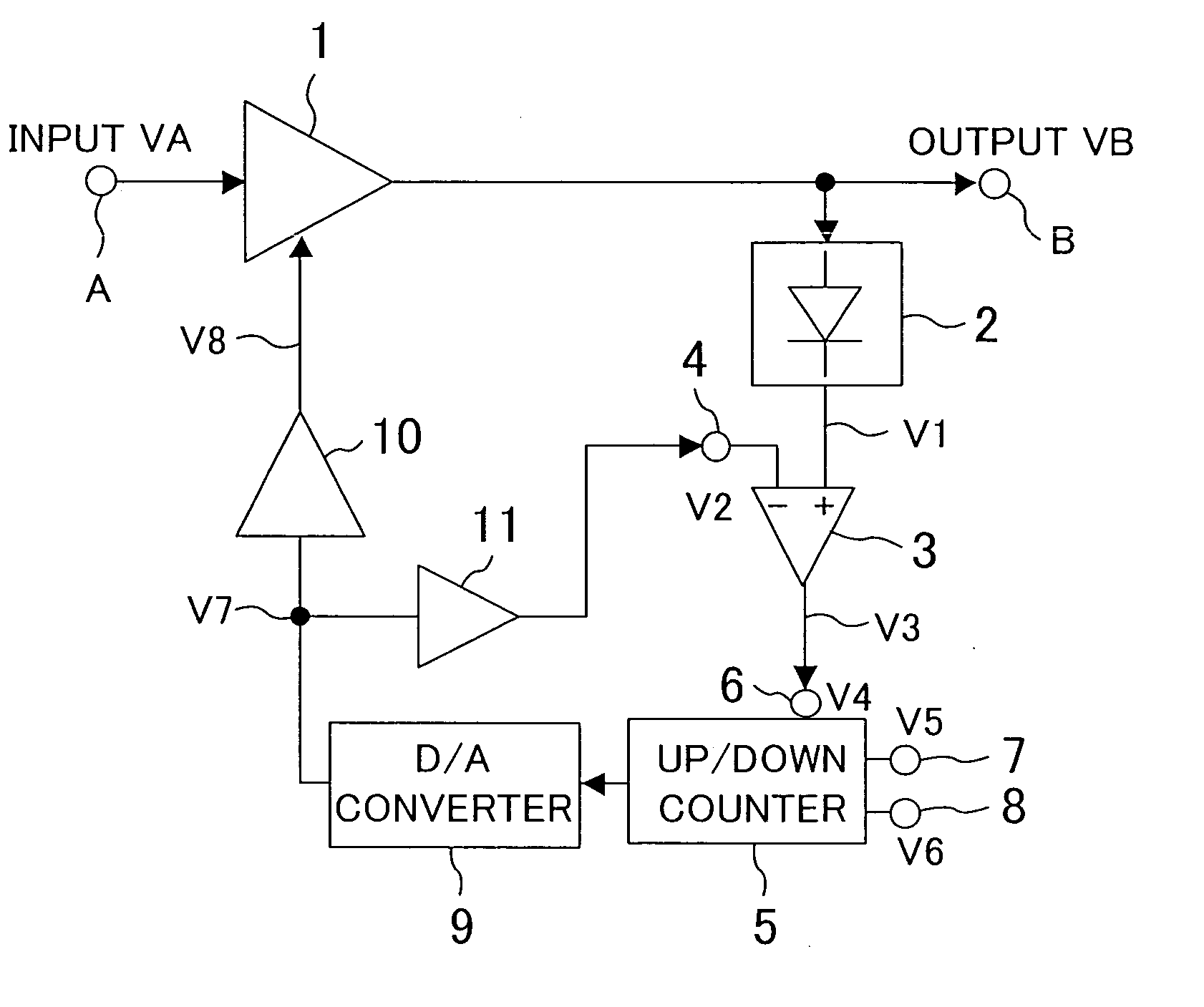

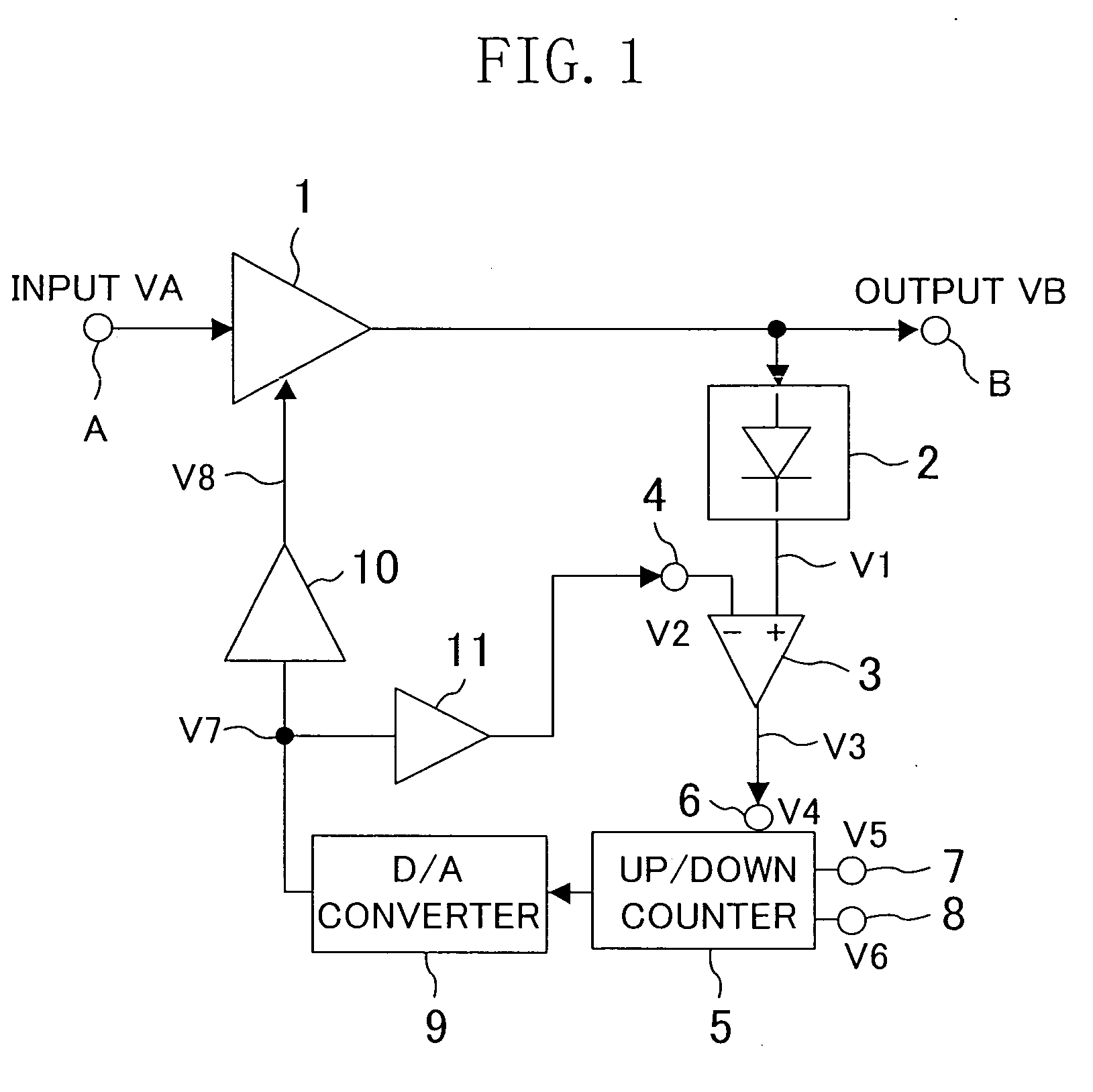

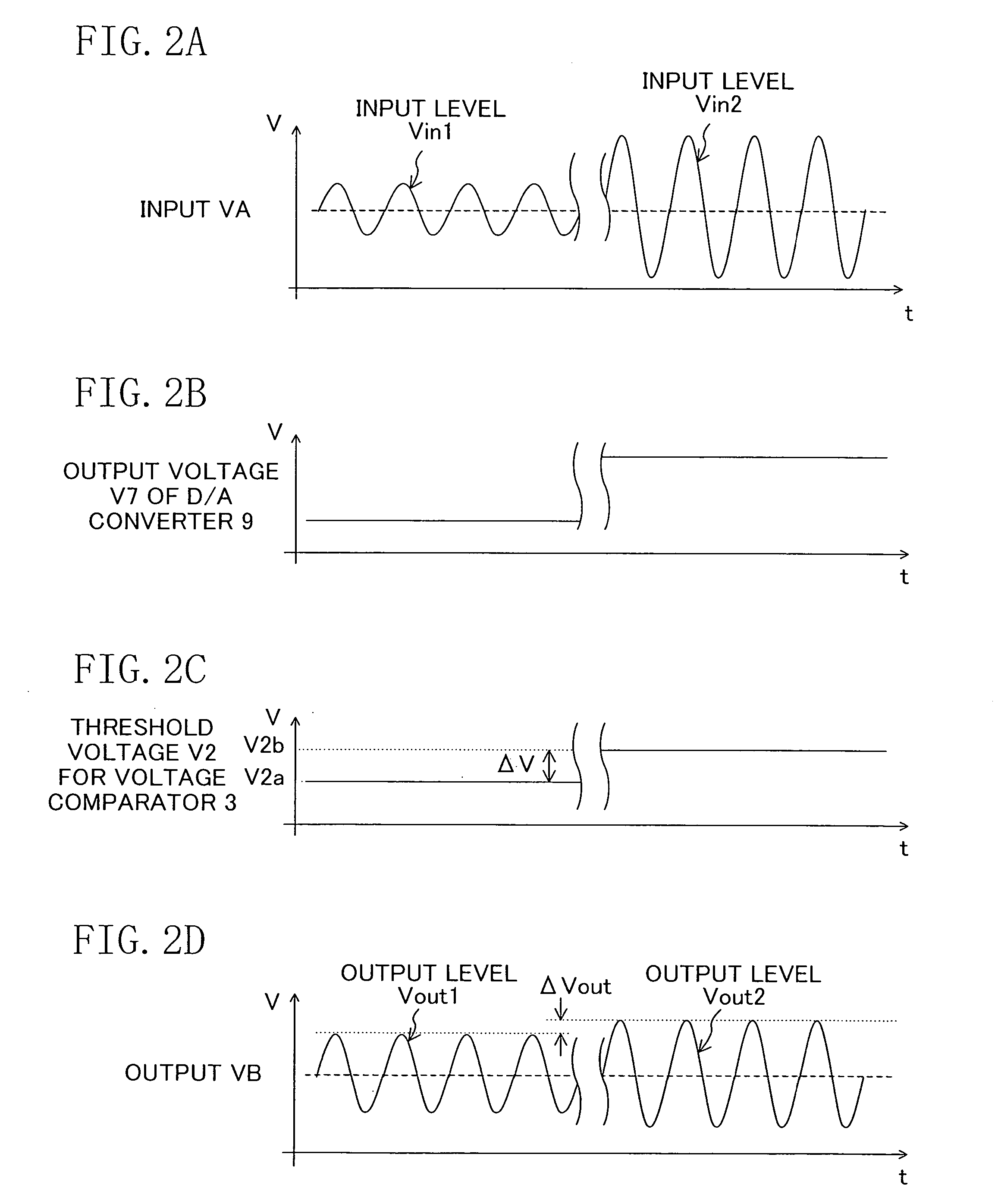

AGC circuit

ActiveUS20060044065A1Easy to mergeEasy to adjustGain controlAmplifier with semiconductor-devices/discharge-tubesVariable-gain amplifierControl signal

An AGC circuit includes: a variable gain amplifier circuit having a gain controlled with a gain control signal; a rectifier circuit for rectifying an output signal of the variable gain amplifier circuit; a voltage comparator for comparing a rectified signal with a threshold voltage; an up / down counter that switches between up-counting and down-counting according to the level of an output voltage of the voltage comparator; and a D / A converter circuit for outputting a voltage corresponding to a count value of the up / down counter. The gain control signal supplied to the variable gain amplifier circuit corresponds to the voltage output from the D / A converter circuit, and the threshold voltage for the voltage comparator is a voltage corresponding to the voltage output from the D / A converter circuit.

Owner:GK BRIDGE 1

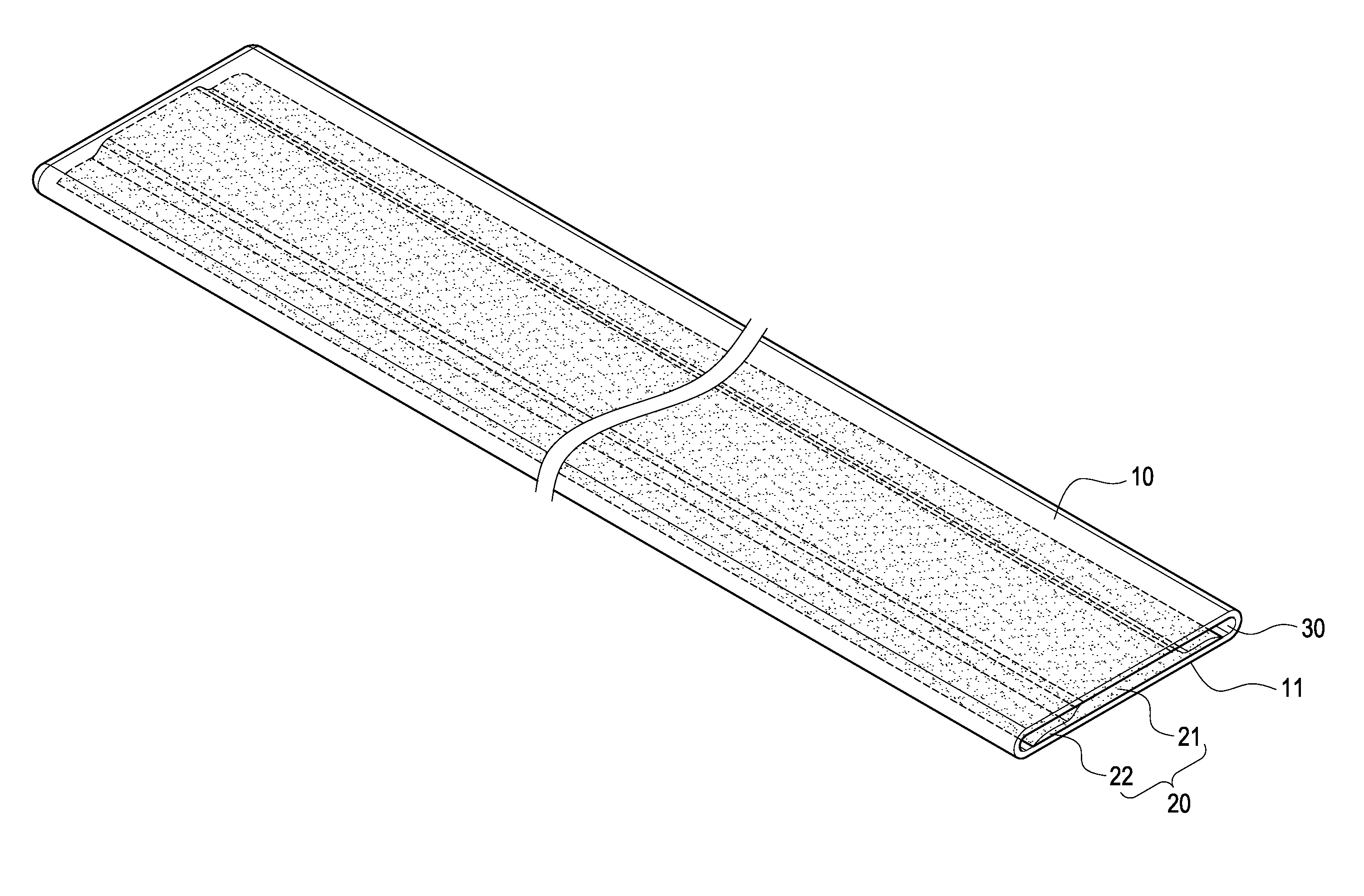

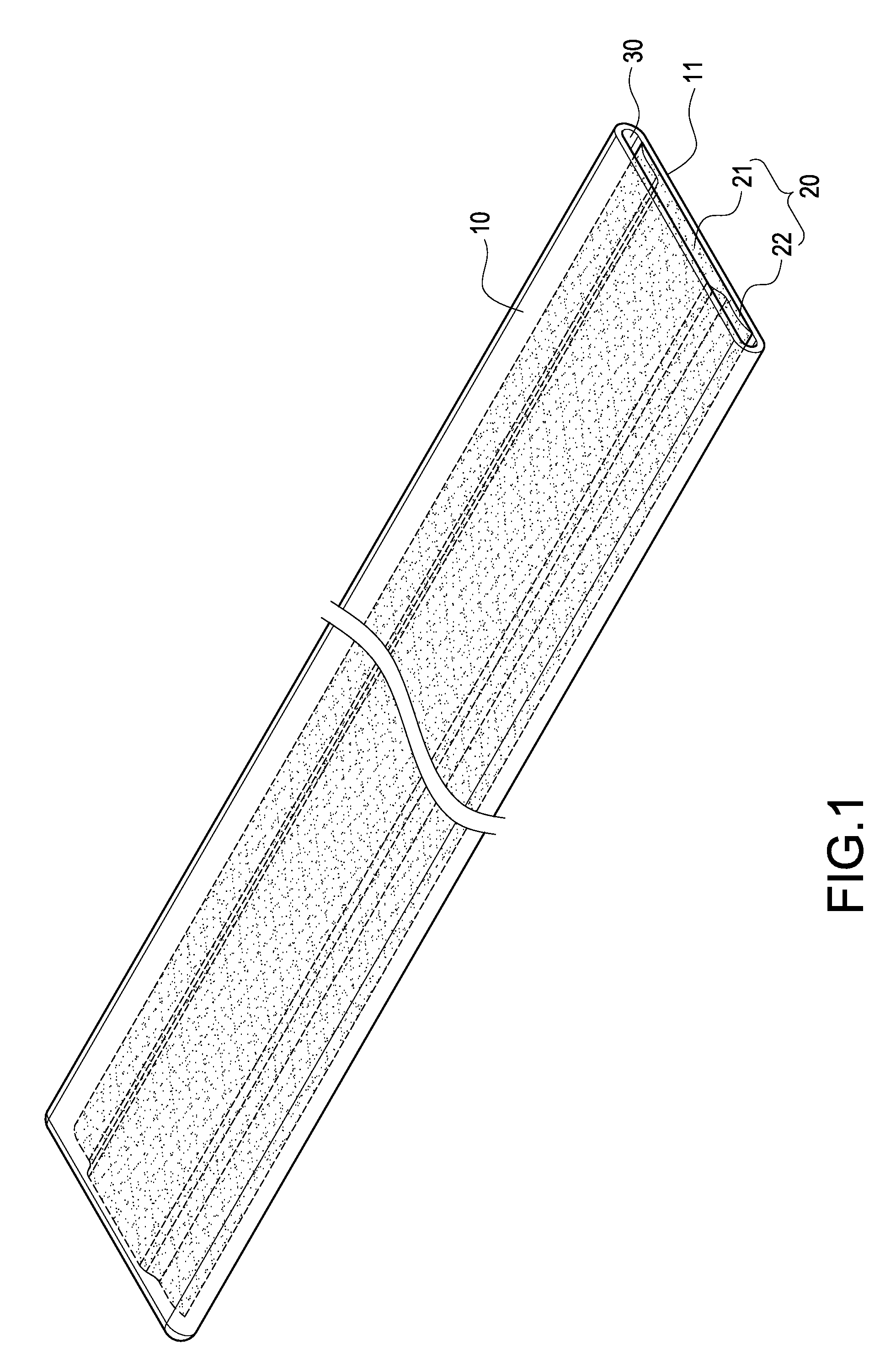

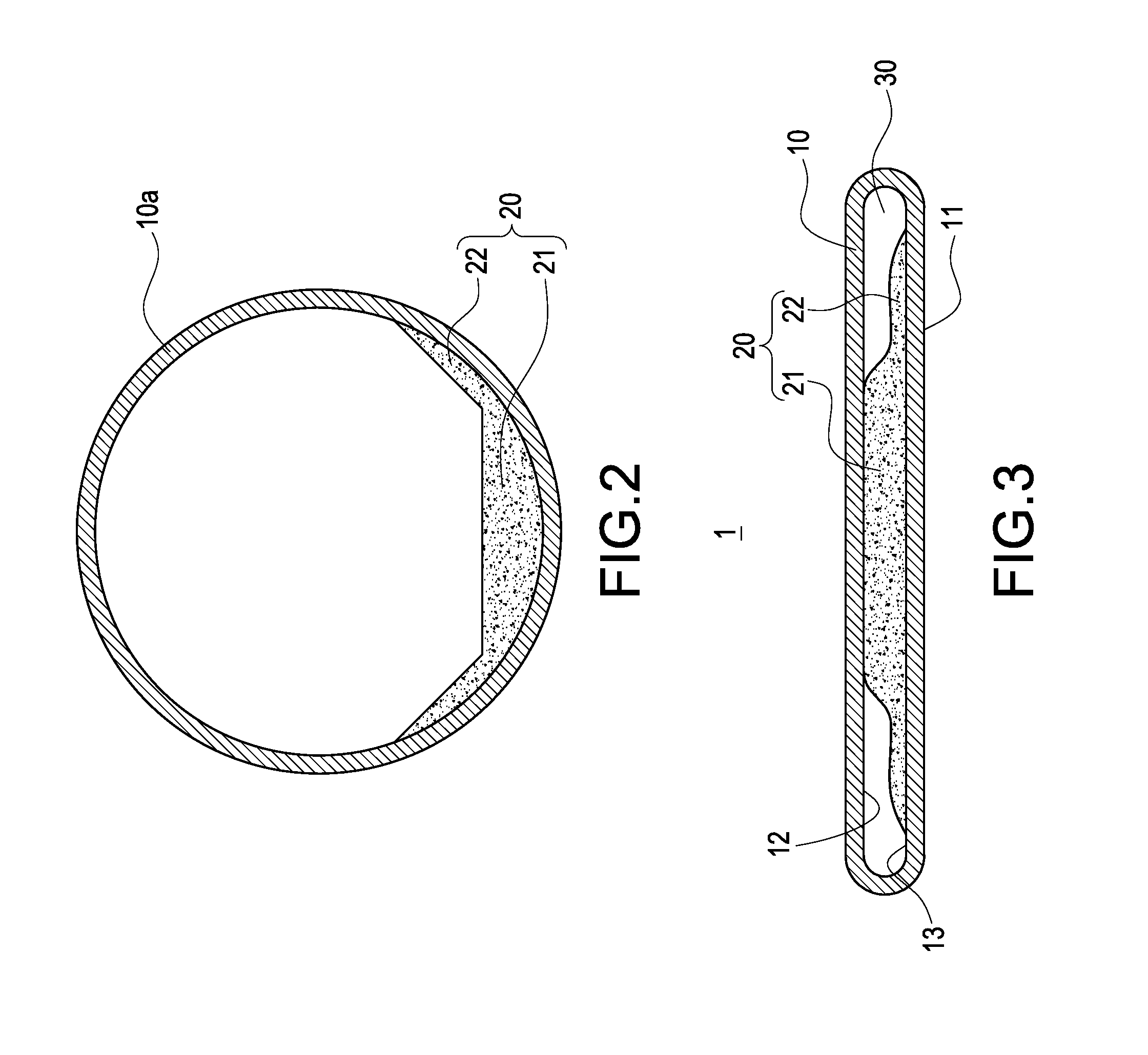

Flat-type heat pipe and wick structure thereof

The present invention provides a flat-type heat pipe and a wick structure thereof. The flat-type heat pipe has a flat tube. The wick structure is arranged inside the flat tube along an axial line of the flat tube. The wick structure comprises a first wick portion and two second wick portions connected on both sides of the first wick portion. The thickness of the first wick portion is larger than that of the second wick portion. The first wick portion abuts against an upper inner wall of the flat tube. An air channel is formed between each of the second wick portions and the upper inner wall of the flat tube. The wick structure supports the inner wall of the flat-type heat pipe without providing additional supporting structure, so that the heat pipe can be made more compact.

Owner:CELSIA TECH TAIWAN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com