Flat-type heat pipe and wick structure thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The detailed description and technical contents of the present invention will become apparent with the following detailed description accompanied with related drawings. It is noteworthy to point out that the drawings is provided for the illustration purpose only, but not intended for limiting the scope of the present invention.

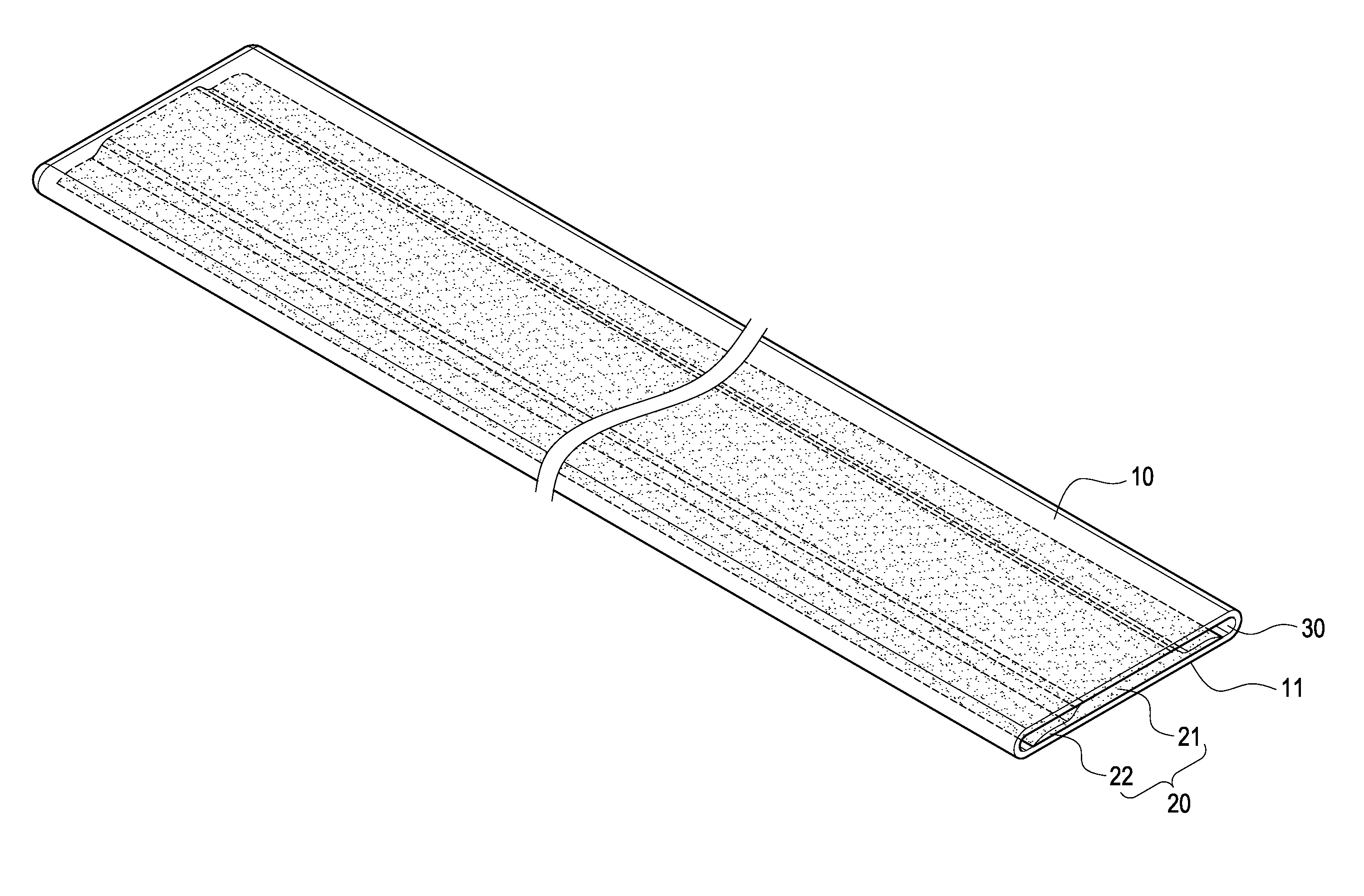

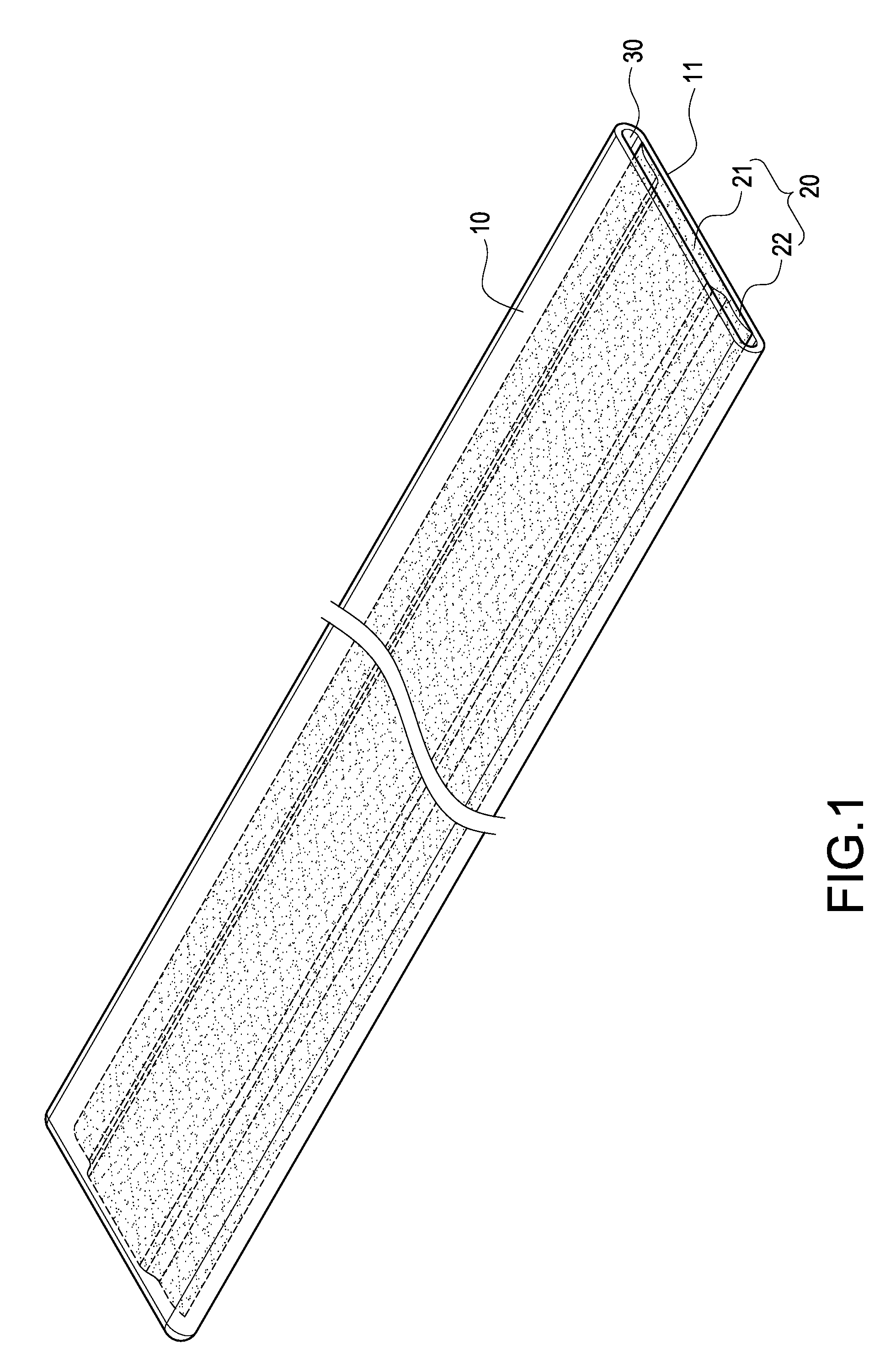

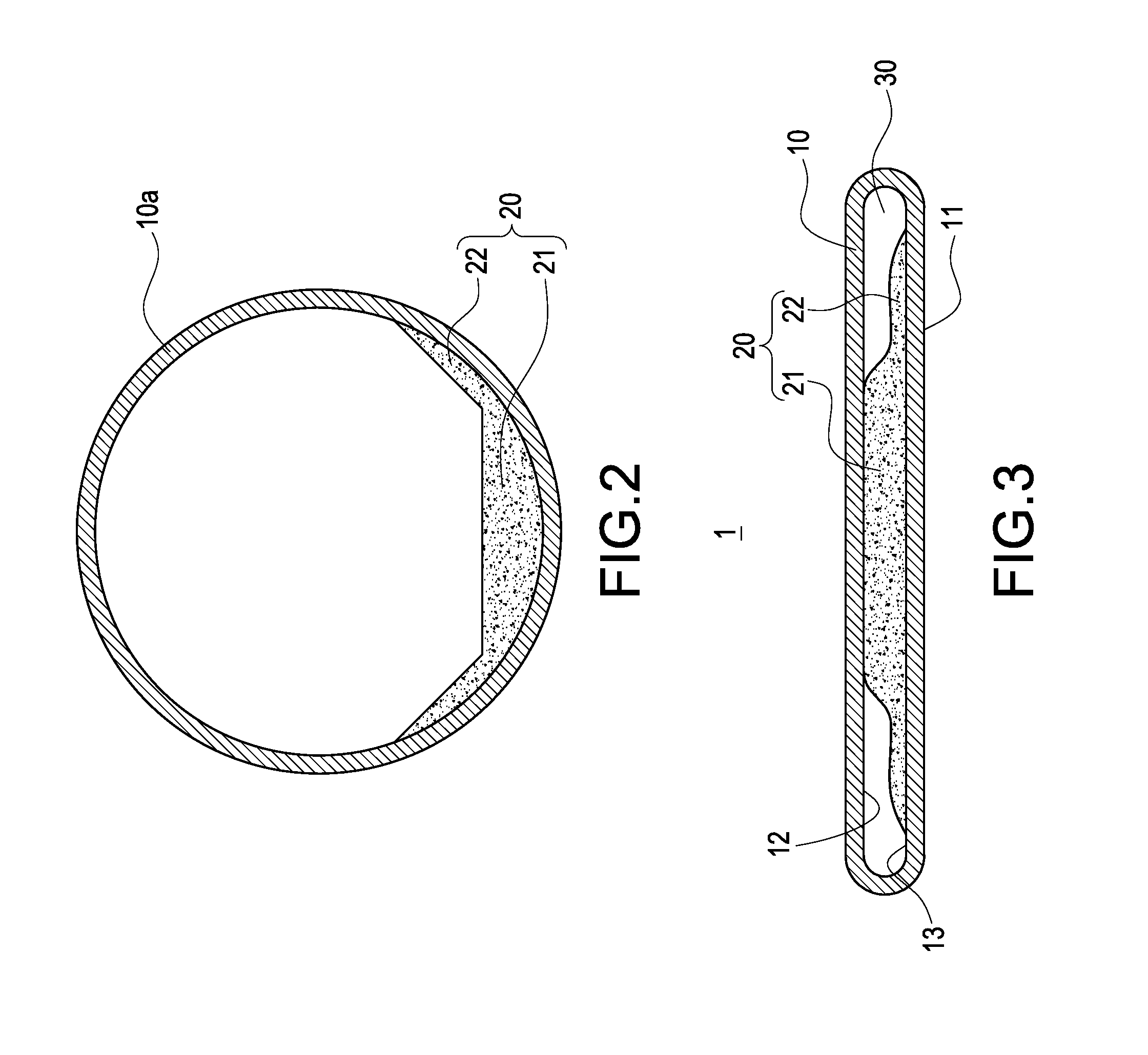

[0025]Please refer to FIGS. 1 to 3. The present invention provides a wick structure of a flat-type heat pipe. The flat-type heat pipe 1 has a flat tube 10. The wick structure 20 is arranged inside the flat tube 10 along an axial line of the flat tube 10. The wick structure 20 is made by sintered metal powder.

[0026]The manufacturing procedure of the present invention will be described as follows.

[0027]First, a circular tube 10a is provided, which has smooth inner walls. Then, a core rod (not shown) is inserted into the circular tube 10a. The outer diameter of the core rod is smaller than the inner diameter of the circular tube 10a. The profile of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com